CFD Project Outsourcing

Outsource your CFD project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including CFD Consultant, CFD Training, and CFD Simulation.

The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Rotary Equipment Engineering?

Rotary Equipment Engineering is a vital field of mechanical engineering focused on the design, analysis, operation, and optimization of industrial machines that feature rotating components. These machines are essential across modern industries like oil & gas, chemicals, power generation, water treatment, manufacturing, and HVAC, where they convert mechanical energy into fluid motion or material processing through rotation. Unlike static equipment, rotary machines handle complex physics including fluid dynamics, vibration, cavitation, and efficiency losses, making specialized engineering critical for reliability and performance.

The core characteristic of Rotary Equipment is its rotating shaft or impeller that performs work on fluids, solids, or gases. This broad category includes both dynamic machines like centrifugal pumps and compressors (turbomachinery) and positive displacement devices like gear pumps, screw compressors, and rotary lobe blowers. While all turbomachinery falls under rotary equipment exchanging energy with continuously flowing fluids via rotating blades not all rotary equipment qualifies as turbomachinery. Positive displacement types trap and move finite fluid volumes mechanically rather than through continuous momentum transfer, serving applications from viscous fluids to metering precise flows.

Common examples of Rotary Equipment span pumps (centrifugal for high flow, gear/screw for viscous media), compressors (reciprocating for high pressure, rotary vane for continuous duty), agitators/mixers (propeller for blending, anchor for high-viscosity), fans/blowers (axial for ventilation, radial for pressure), and specialized units like rotary dryers, valves, and progressing cavity pumps. These devices power 40% of global industrial energy use, where even 1% efficiency gains yield billions in annual savings, and downtime costs average $50K per hour in large plants.

Engineering challenges of Rotary Equipment include cavitation erosion in pumps, surge/stall in compressors, leakage in positive displacement units, bearing failures, and uneven flow distribution leading to wear. CFD simulation addresses these by predicting performance curves (head-capacity, efficiency maps), optimizing impeller geometry, analyzing multi-phase flows (slurry, air entrainment), and validating against manufacturer data or plant measurements with ±5% accuracy targets. Major players like Sulzer, Grundfos, KSB, Atlas Copco, and SPX Flow rely on such advanced analysis for competitive design.

This discipline demands multiphysics expertise combining rotating reference frames (MRF, sliding mesh), FSI for vibration, VOF for free surfaces, and particle tracking for solids ensuring rotary equipment meets operational demands while minimizing energy waste and maintenance costs.

How CFD simulation can be applied in Rotary Equipment Engineering Industries?

Computational Fluid Dynamics (CFD) has become firmly established as a fundamental tool for advancing Rotary Equipment engineering. CFD simulation methods enable engineers in industries like oil & gas, chemicals, power generation, and manufacturing to better understand physical phenomena, simulate designs, and optimize machinery without leaving their workstation. CFD provides comprehensive analyses including fluid dynamics, heat transfer, multiphase flows, and rotating motion effects.

A wide range of Rotary Equipment benefits from CFD simulations from mixers and agitators, heat exchangers, separators, positive displacement pumps (gear, gerotor, lobe, diaphragm), to rotary dryers and bioreactors. Design engineers can virtually test and optimize products in less time and at significantly lower cost using this powerful tool.

Mixing and agitation applications: CFD models powder suspension in baffled tanks using Eulerian multiphase and mesh motion (30rpm propellers), revealing initial bottom settling → gradient layers → turbulent dispersion patterns. Six-blade stirring, side-entry tanks at variable RPM, and bioreactor Rushton turbines optimize blending time, solids uniformity, and oxygen transfer (kLa).

Heat transfer applications: Rotary heat exchangers analyze mass flow effects (0.02-0.08 kg/s) on heat transfer coefficient (h from 33.7 to 224.6 W/m²K non-linearly) between hot CO2 (700°C) and cold water vapor (30°C) at 100rpm. Rotary Equipment cooling systems (400rpm semi-cylinder, 1000 W/m² flux) and brake disk conduction quantify impingement cooling and temperature uniformity.

Separation applications: Centrifuges model two phase air-water separation (Mixture model), while drilling mud and sand hydro cyclones predict phase interfaces, overflow purity, and underflow concentration for oilfield operations.

Positive displacement pumps: Dynamic mesh + UDF rigid body motion simulate gear meshing in internal/external gear pumps, gerotors (cavitation vapor fraction), lobe pumps, and diaphragm pumps. Captures fluid trapping between teeth, pressure ripple, leakage across 0.01-0.15mm clearances, and discharge pulsation with transient animations.

Drying and special applications: Rotary seed dryers use DPM + moving mesh to track particle trajectories, optimizing exposure to hot air streams for uniform drying rates.

CFD modeling helps rotary equipment engineers optimize designs for maximum efficiency, reliability, and sustainability while minimizing energy consumption and maintenance costs. From early-stage concept validation to final performance tuning, CFD accelerates development and delivers validated results (±5% accuracy against test data).

MR CFD services in the Rotary Equipment Engineering Industries

With several years of experience simulating various problems in different CFD fields using ANSYS Fluent software, the MR-CFD Company is ready to offer extensive modeling, Meshing, and simulation services. Our simulation Services for Rotary Equipment simulations are categorized as follows:

-

Mixing and agitation systems analysis (powder suspension, blending time optimization)

-

Rotary heat exchangers and cooling systems (mass flow effects, heat transfer coefficient)

-

Rotating separators and centrifuges (two-phase separation, phase distribution)

-

Positive displacement pumps simulation (gear, gerotor, lobe, diaphragm pumps)

-

Dynamic mesh and rigid body motion for gear meshing

-

Cavitation analysis in rotary pumps

-

Rotary dryers and particle tracking (DPM + moving mesh)

-

Bioreactor flow optimization (Rushton turbine, kLa prediction)

-

Side-entry mixers at variable RPM

-

Multiphase flow modeling (Eulerian, VOF, Mixture, granular)

Mixing and Agitation Systems

MR CFD provides CFD analysis of mechanically agitated tanks, side‑entry mixers, and other Rotary Equipment mixing devices to evaluate flow patterns, blending time, power consumption, and solids suspension quality. By resolving the three‑dimensional rotating flow around impellers and baffles, simulations identify dead zones, short‑circuiting paths, and regions of poor mixing. These insights are used to recommend changes in impeller type, diameter, position, rotational speed, and baffle configuration to achieve more homogeneous mixtures with shorter mixing times and lower energy usage.

Rotary Heat Transfer and Cooling

In Rotary Equipment heat transfer applications, MR CFD simulates rotary heat exchangers, rotating cooled components, and similar devices operating under complex thermal and flow conditions. Temperature and velocity fields, local and average heat transfer coefficients, and thermal resistance are quantified for different mass flow rates, rotational speeds, and boundary conditions. This allows engineers to compare design options, optimize channel geometry and flow distribution, and ensure that thermal performance and temperature uniformity meet process or safety requirements without excessive pressure drop.

Rotating Separation Devices

MR CFD performs CFD simulations of rotating separators such as centrifuges and drilling mud or sand separation units. Using appropriate multiphase models, the distribution of phases, separation efficiency, and the effect of rotational speed and geometry on interface location and product purity are predicted. The results help in refining internal contours, inlet and outlet arrangements, and operating conditions to achieve higher separation performance, reduce entrainment of unwanted phases, and minimize wear and maintenance issues.

Positive Displacement Rotary Pumps

For positive displacement rotary pumps including internal and external gear pumps, gerotor pumps, lobe pumps, and diaphragm pumps MR CFD applies dynamic mesh and rigid‑body motion to resolve the detailed motion of gears and lobes. Simulations capture the trapping and displacement of fluid volumes, pressure build‑up between teeth, leakage through clearances, and transient outlet pulsation. When needed, cavitation models are incorporated to evaluate vapor formation in low‑pressure regions and its impact on efficiency and component life. Based on these studies, design improvements in geometry, clearances, and operating conditions can be proposed.

Rotary Dryers and Special Rotary Systems

MR CFD also delivers CFD services for Rotary Equipment dryers, rotary seed handling equipment, and other specialized rotary systems where particle motion and heat or mass transfer are critical. By coupling the gas flow field with particle tracking or multiphase models, trajectories, residence times, contact with hot or cold regions, and drying or heating rates are analyzed. These results support optimization of rotational speed, internal hardware, and operating parameters to improve product quality, reduce energy consumption, and avoid issues such as uneven processing or material buildup.

Across all these categories, MR CFD provides not only high‑fidelity CFD models but also clear engineering reports, visualizations of key flow and thermal features, and practical design recommendations. When requested, the same simulation setups can be packaged into training material so that clients build internal capability for future rotary equipment simulations while relying on MR CFD’s expertise for complex or time‑critical projects.

Rotary Equipment Engineering MR CFD Projects

MR CFD has completed numerous simulation projects in Rotary Equipment engineering. Below are examples of CFD simulation projects for this field. Engineers working on rotary equipment must consider critical factors such as cavitation damage, internal leakage paths, solids suspension quality, thermal performance under rotation, and separation efficiency, all of which significantly impact equipment reliability, energy consumption, and operational lifespan. Our simulation services for rotary equipment are categorized as follows:

Mixers Analysis

Powder Distribution in Mixer, Transient CFD Simulation

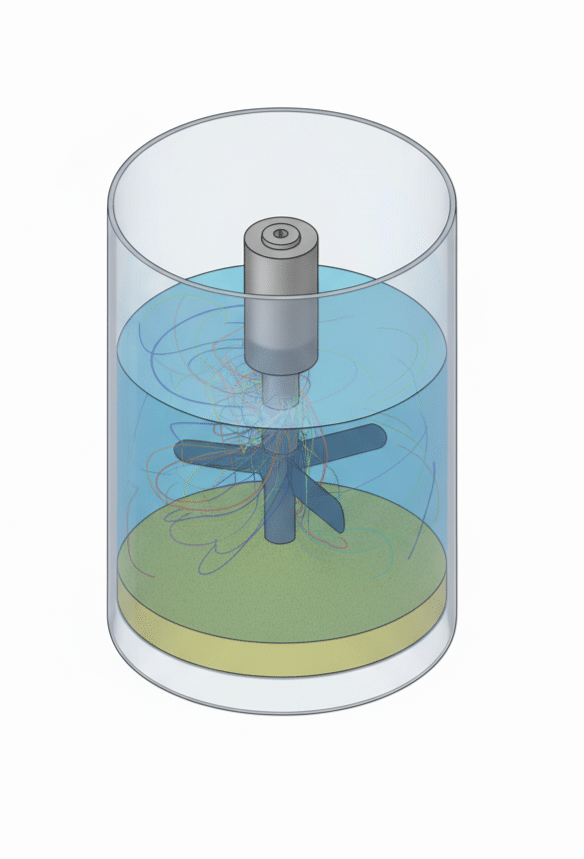

In this project, powder suspension inside a stationary fluid in a mixer tank is simulated using Eulerian multiphase model and mesh motion (30rpm propeller). The simulation shows initial powder settling at tank bottom, gradual dispersion with gradient layers, and turbulent mixing patterns in 657K cell mesh. This analysis optimizes blending time and solids uniformity for industrial mixing applications.

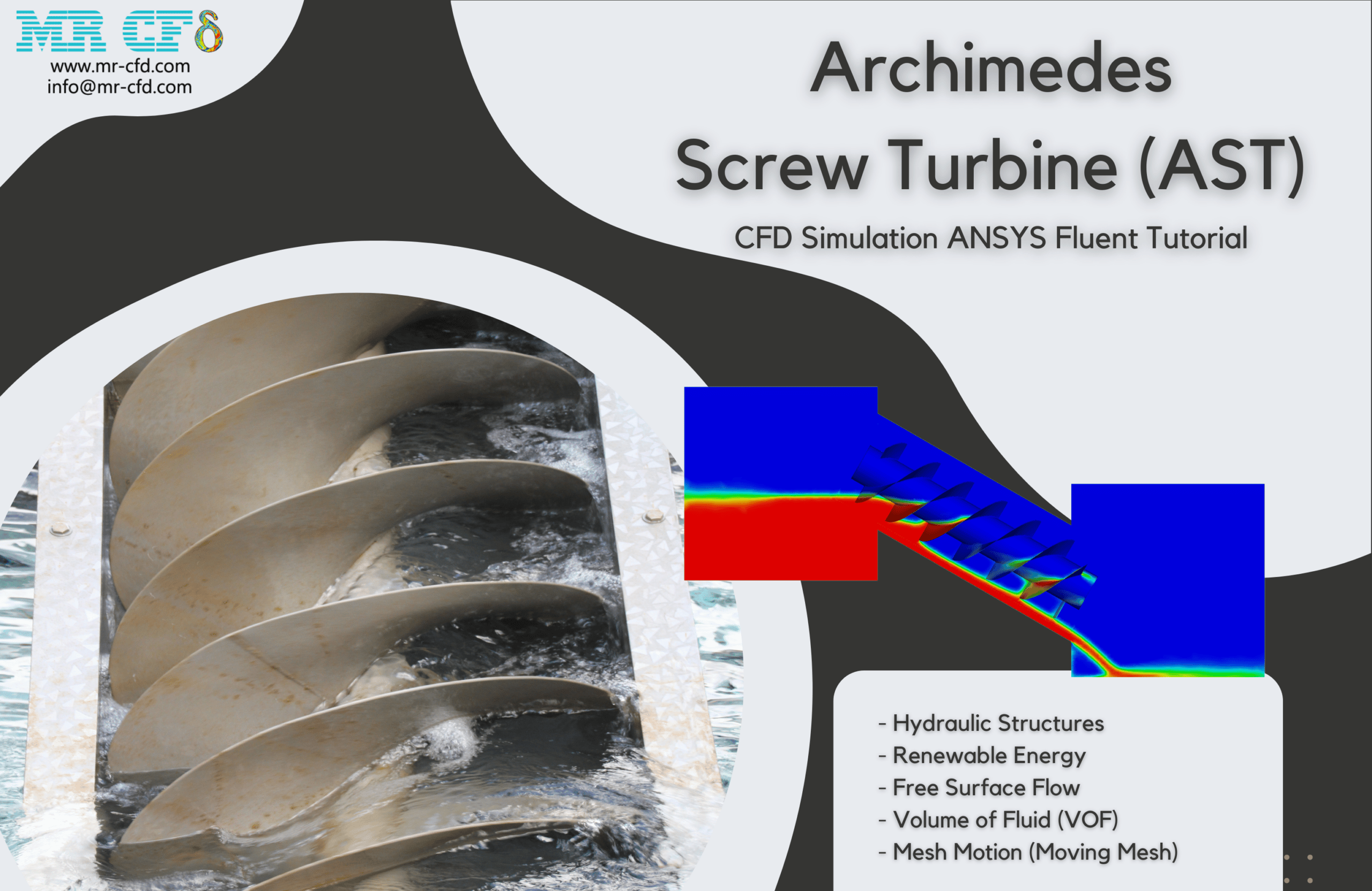

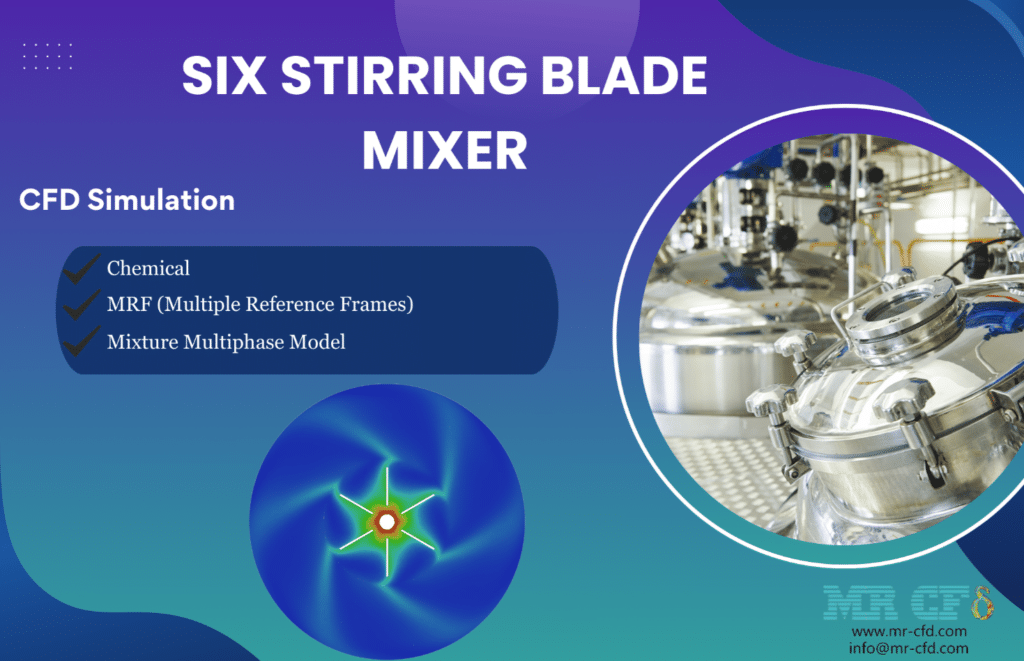

Six Blade Stirring Mixer CFD Simulation

The mixer has six flat wings that rotate swiftly inside a cylindrical tank. This simulation examines the fluid dynamics of a water-air mixture to understand how the liquid phase is dispersed in the tank. The lesson shows how to replicate mixer blade rotation using the Multiple Reference Frame (MRF) method without shifting mesh techniques, which are more computationally costly. The Mixture multiphase model shows how water and air interact, helping us precisely measure water’s volume share during mixing.

The geometry of the solution was created with the ANSYS suite program Design Modeler, ensuring the geometry faithfully reflected the real model required close attention to detail.

After the design stage, an unstructured mesh was generated using the ANSYS Meshing. Higher precision in regions with anticipated volume fraction and pressure gradients was the reason a high-quality mesh was created.

Heat Transfer Analysis

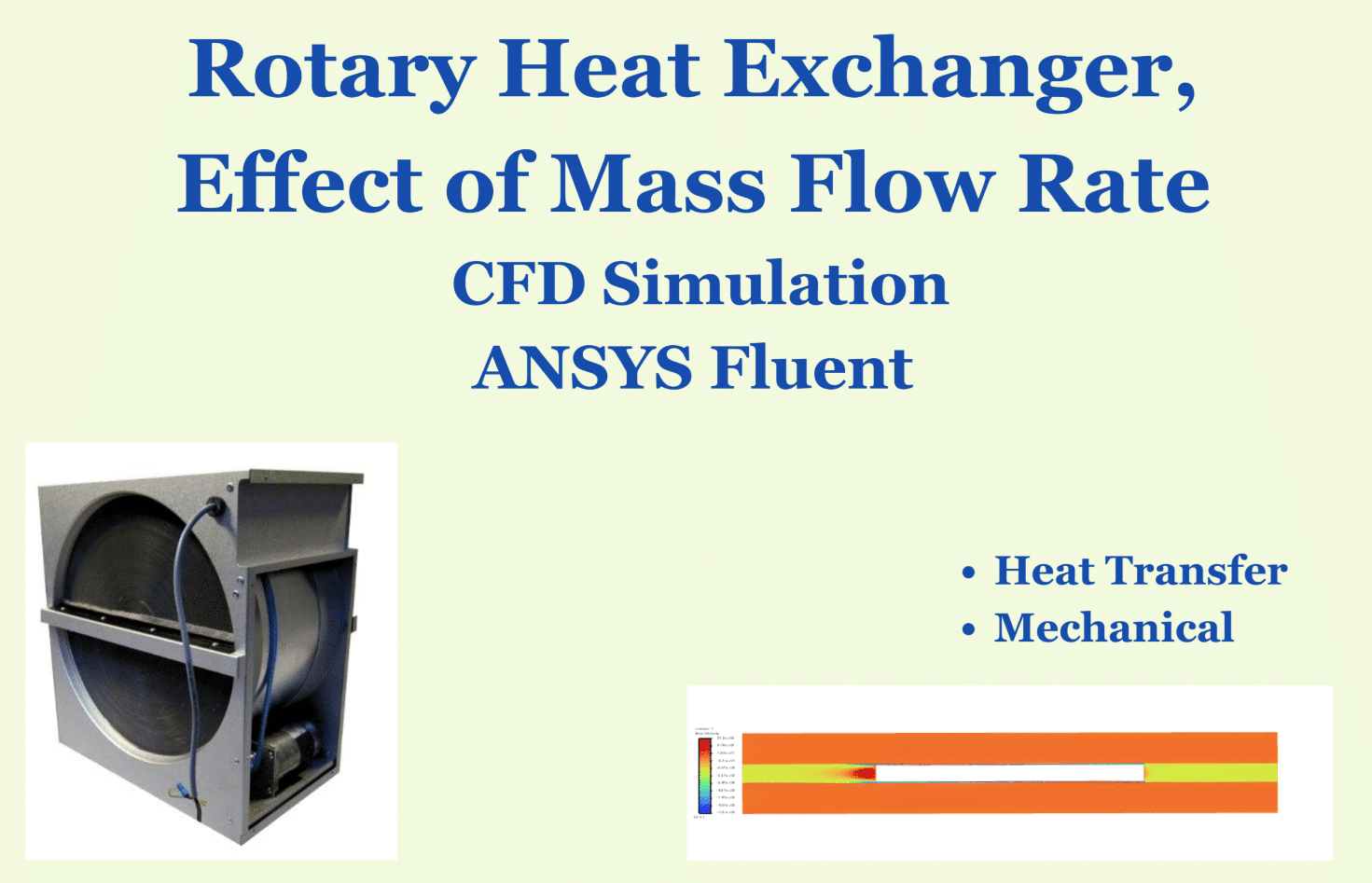

Rotary Heat Exchanger, Effect of Mass Flow Rate

The geometry of the heat exchanger is designed in Design Modeler software. The model consists of 2 regions. One is dedicated to the hot fluid and the other one is designed for the cold one. Next, the model is meshed in ANSYS Meshing software. A structured grid is generated and the total number of elements is 86,598.

Rotary Cooling of Object with Constant Heat Flux

Cooling airflow with a velocity of 29.215 ms-1 (assuming Reynolds 10000 for the inlet airflow to the model) and a temperature of 300 K enter the model through five inlet ducts the outlet section located at the top of the model at equivalent pressure Atmospheric pressure is released.

Separators Analysis

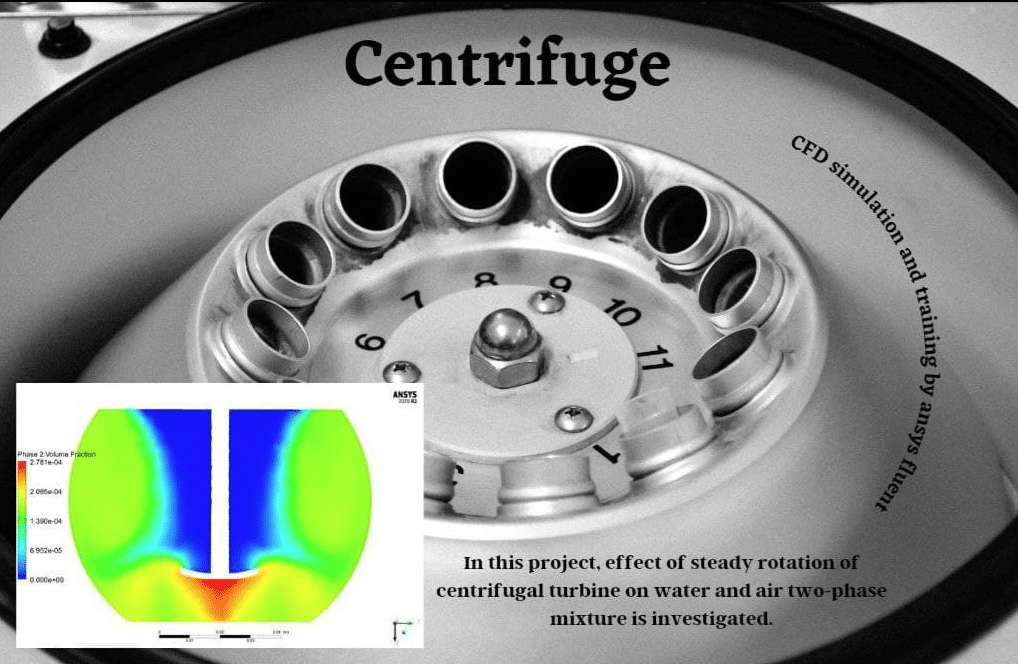

In this Rotary Equipment project, the effect of steady rotation of a centrifugal turbine on a water and air two-phase mixture is investigated by ANSYS Fluent software. Multi-phase MIXTURE model is used to solve water and air phase interactions. The secondary phase (air) volume fraction has very low values in the 0.0001 order, which proves the validity of the mixture multi-phase model in this project, since for applying the Mixture Multi-Phase model, the secondary phase volume fraction should be less than 15%. Slip velocity has been taken into account at the water and air contact interface. The diameter of air bubbles is considered equal to 1 µm. The rotating region of the turbine is considered a separate body that rotates with a rotational speed equal to 500 rpm, which simulates the rotation of the centrifugal turbine at the same rate. Frame Motion (MRF) model has been applied for the rotation simulation.

Well Drilling Mud and Sand Separator

This Rotary Equipment Project simulates well drilling and sludge separation using ANSYS Fluent software. In this simulation, a cylindrical hole is considered a well, inside which a rotating body in the shape of a cylinder is placed. Inside the cavity, a Non-Newtonian material for drilling operations flows; So that the mud particles inside it are mixed. With its rotational motion at 100 rpm, this rotating cylindrical body can separate the mud particles mixed in the non-Newtonian fluid and raise them. Therefore, the Eulerian multiphase model has been used to define the flow in the well. The primary phase of this multiphase flow is related to the same non-Newtonian fluid called CMC, and its second phase is related to mud particles called drilling.

Eulerian multiphase model in cases such as concentration of more than 10 percent of dispersed particles in the base fluid, pneumatic transitions for liquid and solid flows, the slurry flows in a liquid and solid, deposition as two-phase liquid and solid flows, etc. is used. In this simulation, the base fluid within the computational area has a volume fraction equal to 0.87, and the mud solution particles have a volume fraction equal to 0.13. Fluids are also divided into two categories of Newtonian and non-Newtonian fluids in terms of viscosity. The viscosity of a fluid is a parameter that indicates the resistance of that fluid to flow. Newtonian fluids follow Newton’s law of viscosity (shear stress in a Newtonian fluid changes linearly with strain rate).

Pumps Analysis

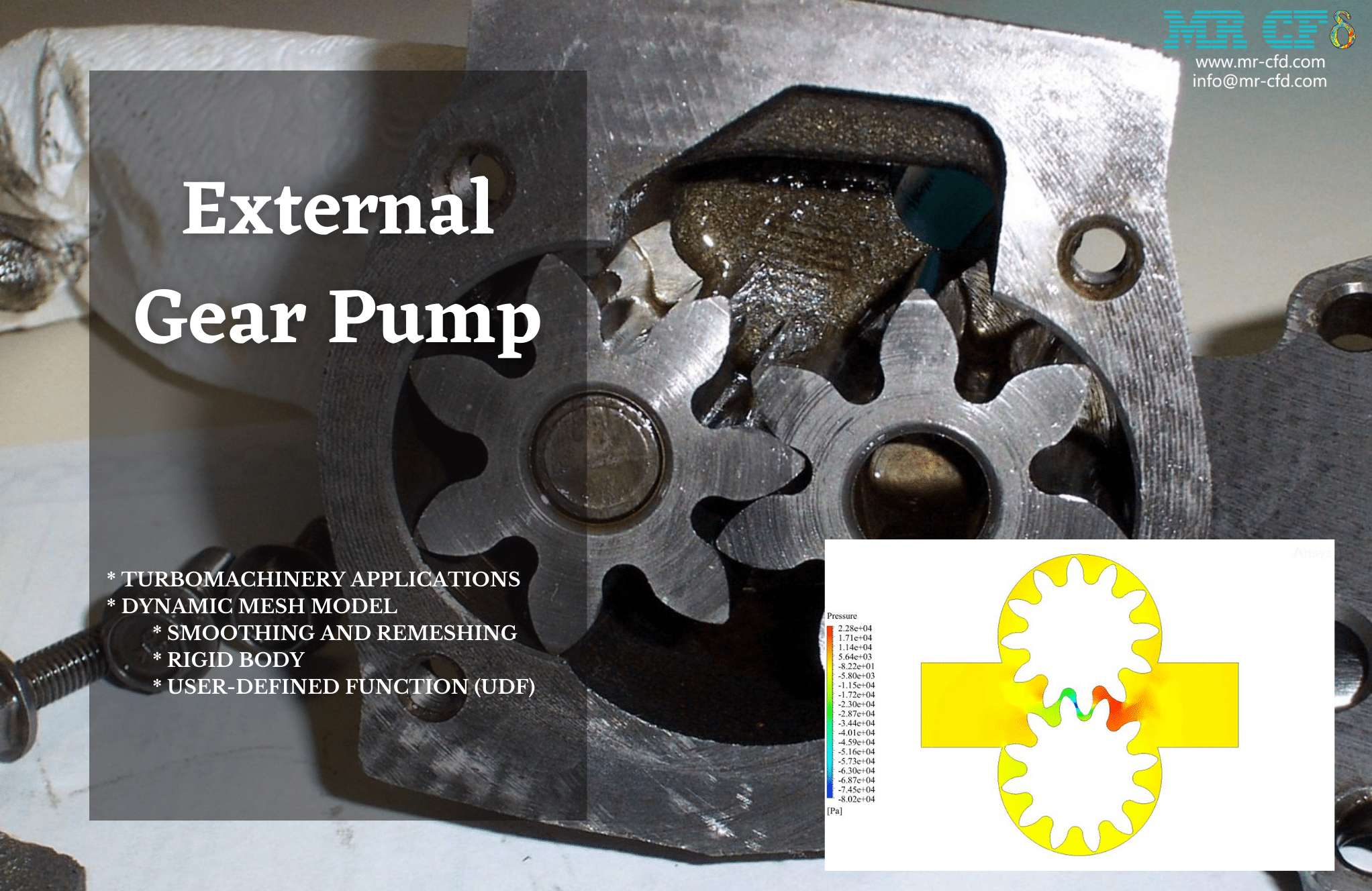

Internal Gear Pump CFD Simulation

This project is related to the numerical simulation of the Internal Gear Pump using Ansys Fluent software. A pump is a mechanical device for moving and transferring all liquids from one place to another. In this way, by increasing the pressure, pumps cause liquids to move to a higher height (by increasing the head) and even lower (such as tanks).

The pump takes mechanical energy from an external source, such as a motor, and transfers it to the fluid passing through it. As a result, the energy of the fluid increases after leaving the pump.

The energy transfer to the pump fluid is done in two dynamic and displacement methods. Therefore, pumps are divided into positive displacement pumps and dynamic or non-positive displacement pumps. Positive displacement pumps are divided into two groups: rotary (such as gear, lobe, and vane) and reciprocating (piston and diaphragm).

A gear pump is one of the most common pumps to increase the hydraulic power of a fluid. Gear pumps move liquids using gears. These gear pumps are made of two types of internal and external gears.

Internal gear pumps consist of two gears that rotate in the same direction, so one gear is inside the other. When two gears make contact with their teeth, fluid is trapped. Now, when the teeth are separated from each other due to rotation, high-pressure fluid is rotated through the ribs to the outlet. In these internal gear pumps, a crescent between the inner and outer gear directs the flow path to the outlet. We modeled the geometry of the project using Design Modeler software.

The geometry is related to an internal gear pump. The computational domain includes the internal space of the pump with two non-concentric gears inside each other. A crescent is also placed in the space between two gears. Then we meshed the model with Ansys Meshing software. The model mesh is unstructured, and the number of cells equals 50,106.

Gerotor Pump with Cavitation

In modern hydraulic systems, gerotor pumps play a crucial role in fluid transfer applications. However, these pumps often face challenges related to cavitation, which can significantly impact their performance and longevity. This study presents a detailed numerical investigation of cavitation phenomena in a gerotor pump using computational fluid dynamics (CFD) simulation. The primary objective is to understand and analyze the cavitation behavior through a two-dimensional model using ANSYS Fluent software.

Rotary Equipment Industrial Companies

Leading rotary equipment manufacturers extensively apply CFD for design optimization and performance validation:

Sulzer & KSB

Global pump leaders use CFD for centrifugal/positive displacement pump impeller optimization, cavitation prediction (NPSH analysis), and multi-stage performance curves. Sulzer’s industrial pumps for oil & gas achieve 15-20% efficiency gains through adjoint-based geometry optimization.

Atlas Copco & Ingersoll Rand

Compressor specialists simulate screw/rotary vane meshing, surge margin prediction, and oil injection cooling. Atlas Copco’s oil-free compressors use transient CFD for 99.9% purity validation and acoustic noise reduction (FW-H formulation).

SPX Flow (Lightnin) & Ekato

Mixing giants analyze impeller power numbers, blending times, and solids suspension in 100m³+ reactors. Lightnin’s Rushton turbines are optimized for kLa (oxygen transfer) using Eulerian-granular models with ±5% experimental validation.

FEECO & Metso Outotec

Rotary dryer experts track particle residence times and heat/mass transfer using DPM + moving mesh. FEECO optimizes fertilizer/mineral dryers for 30% uniform moisture reduction and 20% energy savings.

Alfa Laval

Sanitary lobe pumps and rotary separators use dynamic mesh for gear meshing and multiphase separation efficiency, achieving 98% solids removal in food/pharma applications.

These companies achieve first-pass design success rates >85% using CFD for impeller DOE, FSI vibration analysis, and multiphase validation directly aligning with MR CFD’s rotary equipment simulation capabilities.

MR CFD Industrial Experience in the Rotary Equipment Field

MR CFD has extensive industrial and research experience in rotary equipment engineering, successfully completing numerous outsourced projects for clients in chemical processing, oil & gas, power generation, food industry, and water treatment. Our team has tackled real-world challenges in mixing systems, rotary heat exchangers, separation equipment, positive displacement pumps, and rotary dryers using ANSYS Fluent’s advanced rotating flow capabilities.

Industrial project examples include:

-

Gear Pump Optimization for Chemical Processing: Dynamic mesh simulation of internal gear pump (50K cells) identified leakage paths across gear clearances and optimized tooth profile for 15% higher volumetric efficiency while reducing pressure pulsation at discharge.

-

Rotary Heat Exchanger Performance Analysis: 2D axisymmetric modeling (86K structured grid) quantified heat transfer coefficient variation with mass flow (0.02-0.08 kg/s), achieving 224 W/m²K at design conditions for HVAC heat recovery system.

-

Powder Mixing Optimization: Transient Eulerian-granular simulation (657K cells) of 30rpm propeller mixer reduced blending time by 25% through baffle repositioning and impeller speed adjustment for pharmaceutical batch processing.

These industrial experiences have been distilled into comprehensive training packages available for engineers and students:

Rotary Equipment CFD Simulation Training Package: 9 Beginner Projects by ANSYS Fluent

Covers foundational rotary equipment physics including mixers (powder distribution, six-blade stirring, side-entry tanks), heat transfer (rotary exchanger, rotary cooling), separators (centrifuge, mud/sand), and bioreactors (Rushton turbine agitation).

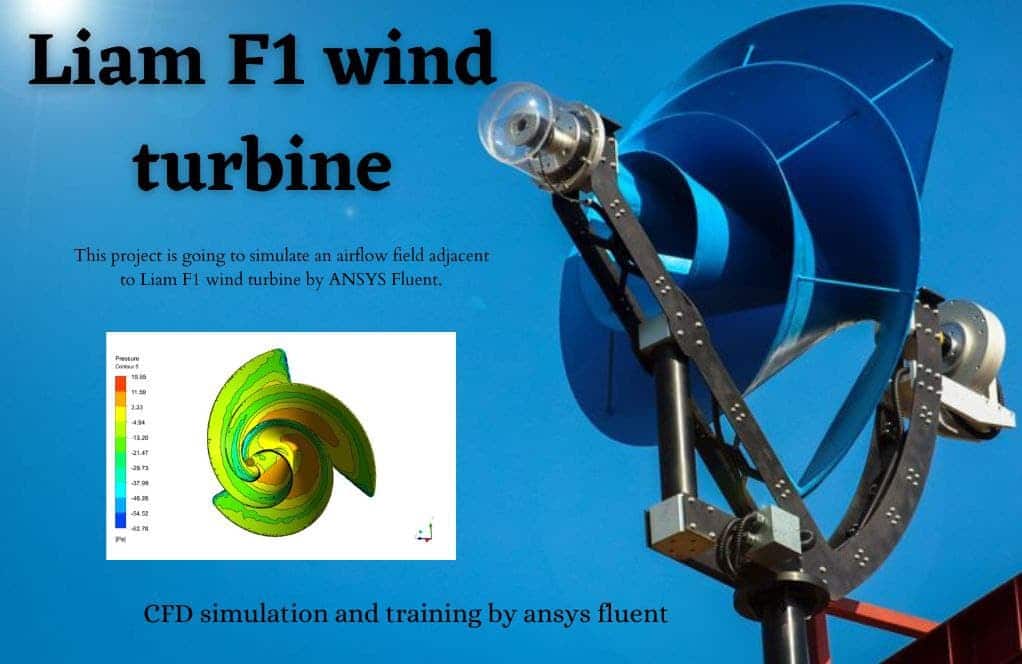

Rotary Equipment CFD Simulation Training Package: 9 Advanced Projects by ANSYS Fluent

Advanced applications including gerotor pumps (with cavitation), gear pumps (internal/external), lobe/diaphragm pumps, rotary seed dryer (DPM+moving mesh), and specialized heat transfer (brake disk, electronic cooling).

Each training package includes complete resource files (geometry, mesh 50K-679K cells, case/data, UDFs), step-by-step tutorial videos, validation reports against experimental data (±5% accuracy), and post-technical support—transforming industrial-grade rotary equipment CFD knowledge into accessible learning material for professional development.