Chemical Engineering Training Package, Intermediates, 10 Practical Exercises

$1,300.00 Original price was: $1,300.00.$219.00Current price is: $219.00. Student Discount

This training package includes 10 practical exercises, using ANSYS Fluent software. MR CFD suggests this training package for all Chemical engineers, who will learn CFD simulation in this field at the INTERMEDIATE level.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Chemical Engineering ANSYS Fluent Training Package, 10 Practical Exercises for INTERMEDIATE Users

This training package includes 10 practical exercises, using ANSYS Fluent software. MR CFD suggests this training package for all Chemical engineers, who will learn CFD simulation in this field at the INTERMEDIATE level.

Chemical Engineering

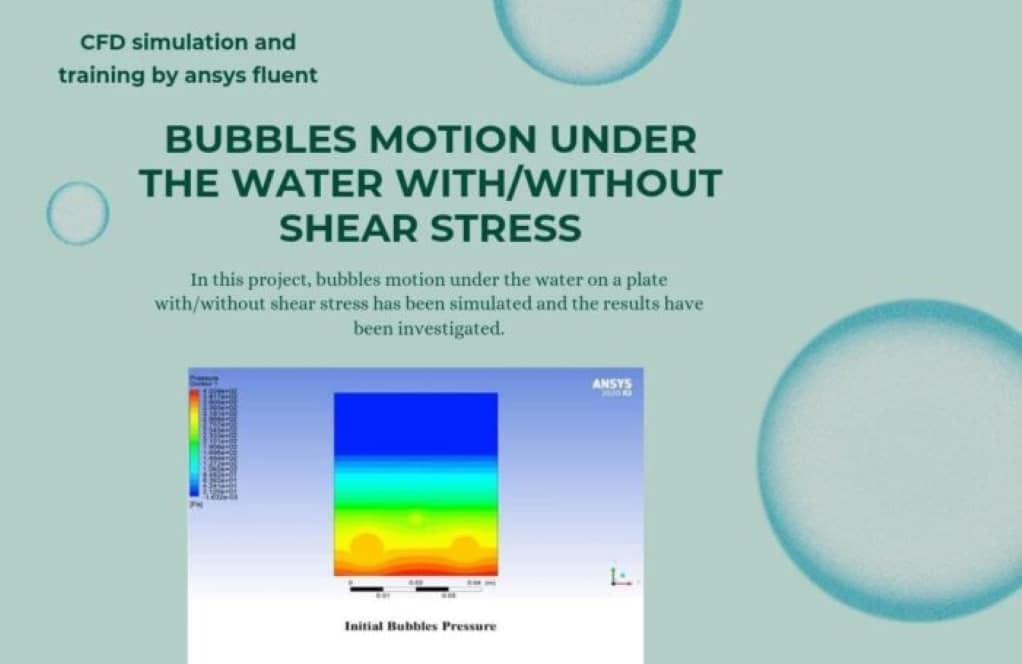

In practical exercise number 1, numerical simulation of bubble motion under the water on a plate with and without shear stress has been done. The VOF model has been used to simulate and solve the two-phase flow field equations. The purpose of this project is to consider the effect of surface tension in simulations where the free surface in phase is investigated.

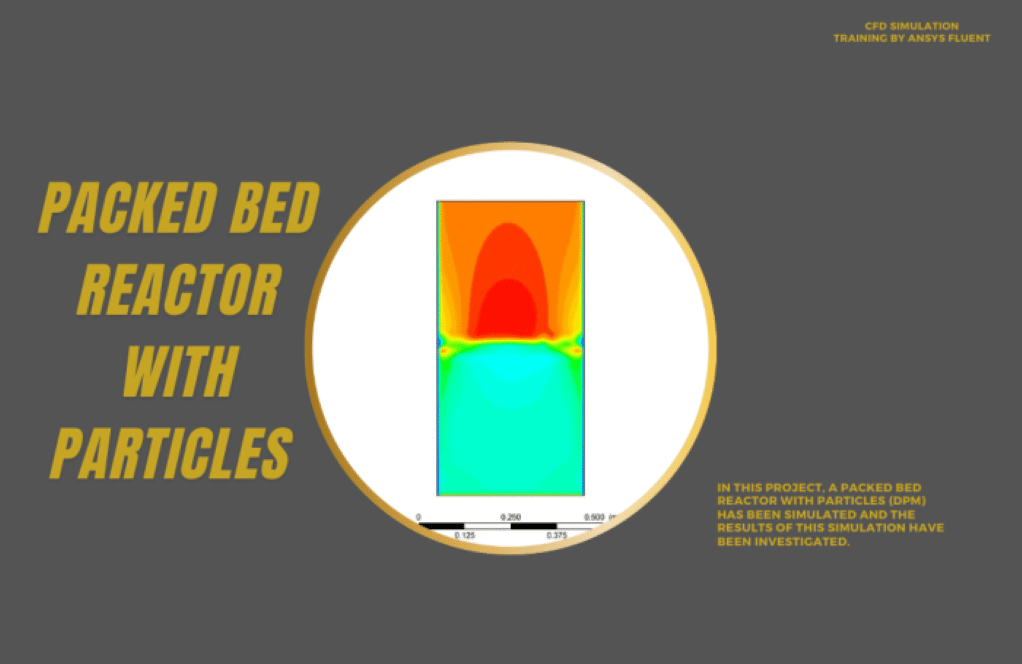

Practical exercise number 2 simulates a Packed Bed Reactor. Packed bed reactors, also known as fixed-bed reactors, are often used for catalytic processes. A packed bed reactor (PBR) is preferred for heterogeneous reactions, where the solid-fluid contact dramatically influences reaction rate.

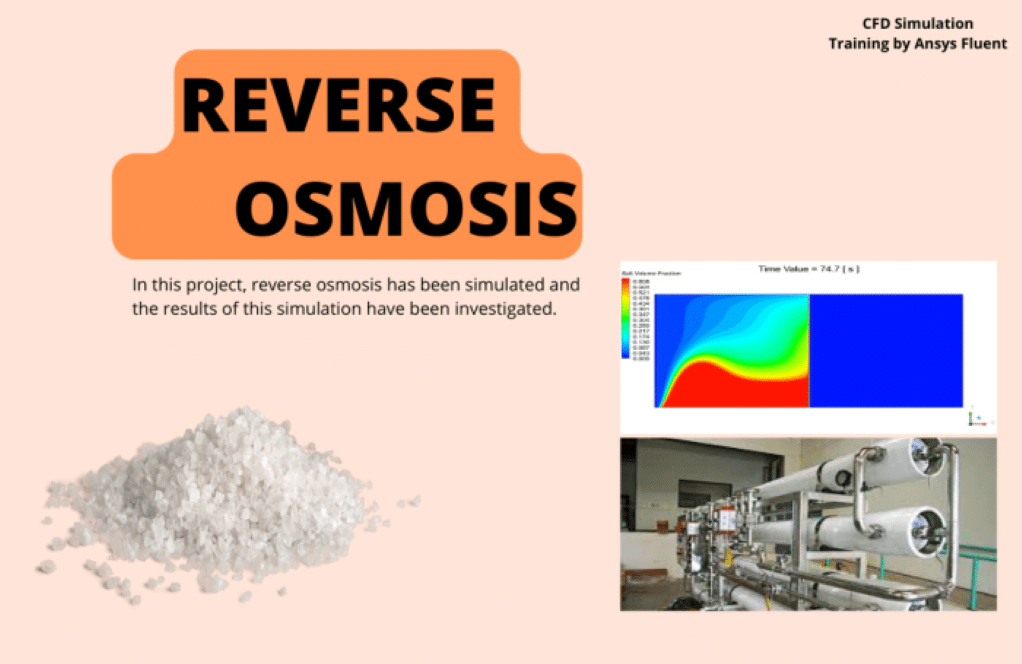

In project number 3, the reverse osmosis mechanism is simulated. This mechanism is used to purify water so that a membrane is placed in front of the saline movement and does not allow the salts in the water to leave and pure water leaves. Eulerian Multiphase model has been used in this project.

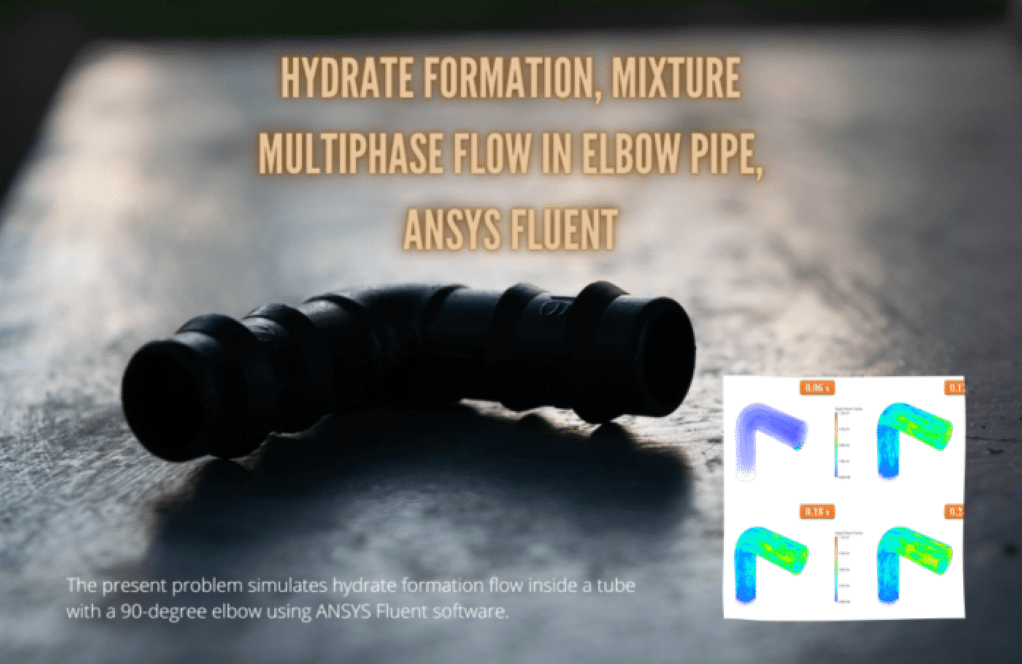

Practical exercise number 4 simulates hydrate formation flow inside a tube with a 90-degree elbow. Hydrates are organic substances that contain water. Hydrates are formed by adding water. The hydrate in this project is a combination of three different materials of water, water vapor, and methane.

Separator

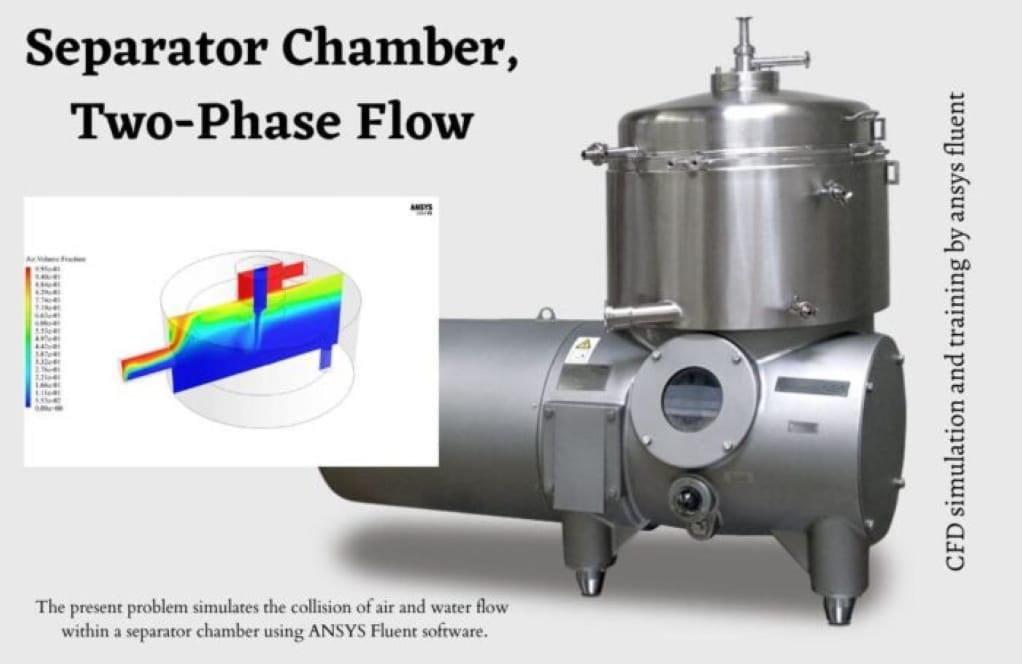

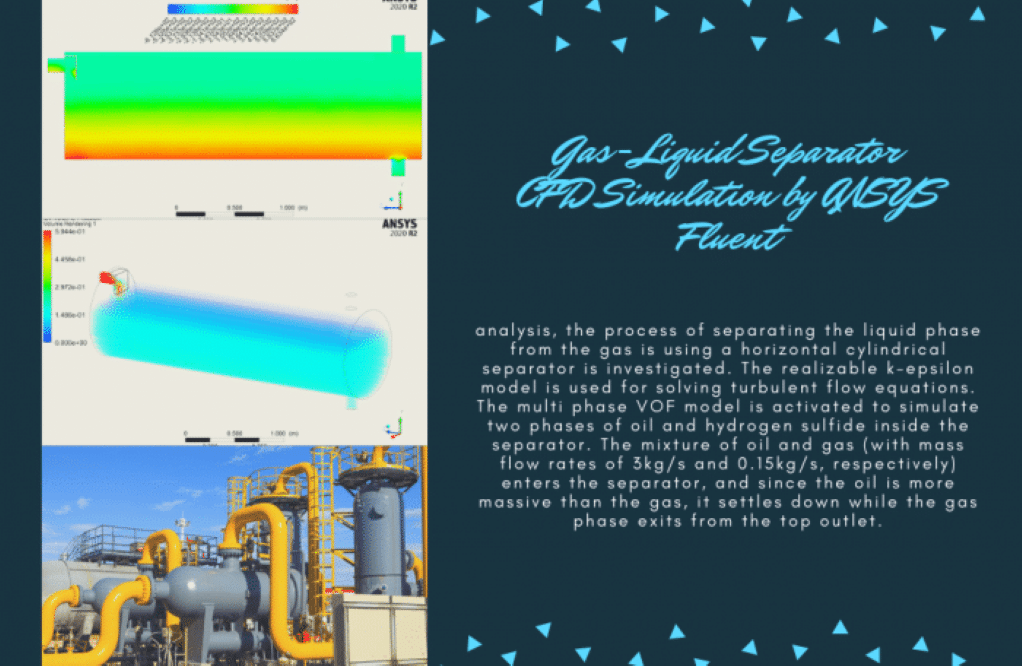

In analysis number 5, the process of separating the liquid phase from the gas using a horizontal cylindrical separator is investigated. The realizable k-epsilon model is used for solving turbulent flow equations. Also, a multi-phase VOF model is activated to simulate two phases of oil and hydrogen sulfide inside the separator. Problem number 6 simulates the collision of air and water flow within a separator chamber. In this modeling, a cylindrical separator chamber is designed whose interior space is full of water. Water then enters through a vertical pipe from the top of the chamber and exits through a bottom pipe located at the bottom of the chamber; While airflow enters from a horizontal tube on the lateral surface of the chamber and exits through a horizontal tube on the lateral surface of the upper part.

Mixing

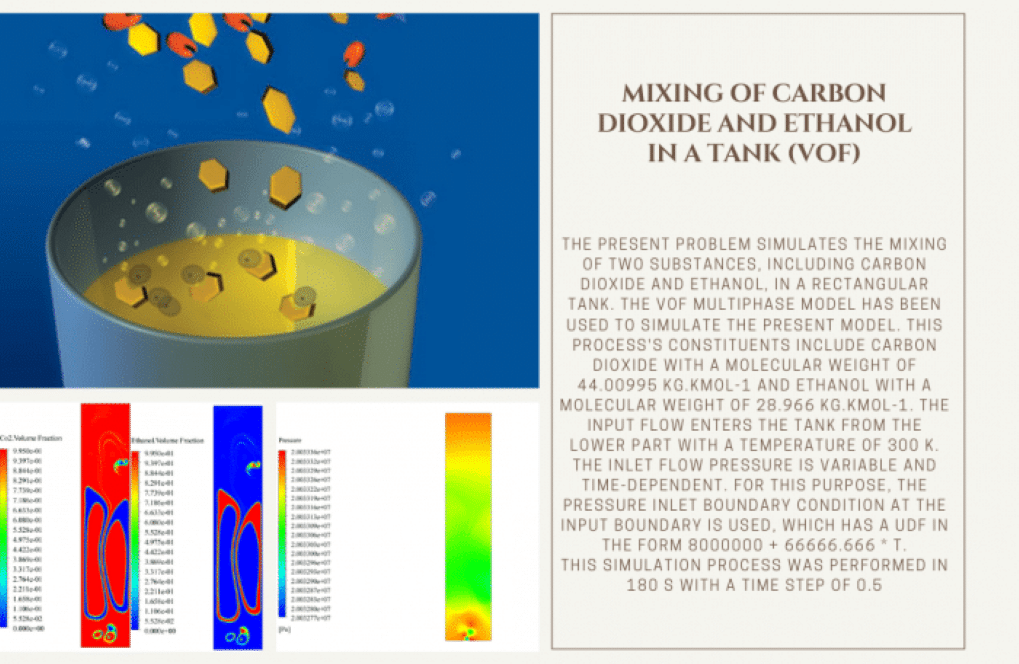

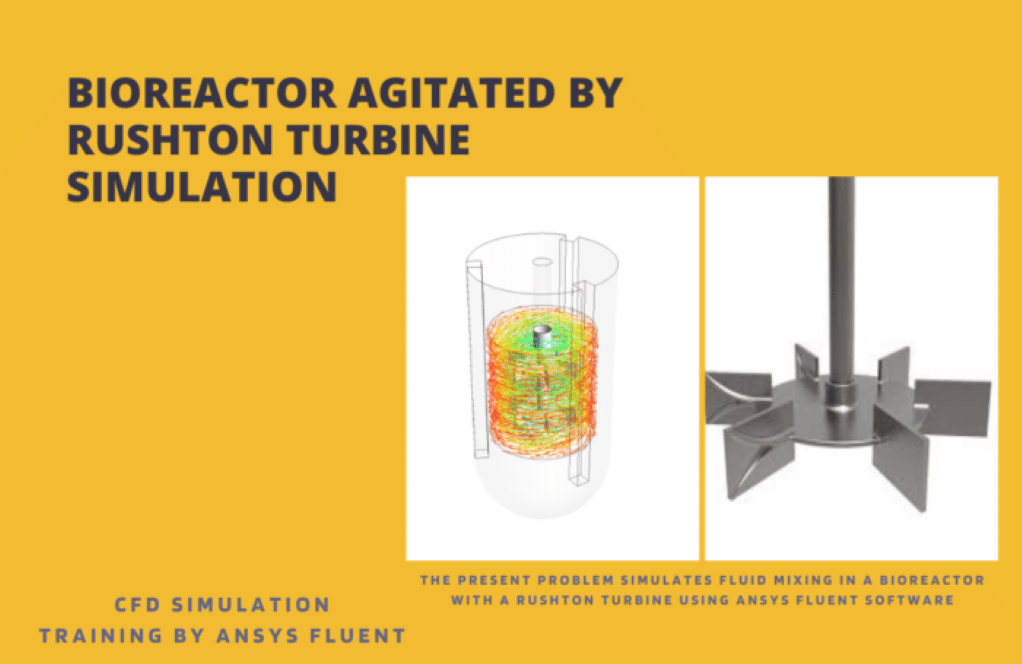

Problem number 7 simulates fluid mixing in a bioreactor with a Rushton turbine. Bioreactors are equipment and systems in which biochemical reactions occur and are used in various industries, including pharmaceutical, food, biochemical, perfumery, chemical, etc. The bioreactor modeled in this simulation has a cylindrical structure. Practical exercise number 8 simulates the mixing of two substances including carbon dioxide and ethanol in a rectangular tank. The VOF multiphase model has been used to simulate the present model. The constituents of this process include carbon dioxide with a molecular weight of 44.00995 kg.kmol-1 and ethanol with a molecular weight of 28.966 kg.kmol-1.

Cyclone

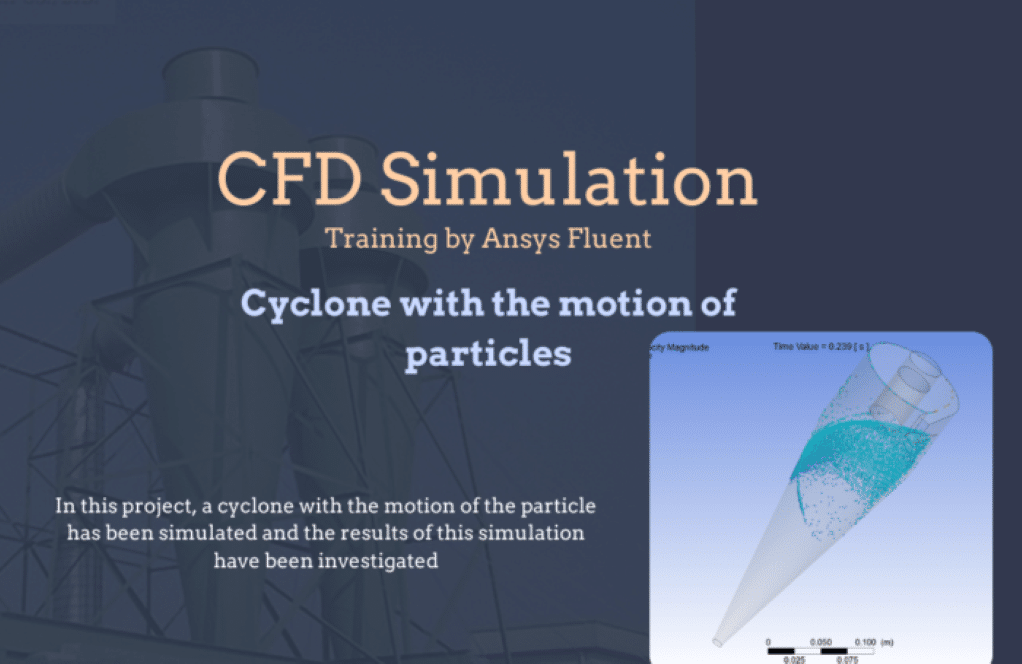

In project number 9, the motion of particles in a cyclone has been simulated. We used the one-way DPM to simulate the discrete phase (particles). A cyclone is a device used to separate particles from gas and has many applications in the chemical industry. Finally, in practical exercise number 10, the motion of particles in a Fly Ash Cyclone has been simulated. The Eulerian-Lagrangian technique is applied in the cyclone separator simulation. In this approach, the gas is treated as a continuum, and individual solid particles are tracked through the flow field by Lagrangian tracking to determine their position. In cyclone separators, the drag and gravity forces are considered significant due to the large ratio of the gas/particle density.

Ms. Angela Fadel DVM –

I’ve found the included 10 practical exercises particularly enhancing to my understanding of CFD applications in chemical engineering. It’s great to see such a comprehensive coverage, from bubble motion and packed bed reactors to cyclone simulations and bioreactors. The added Training Movie is a nice touch for visual learners like me. Thanks to the MR CFD team for this intermediate-level gem!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Chemical Engineering ANSYS Fluent Training Package with its variety of practical exercises has contributed to your understanding of CFD. It’s always our goal to provide an enriching learning experience. We look forward to providing you with more quality training materials that will help you advance your skills.

Lavonne Blanda –

I’ve worked through the exercises in the Chemical Engineering Training Package, and the diversity of applications is impressive. The step-by-step approach in the training movies really solidified my understanding of multiphase flows and reactor design.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you found the training package informative and easy to follow. We strive to provide a diverse range of applications to cater to our clients’ needs. If you have any further feedback or need additional assistance, please feel free to reach out.

Liza Waelchi –

The description is enticing! I’m currently studying particle motion in fluid flows, and project number 9 on cyclone motion caught my attention. Could you elaborate on how the one-way DPM differs from other particle tracking techniques?

MR CFD Support –

Certainly! The one-way Discrete Phase Model (DPM) treats the particle phase as discrete from the fluid phase and assumes that the particles do not significantly affect the fluid flow field. In contrast, other methods, like two-way or four-way coupling, take into account the back-reaction of particles on the fluid, or additional interactions like collision and energy exchange between particles. One-way DPM is computationally less intensive and suitable when dealing with dilute particulate flows where particle-fluid interactions can be neglected.

Ms. Stella Mayert –

The practical exercises included in the Chemical Engineering Training Package seem very comprehensive. I am particularly interested in the exercise simulating the motion of bubbles under water on a plate. Does the exercise incorporate real-world variables, such as varying water temperatures or additional forces acting on the bubbles?

MR CFD Support –

We appreciate your interest in our Chemical Engineering Training Package and your specific question about the bubble motion exercise. Yes, the exercise incorporates real-world variables such as surface tension and can include different water temperatures if that creates a relevant scenario for the bubbles’ motion. Additional forces, like buoyancy, drag, or lift, are also considered in the simulation to mirror the complexities of a real-life situation.

Charley Mosciski –

This training package seems comprehensive, but with 10 different exercises, I’m wondering if support material is included to help guide through complex topics like turbulent flow equations or the Eulerian-Lagrangian technique.

MR CFD Support –

Yes, the Chemical Engineering Training Package for Intermediates includes support materials to guide you through complex topics. Alongside comprehensive training movies for each exercise, you will also find detailed descriptions and tutorials that cover relevant models like turbulent flow equations and the Eulerian-Lagrangian technique to assist with your learning.

Iliana Ritchie DVM –

This training package sounds comprehensive. Would it be appropriate for someone new to ANSYS Fluent, or is prior experience required?

MR CFD Support –

The package is designed for INTERMEDIATE users which suggests that it would be ideal for someone with foundational knowledge of ANSYS Fluent. It assumes users have a basic understanding and experience with the software, so it may not be the best starting point for a complete beginner. I recommend it for users who are familiar with the basics and looking to deepen their expertise.