Volume Of Fluid (VOF), Training Package for Experts, 10 Learning Products

Original price was: $2,430.00.$810.00Current price is: $810.00. Student Discount

This CFD training package is prepared for EXPERT users of ANSYS Fluent software in the Multi-phase Volume Of Fluid (VOF) area, including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Multi-phase (VOF) CFD Simulation Package, ANSYS Fluent Training for EXPERT Users

This CFD training package is prepared for EXPERT users of ANSYS Fluent software in the Multi-phase Volume Of Fluid (VOF) area, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

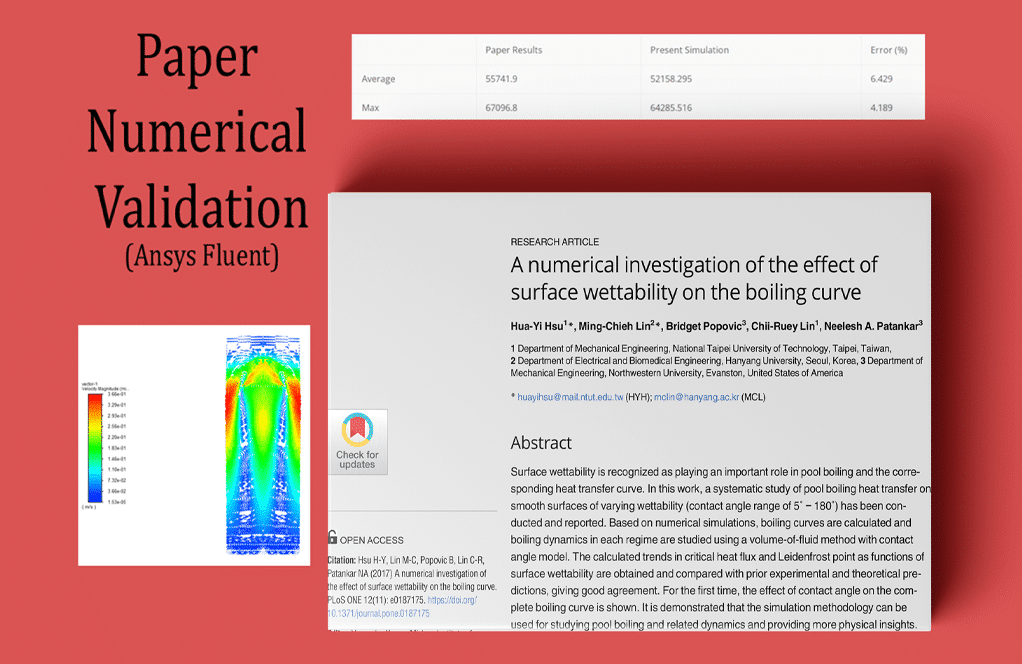

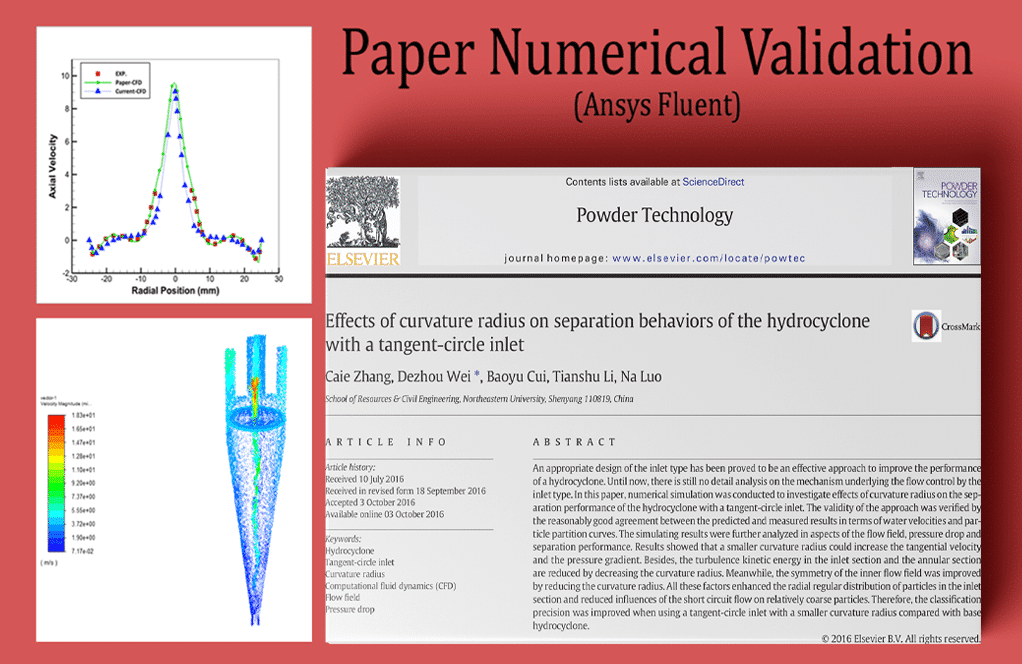

Paper Validation

Project number 1 simulates the two-phase flow of air and water inside a hydrocyclone. The simulation is based on a reference article “Effects of curvature radius on separation behaviors of the Hydrocyclone with a tangent-circle inlet,” and its results are compared and validated with the results in the article. The Reynolds Stress Model is exploited to solve fluid flow equations and VOF multiphase model is used to investigate the phase interactions of the water and air core.

Project number 2 simulates the nucleate boiling inside a vertical channel. The simulation is based on a reference paper “A numerical investigation of the effect of surface wettability on the boiling curve” and its results are compared and validated with the results in the article.

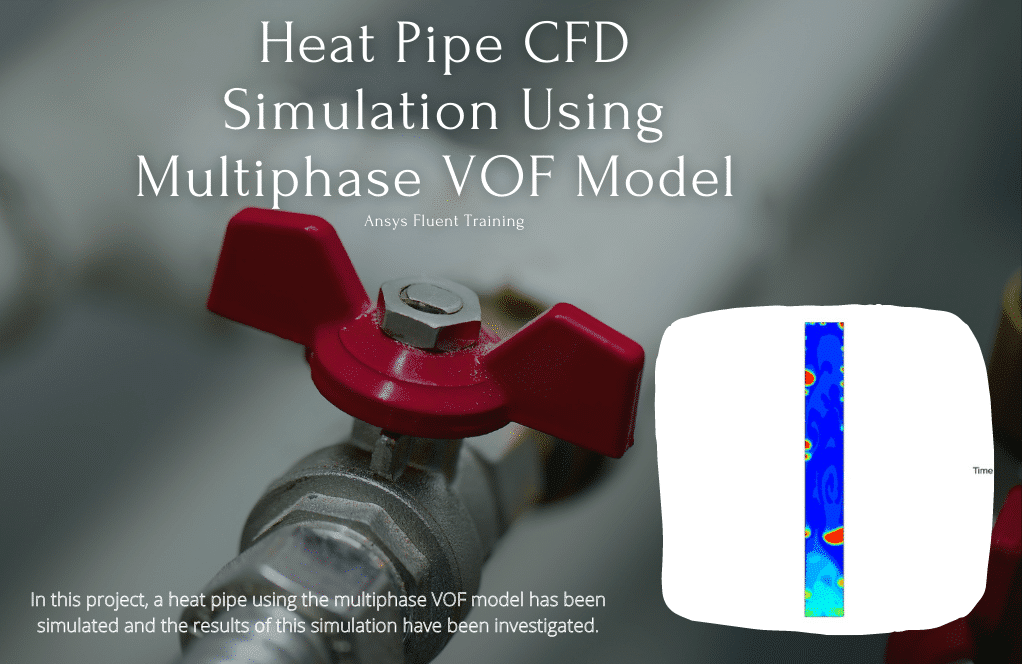

Heat Transfer (Volume of Fluid)

In project number 3, the Heat Pipe problem was simulated. The project was analyzed using the multi-phase VOF model and activating the mass transfer of evaporation and condensation. By solving the problem in a time-dependent manner, the formation of water droplets in the upper part of the geometry and their downward movement were observed due to capillary and gravity.

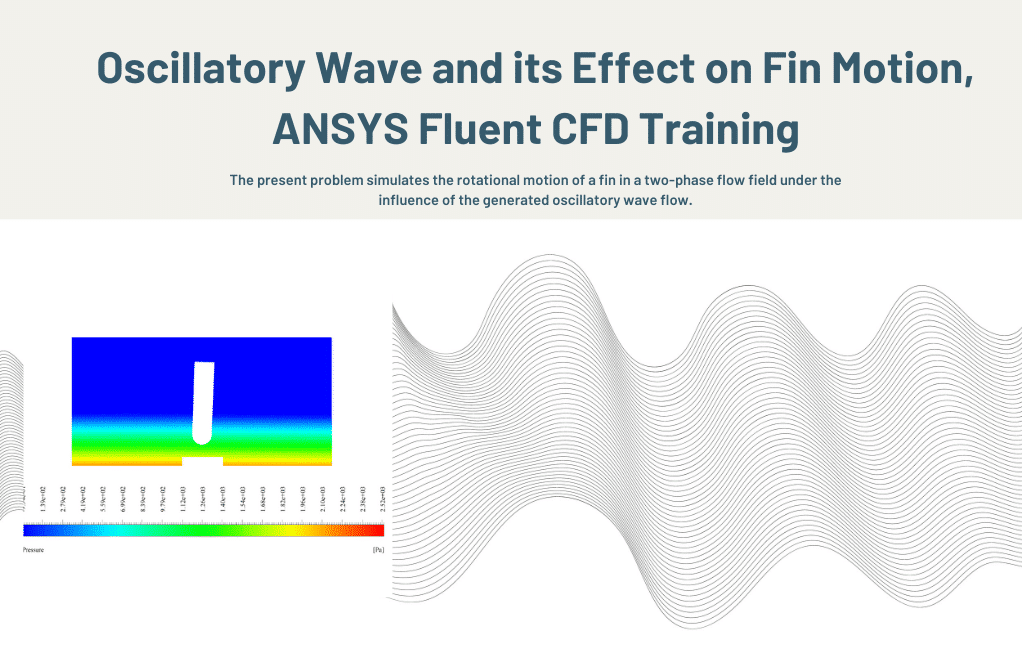

Project number 4 simulates the rotational motion of a fin in a two-phase flow field under the influence of the generated oscillatory wave flow. Due to the nature of the problem requiring displacement at the model boundaries, a dynamic mesh technique was used to define the fluid flow. Also, the UDF (user-defined function) is used to define the reciprocating motion of the scaffold wall that causes the waveform within the domain.

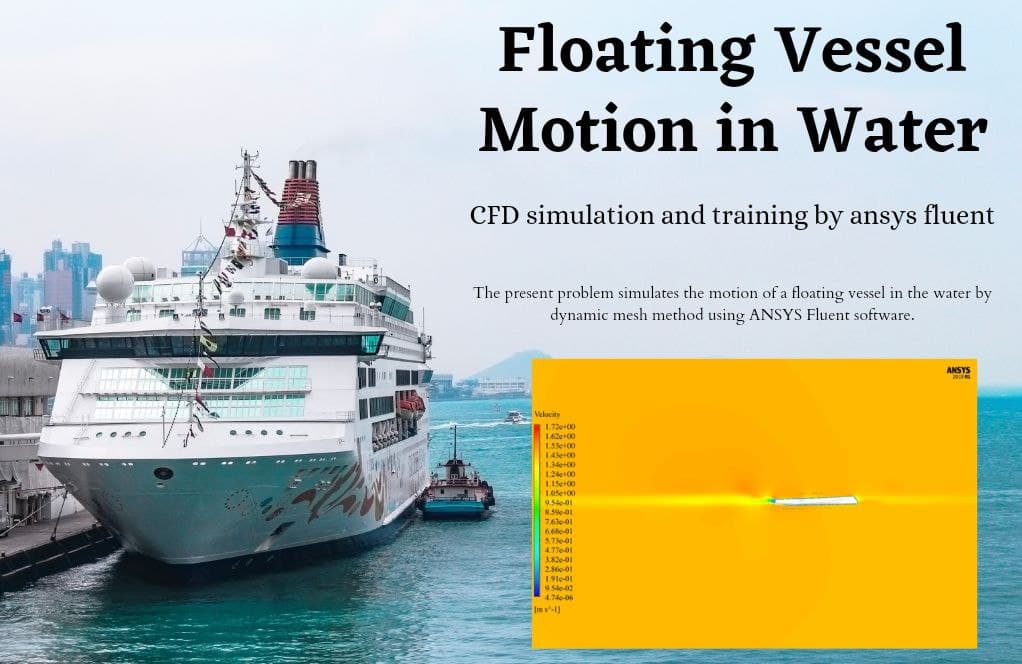

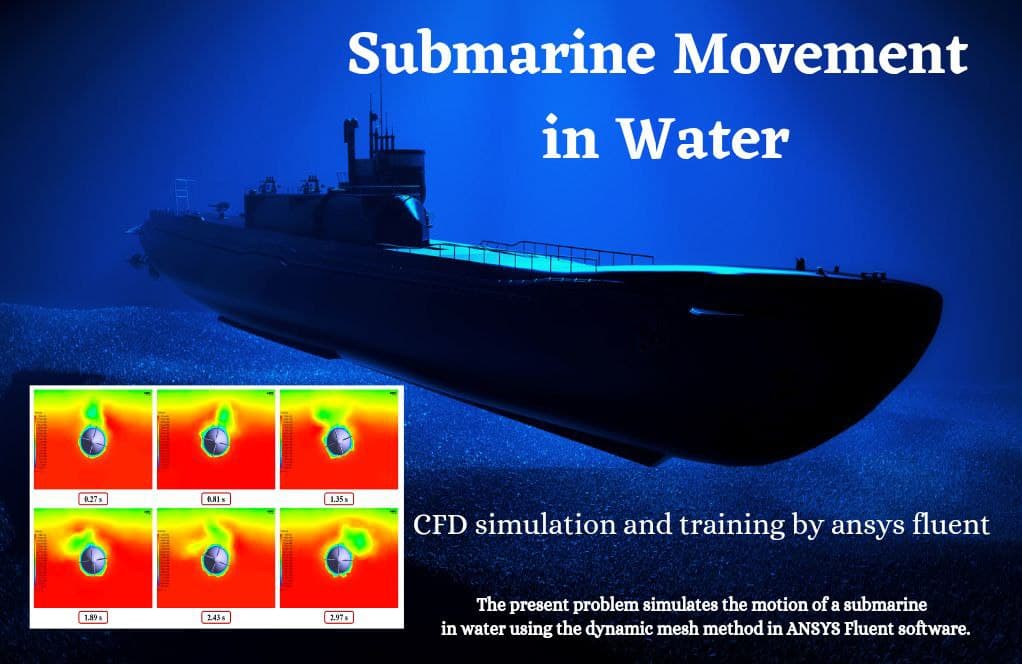

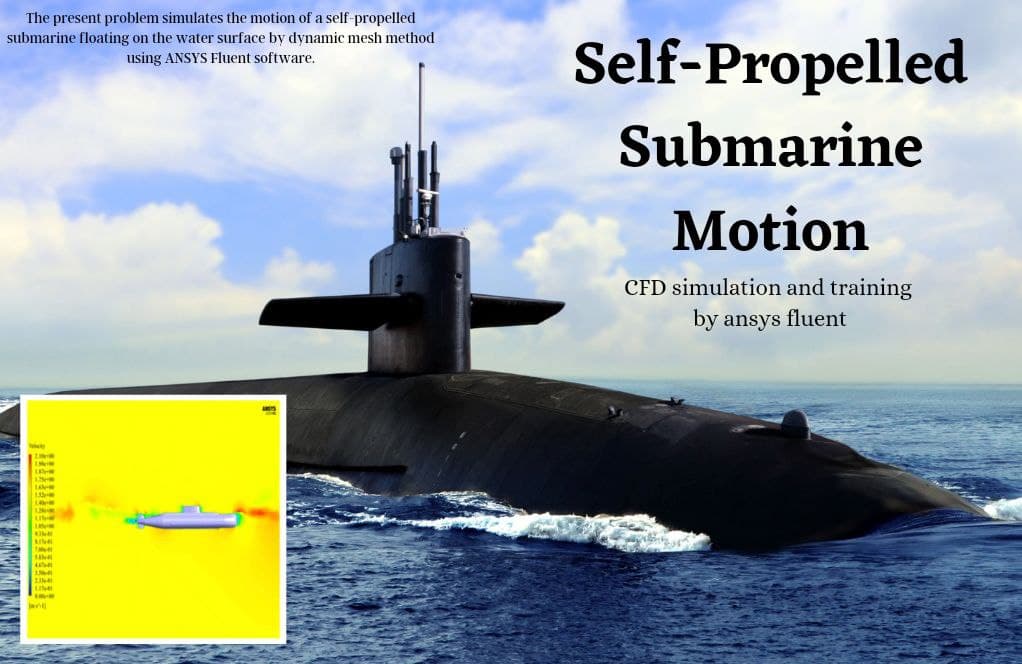

Marine

Project number 5 simulates the motion of a floating vessel in the water by the dynamic mesh method. In this simulation, a computational domain of water with a certain height level is designed with a floating vessel on the water’s surface. In such models, we need a momentary and time-dependent change in meshing based on the type of displacement at adjacent boundaries of grids. Therefore, the Dynamic Mesh model is used to define the instantaneous change of meshing. Six degrees of freedom (6-DOF) have also been used to define the type of dynamic mesh behavior; a UDF is used to define this type of motion with two degrees of freedom.

Project number 6 simulates the motion of a submarine in water using the Dynamic Mesh method. In this simulation, a computational domain including air and water with a certain level of water is designed. Since the submarine has only one degree of freedom and can only rotate around its central axis (x-axis), and in other degrees, it is constrained and has no transient or rotational motion, we use a UDF for defining this type of movement, considering a degree of freedom.

Project number 7 simulates the motion of a self-propelled submarine floating on the water surface by the dynamic mesh method. The properties of six degrees of freedom, including the mass and the moment in different directions for this model, are defined as a UDF.

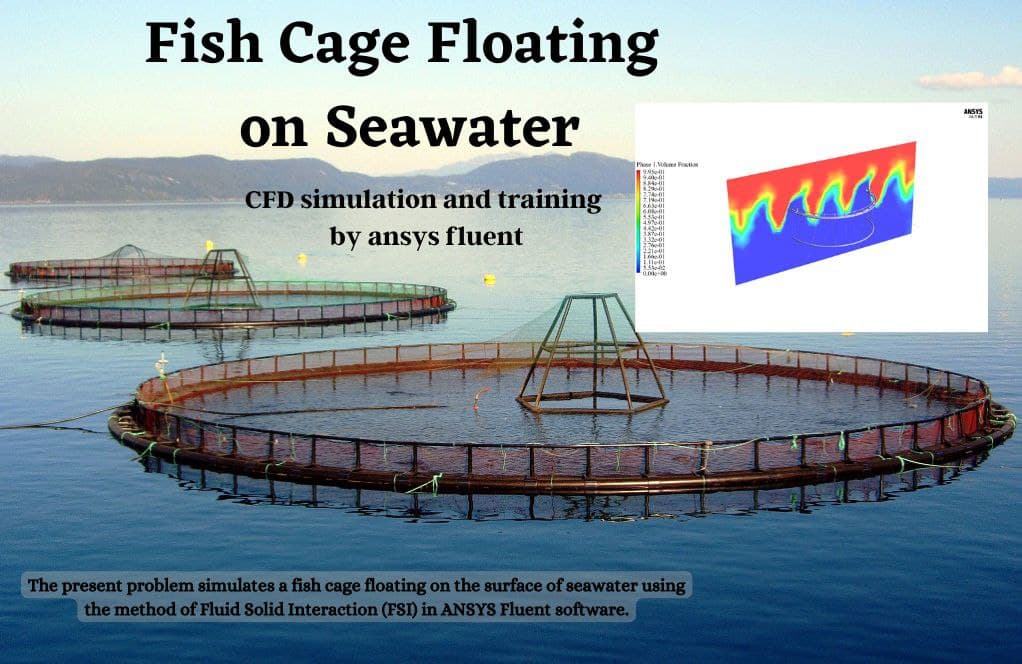

Project number 8 simulates a Fish Cage floating on the surface of seawater using the method of Fluid Solid Interaction (FSI). In this model, we should define the boundaries of the cage on the symmetry plane as Fixed Support. to make a connection or coupling between fluid and solid and to define their effect on each other, Data Transfer must be defined.

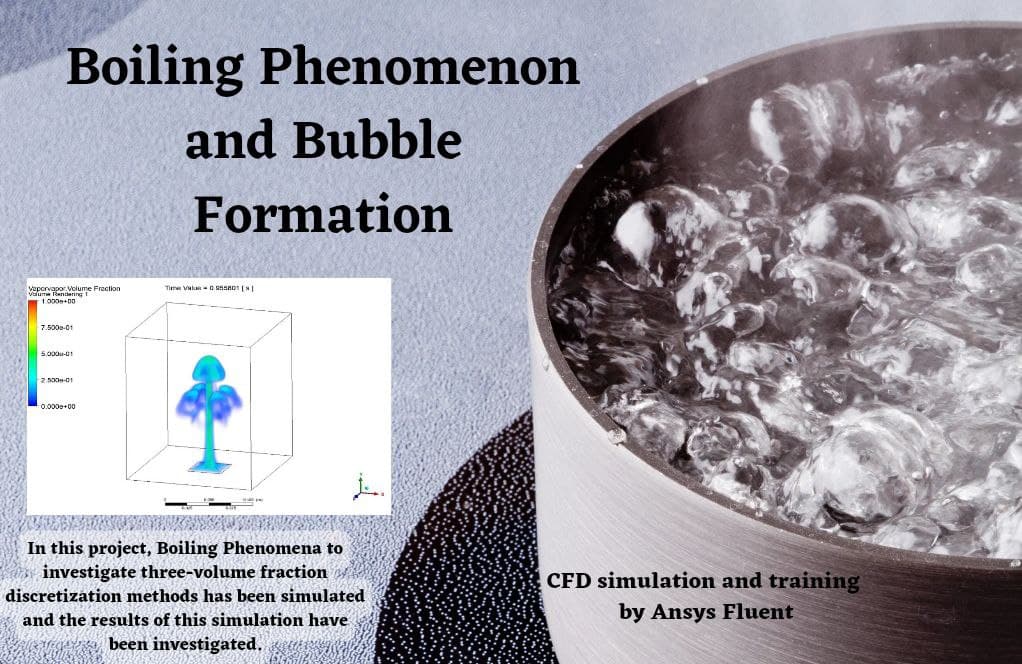

Boiling

In project number 9, the difference between HRIC-compressive-Geo-reconstruct models and their effect on the output results were discussed by changing the volume fraction discretization. The change in volume fraction discretization showed no significant change in surface temperature and heat transfer coefficient. Only the Geo-Reconstruct model visually models a more realistic simulation with a higher computational cost.

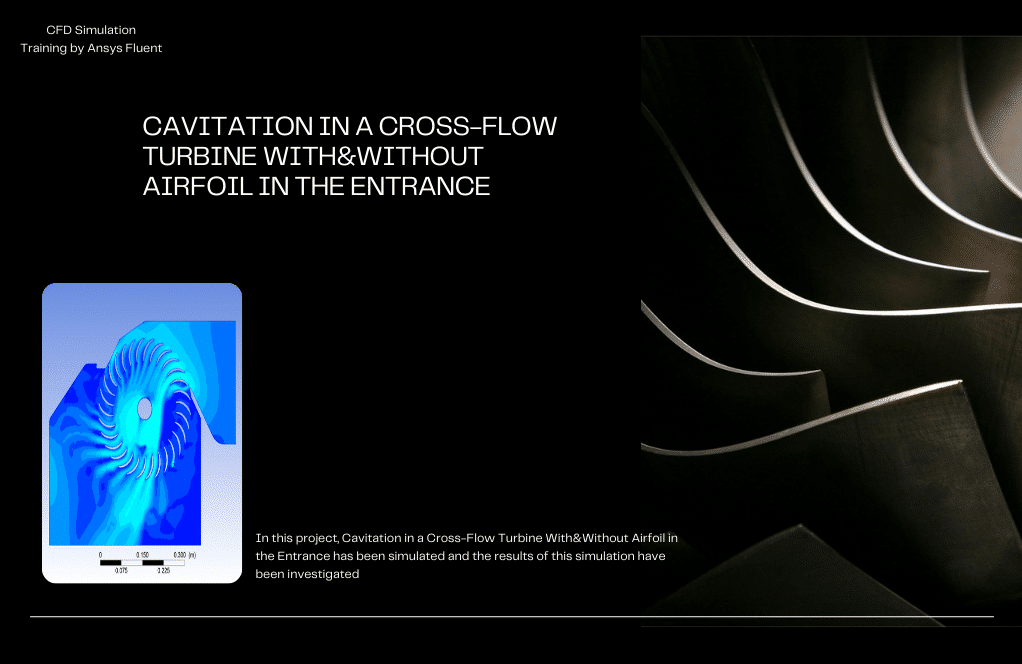

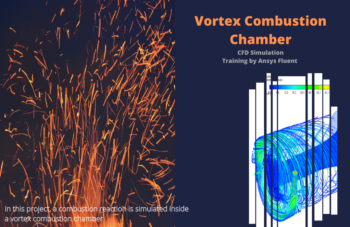

Cavitation (Volume of Fluid)

In project number 10, in which the CFD numerical simulation method was used, cavitation was simulated in a cross-flow turbine. Unlike most turbines where the flow is axial or radial, the fluid flows crosswise. This type of turbine has a low speed and is used for places requiring low head and high flow.

Reviews

There are no reviews yet.