Moving Mesh (Mesh Motion) Training Package, 10 Practical Exercises for BEGINNERS

$440.00 Student Discount

This product includes Geometry & Mesh file and a comprehensive Training Movie.

There are some free products to check our service quality.

To order your ANSYS Fluent project (CFD simulation and training), contact our experts via [email protected], online support, or WhatsApp.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Moving Mesh (Mesh Motion) ANSYS Fluent CFD Simulation Training Package for BEGINNER Users

This training package includes 10 practical Moving Mesh exercises using ANSYS Fluent software. MR CFD suggests this package for BEGINNER users who tends to learn the simulation process of Moving Mesh problems without any strong background.

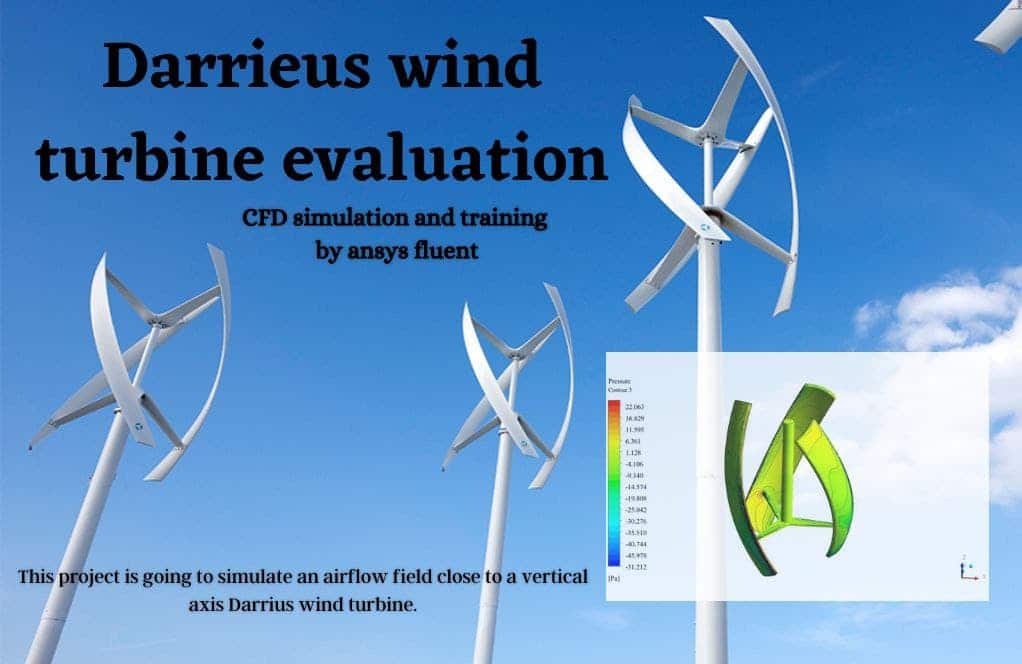

Derrieus Wind Turbine

Vertical Axis Wind Turbine (VAWT) is becoming ever more important in wind power generation thanks to its adaptability for domestic installations. However, it is known that VAWTs have lower efficiency, above all, if compared to HAWTs. Project number 1 is going to simulate an airflow field close to a vertical axis Darrieus wind turbine. The geometry included a rotary zone for the turbine walls and a stationary zone for the rest of the domain. The inlet is considered to wind at 1 m/s, and the turbine zone is rotating at 120 RPM.

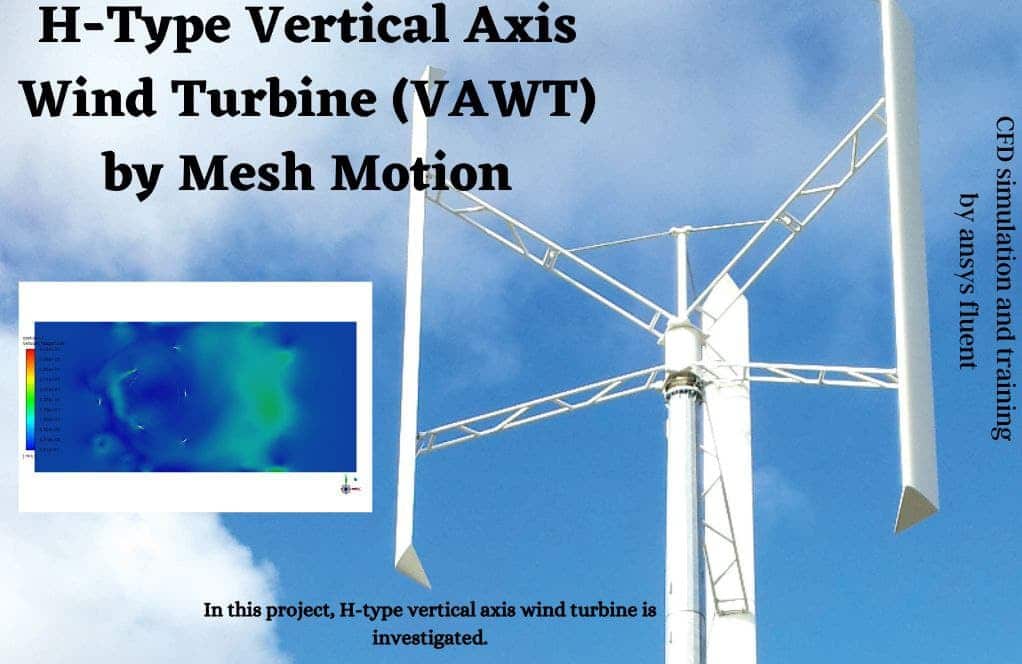

In project number 2, steady airflow in the presence of an H-type wind turbine is. The H-type turbine analyzed in the present work has six blades where three blades are closer to the center of rotation. The turbine rotates in Z-direction with an angular velocity equal to 14.17 rad/s. Air velocity at the inlet is equal to 5.3 m/s. Airflow in the domain is dominantly affected by turbine rotation.

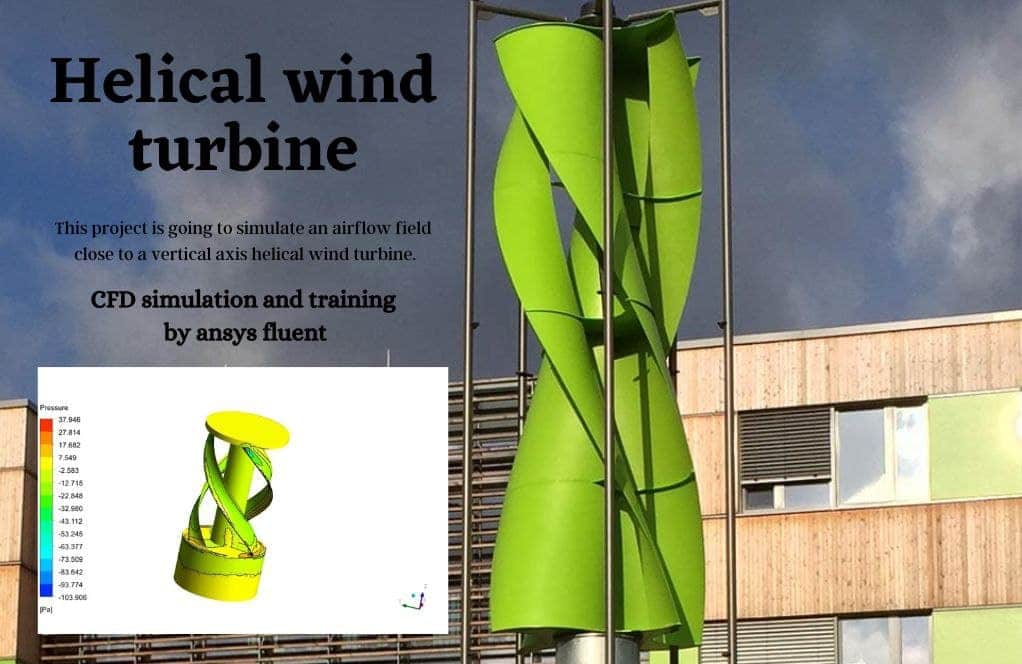

Project number 3 is going to simulate an airflow field close to a vertical axis Helical wind turbine. The geometry included a rotary zone for the turbine walls and a stationary zone for the rest of the domain. The inlet is considered to wind at 1 m/s, and the turbine zone is rotating at 120 RPM. This paper aims to investigate the behavior of airflow and pressure distribution and study drag force.

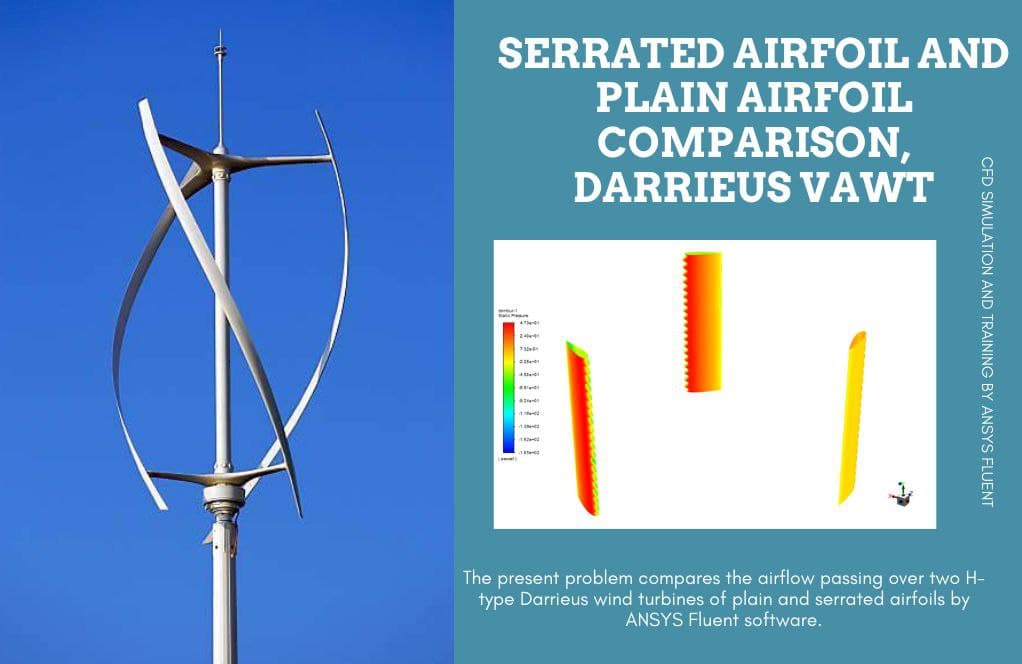

Project number 4 compares the airflow passing over two H-type Darrieus wind turbines of Plain and Serrated airfoils. In this project, the airflow enters the computational domain with a velocity of 7m/s, and we apply the RNG k-epsilon model to solve the turbulent flow equations. Also, it should be noted that the Mesh Motion option was enabled to simulate the rotating motion of turbine blades, and the rotation velocity of the rotating domain was set to 2.8285 rad/s.

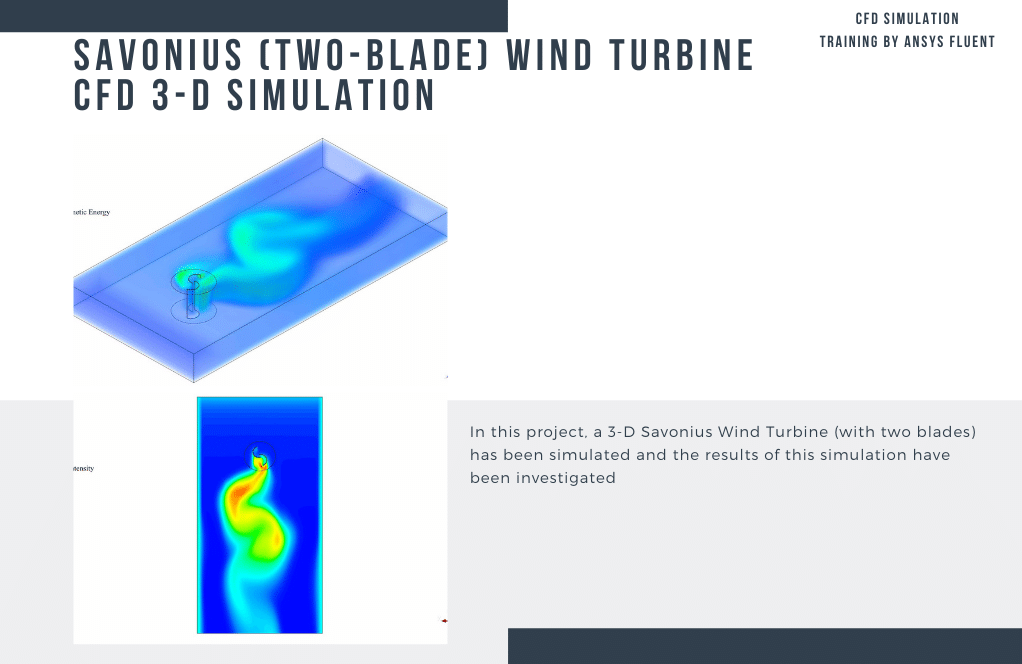

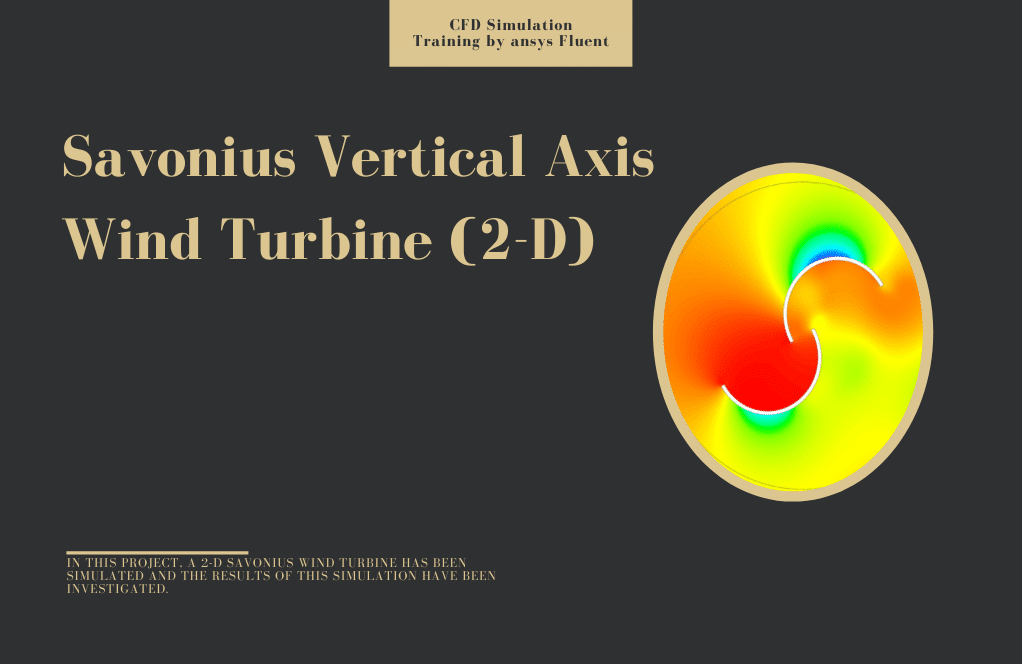

Savonius Wind Turbine

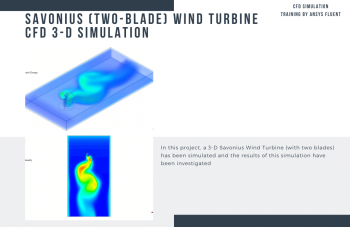

The two most well-known types of these turbines are Savonius and Darrieus. The movement mechanism of the Savonius turbine is based on drag force, while the movement mechanism of the Darrieus turbine is based on lift force.

In project number 5, a two-dimensional two-blade Savonius wind turbine has simulated using moving mesh, and then the results were investigated. Air enters the computational domain from the inlet with 10m/s velocity while the turbine rotates with a constant angular velocity of 10rpm. Our final goal is to illustrate the pressure and velocity distribution and animate the fluid motion. On the other hand, the three-dimensional Savories wind turbine is simulated in project number 6. Air enters the fluid domain from the inlet with 10m/s velocity while the turbine rotates with a constant angular velocity of 40rpm. Our final goal is to illustrate the pressure and velocity distribution and animate the fluid motion behind the turbine.

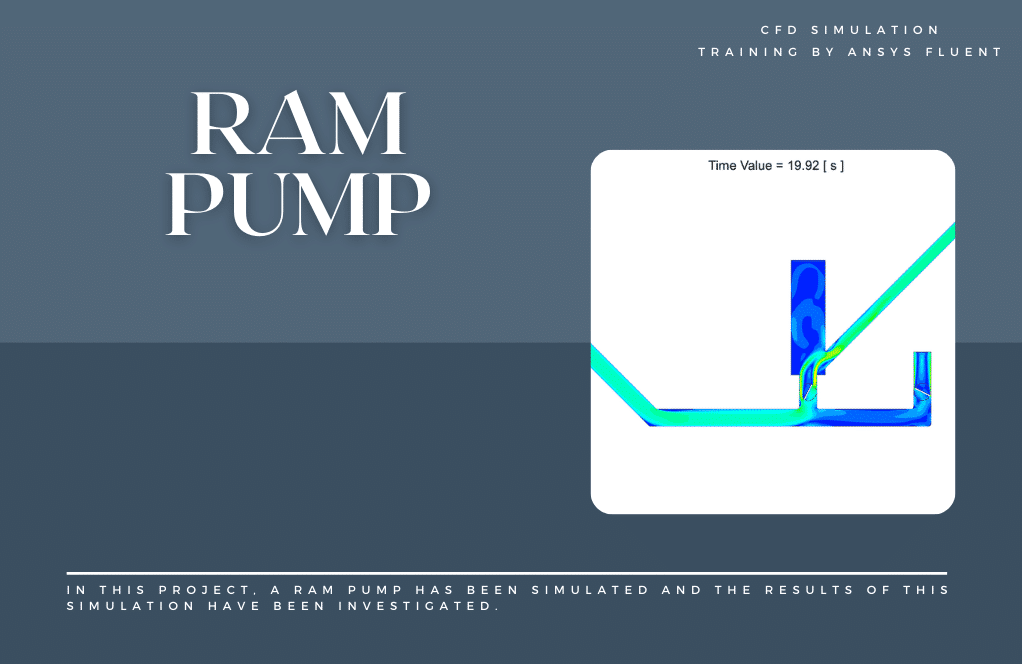

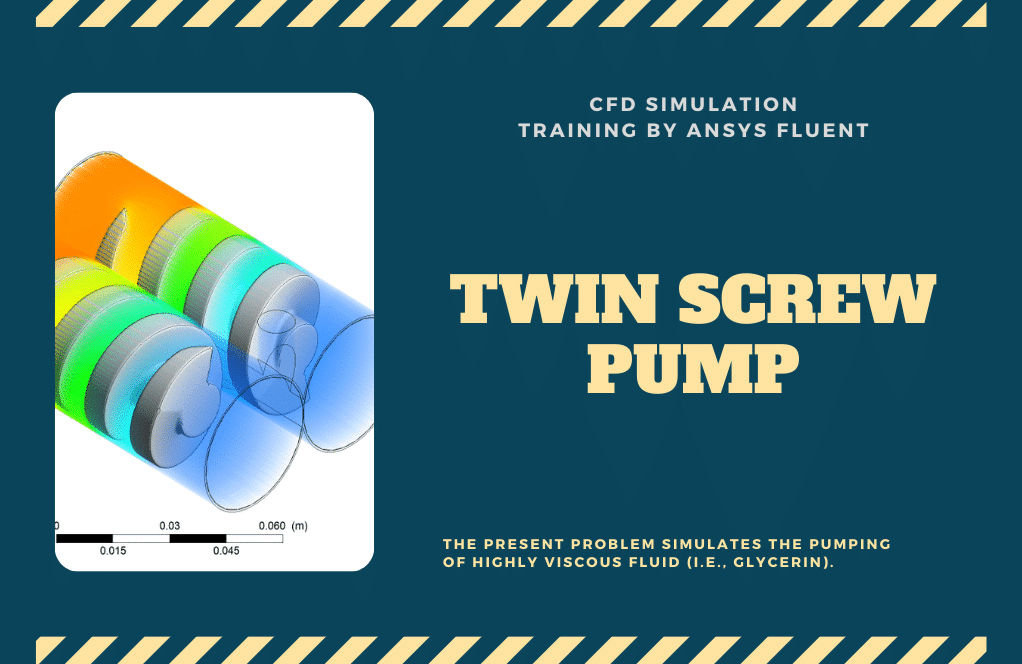

Pumps (Moving Mesh)

Project number 7 simulates the pumping of highly viscous fluid (i.e., Glycerin). The twin-screw pump increases the pressure of the Glycerin and pushes it toward the outlet. The RNG k-epsilon model is exploited to solve the turbulent flow equations. The rotation velocity of the rotating domains was set to 3 rad/s. A twin-screw pump is a positive displacement pump, meaning that the pump transfers a particular volume of product according to the speed and pitch of the screws.

In project number 8, a ram pump has been simulated. In this simulation, a Mesh Motion model with an angular velocity of 1 radian per second has been used, and the input speed has Water is one m/s, and at the outlet, water is discharged at atmospheric pressure.

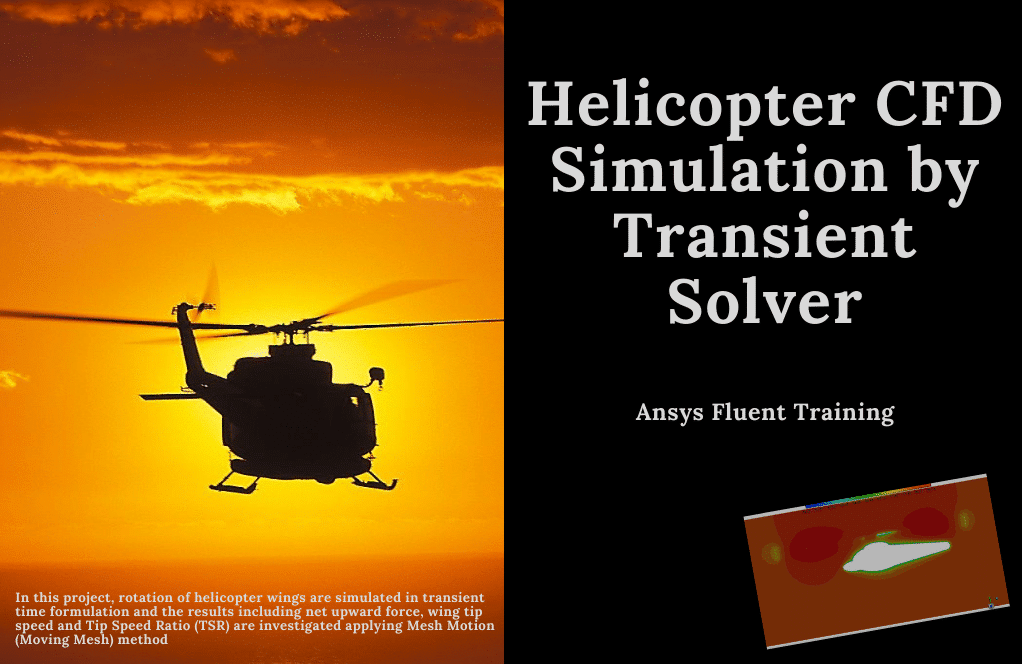

Helicopter

In project number 9, the rotation of helicopter wings is simulated in transient time formulation, and the results including net upward force, wingtip speed, and Tip Speed Ratio (TSR) are investigated. In order to generate upward movement in aerodynamic applications, movement of a certain amount of air in a downward direction is needed, which in return generates upward motion. For helicopters, this movement of air is done using a propeller which consists of 2 or more wing-shaped geometries, rotating around a center. In this simulation, the propeller is rotating with an angular velocity equal to 1250 rpm in Y-direction.

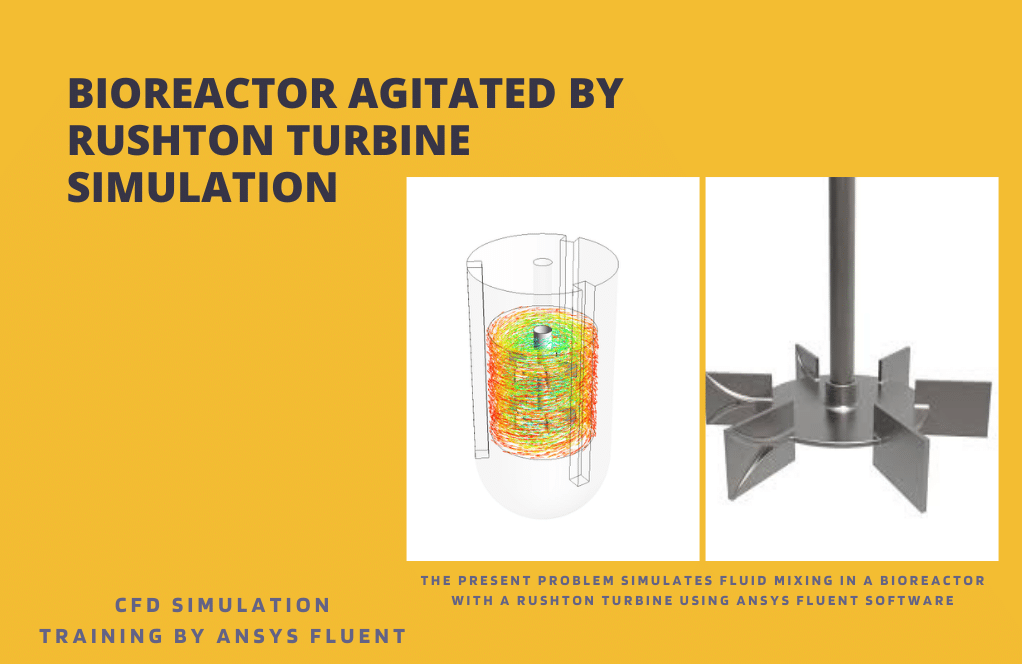

Bioreactor

Project number 10 simulates fluid mixing in a Bioreactor with a Rushton turbine. Bioreactors are equipment and systems in which biochemical reactions occur and are used in various industries, including pharmaceutical, food, biochemical, perfumery, etc. The stirrer used inside this reactor is a Rushton-type turbine. Rushton turbines are in the form of radial flow type impellers widely used in mixing applications in engineering processes. The value of rotational speed in this region is equal to 143 rpm and is defined around the model’s vertical central axis (Y-axis).

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Anya Weissnat MD –

How user-friendly is this package for beginners?

MR CFD Support –

The package is designed to be user-friendly and includes 10 practical exercises for beginners to help get you started.

Buck Feil –

I’m working on a project involving fluid dynamics in a system with moving parts. Can this package accommodate that?

MR CFD Support –

Yes, our package can handle simulations involving fluid dynamics in systems with moving parts. We are also open to contributions and can customize the simulations to suit your project requirements.

Jess Hintz –

The Moving Mesh (Mesh Motion) Training Package for BEGINNERS seems very comprehensive. Can you tell me if the package also includes some guidance on how to troubleshoot common problems that might arise when setting up or running these simulations?

MR CFD Support –

Yes, the Moving Mesh (Mesh Motion) Training Package includes guidelines on troubleshooting common issues. It provides strategies for addressing convergence difficulties, mesh deformation errors, and setting the correct boundary conditions for each case. Additionally, the package comes with a comprehensive training movie which demonstrates how to solve the problem step by step.

Clint Nicolas –

The Moving Mesh package sounds fantastic for beginners. Can you tell me if it includes any tutorials or step-by-step guides to help beginners understand the mesh motion settings in ANSYS Fluent?

MR CFD Support –

Absolutely! As part of the training package, you receive a comprehensive Training Movie that provides detailed instructions on how to solve the problems and extract all the necessary results. The package is specifically tailored for beginners to grasp the simulation process of Moving Mesh problems in ANSYS Fluent, significantly aided by the visual guides.

Miracle Prohaska –

I’m totally new to ANSYS Fluent and CFD simulations. Is this training package beginner-friendly for someone with no prior experience?

MR CFD Support –

Absolutely! The Moving Mesh CFD Simulation Training Package is specifically designed for BEGINNER users with little to no background in CFD or ANSYS Fluent. It includes step-by-step exercises and a comprehensive training movie that guides you through the simulation process and result analysis. Rest assured, it’s a great starting point for learning about Moving Mesh simulations.

Elbert Lynch Jr. –

This package seems well-crafted for beginners, but could you please explain how you cater to users with different learning paces?

MR CFD Support –

Absolutely! The training package is designed for users to work at their own pace. It contains step-by-step instructional videos and detailed written tutorials that allow users to pause and repeat sections as needed. Additionally, the inclusion of various exercises caters to different learning styles.

Mr. Curtis Daugherty –

I recently completed the Moving Mesh Training Package for Beginners–truly made for someone like me. For example, the varied projects, such as the wind turbine simulations and the bioreactor mixing process, were brilliant for understanding different applications. Furthermore, clear instructions on setting up complex problems, like mesh motion and boundary conditions, helped solidify my grasp on ANSYS Fluent. There’s nothing comparable for early-stage learners. Excited for more!

MR CFD Support –

Thank you so much for your positive review! We’re thrilled to hear that the Moving Mesh Training Package for Beginners met your learning needs so well, and that it provided clear and comprehensive guidance for different applications. Knowing that you now feel more confident in using ANSYS Fluent is extremely rewarding. If you ever have any questions or need further assistance, please don’t hesitate to reach out. We’re looking forward to providing you with even more learning resources in the future!

Prof. Penelope Haag IV –

I just finished the Moving Mesh Training Package for BEGINNERS from MR CFD, and as someone new to this field, I appreciate the hands-on learning approach. Going through 10 different exercises with varying complexities helped me gain clarity on the process of solving Moving Mesh problems. It was exactly what I needed to start with, especially the interactive workflow and clear-cut guidelines for setting up simulations. Impressive training package, perfect for beginners!

MR CFD Support –

Thank you very much for your review! We’re glad to hear that our training material hit the mark for you. Our goal is to provide engaging training for beginners that makes complex topics approachable. It’s rewarding for us that the package enhanced your understanding of Moving Mesh simulations. Keep practicing, and don’t hesitate to check out our other training packages to further develop your CFD skills.

Joanne Rowe –

The practical exercises bundled in the ‘Moving Mesh (Mesh Motion) Training Package’ offer tangible learning projects for beginners. The careful selection of diverse simulations like wind turbines, pumps, helicopters, and bioreactors provide a solid foundation in mesh motion techniques. Especially appreciated was the inclusion of multimedia instructional materials, offering a clear step-by-step guide to problem-solving within ANSYS Fluent. Kudos on a well-crafted educational tool!

MR CFD Support –

Thank you for your kind words about our Moving Mesh Training Package. We’re thrilled to hear that you found the selection of exercises and instructional materials helpful for learning mesh motion simulation in ANSYS Fluent. It’s our pleasure to assist beginners in understanding CFD concepts practically. Should you have further feedback or need assistance with other CFD topics, feel free to reach out. Happy simulating!

Dr. D’angelo Jenkins V –

I’ve always been curious about how fluid dynamics can impact engineering designs. It’s fascinating to see how the Moving Mesh (Mesh Motion) Training Package enables beginners like me to understand these principles through practical exercises. I found the helicopter wing simulation particularly interesting—seeing how changing air movement results in directional force. Simply put, the learner-friendly structure of this package has given me confidence to dive deeper into CFD applications!

MR CFD Support –

Thank you for taking the time to leave us such a wonderful review. We are thrilled to hear that the Moving Mesh Training Package has boosted your confidence and understanding of CFD principles, especially through practical simulations like the helicopter wing. Your enthusiasm for learning and applying fluid dynamics in engineering designs is exactly the outcome we hope to achieve with our users. Should you have any questions or need further guidance as you continue to delve into CFD, do not hesitate to reach out.

Robyn Rempel III –

The training package sounds extensive and perfect for someone starting in CFD with ANSYS Fluent. I wonder, does the package include detailed tutorials for setting up the mesh motion in each of the 10 projects, and does it have support material for clearing potential doubts during the learning process?

MR CFD Support –

Definitely, the package includes step-by-step tutorials specifically crafted to guide beginner users through setting up mesh motion in all the practical exercises. Additionally, it provides a comprehensive training movie with each project to ensure clarity. If questions or doubts arise, MR CFD is committed to assisting learners throughout their study via the support system or additional learning materials.

Rhianna VonRueden –

I’m interested in the Moving Mesh (Mesh Motion) ANSYS Fluent Training Package. How does it handle complex geometries in motion?

MR CFD Support –

Our package is designed with robust algorithms that can effectively handle complex geometries. It ensures accurate and efficient simulation of moving parts within the machinery.

Tamara Flatley –

I’ve been working through the Moving Mesh training package and found the wave modeling video especially interesting. I appreciated how it reflects actual physics, but could you provide an example of another real-world application for this method?

MR CFD Support –

Thank you for your positive feedback! One real-world application of the Moving Mesh method beyond wave modeling can be found in the automotive industry, specifically in the simulation of engine pistons movements. As pistons reciprocate within cylinders, the dynamic mesh approach allows for accurate modeling of the fluid flow changes caused by this motion, predicting performance characteristics such as turbulence and combustion efficiency.

Henry Morissette –

I recently completed the Moving Mesh Training Package by MR CFD and found it an excellent introduction to mesh motion in ANSYS Fluent. The variety of projects provided a well-rounded experience, and the step-by-step training videos were incredibly helpful. I feel much more confident in handling moving mesh simulations thanks to this training.

MR CFD Support –

Thank you for your kind review! We’re thrilled to hear that our training package has been effective in boosting your confidence with moving mesh simulations and that the projects provided a comprehensive learning experience. If you have any questions or need further practice with advanced simulations, don’t hesitate to reach out. Your success and satisfaction with CFD learning are important to us at MR CFD!

Xzavier Williamson –

What are the prerequisites for someone to start with this Moving Mesh training package? Does it require any prior knowledge in meshing or CFD?

MR CFD Support –

This training package is designed for BEGINNER users, therefore, it is created with the assumption that those starting with these exercises may not have a strong background in simulation or meshing. It walks through all the necessary steps, so no prior knowledge in meshing or CFD is required. The guidance provided in the package would help users to understand the simulation process from scratch.

Miss Claudine Denesik DDS –

I really found the Moving Mesh training package incredibly helpful as a beginner! The examples covered a diverse array of applications, which I think is great for learning. One question though, does the package provide detailed explanations on how to adjust mesh motion settings depending on the complexity of the simulation, in case I want to apply this knowledge to different types of problems in the future?

MR CFD Support –

We’re thrilled to hear that you’re finding the Moving Mesh (Mesh Motion) training package beneficial! Through the 10 practical exercises, you are exposed to a variety of settings and conditions that systematically build your understanding of mesh motion in distinct contexts. To answer your question, while the training package is designed with step-by-step instructions for each scenario, it also includes comprehensive explanations that underpin the mesh motion settings applied. Through detailed concept discussions in the training movies and accompanying documentation, you gain insights into the rationale behind each setting’s choice. Thus, you’ll have the foundation to extend these principles when facing new and complex simulations beyond the scope of the training exercises. Let’s keep the learning momentum going – your future CFD challenges await!

Mr. Charley Walter IV –

I’ve just started exploring mesh motion simulations, and I’m excited to try this beginner training package! The gradual skill build-up sounds perfect for someone like me. Can’t wait to dive in!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear about your enthusiasm for the Moving Mesh (Mesh Motion) Training Package. It’s wonderful that it aligns perfectly with your level of expertise. If you have any queries or require assistance as you proceed, do not hesitate to reach out. Good luck with your learning journey and enjoy diving into the simulations!

Ms. Marilie Hessel –

I’m entirely new to ANSYS Fluent and havn’t used it before. Is this beginners package useful for someone with zero experience in the software?

MR CFD Support –

Absolutely! Our Moving Mesh training package is designed specifically for users like you who are just starting out. It walks you through basic simulations step-by-step and does not require previous experience. With this package, you’ll gain the practice and confidence needed to handle moving mesh problems in ANSYS Fluent.

Dr. Amira Von MD –

I just finished the ‘Moving Mesh (Mesh Motion) Training Package’ and I must say it was a fantastic introduction into the world of mesh motion simulation. The step-by-step approach in the training videos was amazing, and I appreciated the strong focus on practical examples. Each project guided me seamlessly through the process from problem setup to results analysis, enhancing my comprehension of moving mesh dynamics. With simple and comprehensive instructions, starting with something as innovative as VAWT simulations felt very approachable. Every beginner in CFD should try this training package!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you found great value in our ‘Moving Mesh (Mesh Motion) Training Package’, especially as a beginner. It’s always our goal to present complex concepts in an accessible way, so we’re delighted to know the practical examples and step-by-step videos made a significant difference for you. Your appreciation for the careful curation of our projects is the motivation we need to keep providing such comprehensive training. If you ever need further assistance or wish to tackle more advanced simulations, remember that our team is always here to help you expand your CFD knowledge!

Baron Ullrich –

Can this package simulate heat transfer in machinery with moving parts?

MR CFD Support –

Absolutely. The package includes the energy equation to simulate heat transfer, allowing for an accurate simulation of temperature distribution and the impact on machinery performance.

Ms. Lily Ullrich –

I’ve really enjoyed learning from the Moving Mesh Training Package. The varied projects have given me a broad perspective on dealing with diverse mesh motion scenarios. The step-by-step guidelines allowed me to understand crucial aspects effortlessly, enhancing my grasp of moving mesh techniques. Kudos to MR CFD for such a comprehensive learning tool for beginners like myself!

MR CFD Support –

We are thrilled to hear that you’ve found our Moving Mesh Training Package valuable and educational! It’s wonderful to know the projects provided diverse learning experiences and that the guidance was clear and helpful. Thank you for choosing MR CFD and for your kind words. Your feedback is greatly appreciated and motivates us to continue providing high-quality learning resources. If there’s ever more you wish to learn or any way we can assist you further, please don’t hesitate to reach out!

Troy Dietrich –

How does the package ensure the accuracy of the simulations?

MR CFD Support –

Our package uses advanced algorithms and incorporates the energy equation to ensure the simulations are as accurate as possible.

Mellie Harris –

The Moving Mesh (Mesh Motion) Training Package sounds incredibly comprehensive. I’m looking forward to learning about mesh dynamics without needing advanced prior knowledge. Just one question: does the Training Movie provide step-by-step instructions for complete novices like me?

MR CFD Support –

Yes, the Training Movie is designed to provide detailed step-by-step instructions tailored for beginners. It guides you through the entire process of solving the problems and extracting the desired results, ensuring you can follow along and understand the concepts without the need for advanced prior knowledge.

Brayan Hills I –

I’ve completed some of the exercise but struggled with setting up rotating speed parameters correctly. Could you guide me through adjusting the angular velocity for the turbines?

MR CFD Support –

Certainly! To adjust the angular velocity for rotating turbomachinery like turbines within an ANSYS Fluent Moving Mesh simulation, you’ll typically need to define a rotating zone or boundary within your domain. For these exercises, make sure to correctly set the rotating domain’s ‘Motion Type’ to ‘Rotating’. Then you have to input the appropriate angular velocity value specific to each turbine case, typically defined in radians per second or RPM as per the exercise requirements. If you’re struggling with an exact exercise, please provide that number or details for more tailored support.

Abdul Wintheiser –

I just finished the Moving Mesh (Mesh Motion) Training Package, and I have to say, as a beginner, it was incredibly insightful. Each of the 10 projects built up my skills step by step. The available geometries and the comprehensive training movies made the learning curve much smoother. The difference between the various wind turbine simulations was especially fascinating and seeing the fluid dynamics via the animation was pretty rewarding!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the Moving Mesh Training Package met your learning needs and helped you gain a better understanding of CFD simulations in ANSYS Fluent. Your enthusiasm for the variety and depth of the simulations, particularly with the wind turbines, is very encouraging. If you ever have more questions or need further assistance in advancing your skills, don’t hesitate to reach out. Keep up the great work with your simulations!