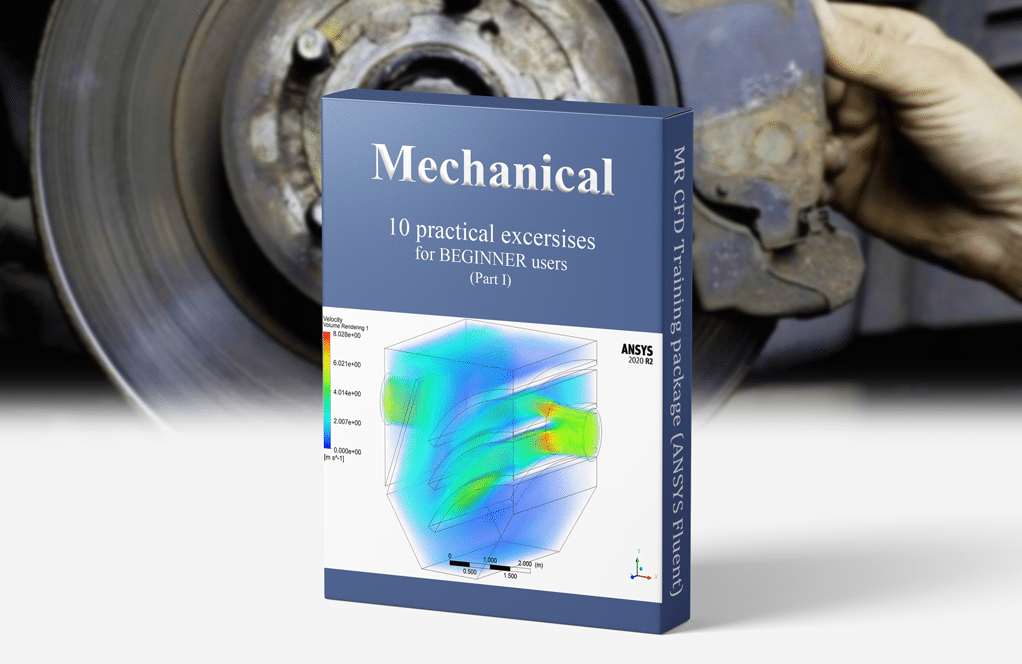

Mechanical Engineering Training Package for Beginners, Part 1, 10 Practical Exercises

$240.00 Student Discount

This product includes Geometry & Mesh file and a comprehensive Training Movie.

There are some free products to check our service quality.

To order your ANSYS Fluent project (CFD simulation and training), contact our experts via [email protected], online support, or WhatsApp.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Mechanical Engineering – ANSYS Fluent Training Package, 10 Practical Exercises for BEGINNER Users (Part 1)

Mechanical engineering is amongst the principal engineering fields. The mechanical engineering field need an comprehension of core regions, including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. It is the chapter of engineering that brings in the design, production, and operation of machinery devices. CFD software has armed us with strong instrumentation to simulate mechanical engineering processes and fluid mechanics projects impressively. As all of us know, the fluid mechanic branch is the basic field of mechanical engineering, and the primary method for predicting fluid mechanic behavior is computational fluid dynamics.

There are 10 different practical projects (practical exercises) in this training package by ANSYS Fluent software. This package presents how to simulate different mechanical devices for all BEGINNER users.

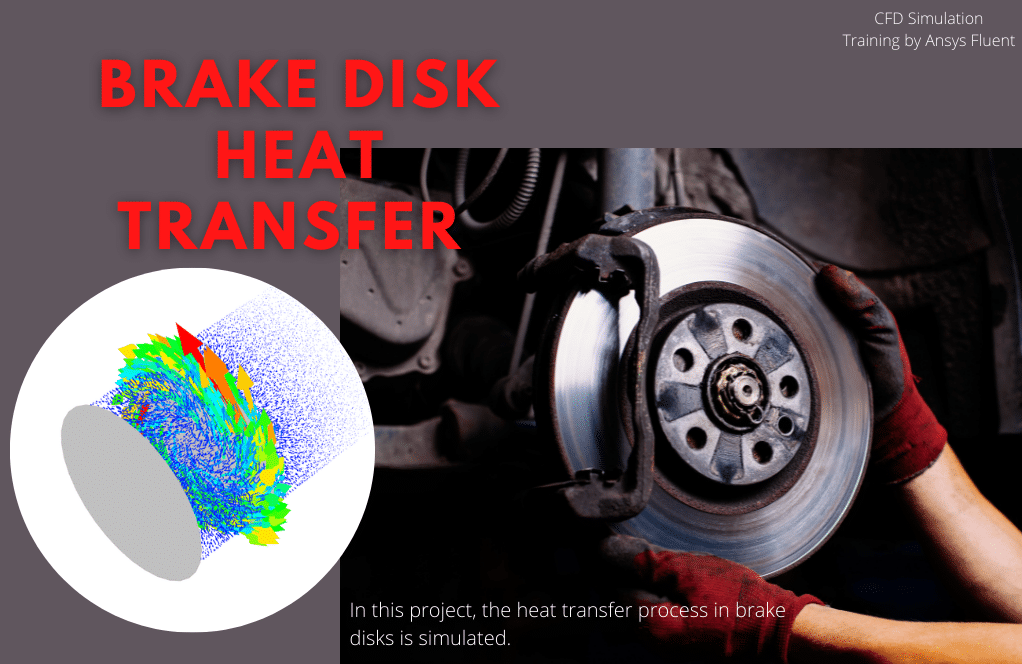

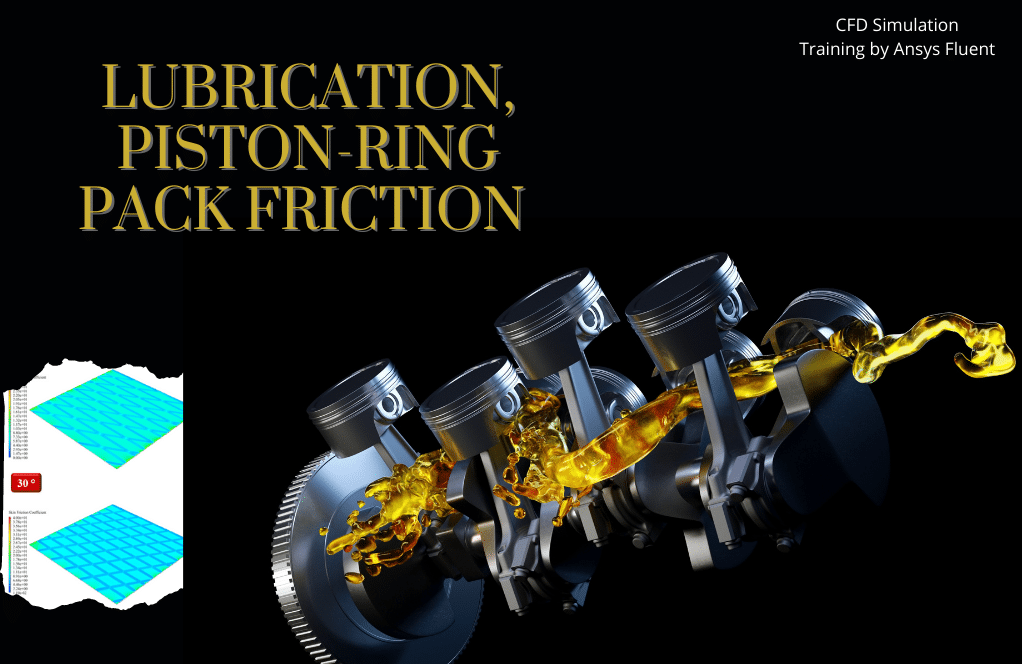

The problem number 1 simulates the lubrication process effect on friction factor in the space between the cylinder and the ring in an engine considering various groove texture patterns. In fact, the movement of the ring on the inner surface of the cylinder of an engine causes friction between the surfaces. The lubrication process can be used to reduce friction between surfaces. In project number 2, the heat transfer process in brake disks is simulated. “Disk2” has a rotating motion with a rotational velocity of approximately 343rpm. The existing disks have the same temperature equal to 343 K. since “Disk1” is stationary, it will cause “Disk2” to slow down and exerts friction to it.

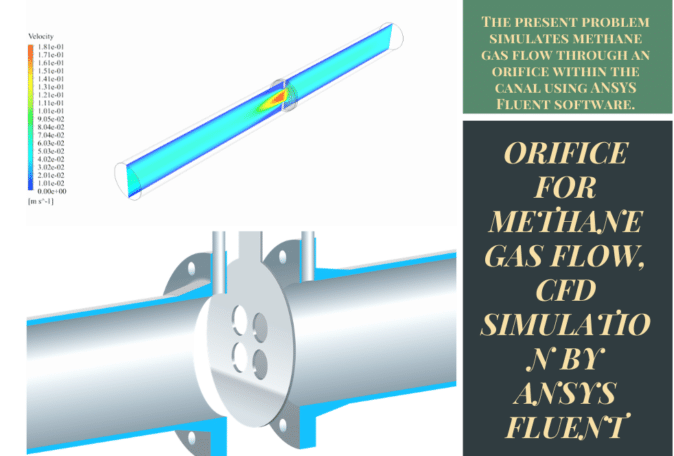

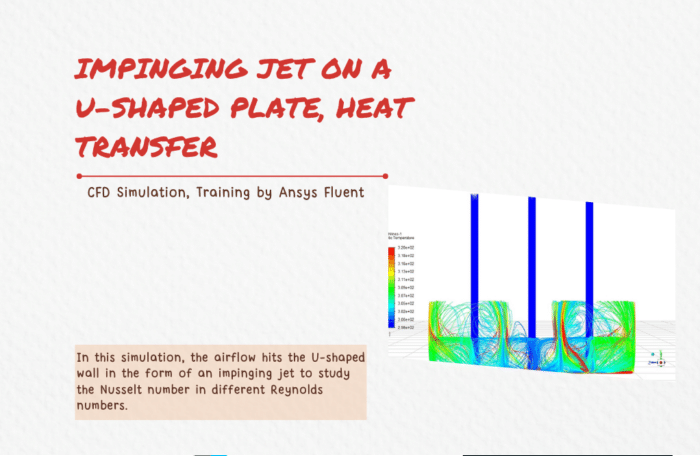

The problem number 3 simulates methane gas flow through an orifice within the canal. The orifice is one of the most common devices for measuring mass flow using Differential Pressure (DP) transmitters. The simplest orifice model consists of a perforated plate perpendicular to the desired channel’s fluid flow path. In the simulation number 4, the airflow hits the U-shaped wall in the form of an impinging jet to study the Nusselt number in different Reynolds numbers. An impinging jet is a fluid jet that strikes a surface vertically or at a specific angle for cooling or heating. Impinging jets have excellent heat transfer properties due to their turbulence and high speed.

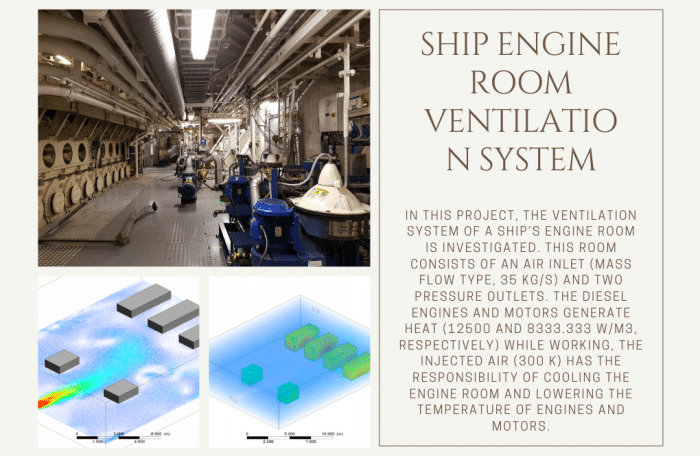

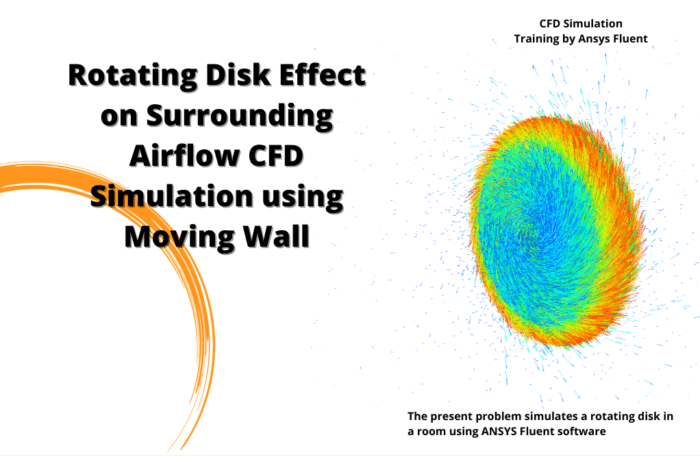

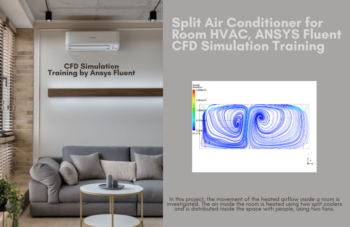

In the project number 5, the ventilation system of a ship engine room is investigated. This room consists of an air inlet (mass-flow type, 35 Kg/s) and two pressure outlets. The diesel engines and motors generate heat (12500 an 8333.333 W/m3 respectively) while working, the injected air (300 K) has the responsibility of cooling the engine room and lowering the temperature of engines and motors. The problem number 6 simulates a rotating disk in a room. The purpose of this work is to investigate the airflow behavior under the influence of rotational motion of a rotating disk. In this simulation, there is an air flow in a computational domain (room) and in the middle of this room, a rotating disk with a certain rotational speed is placed.

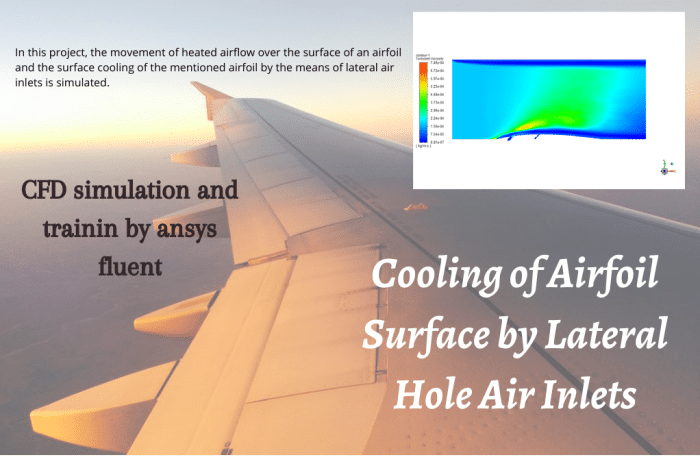

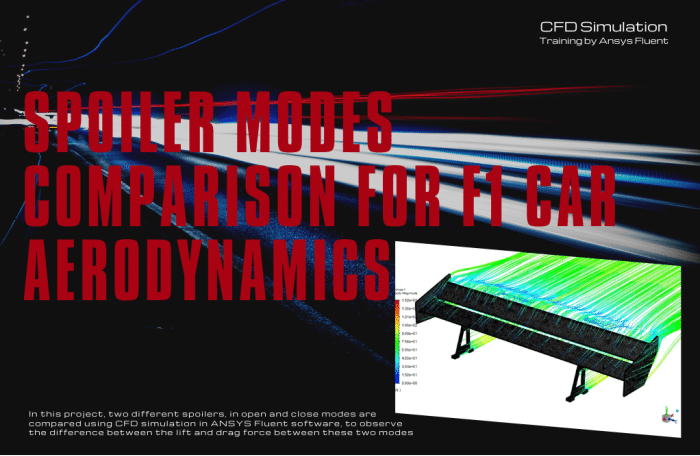

In the project number 7, the movement of heated airflow over the surface of an airfoil body and the airfoil cooling by means of lateral hole air inlets is simulated. The heated air enters the computational domain with velocity and temperature of 15 m/s in the X direction and 600 K respectively. Two lateral air inlets are responsible for the surface cooling of the blade or airfoil. In the practical exercise number 8, two different F1 spoilers, in opening and closing modes are compared using CFD simulation in ANSYS Fluent software. The car as a moving device has always been involved with air flow, so the science of aerodynamics has helped engineers bring the best performance to the car.

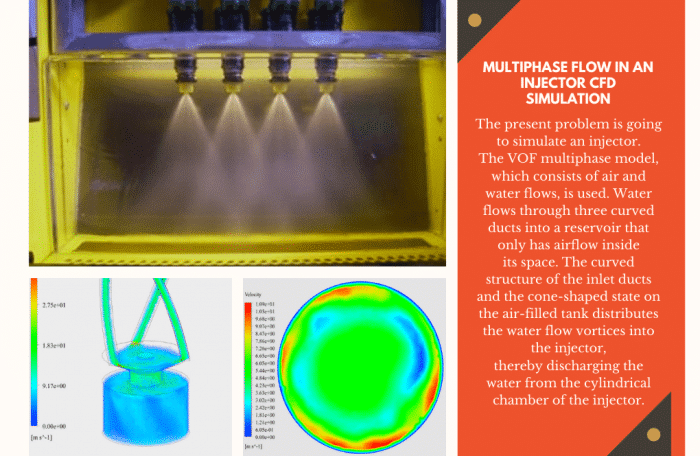

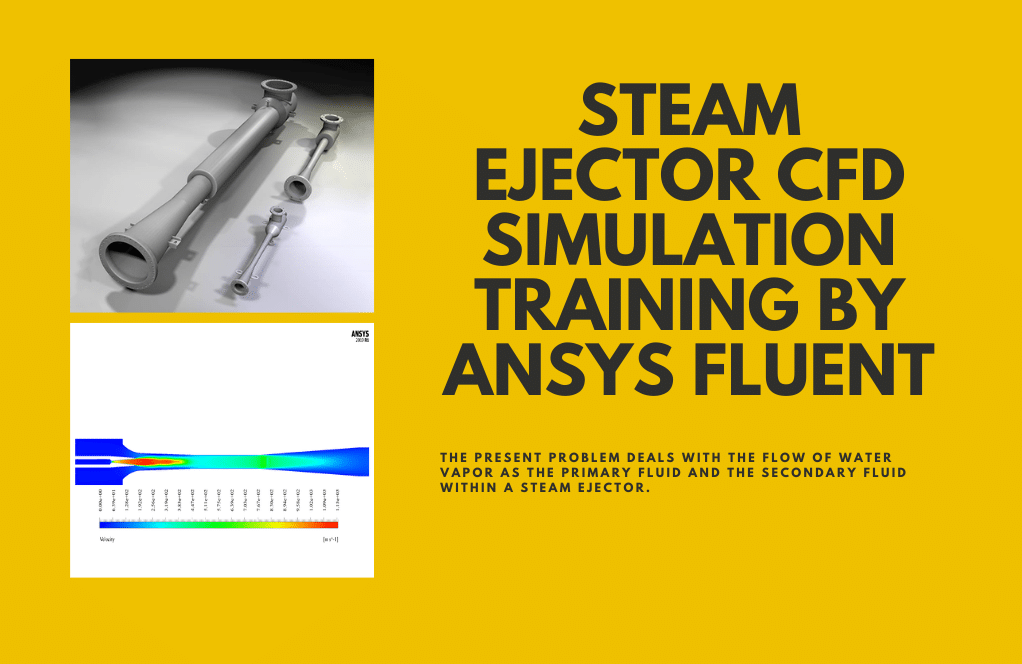

The problem number 9 deals with the flow of water vapor as the main fluid (primary) and the secondary fluid (suction) within a convergent-divergent steam ejector. The purpose of the present simulation is to investigate the behavior of primary and secondary fluid after passing through the internal convergent-divergent nozzle and the ejector diffuser. In the present model, due to the vacuum pressure difference between the two inlet fluids, the suction phenomenon for the secondary fluid has to occur. The last problem (practical exercise number 10) is going to simulate an injector. The Multi-Phase model, which consists of air and water flows is used. Water flows through three curved injectors into a reservoir that only has airflow inside its space.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Mark Tromp –

Absolutely fascinating training package for anyone starting in mechanical engineering! The diverse projects touch upon many critical aspects of mechanics, thermodynamics, and fluid dynamics, offering hands-on practical learning. Mastering such foundational simulations in ANSYS Fluent is certainly going to boost my understanding and skills.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you’ve found the Mechanical Engineering Training Package for Beginners valuable and that it’s enhancing your understanding and skills. Your enthusiasm for learning is inspirational, and we wish you continued success in your studies with ANSYS Fluent!

Mrs. Rachael Koch Jr. –

The package covers a detailed range of mechanical engineering exercises. Could you clarify how the training movie guides through the solution process, especially for someone who’s completely new to ANSYS Fluent?

MR CFD Support –

In our training movie, we guide you step-by-step, starting from the basics. We introduce you to the interface of ANSYS Fluent, show you how to set up your simulation, define materials, apply boundary conditions, and input initial conditions. We also walk through post-processing results and interpreting the data. For beginners, we ensure to explain every step clearly and provide practical tips for efficient workflow in ANSYS Fluent.

Julio Cummings –

I’ve completed the exercises in the package. They were well-organized and easy to follow. It was particularly helpful to see the various applications of fluid dynamics in mechanical engineering. The progression from basic to more complex simulations has solidified my understanding of CFD using ANSYS Fluent. Excited to go on to Part 2!

MR CFD Support –

We’re so pleased to hear that you found the Mechanical Engineering Training Package for Beginners valuable and educational. Your feedback motivates us to continue developing high-quality learning materials for enthusiastic learners like you. We are excited for you to start Part 2 and wish you great success in further expanding your ANSYS Fluent skills. Thank you for choosing our training package!

Colt Sporer –

Is there a dedicates support available if I don’t understand a part of the training?

MR CFD Support –

For any questions or difficulties you encounter during the training, MR CFD Company provides dedicated support to ensure that all of your queries are addressed and that you can understand and complete your practical exercises with confidence.

Rosalia Stamm –

The training package sounds extremely detailed! How beginner-friendly is the tutorial movie? I’m quite new to ANSYS Fluent and want to make sure I can follow along easily.

MR CFD Support –

The video tutorial for these training exercises is designed specifically with the beginner in mind. It guides you step-by-step through the problems, providing clear instructions and demonstrating each action required in ANSYS Fluent to solve the problems and extract results. It ensures that beginners can follow along without prior extensive knowledge of the software.

Tyra Welch –

I am truly impressed with this mechanical engineering training package! The range of exercises provided a practical glimpse into the diverse aspects of CFD applications in mechanical systems. The step-by-step approach in the tutorial videos was especially helpful for someone like me who is just starting out with ANSYS Fluent. Will there be a Part 2 with more advanced topics?

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found the beginner’s training package useful and educational. Yes, there is a plan for Part 2 which will cover more advanced topics and simulations. Keep an eye out for updates and new releases that will further enhance your skills and understanding of CFD applications in mechanical engineering.

Elyse Weissnat –

I cannot thank MR CFD enough! Through the Mechanical Engineering Training Package for Beginners, as a newbie in the field, I’ve been able to learn immensely about mechanical systems and CFD. Each project was engaging and took me through the complexities of simulations, step by step, bolstering my confidence. Highly recommended for anyone starting out!

MR CFD Support –

We’re thrilled to hear that you’re satisfied with the Mechanical Engineering Training Package for Beginners! It’s great to know that our projects could make learning CFD simulations more accessible and understandable. We appreciate your recommendation and look forward to providing you with more quality learning materials. Thank you for taking the time to let us know about your positive experience!

Margarete Stiedemann –

This package seems vast. Can I prioritize simulations based on difficulty level? Will beginners be able to perform all exercises smoothly?

MR CFD Support –

Each exercise in this training package is designed to be progressively more challenging as you move forward, but they’re structured for beginners to follow along effectively. If you’re completely new, it may help to start with the first exercises and advance in order to build up your understanding and skills in ANSYS Fluent. There is comprehensive guidance and a training movie that should ensure a smooth learning experience even for beginners.

Prof. Wade Fahey PhD –

I just finished project number 3 on methane gas flow through an orifice using the ANSYS Fluent software from the Mechanical Engineering Training Package for Beginners. It was a fantastic hands-on learning experience that not only reinforced my understanding of computational fluid dynamics but also deepened my appreciation for practical applications in mechanical engineering.

MR CFD Support –

Thank you so much for your positive feedback! We are thrilled to hear that you had a great learning experience with our project focused on simulating methane gas flow. It sounds like you’ve made excellent progress, and we hope that the skills you’ve gained will serve you well in your future endeavors in mechanical engineering and CFD analysis. Keep up the great work!

Marilou Lubowitz –

Terrific learning package. Each practical exercise provided a clear understanding of different mechanical concepts using ANSYS Fluent. Loved the balance between theory and actual CFD application – made for an engaging study throughout.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that the package met your learning needs and helped you gain a better understanding of mechanical engineering concepts through ANSYS Fluent simulations. Your appreciation motivates us to continue providing high-quality learning materials.

Armani Jaskolski –

I’ve recently completed the Mechanical Engineering Training Package for Beginners, Part 1. Can’t praise it enough – it provided me exactly what I needed to get started! Having a hands-on approach with 10 diverse practical exercises gave me a solid understanding and practical insight into how the ANSYS Fluent software can be used for a range of simulations. From exploring lubrication effects in engines to analyzing the ventilation system in a ship’s engine room – each exercise was crafted to both challenge and educate. What stood out to me the most was the clarity of the Tutorial Movies; they were particularly helpful in guiding me through the processes step-by-step.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that the Mechanical Engineering Training Package for Beginners was instrumental in facilitating your understanding of the fundamentals of ANSYS Fluent simulations. It’s rewarding for us to know that the clarity of our Tutorial Movies has made your learning experience efficient and enjoyable. Your success in utilizing our training to master a variety of simulations across different mechanical engineering applications is precisely what we aim to achieve. Keep on exploring and applying your skills, and should you ever need further training or support, know that MR CFD is here to assist you. Shine on!

Gladys Hayes –

The Mechanical Engineering Training Package for Beginners sounds fantastic. The diversity of practical exercises provided is sure to give a comprehensive understanding of various mechanical principles through ANSYS Fluent. I’m especially intrigued by the various applications from engine lubrication to aerodynamics and the cooling systems. Can’t wait to delve into the simulations and enhance my skills!

MR CFD Support –

Thank you for the kind words! We’re thrilled to hear that you’re excited about our Mechanical Engineering Training Package for Beginners. It’s our pleasure to provide a tool that makes learning complex engineering concepts more accessible and engaging. We’re confident that as you work through the exercises, you’ll gain a deeper understanding of fluid dynamics and its practical applications in mechanical engineering. Should you have questions or need support as you progress, feel free to reach out to us. Enjoy your learning journey!