Chemical Engineering Training Package, Advanced Users, 10 Practical Exercises

$1,660.00 Original price was: $1,660.00.$279.00Current price is: $279.00. Student Discount

This training package includes 10 practical exercises, using ANSYS Fluent software. MR CFD suggests this training package for all Chemical Engineers, who will learn CFD simulation in this field at the ADVANCED level.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Chemical Engineering ANSYS Fluent Training Package, 10 Practical Exercises for ADVANCED Users

This training package includes 10 practical exercises, using ANSYS Fluent software. MR CFD suggests this training package for all Chemical Engineers, who will learn CFD simulation in this field at the ADVANCED level.

Chemical Engineering

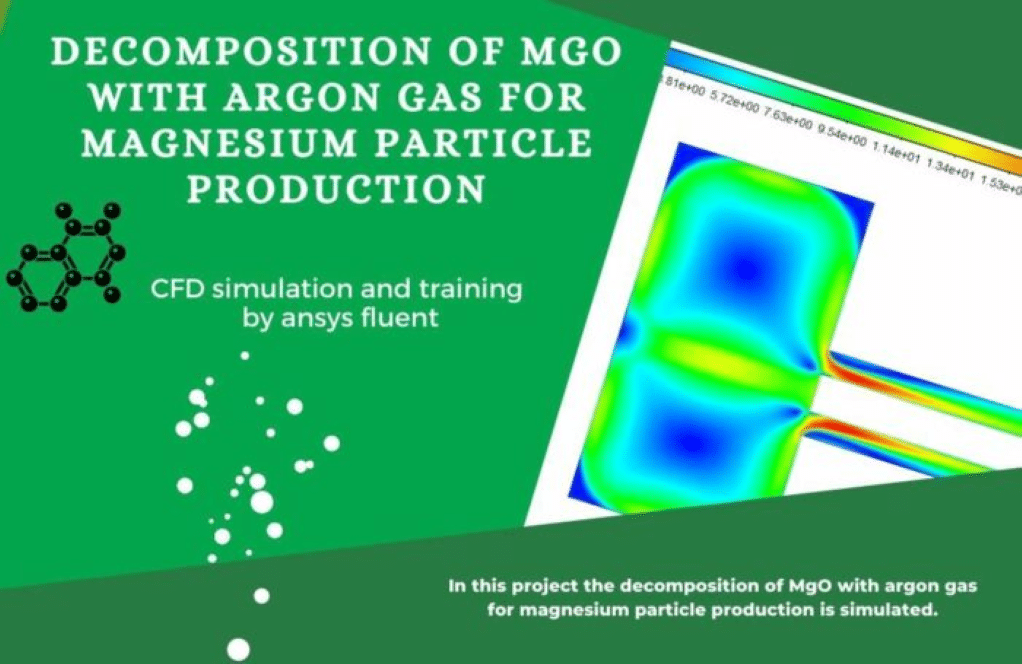

In practical exercise number 1, according to the geometry, the design and grid generation has been done. The combination of DPM (discrete particle method) and species transport methods was used to investigate the Decomposition of MgO with Argon Gas for Magnesium Particle Production. The thermodynamic properties of the particles, along with the necessary boundary conditions, were applied in the settings.

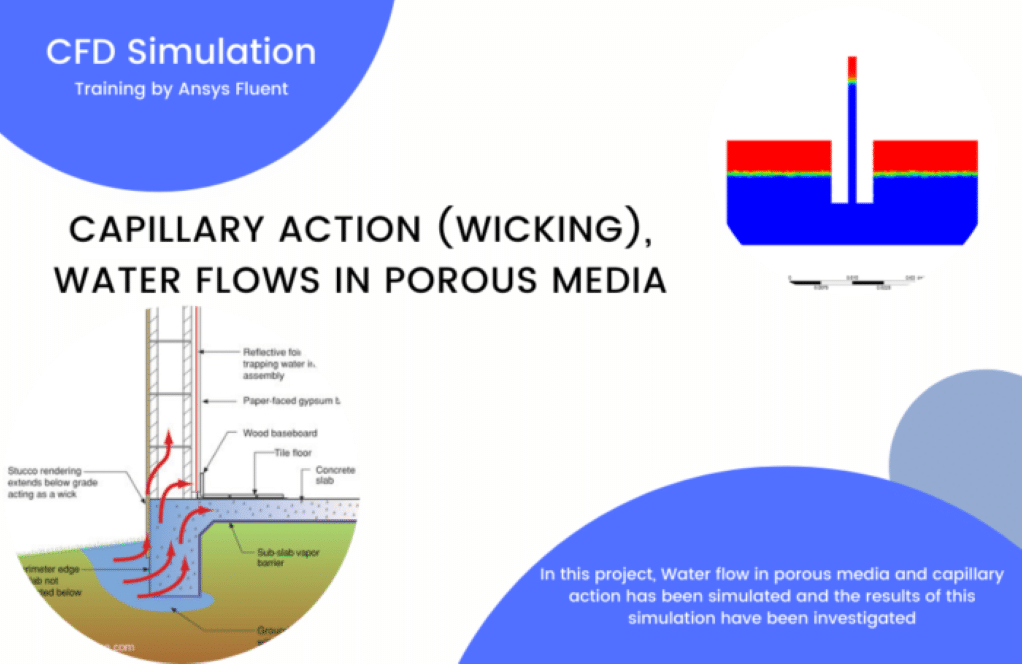

In project number 2, we simulated the water flows in porous media. The goal of this simulation is to model a simple capillary action (Wicking) through vertical Plant vessels (porous). The porous media model can be used for a wide variety of single-phase and multiphase problems, including flow through packed beds, filter papers, perforated plates, flow distributors, and tube banks.

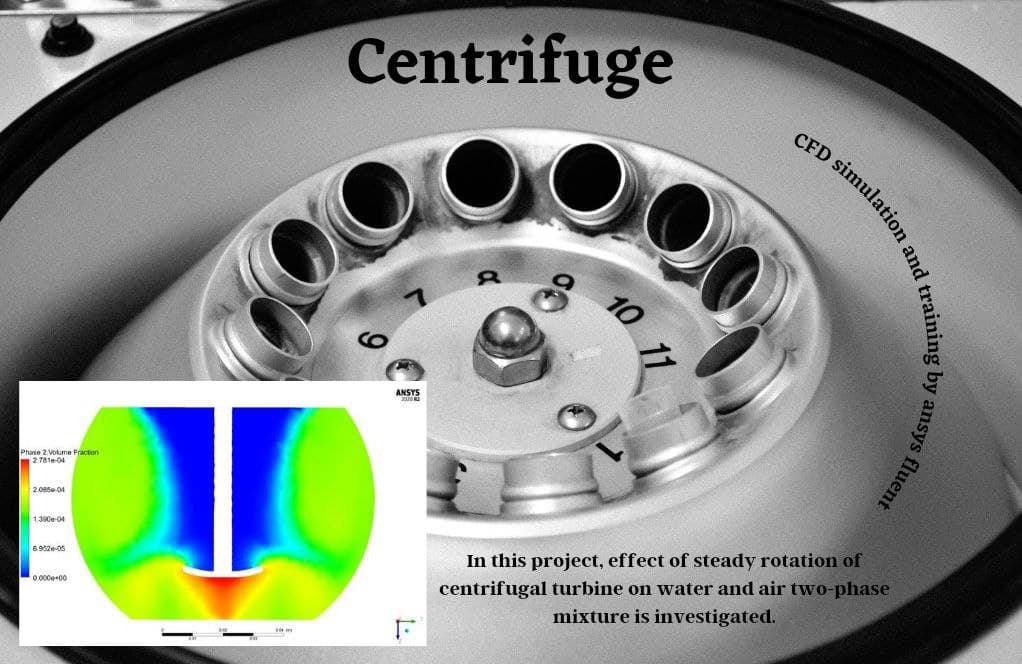

In project number 4, the effect of steady rotation of centrifugal mixer turbine on water and air (two-phase) mixture is investigated. The multiphase mixture model is used to mix water and air phases interactions. The secondary phase (air) volume fraction has very low values in the 0.0001 order which proves the validity of the mixture multiphase model in this project since for applying the Mixture Multi-Phase model the secondary phase volume fraction should be less than 15%.

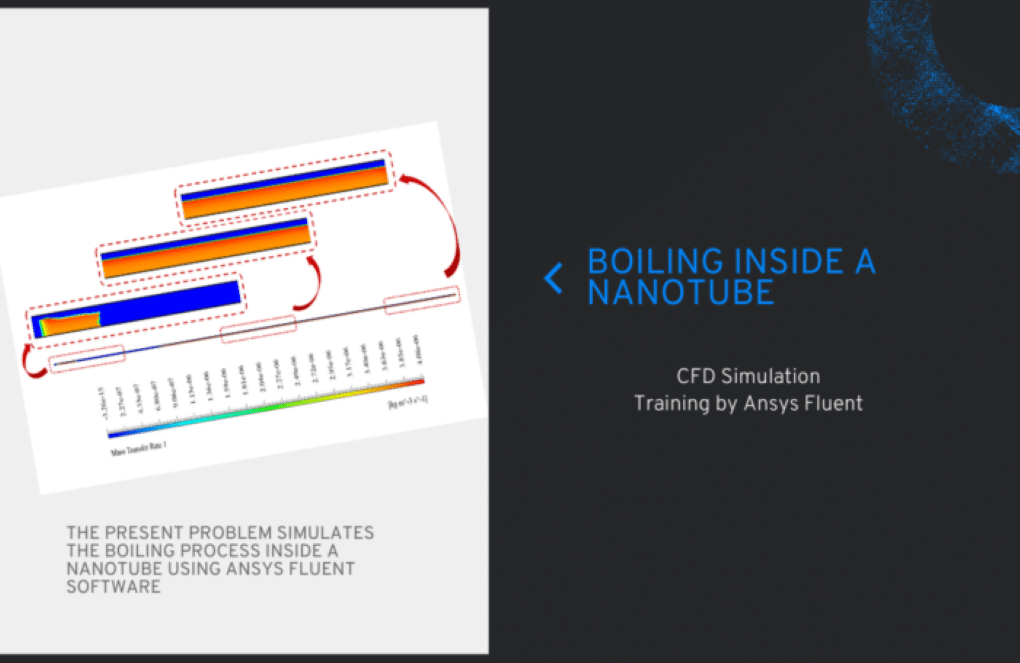

Problem number 5 simulates the boiling process inside a nanotube. A nanotube is a tube that is made at the nano-scale by nano-particles. This type of tube’s diameter can be about a few nanometers; While their length can reach several millimeters.

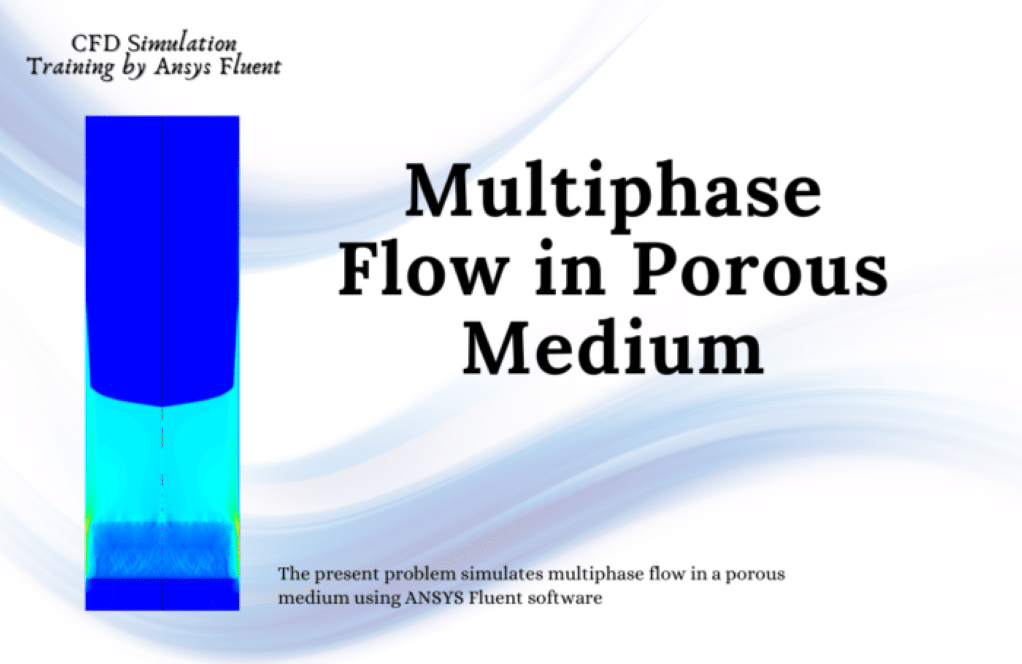

Practical exercise number 6 simulates multiphase flow in a porous medium and filter cake formation. Water flow with a relative pressure of 100,000 pascals and a temperature of 288.15 K enters from the top of a vertical column. It enters a porous media at the end of the column.

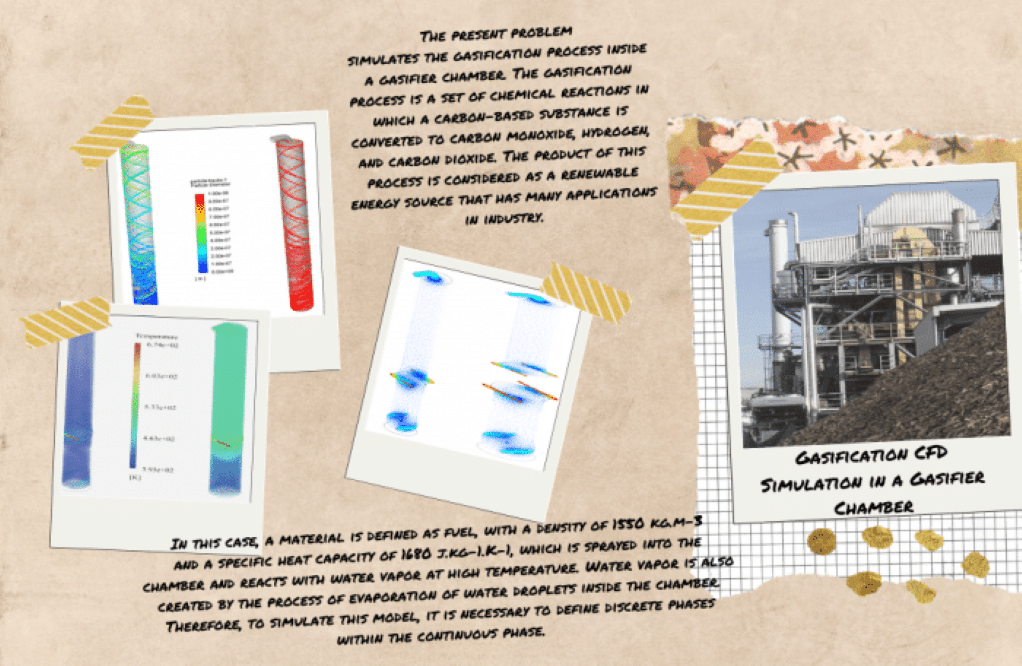

Problem number 7 simulates the gasification process inside a gasifier chamber. The gasification process is a set of chemical reactions in which a carbon-based substance is converted to carbon monoxide, hydrogen, and carbon dioxide. The product of this process is considered a renewable energy source that has many applications in the chemical industry.

Combustion

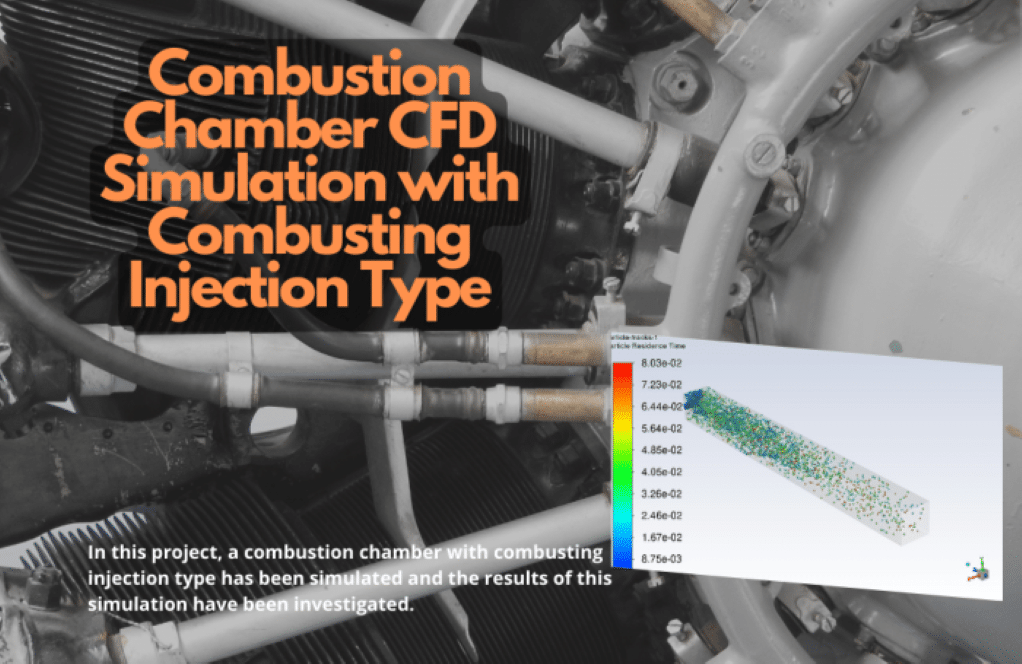

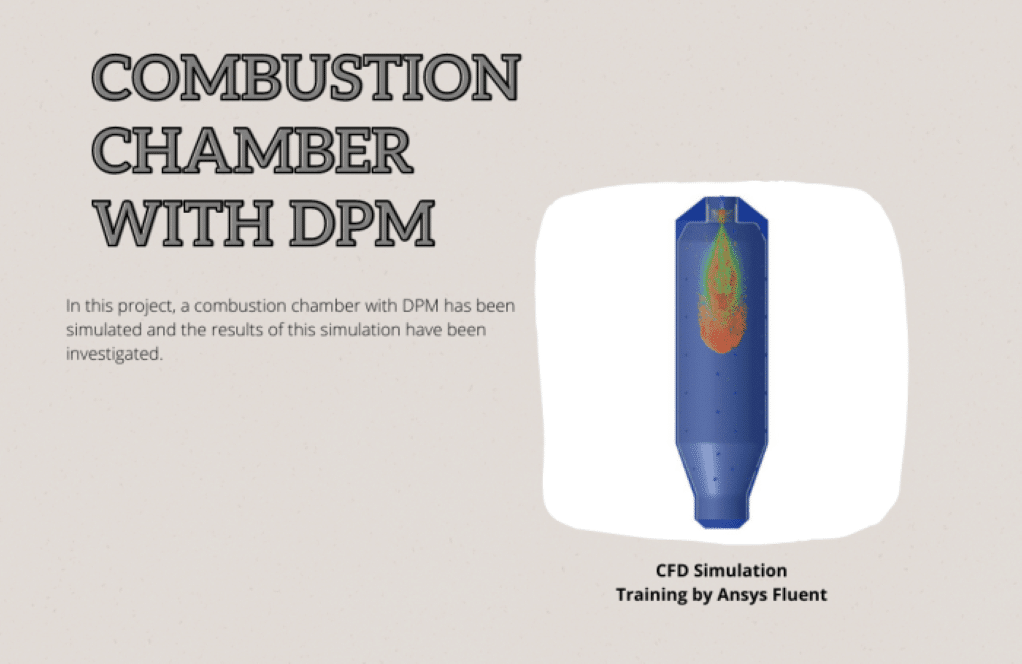

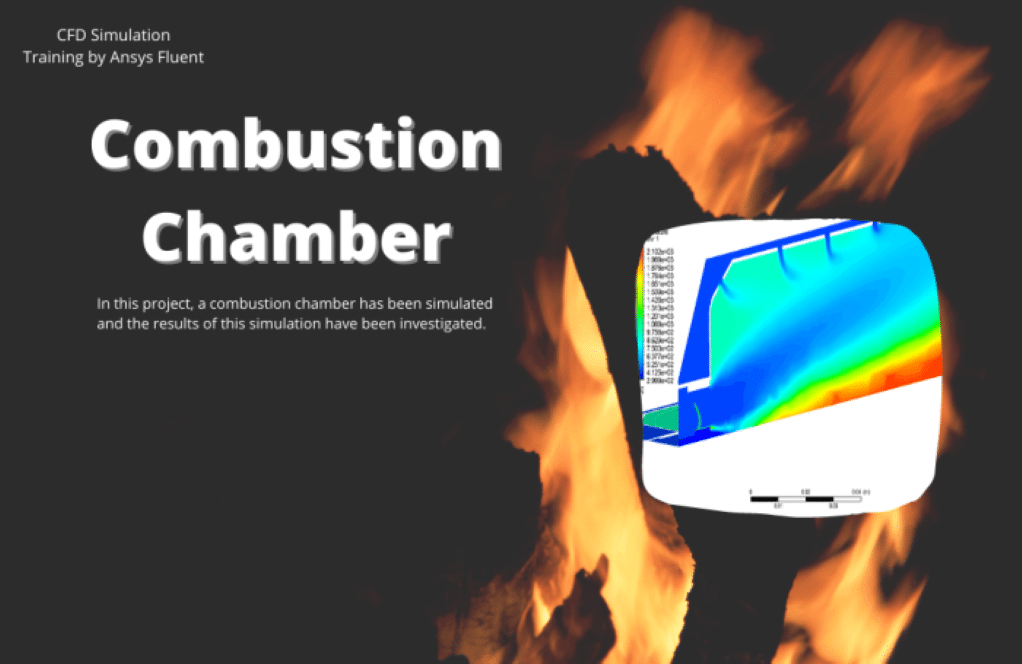

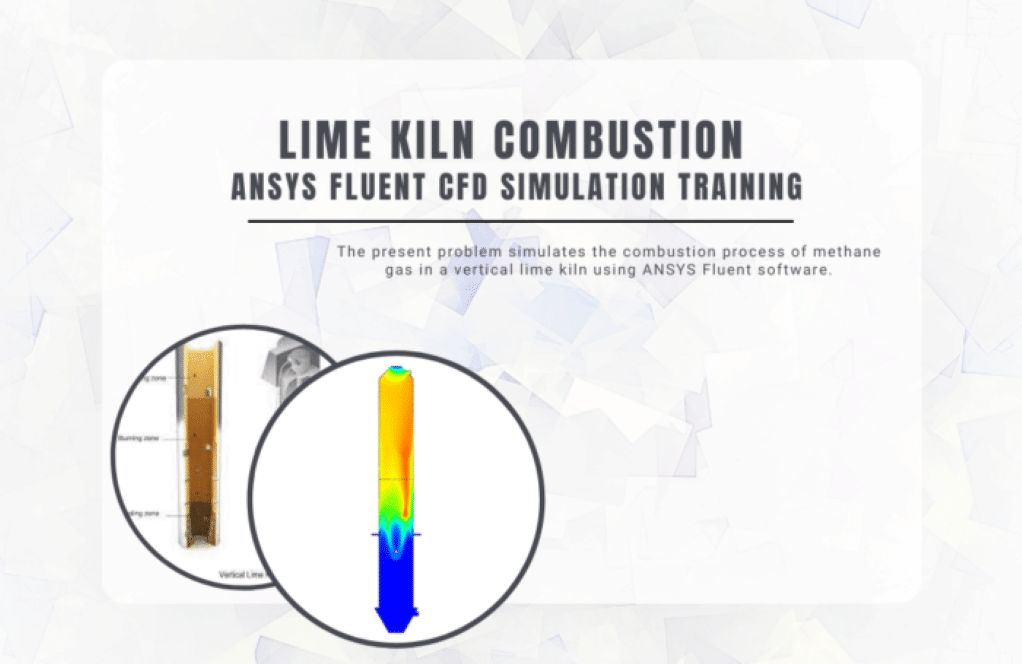

The combustion chamber is one of the most widely used devices in the chemical industry. Therefore, experts are working to improve the performance of the combustion chamber. In practical exercise number 3, a combustion chamber is simulated. Practical exercise number 8 simulates the combustion process of methane gas in a vertical lime kiln. The construction of a vertical lime kiln consists of two main parts, including the combustion zone and the preheating zone. The fuel and air enter from the middle of the lime kiln and form a combustion reaction. In project number 9, we have simulated the gas turbine combustion chamber using a Discrete Phase Model (DPM) and Species Transport Model. In this case, the effect of spraying Benzene particles is done using the Eddy- dissipation combustion model. This combustion chamber is commonly used for jet engine users.

Finally, in project number 10, a Combusting Particles Combustion in a combustion chamber is simulated. We used two-way DPM for particles and anthracite as an injection material has been used in this simulation. Anthracite is the best type of coal with the highest calorific value.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Alberta Senger –

I finished all the practical exercises, and the results were excellent. The real-life chemical engineering scenarios were truly insightful, and I learned so much. The combination of learning both the theoretical background and executing simulations truly solidified my understanding. Excellent resource for advanced learners!

MR CFD Support –

Thanks for your positive review! We’re thrilled to hear that you benefitted greatly from the Chemical Engineering Training Package and found it applicable to real-world scenarios. We always strive to provide comprehensive, practical learning material that enhances understanding effectively for our advanced users. Should you have any more feedback or need further assistance, feel free to reach out!

Dr. Wayne Walsh –

The diversity of projects in the Chemical Engineering Training Package seems to be vast. What level of expertise is needed to follow along with the practical exercises? Are there additional supports or documentation provided for less experienced users?

MR CFD Support –

This Advanced Chemical Engineering Training Package is designed for users with a solid foundation in ANSYS Fluent and Chemical Engineering principles. The complexity and detail of the exercises assume prior knowledge in using CFD simulation tools and understanding chemical processes. For users who are not as experienced, MR CFD company does provide comprehensive training movies with step-by-step instructions for each exercise, which can aid in understanding and completing the simulation tasks. Moreover, MR CFD is often willing to offer additional support and resources when needed. It is recommended to build a basic understanding of CFD and ANSYS Fluent through MR CFD’s beginner and intermediate training packages before tackling advanced-level exercises.

Vaughn Haag –

The Chemical Engineering package seems comprehensive! I’ve just completed the exercises and they provided an in-depth insight into advanced chemical process simulations. Kudos to MR CFD for the practicality and real-world applications included!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear our Chemical Engineering Training Package for advanced users met your needs and expectations. We strive to provide relevant and engaging materials and are glad that you found the practical exercises beneficial. Your appreciation is highly appreciated, and we look forward to assisting you in future learning endeavors!

Desiree Cremin –

Outstanding advanced training module for seasoned chemical engineers! It combines front-end research methodology with real-world applications, bumping up its practicality.

MR CFD Support –

Thank you for your review! We’re pleased to hear that you found the Chemical Engineering Training Package for ADVANCED Users valuable and applicable to real-world scenarios. MR CFD is committed to providing comprehensive and practical learning experiences. We appreciate your feedback!

Russel Yost –

I recently completed the advanced chemical engineering training package and I have to say, the variety of practical exercises provided an outstanding learning experience. The step-by-step guide through each project was particularly helpful for understanding complex simulations like boiling in nanotubes and gas turbine combustion. The integration of multiphase models and species transport convincingly demonstrated real industrial applications. It’s commendable how the package combines theory with hands-on practice.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our Advanced Chemical Engineering Training Package with its variety of practical exercises has provided you with a well-rounded and comprehensive learning experience. At MR CFD, we strive to offer practical, industry-relevant knowledge, and it’s rewarding to know that you found the hands-on practice to be in line with real-world applications. We appreciate your recognition of the effort put into developing this training and hope we can continue to assist you in your journey to mastering CFD simulations!

Asha Bauch –

The Chemical Engineering Training Package seems to offer a plethora of practical exercises that can elevate my knowledge to the advanced level. The variety of applications covered from multiphase flow to combustion chambers provides a comprehensive learning experience. I’m particularly interested in the DPM and species transport methods used. Were the training materials easy to follow for setting up complex simulations such as these?

MR CFD Support –

Thank you for your interest in the Chemical Engineering Training Package. Our materials are designed with the advanced user in mind, providing detailed instructions and step-by-step guides on setting up complex simulations. With your understanding of CFD fundamentals, you will find the combination of geometry setup, meshing, boundary conditions, solver settings, and result interpretation both logical and user-friendly, enhancing your learning experience.