Combustion CFD Simulation Training Package, Intermediates, 10 Exercises

$2,267.00 $767.00 Student Discount

- Hypersonic combustion in scramjet with viscous heating

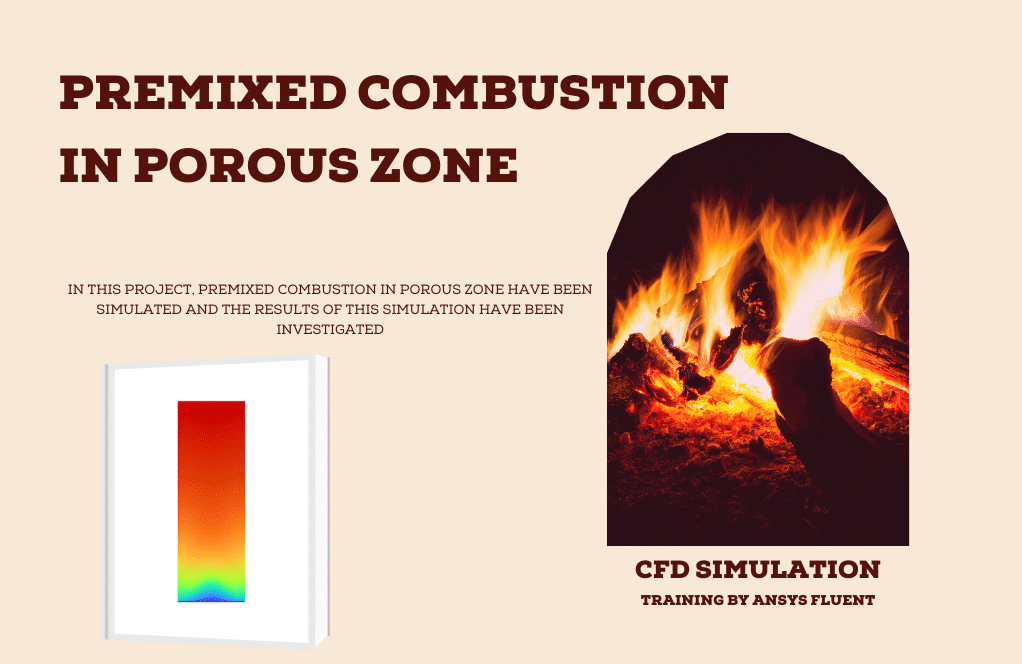

- Premixed combustion in the porous zone

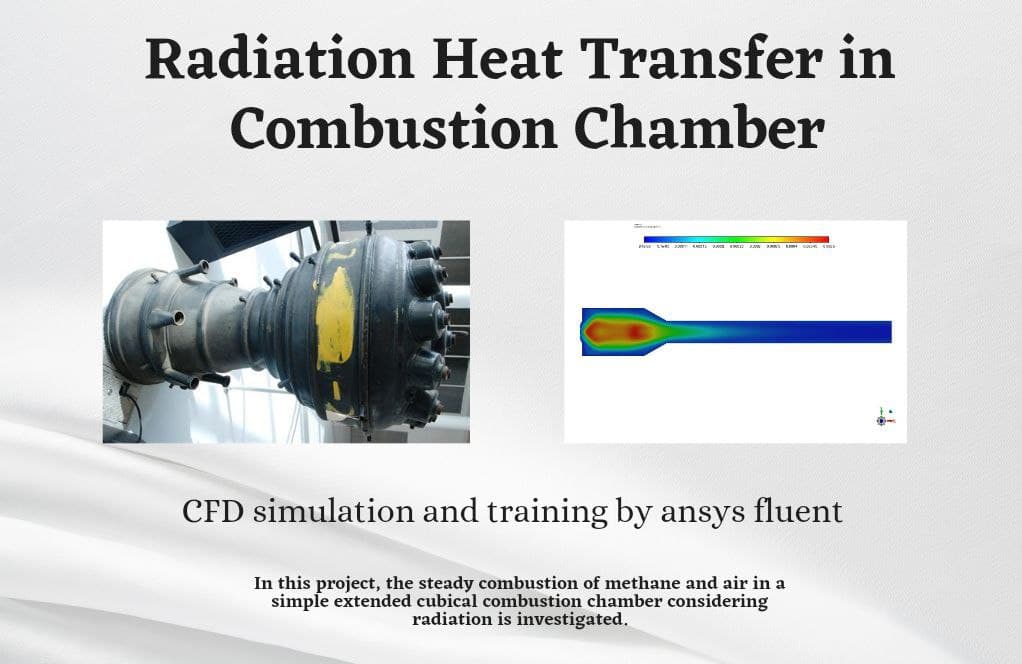

- Radiation in the combustion chamber

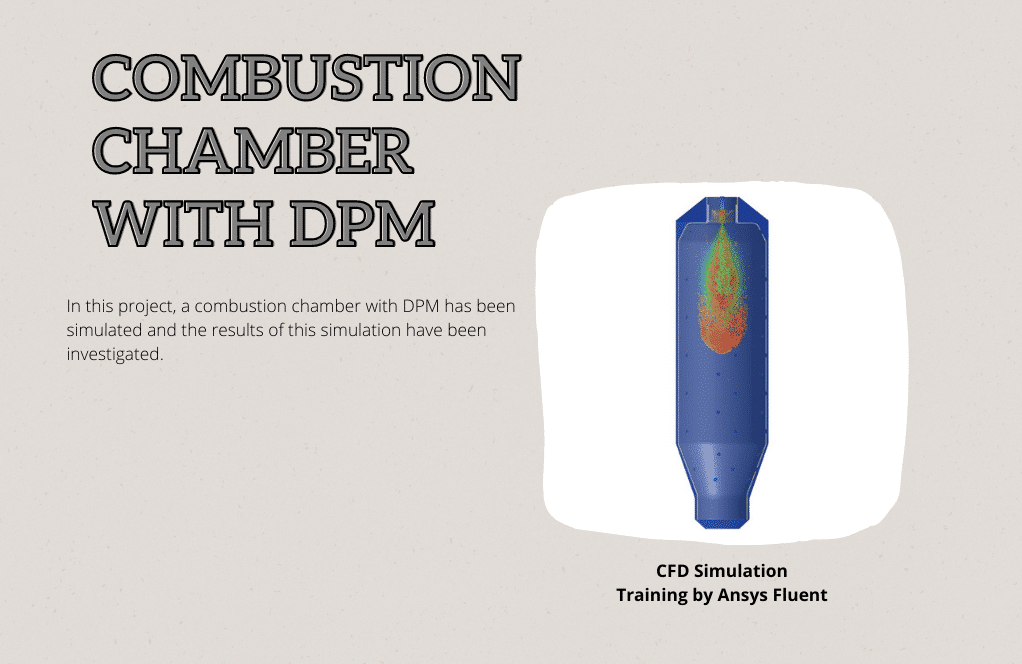

- DPM spray in a combustion chamber

- Combustion inside a boiler

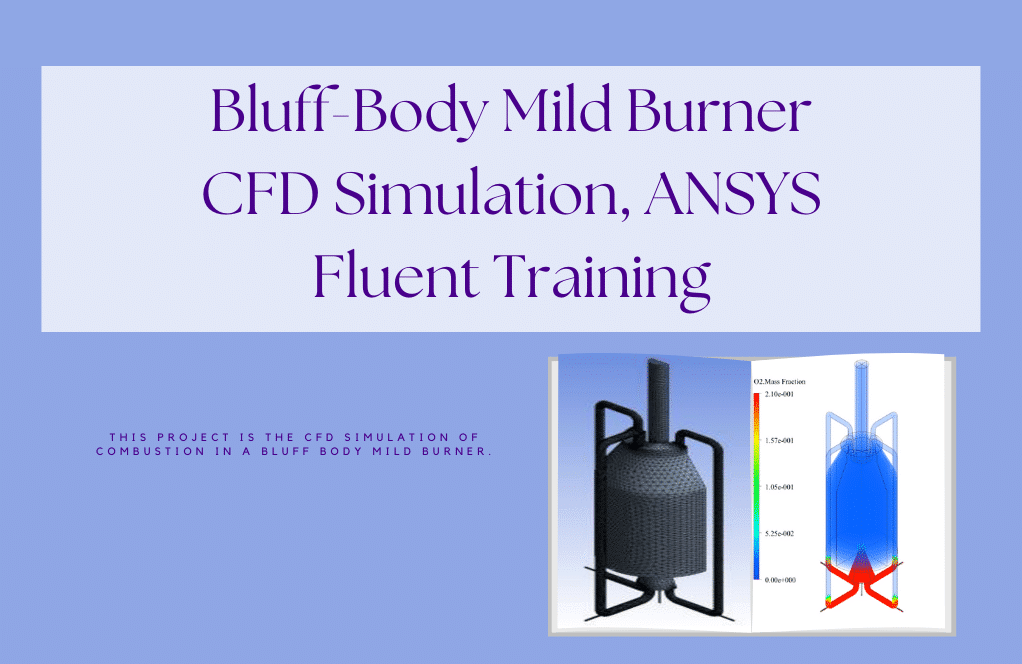

- Bluff-body mild burner

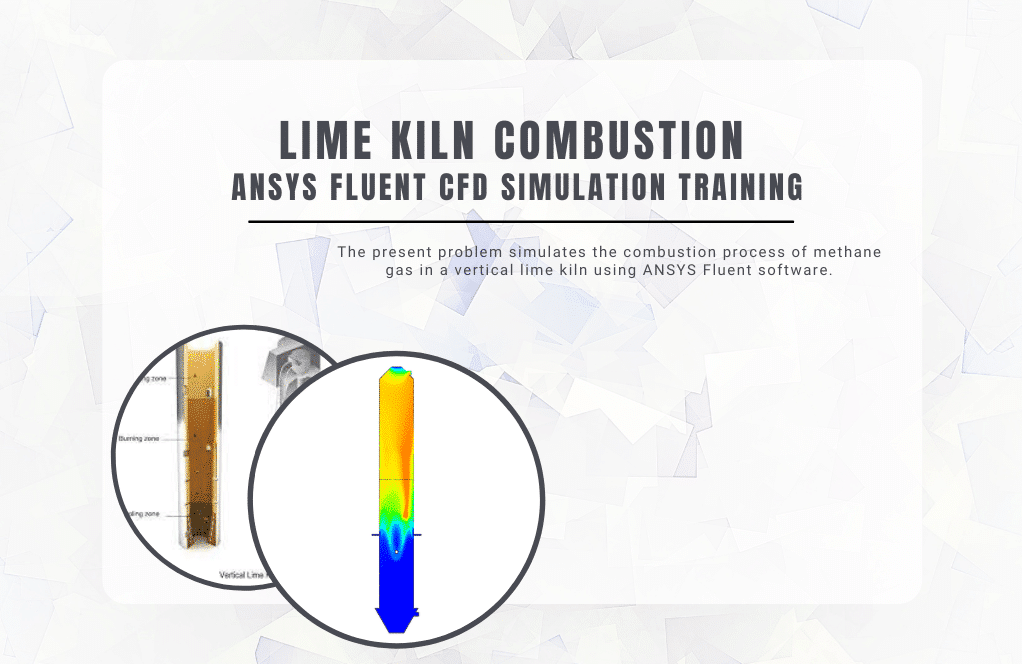

- Limekiln combustion

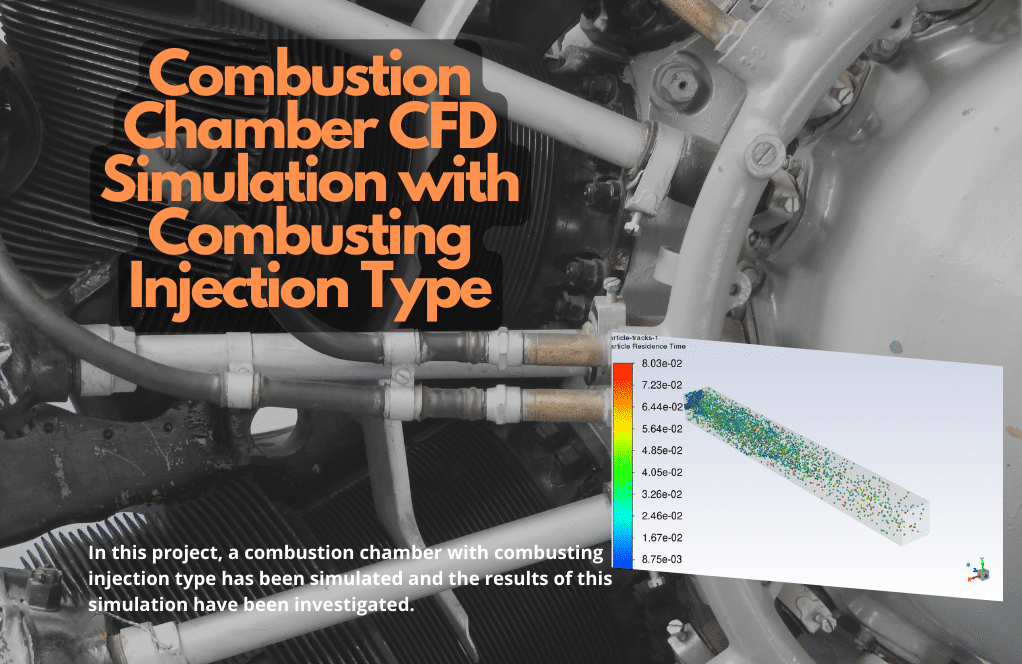

- Combusting particles

- Biomass combustion

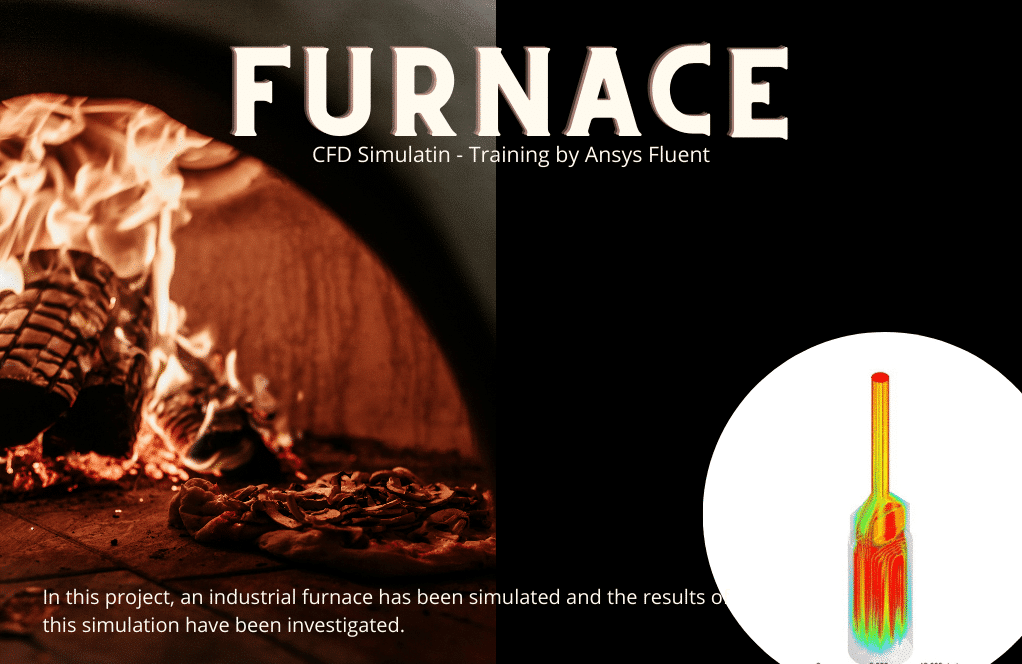

- Industrial furnace

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Combustion ANSYS Fluent CFD Simulation Training Package for INTERMEDIATE Users

The Combustion Simulation Training Package includes 10 practical Combustion exercises using ANSYS Fluent software. MR CFD suggests this package for INTERMEDIATE users familiar with elementary combustion theories and simulation and who want to become professionals.

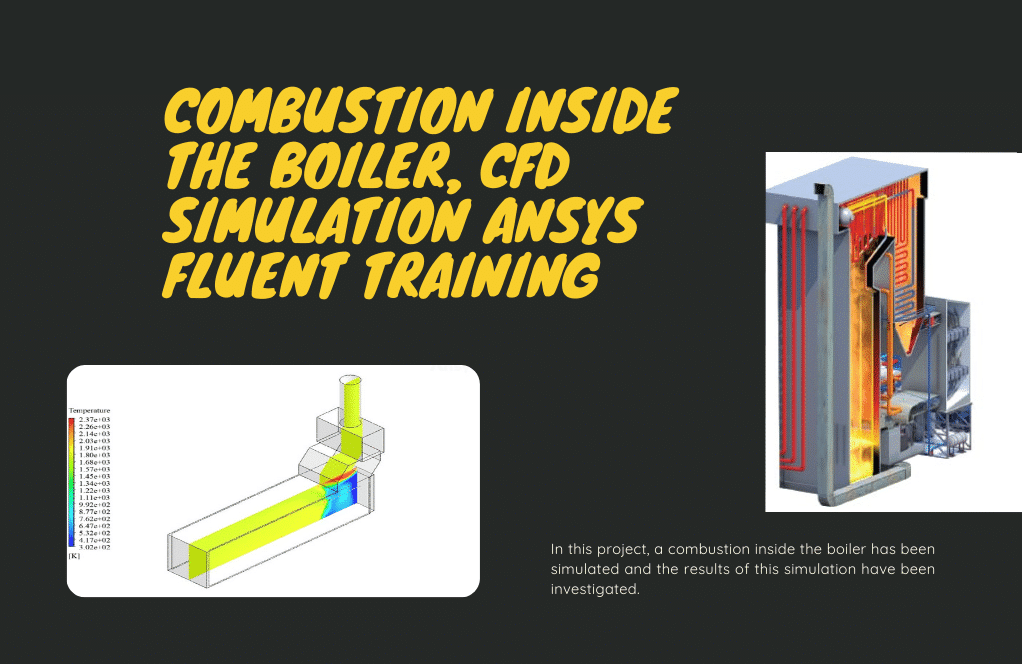

Introduction to Intermediate Combustion Simulations (Species Transport)

In the Combustion Ansys Fluent CFD Simulation package for BEGINNER users, we’ve learned Combustion’s basic theories and elementary projects. Ansys Fluent provides a species transport module to do combustion projects considering simplification of a real industrial project. For example, in project number 1, combustion inside a Boiler is performed using a species transport module. Boilers are pressurized tanks that carry out the boiling or heating fluid. The current boiler consists of two different inputs, airflow inlet, and fuel flow inlet. Airflow with a temperature of 303.15 K and mass flow rate of 3.375 kg.s-1 enters from the side of the boiler, and a combination of several different fuels with a temperature of 300 K and mass flow rate of 0.6135 kg.s-1 enters from the narrow pipes of the lower part of the boiler.

As another example, project number 2 simulates an Industrial FURNACE combusted with methane fuel to heat the Methane in the pipes to move the Methane more quickly and with less force.

Combustion considering the Radiation effects (Species Transport + Radiation)

In previous projects, we have ignored the heat transfer through the Radiation mechanism, although it can significantly affect the results. It is recommended to ignore radiation effects in most engineering projects, but when it comes to Combustion, normally, we’re dealing with extremely high temperatures, and this simplification cannot be a valid solution anymore.

Project number 3 is the CFD simulation of Combustion in a bluff-body mild burner. The way this burner works is that the fuel is sprayed through a special jet inlet into the chamber, and the gas flows symmetrically into the chamber in four directions, thus combining the fuel and air from the flame. Also, the operating system of the enclosure is that the gas flow path inside the chamber is cyclic, some of it exits the exhaust section and another part of it returns to the enclosure from the same circular path.

In project number 4, the steady Combustion of Methane and air in a simple extended cubical combustion chamber is investigated. In this project, the mixture’s static temperature has a maximum of 3500K within the chamber. The chemical reaction between Methane and air produces CO2 and H2O, and since the Combustion is air-rich, oxygen and nitrogen are left unused at the end of the reaction.

Combustion in a Porous zone (Species Transport + Porous)

Project number 5 aims to model Simple Premixed Combustion in a porous zone and see how a POROUS ZONE affects combustion temperature and stabilizes it. This simulation is a matrix-stabilized burner, and results are compared to the same premixed Combustion without porosity.

Project number 6 simulates the combustion process of methane gas in a vertical Lime Kiln. The construction of a vertical lime kiln consists of two main parts, including the combustion zone and the preheating zone. In addition, porous materials have been used inside the lime kiln. The porous area is made of aluminum with a porosity coefficient of 0.3 and has an inertial resistance equal to 907.4 1.m-1 and a viscous resistance equal to 1100000 1.m-2.

Combustion considering Combusting Particles (Species Transport + DPM)

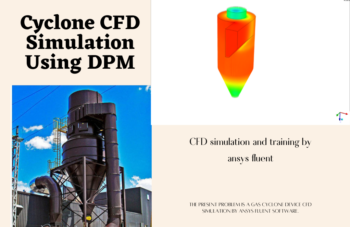

Project number 7 simulated the gas turbine combustion chamber using a discrete phase model (DPM) and species. In this case, the effect of spraying Benzene particles is done using the Eddy-dissipation combustion model. This combustion chamber is commonly used for jet engine users.

Due to the increasing industrial use of coal consumption and the importance of finding clean energy coal technology development, modeling its combustion characteristics is very important. In project number 8, a combustion chamber is simulated. We have used two-way DPM for particles and anthracite as an injection material.

Comprehensive Combustion simulation(Species Transport + Radiation + DPM)

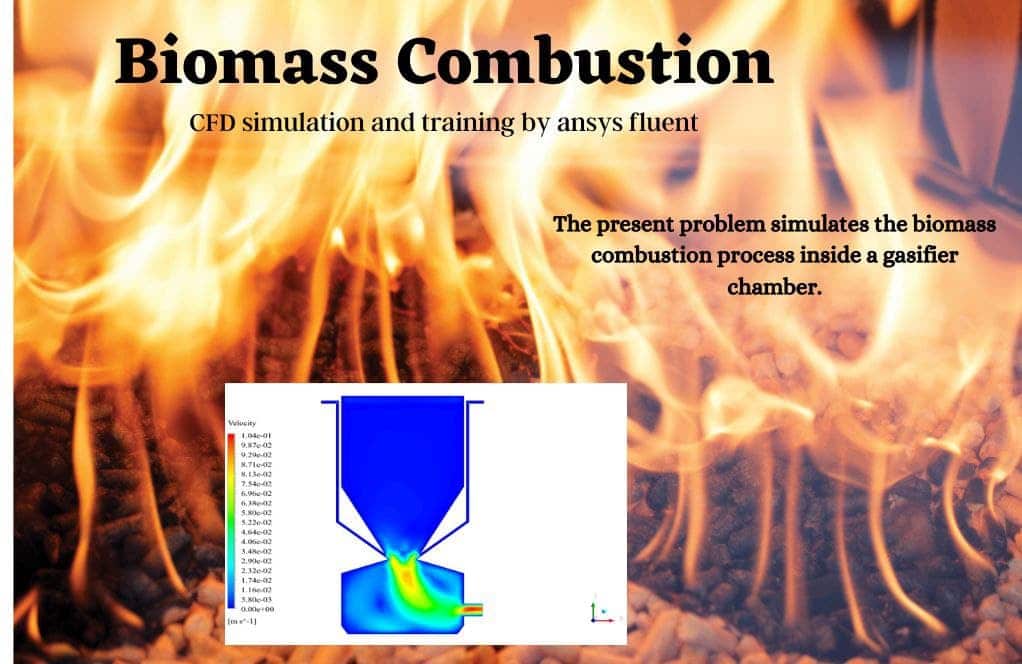

The gasification process is defined as the conversion of biomass raw materials into synthesis gas.

Project number 9 simulates the biomass combustion process inside a gasifier chamber. The material used for Combustion is biomass, which reacts with the oxidizer. Also, the incoming fuel must enter the chamber as discrete particles; This means that the injection of this substance into the chamber is defined based on the Lagrangian view. Therefore, the Discrete Phase Model has been used. Also, since there is radiant heat energy from the flames in the combustion process, the Radiation model is defined.

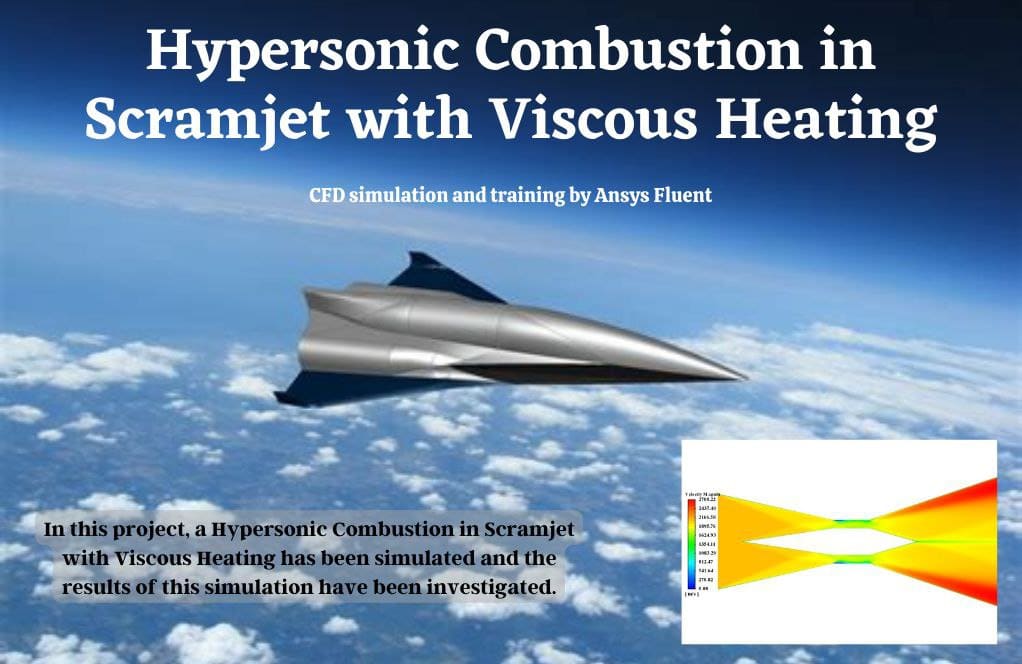

Combustion considering the compressibility of the fluid

In many engineering applications, the compressibility of the working fluid could be an essential component that needs to be considered.

Scramjets are a type of ramjets that can travel at hypersonic speed while there is no motion device in its engine. In project number 10, Hypersonic Combustion in a Scramjet engine with Viscous is simulated. The Mach number of inlet air is set to 6, and the temperature of the whole domain equals 300k.

Adell Fritsch –

I’m interested in simulating pollutant formation in combustion processes. Does this package cover that?

MR CFD Support –

Yes, indeed. The package includes exercises that delve into the simulation of pollutant formation like NOx and soot. This is particularly useful in understanding and mitigating environmental impacts of combustion processes.

Kathryne Block –

How well does this package handle the simulation of turbulence-chemistry interaction?

MR CFD Support –

The package is designed to give you a deep understanding of turbulence-chemistry interaction, which is crucial in accurately predicting flame characteristics in turbulent flows.

Kallie O’Reilly –

Does this package cover different types of combustion models?

MR CFD Support –

Absolutely, Shima. This package provides detailed exercises on various combustion models like non-premixed, premixed, and partially premixed combustion. This ensures you have a comprehensive understanding of different combustion scenarios.

Hyman Nitzsche –

I just finished the Intermediate Combustion Simulations training package by MR CFD and was really impressed with the level of detail and depth in the exercises. The individual projects built upon my existing knowledge and by project number 10 I felt significantly more confident in handling complex combustion scenarios. The inclusion of various factors like porosity, particle combustion, and radiation made the simulations a lot more realistic and challenging!

MR CFD Support –

Thank you very much for your positive feedback! We’re delighted to hear that our Combustion Simulation Training Package was instrumental in boosting your confidence and giving you a more detailed understanding of ANSYS Fluent simulations. We strive to provide comprehensive learning materials and are glad that the depth and variety of the projects met your expectations. Your progress is commendable, and if you have any further inquiries or require additional support, don’t hesitate to reach out!

Loren Rempel –

Can the package simulate the behavior of reacting flows in compressible conditions?

MR CFD Support –

Absolutely. The package includes exercises that cover reacting flows in compressible conditions. These are important phenomena in many high-speed combustion applications.

Nedra Hermiston II –

Just wanted to say I am thoroughly impressed with the comprehensive nature of the Intermediate Combustion Simulations Training Package. The variety of projects, from boilers and furnaces to scramjet engines, provides an impressive range to learn about different applications of combustion in CFD. It’s excellent to see the inclusion of factors like radiation and porous materials that closely represent real-life scenarios. I’ve definitely gained a deeper understanding of the complexities in combustion processes through this course.

MR CFD Support –

We’re thrilled to hear that our Combustion CFD Simulation Training Package for Intermediates has been so beneficial to your learning experience. It’s fantastic to know that the range of projects and real-life scenarios included in this package have enhanced your understanding of combustion processes. We genuinely appreciate you taking the time to share your positive feedback, and we hope you continue to find our training materials enriching and helpful. If you ever have any questions or need further assistance as you work through our training packages, please don’t hesitate to reach out.

Elody Swaniawski –

Absolutely exceeded my expectations! The array of exercises in this Combustion CFD Simulation Training Package for intermediate users is well-designed and engaging. Project number 4 particularly helped me deepen my understanding of the high-temperature combustion process for methane and the importance of including species transport plus radiation models to capture accurate chemical reaction dynamics. The step-by-step guidance through various combustion scenarios truly bridges the gap between theoretical knowledge and practical application. Great job, MR CFD!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Combustion CFD Simulation Training Package has been helpful and effective for your learning experience. It’s particularly gratifying to know that Project number 4 has deepened your understanding of methane combustion. We always strive to provide comprehensive training that enables learners to apply their knowledge practically. Your success is our success—keep up the great work in your CFD pursuits!

Fanny Herman Jr. –

Just finished my training with the Combustion CFD Simulation Training Package. The variety of examples really helped broaden my understanding, especially the discussions on how the porous zone affects combustion temperature and the gas turbine combustion chamber demonstration. Helped me connect theory with practical application proficiently. Thanks for such a well-structured learning experience.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear our Combustion CFD Simulation Training Package provided you with a thorough understanding and practical experience. Your success in connecting theory with real-world applications fulfills our goal of providing an effective learning journey. If you have further inquiries or need assistance in future projects, feel free to reach out. Happy simulating!

Barry Schoen –

This training package has immensely bolstered my understanding of intermediate-level combustion simulation. The gradation in complexity from species transport modeling to incorporating radiation and DPM has provided me a solid grounding in approach and theory application. I particularly appreciate being walked through various real-world examples which personified the concepts being taught.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that the Combustion CFD Simulation Training Package proved beneficial to your learning experience. It’s great to know that the variety of real-world examples and the step-wise increase in complexity added value to your understanding of combustion simulations. If you have any more questions or need further assistance, please don’t hesitate to ask.

Noe Satterfield –

I purchased the Combustion CFD Simulation Training Package for intermediates and have completed all 10 exercises—such a fulfilling and educational experience. The range of topics from species transport, to considering radiation effects, modeling combustion in porous zones, and investigating combusting particles provided a broad spectrum of scenarios very typical in practical engineering field. The detailed step-by-step guidance was superb for understanding the complexities of multiphysics scenarios in combustion processes. Highly recommend for anyone looking to up their game in CFD simulation proficiency.

MR CFD Support –

Thank you so much for your positive review! We are thrilled to hear that our Combustion CFD Simulation Training Package for intermediate users has helped enhance your understanding and skills in this complex area. Your recommendation means a lot to us, and we couldn’t be happier to know that you found the exercises both fulfilling and educational. Should you need any further guidance or more advanced training, know that MR CFD is here to support your continuous learning journey. Keep up the great work!

Reilly Hermiston –

I recently completed using the Combustion CFD Simulation Training Package for intermediates. Thanks to the variety of projects, I’ve acquired a better understanding of combustion simulation concepts. The step-by-step progress through different complexity levels helped me immensely. The use of species transport, with radiation and porous media, provided a diverse learning experience, and the blend of theoretical understanding with software application was perfect. The projects offered realistic challenges that a CFD engineer would face. A big thank you to MR CFD for creating a comprehensive training package like this!

MR CFD Support –

Thank you so much for your wonderful review! We are thrilled to hear that our Combustion CFD Simulation Training Package for intermediates has provided you with a comprehensive and practical learning experience. It’s great to know that the content was relevant and beneficial to your understanding of combustion simulations. We always strive to equip our users with the knowledge they need to excel in the field of CFD. If you have any more feedback or require further enrichment, never hesitate to reach out. We look forward to nurturing your growth continuously!

Chyna Bins –

I have just completed all the exercises in the Combustion CFD Simulation Training Package for Intermediates from MR CFD. The step-by-step approach to progressively more complex simulations was fantastic. Specifically, the Radiation and Porous Zone simulations deepened my understanding significantly. The practicality of the examples made it feel like I was working on real-world scenarios. Truly beneficial for any aspiring CFD analyst.

MR CFD Support –

Thank you so much for your kind words and positive review! We’re delighted to hear that the practical exercises and the structured progression of complexities in the training package provided you with a beneficial learning experience. It’s great to know that our approach helped deepen your understanding of Radiation and Porous Zone simulations within combustion scenarios. Your feedback is tremendously appreciated, and we look forward to offering you and others more valuable learning experiences in the future!

Dr. Diego Hyatt DDS –

Does the package cover the effect of radiation heat transfer in combustion processes?

MR CFD Support –

Yes, it does. The package includes exercises that explore the effect of radiation heat transfer in combustion. This is particularly useful in high-temperature combustion processes.

Darren Eichmann –

I’ve made noticeable progress with my recent training, mainly due to the advanced principles methodically covered in this Combustion CFD Simulation Package. The detailed instruction and variety of simulation scenarios greatly enhanced my understanding of combustion dynamics in different systems. Highly recommended for anyone serious about elevating their skills in this field!

MR CFD Support –

We appreciate your positive feedback about our Combustion CFD Simulation Training Package for Intermediate-level users! It’s wonderful to hear that the package has contributed significantly to your understanding and skill improvement. Thank you for recommending our training program – we’re committed to providing valuable learning resources for our users!

Myra Metz Sr. –

I recently completed the Combustion CFD Simulation Training Package for Intermediates and I must say the diversity and depth of projects provided me with a comprehensive understanding of various combustion processes and simulation techniques. The clear progression from simpler concepts to more complex simulations was adequately calibrated for intermediate-level competence.

MR CFD Support –

We truly appreciate your positive review of our Combustion CFD Simulation Training Package for Intermediates. It’s our goal to provide a logical and progressive pathway through complex CFD topics. Your feedback validates our efforts and we’re thrilled to know it enhanced your simulation skills. Thank you for choosing MR CFD!

Mr. Donato Grady MD –

This package sounds comprehensive. What level of competency in ANSYS Fluent should someone have before starting these intermediate exercises?

MR CFD Support –

Before starting these intermediate exercises, individuals should ideally have a strong understanding of the basic functionalities of ANSYS Fluent, including familiarity with the workflow, primary physics setup, and elementary combustion theories. Basic experience with performing simulations in Fluent is also expected to fully benefit from this training package.

Kamron Maggio –

I recently completed the Intermediate Combustion Simulations training package by MR CFD, and the depth and breadth of the projects were impressive! I especially appreciated the incorporation of radiation effects and combustion in porous zones and how each unique project expanded my understanding. The steps were detailed, and simulations were incredibly hands-on.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the Combustion CFD Simulation Training Package for INTERMEDIATE users beneficial and educational. It’s fantastic to know that the projects challenged you and broadened your understanding of combustion simulations. We look forward to providing you with more quality learning materials in the future!

Morris Wolf –

I have completed the ‘Combustion considering the Radiation effects’ tutorial, and the simulation was particularly insightful. The radiation model added complexity and certainly brought the scenario closer to real-life combustion applications. Thank you for including that aspect!

MR CFD Support –

Thank you for your review! We’re thrilled to hear that you found the tutorial insightful and that the inclusion of radiation effects enhanced your learning experience. Your feedback is greatly appreciated and motivates us to continue improving our simulation packages.

Jadyn Jones –

In which projects from the training package do I need to consider radiation effects for accurate results?

MR CFD Support –

For accurate results in the Combustion CFD Simulation Training Package for Intermediates, radiation effects need to be considered particularly in projects number 3, where a bluff-body mild burner is being simulated, and project number 4, which deals with the Combustion of Methane and air in an extended cubical combustion chamber. These cases involve extremely high temperatures where radiation plays a significant role in heat transfer.

Kasandra Donnelly –

This package was immersive and thorough. As a intermediate learner, understanding how to handle the specie transport, radiation, porous zones and dealing with combustion particles via DPM made transitioning from theory to actual simulation projecttasks seamless. The gradual complexity across the 10 exercises ensured that, by the end, I felt competent with a variety of combustion scenarios. Admin, I would love to see more industrial applications, particularly regarding biomass combustion – fascinating subject!

MR CFD Support –

Thank you for your insightful review! We’re thrilled to hear that you found the stepwise increase in complexity across the exercises beneficial for your learning experience. We appreciate your interest in more industrial applications, especially in biomass combustion. We want to provide content that covers a broad spectrum of practical applications and simulating those aspects will certainly yield rich insights. Your feedback is invaluable and helps us enhance our training packages constantly!

Evan Brown –

The training package looks comprehensive, covering various combustion scenarios. What does the species transport module actually provide in these simulations, and how critical is it for predicting accurate combustion processes?

MR CFD Support –

The species transport module in ANSYS Fluent provides the capability to track and model the mixture and reaction of chemical species within the simulation environment. It is critically important for predicting accurate combustion processes as it allows for the detailed assessment of chemical reactions, combustion efficiency, formation of pollutants, and overall flame characteristics. By incorporating the transport and interaction of different species, the module enables more realistic simulations that account for complex chemistry and mixing, which are fundamental to combustion dynamics.

Haylee Armstrong III –

This package is perfect for advancing skills. The exercises are diverse and well-structured, covering various aspects of combustion simulation very effectively.

MR CFD Support –

Thank you for the compliment on our Combustion CFD Simulation Training Package for intermediate users. We are thrilled to hear that you found the exercises diverse and instrumental in advancing your simulation skills!

Carolanne Leffler –

I’ve finished projects 1 to 7 and learned a great deal about combustion simulation. For project 8, how important is the choice of injection material, and why was anthracite selected for this exercise?

MR CFD Support –

The choice of injection material in combustion simulations is crucial, as different materials have varying combustion characteristics impacting flame temperature, stability, and pollutant formation. Anthracite was selected for project 8 due to its relevance in the industry as a high-carbon, low-volatility coal, which highlights the behavior of solid fuel particles during combustion and their interaction with the surrounding gas phase. This decision allows simulation of realistic industrial processes involving coal and is beneficial in emphasizing the need for clean coal technologies.

Shaun Hackett –

I just finished going through the combustion CFD simulation training package, and I must say, I’m thoroughly impressed. As an intermediate user, the step-up in complexity was welcome, and it certainly pushed my understanding of species transport and radiation effects in combustion processes. The variety in exercises, from simulating boilers and furnaces to tackling complex scramjet engines, kept the learning process engaging and challenging. It’s rare to find such a well-structured progression in practical learning tools. The added complexity of accounting for porous zones and particulates was particularly enlightening. Kudos to MR CFD for designing a hands-on learning experience that bridges the gap between theory and advanced practice.

MR CFD Support –

We are thrilled to hear such positive feedback on our Combustion CFD Simulation Training Package for intermediate users. It is our aim to provide comprehensive and engaging learning materials that help our users move from theoretical understanding to practical expertise. Your appreciation for the diversity and complexity of the simulations in the package is extremely rewarding. Thank you for choosing MR CFD and taking the time to share your learning experience with us. If you ever have more questions or need further assistance with your simulations, do not hesitate to reach out.

Mr. Easton Terry DDS –

I received the Combustion CFD Simulation Training Package, Intermediates, 10 Exercises, and just completed the modules. Projects were diverse and depth on combustion simulation adaptations such as how varying inlet conditions or adding porous media can affect combustion stability and outcomes was incredibly educational. Particularly insightful was learning to consider heat transfer through radiation in high temperature scenarios. Grateful for how MR CFD tailors these training sessions to fit intermediate user levels, adequately challenging without being overwhelming.

MR CFD Support –

Thank you for your positive feedback on the Combustion CFD Simulation Training Package for Intermediates! We are thrilled that you found the exercises and the incorporation of real-life application adaptations educational. It’s wonderful to hear that the training sessions were both challenging and suitable for your skills level. MR CFD is committed to providing high-quality learning experiences, and your satisfaction is our priority. We look forward to assisting you as you continue to progress in your CFD learning journey!

Lazaro Kris –

I couldn’t be more thrilled with the Combustion CFD Simulation Training Package for intermediate users! The exercises were not only engaging, but also challenged me to deepen my understanding of various combustion processes. The crawling incremental difficulty from one project to the next perfectly honed my skills.

MR CFD Support –

We’re delighted to hear that the training package met your expectations and helped you advance your combustion simulation skills. Thank you for the positive feedback, and we wish you continued success on your learning journey!

Webster Hoppe –

I am thoroughly impressed with the range of topics covered in the Combustion CFD Simulation Training Package. The various advanced techniques and scenarios provide an invaluable learning path from intermediate to advanced CFD analysis. Particularly, the inclusion of effects such as radiation, porosity, and combustion particles provide an excellent foundation for tackling real-world engineering problems. Kudos to MR CFD Company for compiling such an enriching and comprehensive training guide!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that you found the Combustion CFD Simulation Training Package comprehensive and beneficial for your progression from intermediate to advanced CFD analysis. MR CFD Company is committed to providing high-quality simulation training materials and we appreciate your recognition of our efforts. If you have any further questions or need additional support while going through the exercises, feel free to reach out!

Dr. Gregory Lind –

The training package covers diverse scenarios, but I’m curious how beginner users bridge the gap before tackling intermediate projects?

MR CFD Support –

The package is designed for INTERMEDIATE users with some familiarity in combustion and CFD. Beginners should initially focus on understanding basic theories and elementary projects by going through beginners’ materials or foundational exercises that are offered before starting with intermediate-level simulations. MR CFD provides foundational training packages that serve as precursors to this intermediate package, ensuring a comprehensive learning path.

Aurore McLaughlin –

This training package seems comprehensive, but it feels a tad overwhelming. Have you found an effective way to progress through the materials to build proficiency without getting lost in the complexity?

MR CFD Support –

The training is designed to progress in complexity, with each project building on the knowledge from the previous ones. Start from project number 1 and work your way up, ensuring you understand each concept before proceeding. Don’t hesitate to revisit earlier exercises if needed. This incremental approach is intended to solidify your understanding as you develop your skills through the package.

Sanford Zboncak –

This training really expanded my knowledge! Thanks for providing such an extensive and deep coverage of combustion simulations. Before going further, I’d like to know if understanding of specific chemical reaction mechanisms is required prior to using these tutorials or are they explained within the training material?

MR CFD Support –

We appreciate your feedback! In our Combustion CFD Simulation Training Package for Intermediates, we do cover some fundamental combustion theories and their application in ANSYS Fluent. The training includes practical exercises with step-by-step instructions where necessary chemical reaction mechanisms are explained. For users with a basic understanding, this should enhance their knowledge even if they don’t specialize in reaction mechanisms. Furthermore, contextual guidance provided within the exercises should supplement the understanding of these concepts.

Tierra Cormier –

The package seems very detailed, but can you confirm if solid fuel combustion simulations are included in any of the 10 exercises, especially something similar to coal combustion but for different solid fuels?

MR CFD Support –

Unfortunately, the description for the Combustion CFD Simulation Training Package doesn’t explicitly mention any solid fuel combustion simulations other than coal combustion. To clarify, project number 8 involves coal combustion using the anthracite coal model. If you’re looking for simulations involving other types of solid fuels, it would be best to contact MR CFD to see if they are included in any of the projects or maybe available in another part of their training materials.

Mathias Pfannerstill –

I’ve just completed the Combustion CFD Simulation Training Package for Intermediates, and I can’t say enough about the depth it added to my CFD skills. The blend of theory and practice within the package really cemented my understanding of complex combustion concepts. Not only can I implement what I learned in my academic projects, but it has significantly boosted my confidence for future professional challenges in this field. Kudos to MR CFD Company for designing such a robust and instructive training program!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Combustion CFD Simulation Training Package for Intermediates has contributed so meaningfully to your academic growth and professional confidence. It is our goal to provide comprehensive learning materials that enhance skills and understanding, and we’re glad we could achieve that for you. Should you need any further assistance, feel free to reach out. Wishing you continued success in all your endeavors with CFD!

Megane Kshlerin –

This training package looks comprehensive. Just wondering if project examples are taken from real-life scenarios or are they hypothetical applications?

MR CFD Support –

The training package projects are based on simplified real-world scenarios. They represent typical combustion problems in industrial environments, designed to help intermediate learners transition to expertise in designing and assessing combustion simulations.

Mr. Orrin Boyer –

This advanced training package for combustion simulation is impressive. The comprehensive coverage from various angles including radiation effects, porous zones, and different fuels is exemplary for any intermediate CFD user. The modules seem to bridge the gap perfectly between theory and the application of these combustion simulations.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our Combustion CFD Simulation Training Package meets your expectations and provides valuable insights for intermediate users. MR CFD is dedicated to providing comprehensive learning materials to help users deepen their understanding and expertise in combustion simulation with ANSYS Fluent.

Dr. Jennifer Schaden II –

I’ve recently worked through the combustion CFD simulation training package by MR CFD and as an intermediate learner, I have found the variety and depth of simulations to be immensely helpful. Each project presented unique challenges that improved my understanding of combustion processes as well as how to effectively use ANSYS Fluent.

MR CFD Support –

We’re thrilled to hear that the Combustion CFD Simulation Training Package has been beneficial for your learning journey! Thank you for acknowledging the variety and depth of our simulations. It’s great to know that the projects provided you with the necessary challenge to advance your understanding of combustion and ANSYS Fluent. We appreciate your feedback, and if there’s anything else we can assist you with, please let us know.

Dr. Terrell Dooley V –

Just finished the combustion CFD simulation training package by MR CFD. Each exercise pushed my understanding further and having the tangible examples to follow made a huge difference. Felt particularly challenged and gained deep insights from the lime kiln and gas turbine simulations!

MR CFD Support –

We’re thrilled to hear that our combustion CFD simulation training package has been so beneficial to your learning journey! Those exercises on the lime kiln and gas turbine are indeed challenging and insightful. Thank you for taking the time to share your positive experience – your feedback is incredibly appreciated!

Chelsea Bins –

I’ve just gone through the Intermediate Combustion Simulations package, and I found it very informative! The transitions from theories into the practical exercises were seamless. The variety strengthened my understanding of how different scenarios involve distinct characteristics of combustion, notably when dealing with high-temperature radiation effects or the complexities of porous zones that influence combustion stability. The training really bridged the gap between basic combustion simulations and more advanced applications.

MR CFD Support –

We are thrilled to hear that the Intermediate Combustion Simulations package met your expectations and enhanced your skillset! At MR CFD, our goal is to provide comprehensive and practical knowledge to our users. It’s great to know you found the transition from theoretical to practical exercises smooth and beneficial. Thank you for choosing our training package, and we’re here for any further education or support you may need. Keep on learning and practicing!

Jerald Bernhard V –

Hard to find courses that cover such a broad range of advanced combustion topics. The examples provided are insightful and practical. Appreciate the depth of scenarios covered in this package!

MR CFD Support –

We’re glad to hear you found the training package comprehensive and valuable. It’s our goal to provide detailed and practical learning experiences that meet the needs of our users. Thank you for your positive feedback!