Species Transport CFD Training Package, 10 Products for Advanced Users

$2,350.00 Original price was: $2,350.00.$1,567.00Current price is: $1,567.00. Student Discount

Species Transport CFD Simulation Package, ANSYS Fluent Training for ADVANCED Users

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Species Transport CFD Simulation Package, ANSYS Fluent Training for ADVANCED Users

This CFD training package is prepared for ADVANCED users of ANSYS Fluent software in the Species Transport area, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

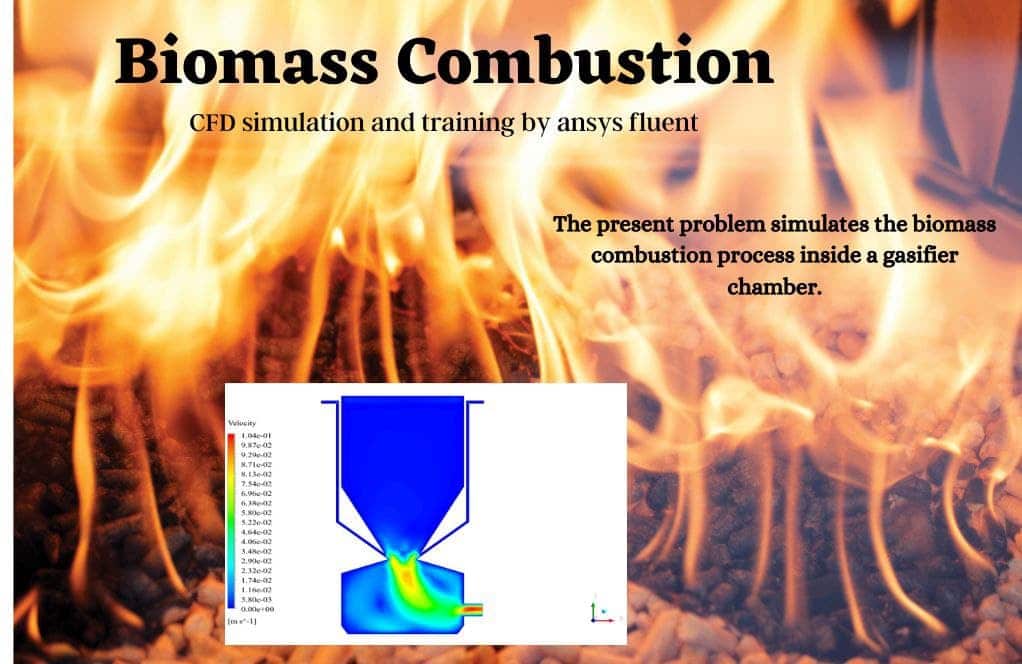

Combustion

Project number 1 simulates the biomass combustion process inside a gasifier chamber. The material used for combustion is biomass, which reacts with the oxidizer. It is a biomass substance made from wheat straw that reacts with oxygen to produce synthetic gas as a healthy fuel. In the present model, fuel containing biomass and air enters the chamber from two separate inlets from the upper area. It creates a mass of materials, including ash and semi-combustible coal, in the lower part of the chamber.

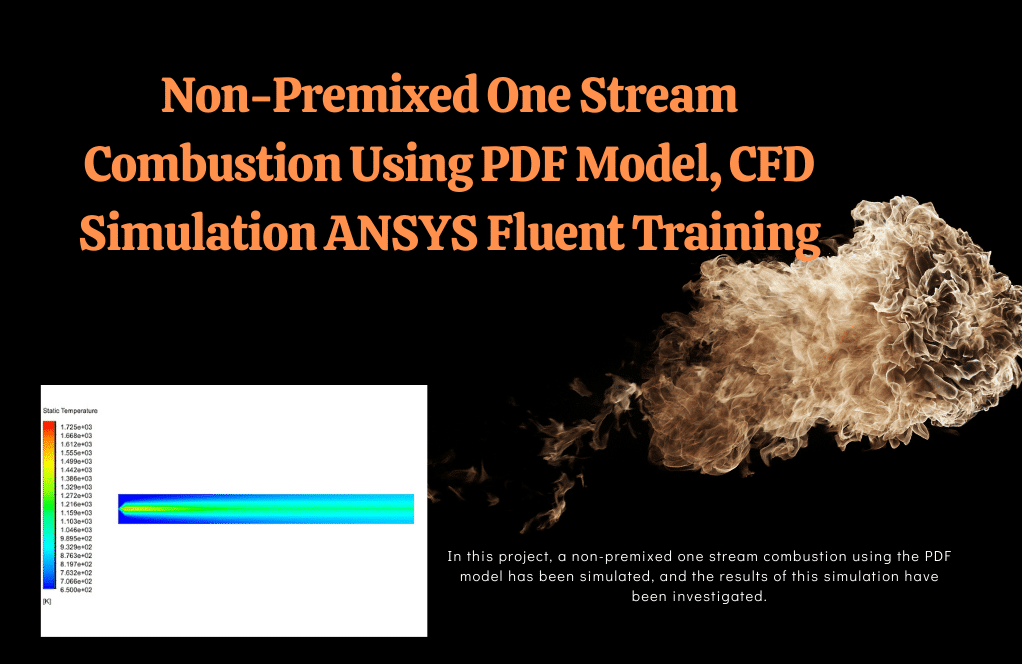

In project number 2, we have simulated non-premixed one-stream combustion using the PDF model (probability density function). A two-dimensional channel is drawn in this project as a combustion chamber. Air enters the channel at a speed of 1 meter per second and a temperature of 650 Kelvin. Pentane fuel is injected into the canal in liquid droplets with a diameter of 100 microns and a temperature of 300 K in a solid cone of 45 degrees with a flow rate of 0.004 kg / s. The channel wall temperature is 1200 Kelvin.

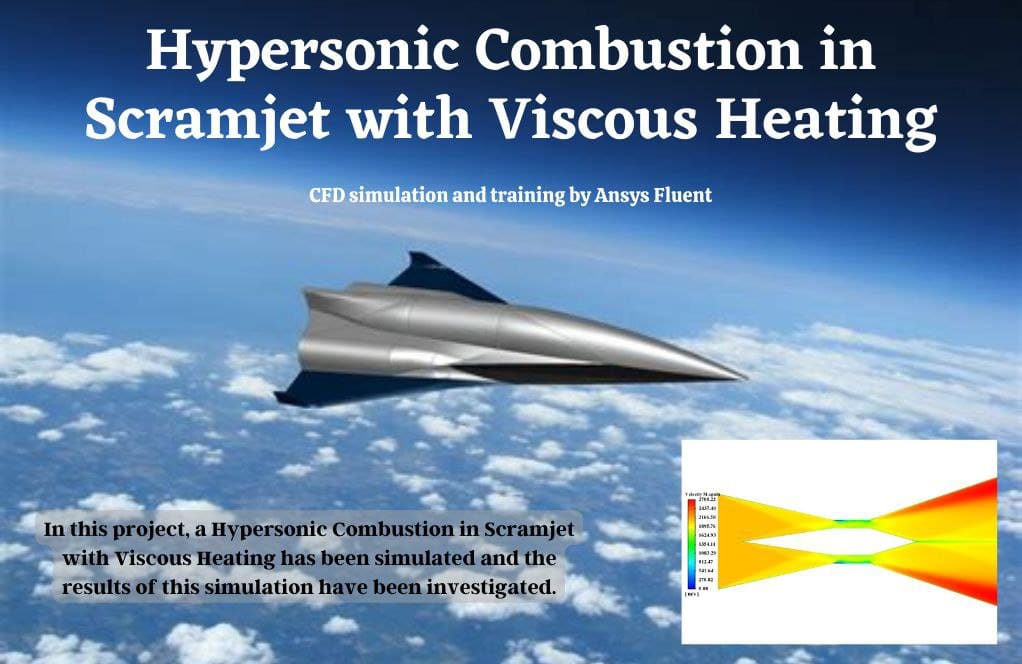

In project number 3, Hypersonic Combustion in a Scramjet engine with Viscous is simulated. The Mach number of inlet air is set to 6, and the temperature of the whole domain equals 300k. At the middle part of the nozzle, in which the Mach number reaches 1, hydrogen injects into the flow with a Mach number of more than 1, and consequently, the combustion will occur in the nozzle.

Drying

In project number 4, which has been done by CFD numerical simulation method, The spray drying chamber is simulated by the two-way DPM & Species Transport model. The particle diameter is 1 mm, and the flow moves at one m/s.

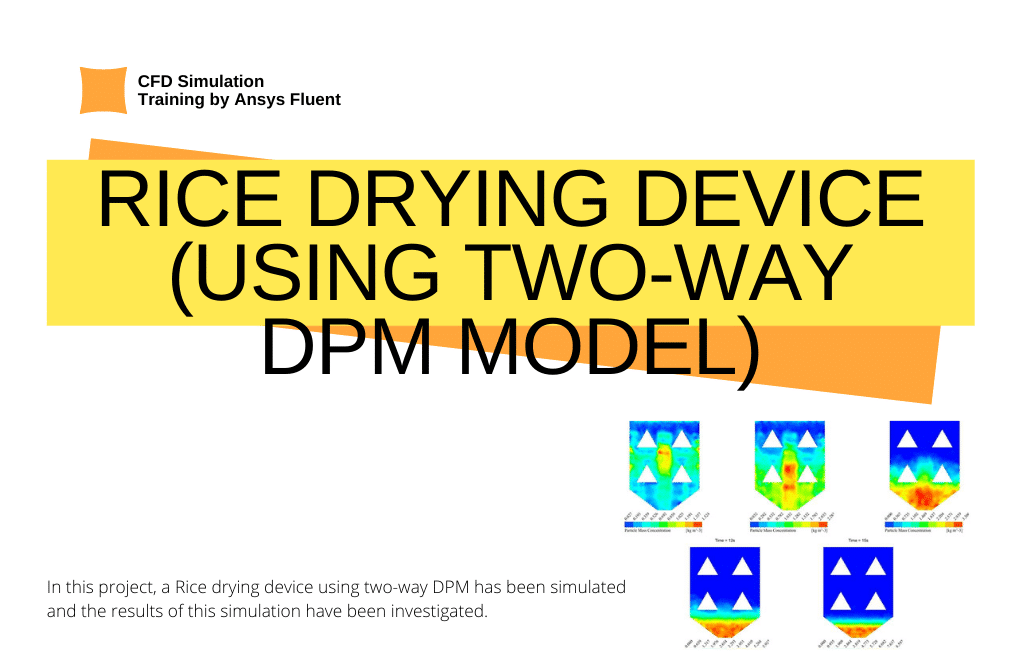

In project number 5, a rice drying device has simulated using the Two-way Discrete Phase Model (DPM) & Species Model, and then the results were investigated. Hot air enters the drying device, and then 120000 rice grains with 10% moisture are injected randomly for 6 seconds. The evaporation process continues for 9 seconds after the complete injection. Furthermore, the hot surfaces are in contact with the hot exhaust smoke of the engine, which provides an efficient condition for the drying device.

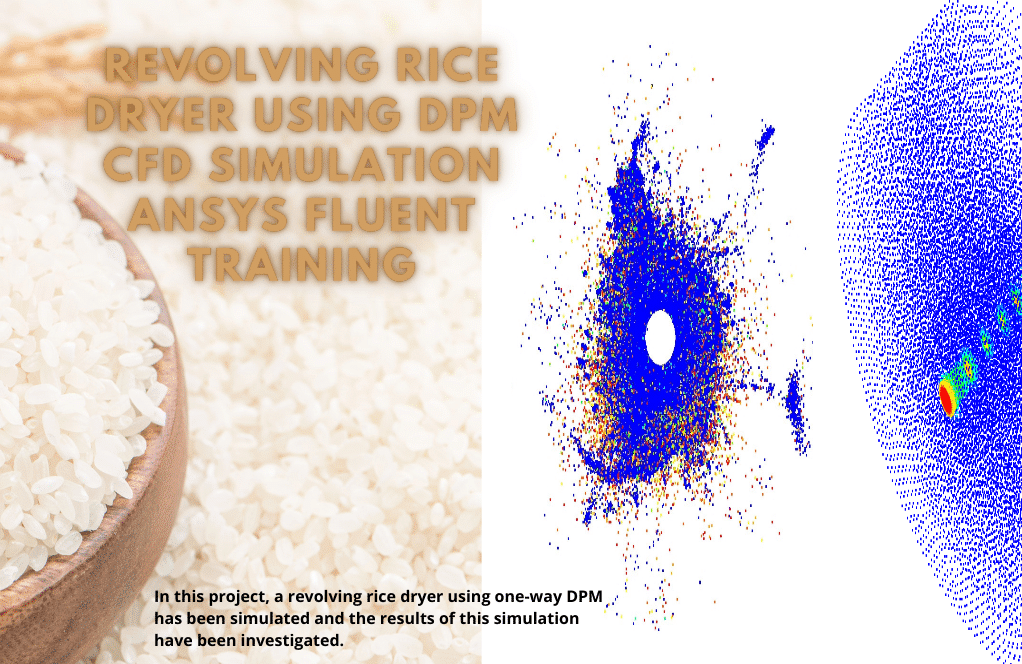

In project number 6, a revolving rice dryer device was simulated using Evaporating droplets with a one-way DPM model, and then the results were investigated. Hot air enters the rice dryer through the holes on a porous tube located at the center of the enormous chamber. About three million rice particles are injected with 15% moisture droplets into a chamber revolving with 100rpm angular speed.

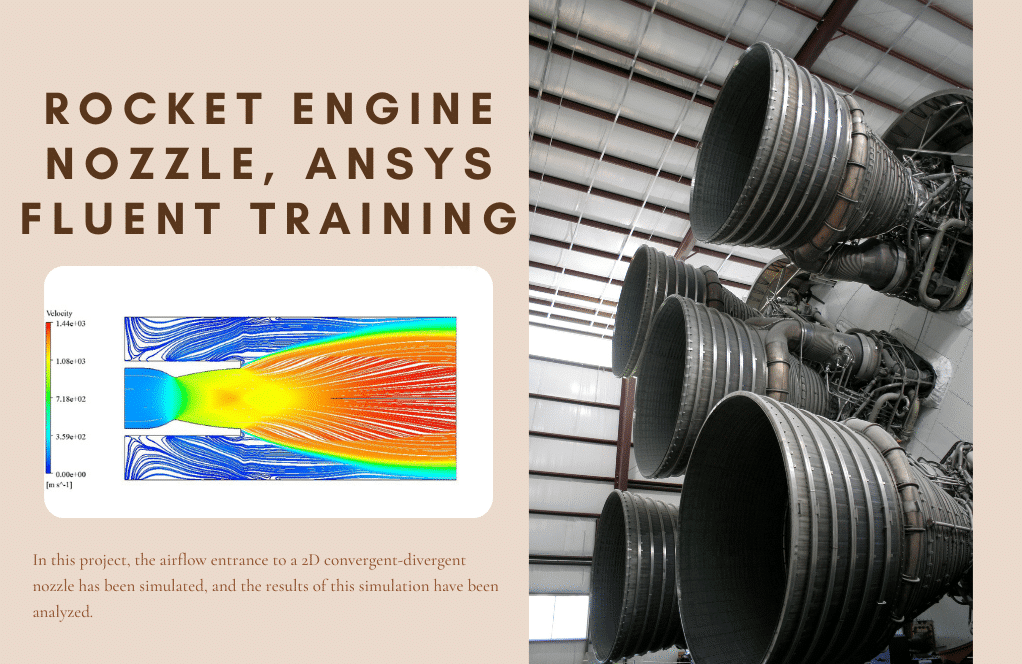

Nozzle

Project number 7 is about the rocket engine nozzle. A rocket engine nozzle is a type of propellant nozzle; This means that the internal energy of the gas is converted into a driving force and forms a high-velocity fluid jet. This nozzle is used in rocket engines to expand and accelerate the combustion gases produced by burning fuels in propellants. The exhaust gases exit the nozzle at supersonic speed.

Furnace

In project number 8, ANSYS Fluent software stimulated an industrial Furnace numerically. The furnace simulated in this project is combusted with methane fuel to heat the Methane in the pipes so that the Methane can be moved more quickly and with less force. By observing the results, it can be seen that the outlet temperature of methane pipes has increased compared to the inlet temperature.

Population Balance Model (PBM)

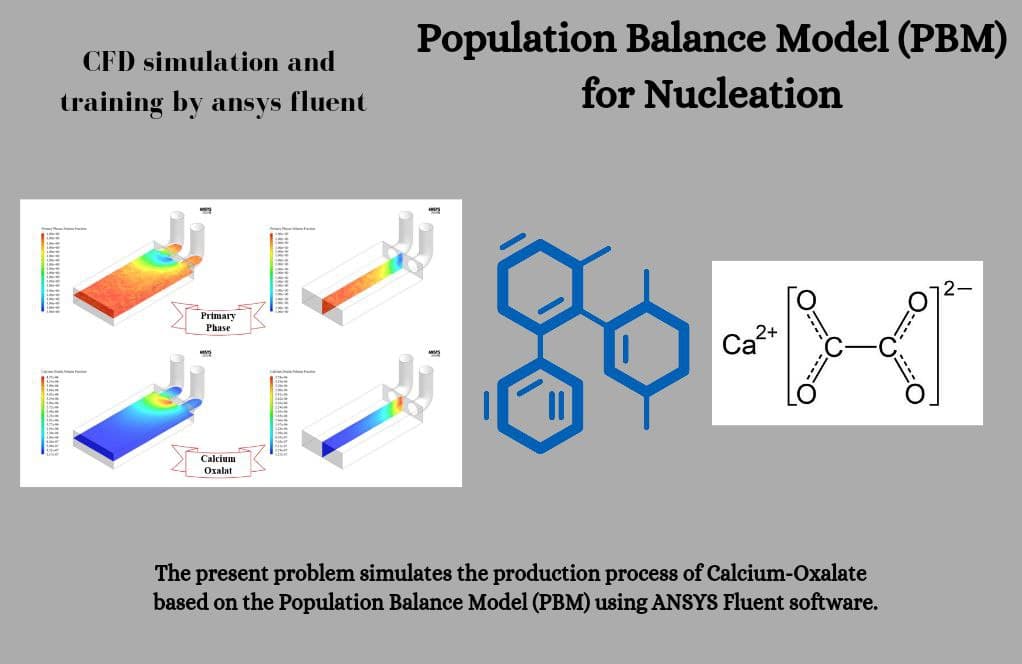

Project number 9 simulates the production process of Calcium-Oxalate based on the Population Balance Model (PBM). In this project, the calcium-oxalate production process is modeled, and then the PBM is analyzed using the production, growth, and displacement of production particles. The mechanism of the studied system is such that the flow of water carrying calcium and oxalate enters a chamber through two pipes.

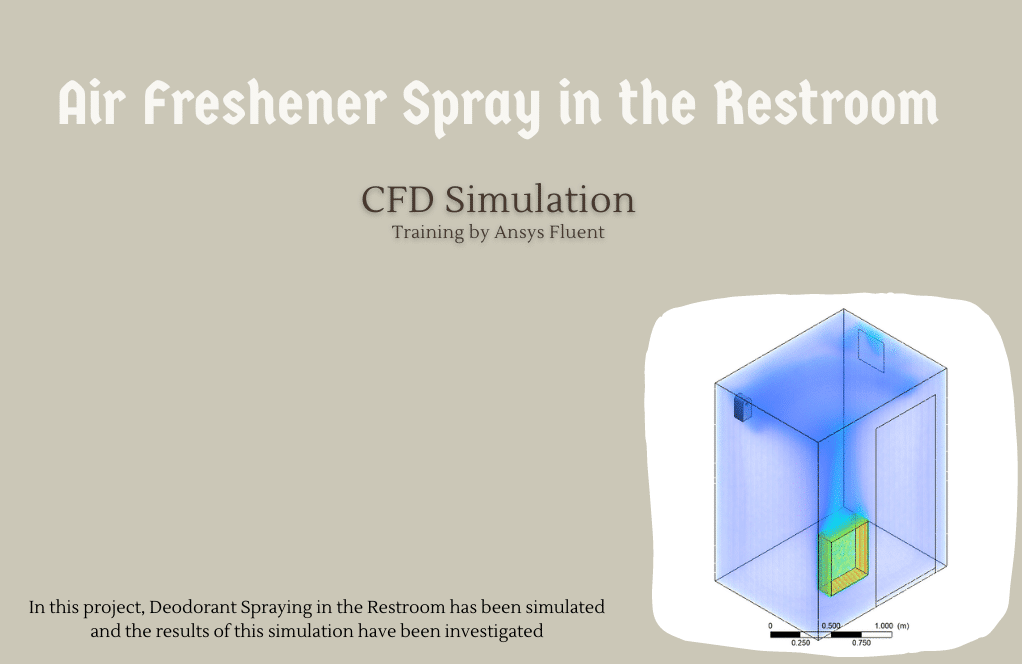

Spray

Project number 10 investigates the spraying of Air fresheners in the restroom by the Two-way DPM method. According to this definition of injection, fragrance particles are physically expelled from the device by water droplets that evaporate in space. These droplets have a temperature of 310 K, a velocity of 50 m.s, and a mass flow of 0.018 kg.s-1, which are emitted at intervals of 0s to 0.1s. The particle diameter is not constant during diffusion, and the rosin-rambler-logarithmic distribution method is considered for the diameter of the Particles.

Dr. Emelia King –

I’ve just completed the Species Transport CFD Simulation Package – it’s really elevated my understanding of ANSYS Fluent! The variety of practical examples provided thorough insight, especially project number 5 with the rice dryer. The step-by-step guidance was spot-on. Wonderful resource for advanced users wanting to deepen their skills in species transport simulations.

MR CFD Support –

Thank you so much for your feedback! We are thrilled to hear that the Species Transport CFD Simulation Package was helpful in advancing your understanding and skills in ANSYS Fluent. It’s fantastic to know that Project 5, in particular, resonated with you. We always strive to provide practical and in-depth training, and we’re glad to hear it’s making a difference for users like yourself. If you have any more questions or need further assistance in your learning journey, feel free to reach out. Continue with your great work in CFD simulations!

Cecelia Simonis –

I recently completed the Species Transport CFD Training Package and have to say I’m thoroughly impressed. Each project challenged me to apply advanced simulation techniques, greatly improving my proficiency with ANSYS Fluent in the context of species transport phenomena. I particularly appreciated the combination of real-world examples such as combustion in gasifiers and hypersonic combustion, together with industrial applications like dryers and furnaces. This diverse exposure has widened my perspective on what’s possible in CFD simulation and has directly contributed to my professional development.

MR CFD Support –

We’re delighted to hear that you had such a positive and enriching experience with our Species Transport CFD Training Package! Thank you for your thoughtfully composed feedback. It’s fantastic to know the projects were challenging yet beneficial in enhancing your skills and offered the practical, real-world problem-solving experience that we aim for. If you need any further support or wish to continue your learning journey with us, we’re just a message away. Thanks again for choosing MR CFD for your advanced learning, and we hope to assist you in the future!

Rosalee Gerlach –

The projects in this training package seem incredibly comprehensive. Can you tell me how detailed are the steps provided in the tutorials for each project? Do they guide through setting up the simulations as well as the analysis of results?

MR CFD Support –

The tutorials provided in the Species Transport CFD Training Package are very detailed. Each tutorial guides you through the necessary steps to set up the simulation, including defining materials, boundary conditions, and solvers. They also cover how to perform the analyses of the results step-by-step, ensuring a thorough understanding of each project.

Sedrick Kiehn Jr. –

The variety across the projects is impressive! Each one explores different aspects of species transport phenomena with practical applications, broadening our understanding and expertise in advanced CFD simulations.

MR CFD Support –

Thank you for appreciating the diversity of our Species Transport CFD Training Package. We’re glad to know the projects provided you with a comprehensive understanding of species transport applications and improved your simulation skills.

Prof. Breanna Koss PhD –

This package seems very comprehensive and advanced. Could the species transport model also be applied for simulating chemical reactions in aqueous solutions or is it mostly applicable for gas-phase simulations?

MR CFD Support –

The species transport model in ANSYS Fluent is versatile and can handle both gas-phase and liquid-phase simulations, including aqueous solution reactions. It accounts for the mass transfer due to convection, diffusion and can incorporate reaction kinetics, making it suitable for various chemical processes.

Kaia Quitzon –

I was absolutely blown away by the depth and range of simulations included in the Species Transport CFD Training Package. Each project was unique, providing insights into different real-world scenarios. The step-wise approach and level of detail in each exercise closely tied theoretical concepts with practical skills, enriching my learning process. It’s amazing to see how biomass combustion, hydrocarbon fuels, industrial drying processes, even perfume dispersion in air, can be simulated with such accuracy. Hats off to the creators for bringing such a powerhouse of knowledge. This is an incredible resource for any advanced user looking to thoroughly understand and apply species transport in CFD within ANSYS Fluent.

MR CFD Support –

Thank you so much for your detailed and enthusiastic review! We’re thrilled to hear that you found the Species Transport CFD Training Package an enriching and practical resource for advancing your skills. Our aim is always to provide comprehensive and real-world relevant exercises that enable our users to understand complex phenomena and tackle challenging simulations. It’s gratifying to know that your learning experience with our training package was both insightful and impactful. We look forward to continuing to support your progress in the field of CFD!