Aerodynamic and Aerospace Training Package, Intermediates, 10 Projects

$199.00 $99.50 Student Discount

This training package includes 10 practical aerodynamic and aerospace engineering exercises using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Aerodynamic & Aerospace ANSYS Fluent CFD Simulation Training Package for INTERMEDIATE Users

This training package includes 10 practical aerodynamic and aerospace engineering exercises using ANSYS Fluent software. MR CFD suggests this package for all aerodynamic and aerospace engineers who will learn CFD simulation in this field at the INTERMEDIATE level.

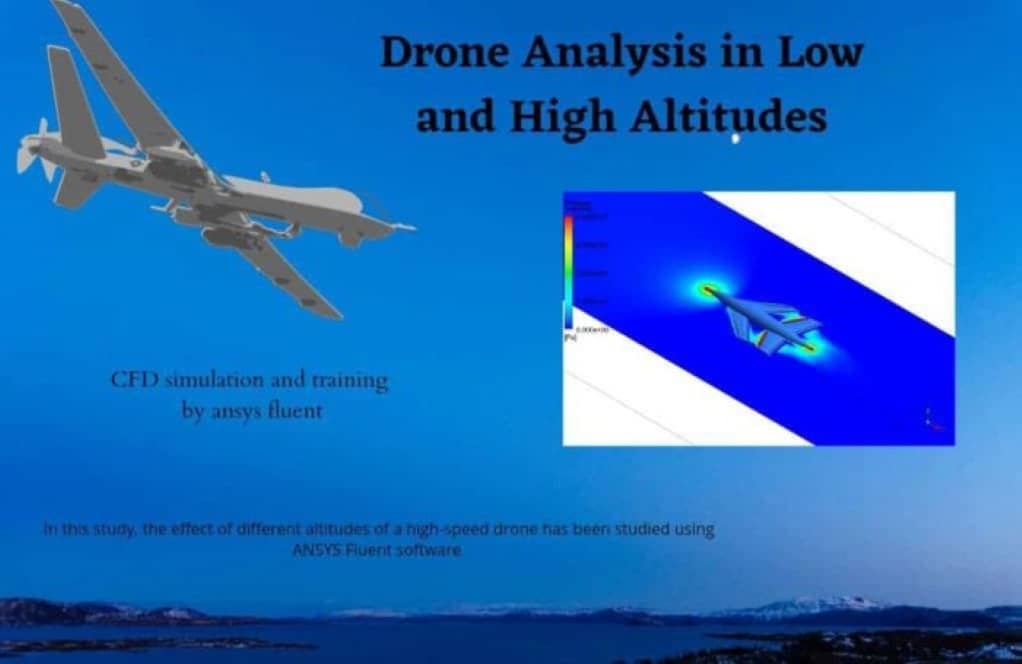

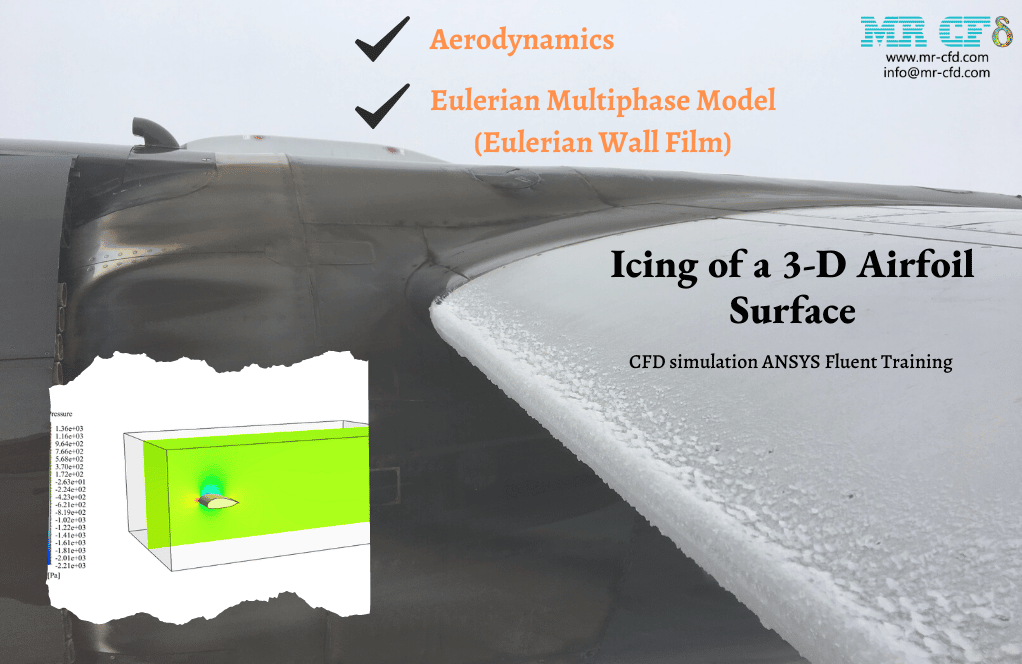

Compressible Flow

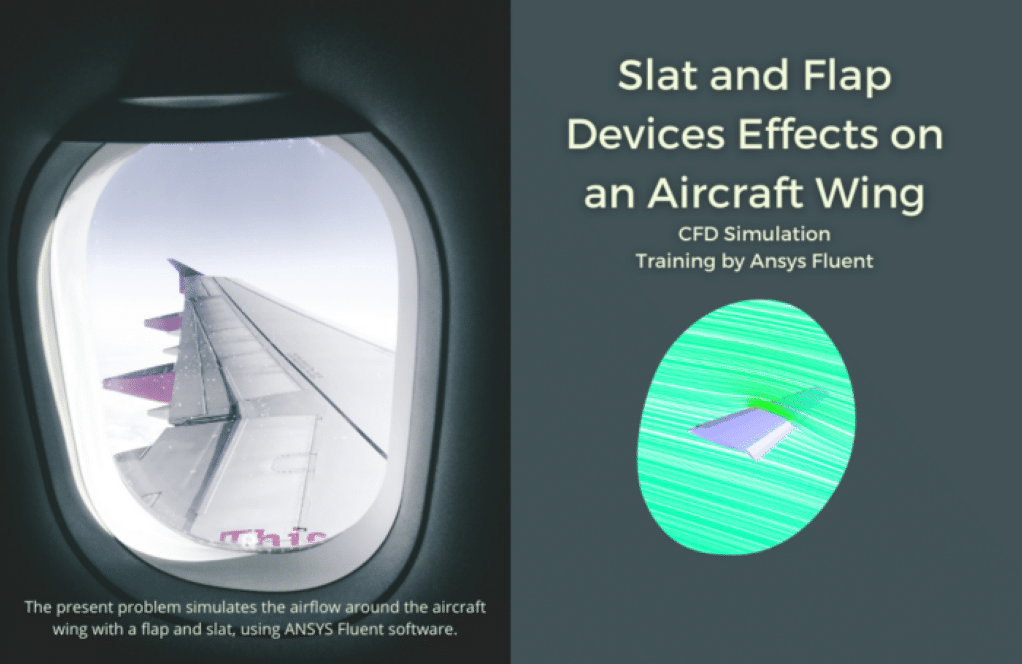

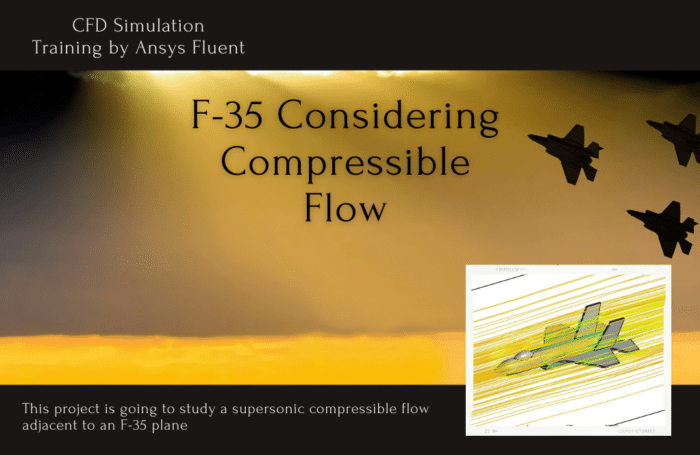

In practical exercise, number 1, a wind tunnel and a specific body placed inside it are modeled considering compressible flow. The effect of drag force on this body is investigated. The energy model and standard k-epsilon model with standard wall functions are activated. Project number 5 will study a Supersonic Compressible Flow adjacent to an F-35 plane. The geometry is a 20-meter F-35 plane inside a 150-meter wind tunnel. The air is considered a compressible ideal gas, and the Mach number of 2.0 was achieved at the maximum speed of 544 m/s. Problem number 7 simulates the compressible airflow around the aircraft wing with a flap and slat. In this project, a 3D airplane wing is designed; In such a way a Flap is on the trailing edge, and a Slat is on the wing’s leading edge.

In study number 8, the effect of different altitudes of a high-speed drone has been studied. The fluid is air, and we consider it a compressible ideal gas. The maximum speed of the drone is 30 m/s, and the investigated altitudes are 20m and 2000m as low and high, respectively.

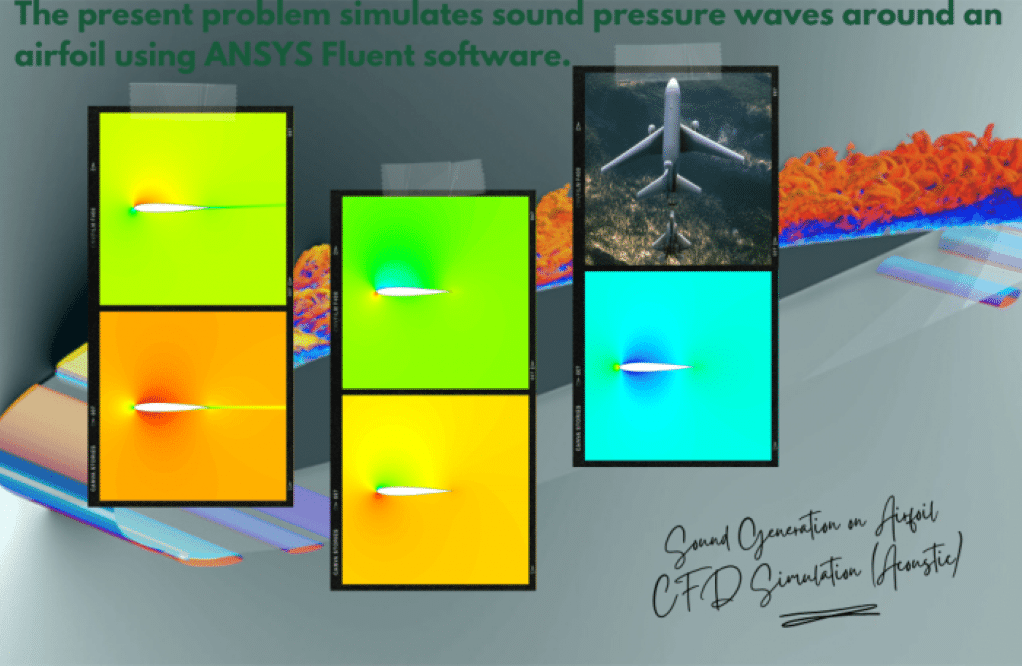

Acoustic in Aerodynamic

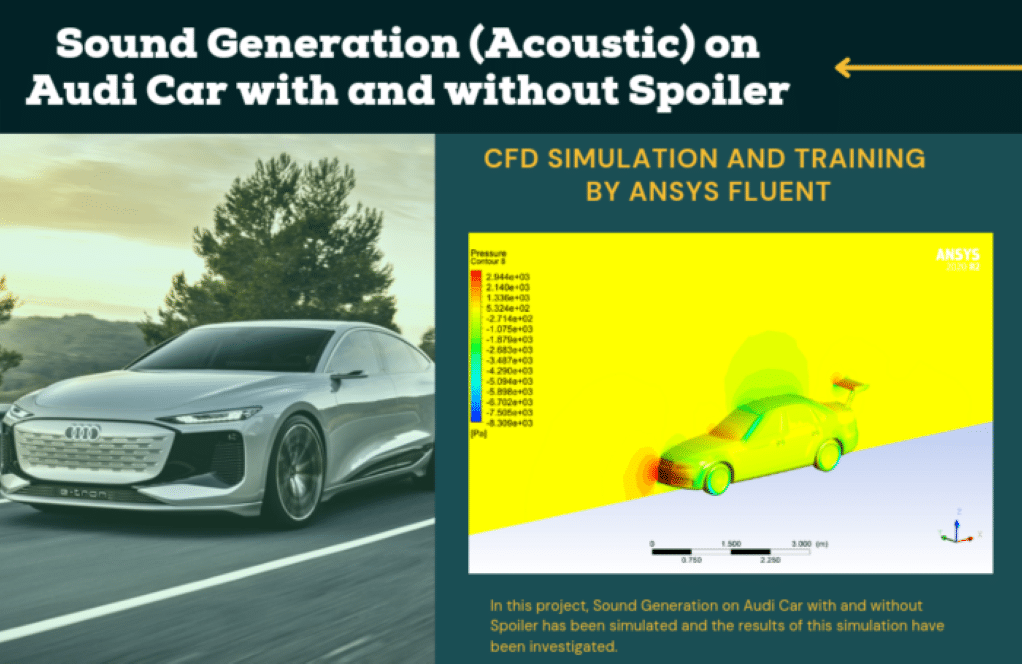

Problem number 2 simulates sound pressure waves around an airfoil. This project examines the sound waves generated around the body of an airfoil. This project uses an acoustic model in Fluent software to simulate and analyze sound or acoustic waves. The Broadband Noise Sources model has also been used to define the type of acoustic model of the present work. Problem number 6 simulates sound pressure waves around an AUDI car with and without a spoiler. Aeroacoustics is a branch of acoustic science that investigates the production of Noise. In general, Noise can be generated by the movement of turbulent fluid or from collisions of aerodynamic forces with surfaces.

Moving Mesh (Mesh Motion) & Dynamic Mesh

In project number 3, the rotation of helicopter wings is simulated in transient time formulation, and the results, including net upward force, wing tip speed, and Tip Speed Ratio (TSR), is investigated. To generate upward movement in aerodynamic applications, movement of a certain amount of air in the downward direction is needed, generating upward motion. This air movement is done for helicopters using a propeller consisting of 2 or more wing-shaped geometries rotating around a center. In practical exercise number 4, a golf ball movement with an aerodynamic point of view has been studied applying Dynamic Mesh, the force applied to the ball is equal to 200 N. Due to the impact, the golf ball displacement has been studied in terms of time.

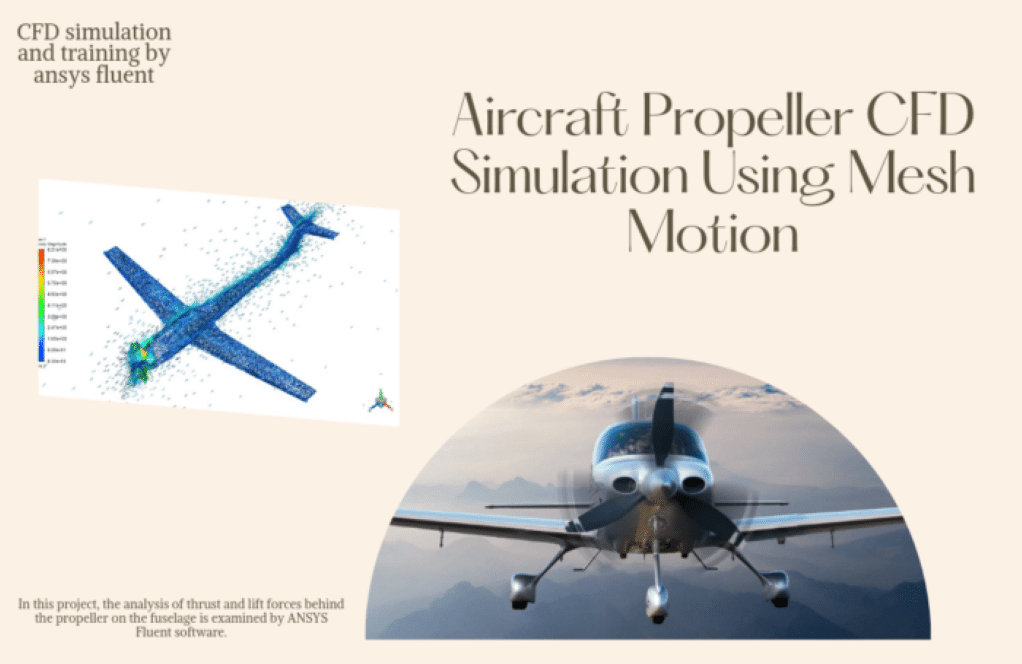

Project number 9 examines the analysis of thrust and lift forces behind the propeller on the fuselage. Aircraft and propeller modeling is performed in two zones rotational and stationary. The rotating computational domain must rotate around the impeller axis to model the impeller rotational motion using the Mesh Motion method.

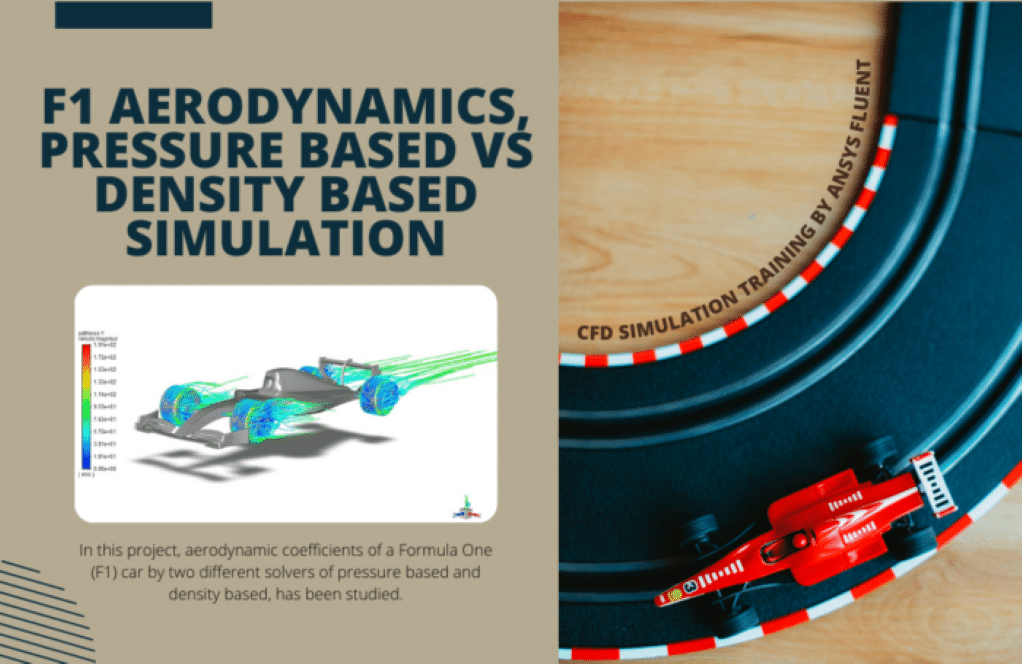

Pressure-Based & Density-Based Solvers

Finally, In practical exercise number 10, the aerodynamic coefficients of a Formula One (F1) car by two different solvers, pressure-based and density-based, have been studied at a speed of 108 meters per second at a lateral angle of zero degrees (actually a straight path). This velocity at the ground level is equivalent to a Mach number of approximately 0.32. We know this area from Mach number is the transition zone from incompressible to compressible flow, so on this geometry, the drag coefficient is investigated using two pressure-based and density-based solvers is discussed.

Reviews

There are no reviews yet.