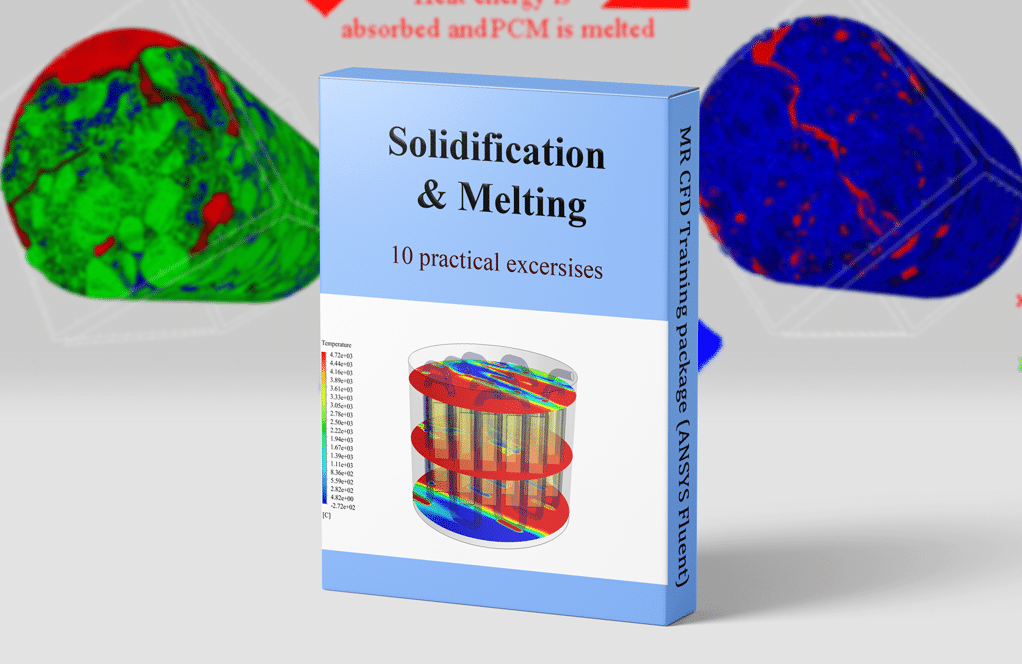

Phase Change Material (PCM) CFD Training Package, 10 Learning Products

Original price was: $1,140.00.$127.00Current price is: $127.00. Student Discount

- Corrugated Tube

- Storage Tank

- Glass-coated circular chamber

- Battery Cooling

- Finned Tube

- Fuel Tank

- Air Conditioning

- Shell and Tube Heat Exchanger

- Sandwiched PCM

- Solar Heater

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Phase Change Material (PCM), Solidification and Melting ANSYS Fluent CFD Simulation Training Package, 10 CFD Projects

This CFD training package is prepared for BEGINNER, INTERMEDIATE, and ADVANCED ANSYS Fluent software users interested in the Solidification & Melting modules, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

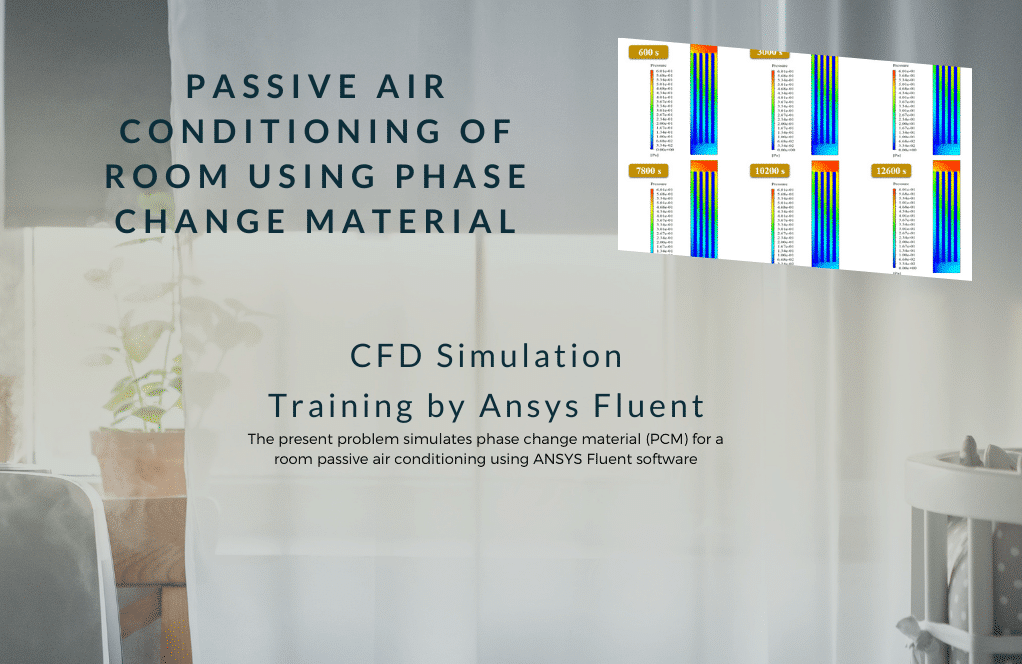

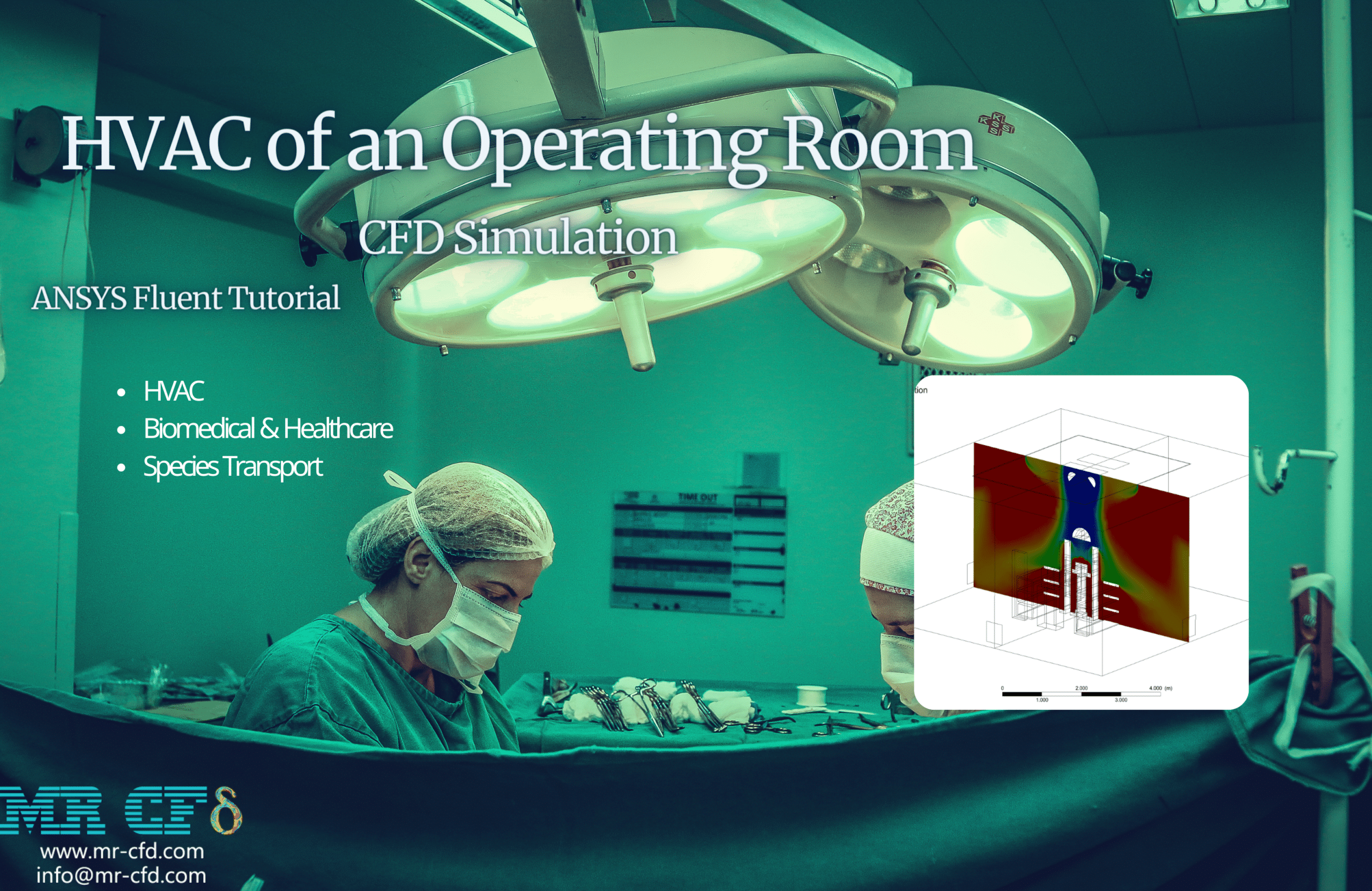

Air Conditioning

Project number 1 simulates phase change material (PCM) for a room’s passive air conditioning. In general, phase change materials are materials with organic compounds that can absorb and store large amounts of latent thermal energy. Thermal energy storage in these materials is achieved during the phase change process (solid phase to liquid or vice versa).

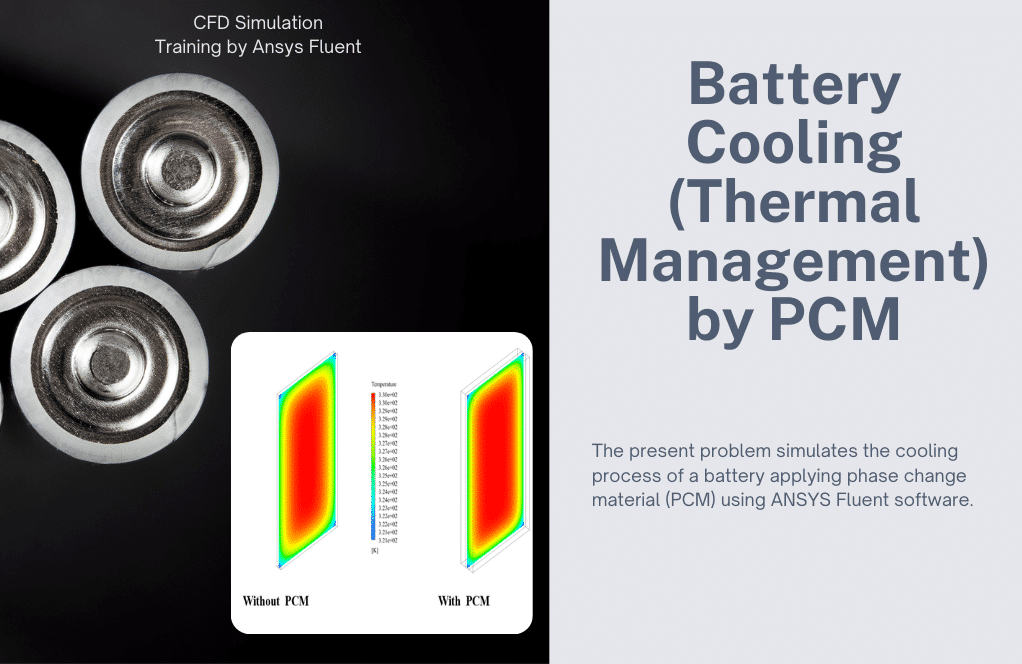

Battery Cooling

Project number 2 simulates the cooling process of a battery (battery cooling) by applying phase change material (PCM). Modeling is related to a lithium battery used in vehicles. The present simulation is performed in two stages; In the first stage, only one lithium battery is modeled, and in the second stage, two layers of phase change material are used on both sides of the battery. This work aims to investigate the effectiveness of phase change materials in the cooling process of the battery.

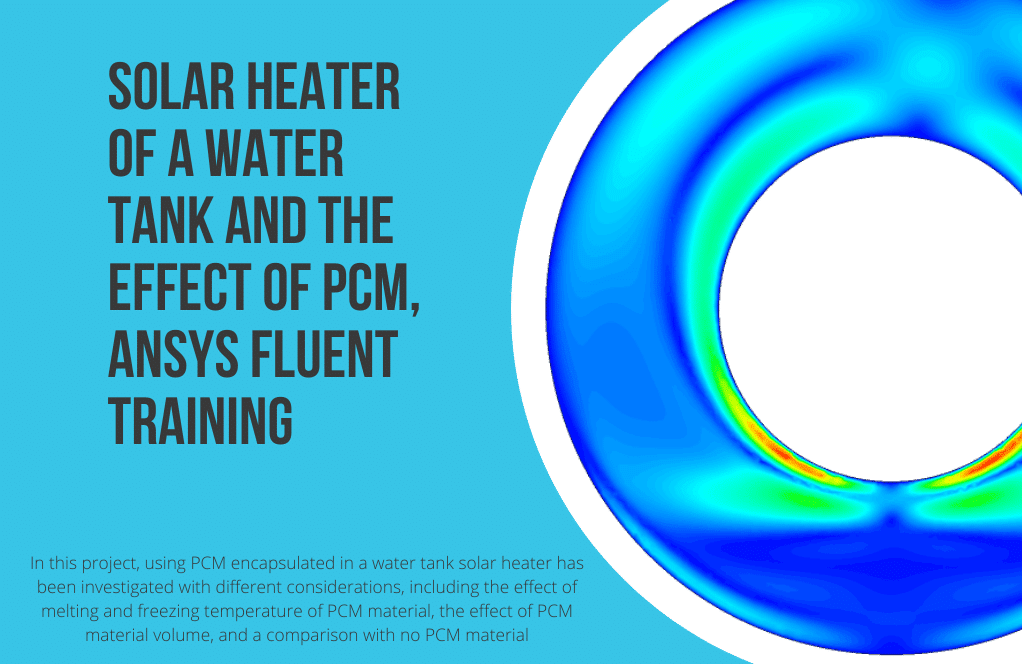

Solar Heater with Phase Change Material (PCM)

In project number 3, using PCM encapsulated in a water tank solar heater has been investigated with different considerations, including the melting and freezing temperature of PCM material and PCM material volume and comparison with no PCM material. The PCM space’s inner wall is considered a wall with a temperature condition of 603.3 K and a thickness of 0.0015 m.

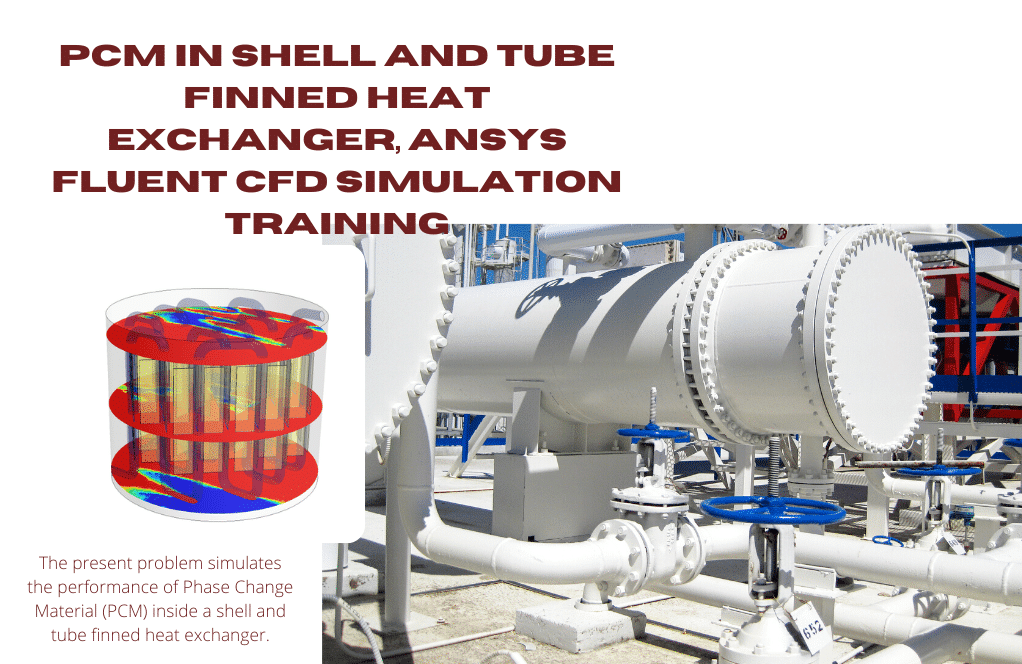

Shell & Tube Heat Exchanger

Project number 4 simulates the performance of Phase Change Material (PCM) inside a shell and tube-finned heat exchanger. The shell is designed as a cylindrical tank carrying phase change materials and these PCMs are evenly distributed inside the tank. Since the PCMs of the present model are based on the phase change between the liquid and solid phases, the solidification and melting model has been used for the current simulation.

Sandwiched PCM

In project number 5, the phase change materials (PCM) sandwiched between two concentric cylindrical tubes have been simulated. PCM is trapped inside two cylindrical walls, and the inner wall has a high temperature. These materials can store thermal energy and energy storage and discharge.

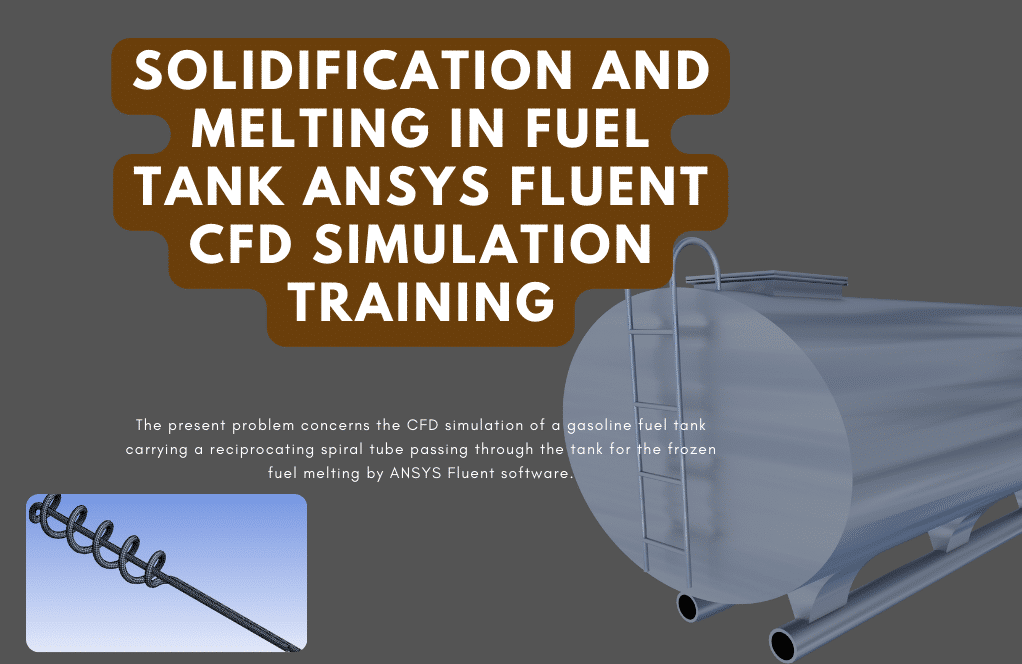

Fuel Tank with Phase Change Material (PCM)

Project number 6 concerns a gasoline fuel tank simulation carrying a single-way reciprocating spiral tube passing through the tank. This inner tube carries a flow of water at a temperature higher than the gasoline temperature to increase the fuel temperature by creating heat transfer between the diesel and the water, thus preventing freezing inside the tank. Therefore, the present model uses a solidification and melting module for the simulation.

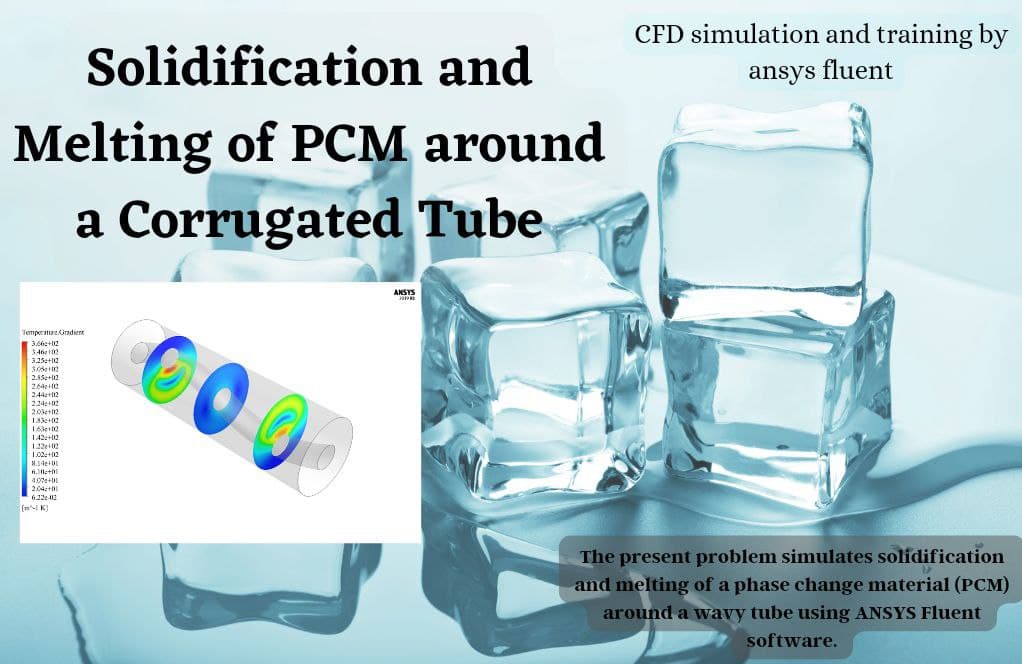

Corrugated Tube

Project number 7 simulates the solidification and melting of a phase change material (PCM) inside a tube with a wavy inner surface. In general, phase change materials are materials with organic compounds that can absorb and store large amounts of latent thermal energy. The phase change material studied in this simulation is paraffin.

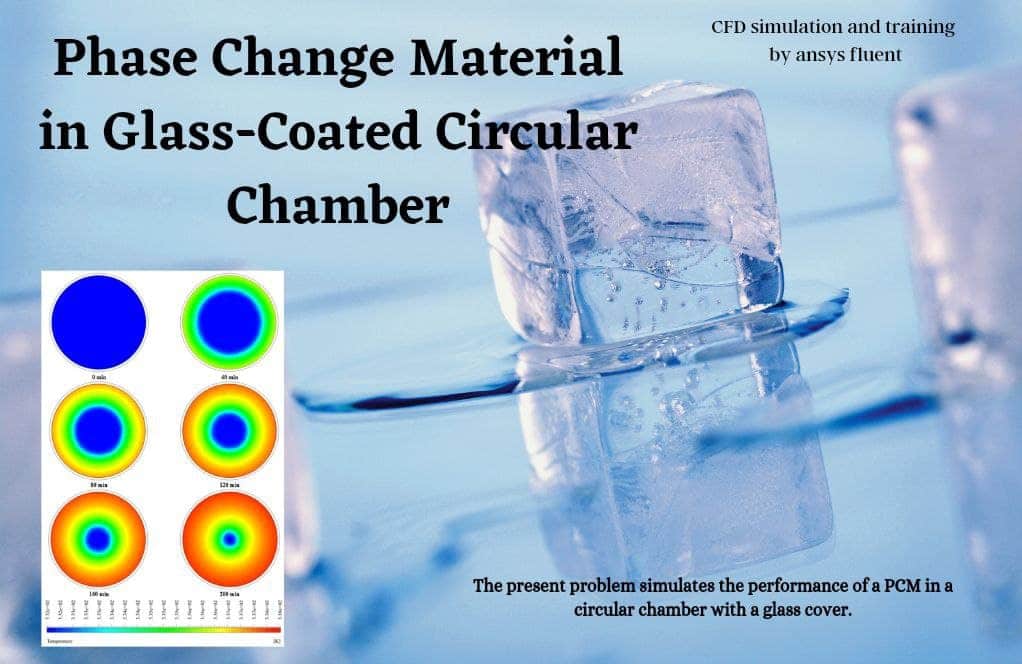

Glass-coated circular chamber

Project number 8 simulates the performance of phase change material in a circular chamber with a glass cover. This PCM is evenly distributed inside the chamber. Since the nature of the PCMs of the present model is based on the phase change between solid and liquid phases, the solidification and melting model has been used for the simulation. PCMs are materials with inorganic or organic compounds capable of absorbing and storing large amounts of latent thermal energy.

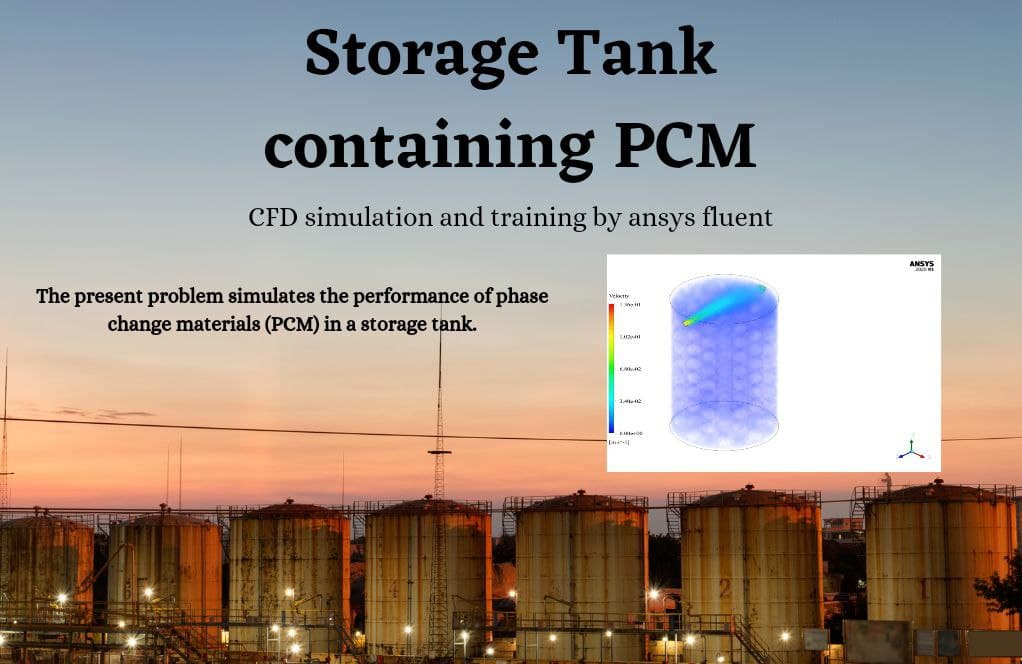

Storage Tank with Phase Change Material (PCM)

Project number 9 simulates the performance of phase change materials (PCM) in a storage tank. These PCMs are a set of spherical shapes inside the interior of a vertical cylindrical storage tank. The water flow comes out of the upper part of the tank. Since the nature of the PCM of the present model is based on the phase change between the two solid and liquid phases, the Solidification and Melting model has been used for simulation.

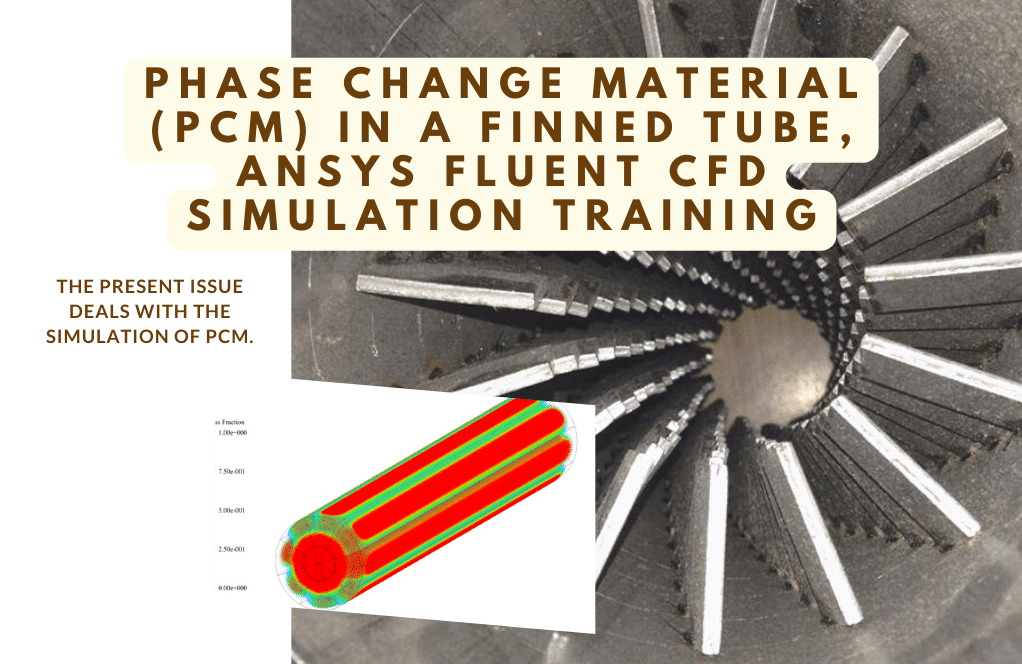

Finned Tube

Project number 10 deals with the simulation of PCM. PCMs are embedded in a three-layer tube heat exchanger as a latent heat storage tank; The inner tube body and its fins are made of copper, which has good Thermal Conductivity, and the fluid in the inner tube is liquid silicone type, and also the PCM is Erythritol. Since the nature of the PCMs of the present model is based on the phase change between the two solid and liquid phases, a Solidification and Melting module is used for CFD simulation.

Miss Erika Balistreri V –

The depth and variety of this PCM CFD Training Package is truly impressive. Each project tackles a unique real-world application which has helped me understand the complexities of PCMs in different scenarios. Particularly, the inclusion of organic compounds and their latent thermal energy storage capacity is fascinating. Every simulation’s explanation is thorough, making difficult concepts much more accessible. It’s evident that a lot of thought and expertise has gone into crafting these learning materials.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the Phase Change Material (PCM) CFD Training Package informative and to your satisfaction. It’s our goal to provide comprehensive and practical training to enhance understanding across various scenarios, and it sounds like we’ve hit the mark for you. Your appreciation motivates us to continue delivery high-quality learning products. If you need further assistance or have any more feedback, don’t hesitate to reach out!

Clovis Schmidt –

The training package for simulating phase change materials was extremely well-constructed and comprehensive. It provided a brilliant hands-on approach to learning complex CFD simulations.

MR CFD Support –

We’re thrilled to hear that the PCM CFD training package met your expectations and helped you learn the intricacies of CFD simulations effectively! Thank you for choosing MR CFD Company’s learning products, and we appreciate your positive feedback.

Dr. Valerie Zboncak PhD –

I’ve recently completed the PCM CFD Training Package, and the variety of projects provided a well-rounded understanding of various applications. The step-by-step guidelines were particularly helpful in grasping the complexities of phase change simulations.

MR CFD Support –

Thank you for acknowledging the usefulness of our Phase Change Material CFD Training Package. We’re thrilled to hear that our step-by-step approach has enhanced your understanding of phase change simulations and provided a valuable learning experience across different applications.

Lisandro Langworth IV –

I’ve noticed phase change materials come in many forms and can be set in various configurations. Can you elaborate on the criteria for choosing a suitable PCM for a particular application?

MR CFD Support –

Absolutely! In selecting a suitable Phase Change Material (PCM) for an application, you’ll consider factors such as the operating temperature range, thermal conductivity, latent heat capacity, density, and compatibility with the surrounding materials. For example, specific PCMs with higher thermal conductivity are preferred in applications requiring fast thermal response, while those with larger latent heat capacities are suitable where energy storage is the priority.

Zena Aufderhar Sr. –

The PCM training pack has vastly exceeded my expectations! It provided detailed guidance for handling various applications, from air conditioning to complex heat exchanger structures. Not only has it built a strong foundation in solidification and melting processes, but it also bolstered my confidence in conducting simulations for heat storage systems using ANSYS Fluent.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that our PCM training package has enhanced your understanding and application of phase change material (PCM) simulations in ANSYS Fluent. It’s our pleasure to contribute to your successful learning experience and to support you in strengthening your simulation skills. If you need further assistance or want to explore more topics, do not hesitate to reach out.

Zelma Connelly –

What a comprehensive training package on PCM and CFD analysis! The practical exercises designed to cater to varied proficiency levels are especially useful.

MR CFD Support –

Thank you for the positive feedback! We are delighted to hear that you appreciate the structure and thoroughness of our Phase Change Material CFD Training Package. If you have any more thoughts or need further assistance, feel free to reach out.

Mohamed Schulist –

I’ve recently completed the ‘Sandwiched PCM’ tutorial from the PCM CFD Training Package, and it was a game-changer for me. Not only was the tutorial detailed and user-friendly, but it also allowed me to understand the intricate process of thermal energy storage with PCMs. The step-by-step guidance through setup, boundary conditions, and result analysis with detailed explanations of each choice was particularly useful. Well done!

MR CFD Support –

We’re thrilled to hear that the ‘Sandwiched PCM’ tutorial from our Phase Change Material CFD Training Package met your expectations and proved to be a valuable learning resource for you! Understanding thermal energy storage with PCMs can indeed be complex, and we are glad our tutorial made the process clear and approachable. Thank you for your feedback, and we look forward to continuing to support your journey in mastering CFD simulation!

Ian Fisher II –

This suite of training projects on PCM looks incredibly comprehensive! Really like how it offers a range of applications from air conditioning to solar heaters and beyond. The detailed descriptions of each project give a good sense of what one will learn. I’m especially interested in the battery cooling aspect; effective thermal management is so crucial for EV batteries today.

MR CFD Support –

Thank you for your kind words about our Phase Change Material (PCM) CFD Training Package! We’re thrilled to hear you found our range of applications and detailed project descriptions insightful. It’s great that the battery cooling project caught your interest as thermal management in EVs is indeed a critical area. Should you have any further questions or need assistance with your learning, please feel free to reach out. We’re here to help you deepen your understanding and skills in CFD!

Mallie Krajcik –

I’ve recently completed the ‘Phase Change Material (PCM) CFD Training Package’ and I have to say, the range of projects provided a comprehensive learning experience. From the air conditioning applications to the elaborate finned tube heat exchanger simulations, I was able to grasp the nuanced applications of PCM in various engineering tasks. The sequential build-up of knowledge from beginner to advanced levels allowed me to confidently handle the solidification and melting modules in ANSYS Fluent. It was particularly enlightening to understand how PCMs can be optimized in battery cooling and how they contribute significantly to energy conservation in solar heaters. Moreover, the inclusion of different geometric configurations, such as the corrugated tube and the glass-coated chamber, broadened my understanding of the impact of design on the effectiveness of PCM. Not only has this training package bolstered my simulation skills, but it also has inspired numerous ideas for my future projects.

MR CFD Support –

We are thrilled to hear about your positive experience with the ‘Phase Change Material (PCM) CFD Training Package!’ It’s wonderful to know that our diverse collection of CFD projects equipped you with a deep understanding of PCM applications and simulation proficiency in ANSYS Fluent. We meticulously curated the increasing complexity in the tutorial flow to ensure learners like yourself can seamlessly transition from basic to sophisticated models. Your feedback about gaining valuable insights and the inspiration it sparked for your forthcoming ventures immensely gratifies our efforts. We express our sincerest appreciation for your commendation and look forward to contributing further to your journey in computational fluid dynamics. Thank you for choosing and trusting our educational content!

Ulises Johns –

My capstone project involves phase change material in heat transfer applications, and this training package really piqued my interest. Could you detail how beginner-friendly this training material is, and if there are preliminary lessons that cover the basic concepts of PCM and ANSYS Fluent before diving into the complex simulations?

MR CFD Support –

The training package is structured to cater to various skill levels; thus, it gradually escalates in complexity starting from beginner-friendly projects. Fundamental concepts regarding PCM behavior and the interface of ANSYS Fluent are indeed covered in the initial exercises. This ensures a smooth transition into more demanding simulations for beginners, with an overarching goal to solidify understanding before heading into intricate applications.

Ellie Ruecker –

I have just completed the PCM CFD Training Package and I’m thoroughly impressed! Every project added to my understanding of phase change materials, and the gradual build-up from simpler to more complex simulations really solidified my knowledge. Great curriculum for anyone looking to dive deep into CFD analysis and PCMs applications!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear the training package met your expectations and provided you with a comprehensive understanding of phase change materials and CFD simulations. We aim to deliver a well-structured learning path for our learners, and we’re glad to hear you found it beneficial. If there’s ever any more you wish to explore or learn, don’t hesitate to check out more of our resources!

Mrs. Dayna Haley –

This training package has firmly grasped my understanding of PCMs and their application in various systems. Every project tackled a distinct real-world scenario that not only built my theoretical knowledge but also enhanced my hands-on expertise with ANSYS Fluent. The step-by-step approach from basic to advanced levels ensured a smooth learning curve. How enriching and well-structured these learning project simulations are!

MR CFD Support –

We greatly appreciate your positive feedback and are thrilled to hear our PCM CFD Training Package met your expectations. It’s encouraging to know that the structured progression of projects from basic to advanced levels has contributed meaningfully to your understanding and simulation skills. Thank you for your review, and we are always here to provide further learning tools to help you continue advancing in your CFD proficiency!

Rozella Turcotte –

I’m astounded by the comprehensive nature of this PCM CFD Training Package. Each project seems well-designed to address specific scenarios where PCMs can be applied effectively. It’s fascinating to see applications ranging from air conditioning to fuel tank insulation. Advanced simulations such as those encompass introduced me to different analytical procedures and the adaptation of various materials for thermal management. The progression from beginner to advanced level ensured that as my skills grew, the projects remained challenging and educational. This training package significantly enhanced my understanding of phase change materials and their usage in practical scenarios.

MR CFD Support –

Thank you for your positive feedback! We’re very happy to hear that the Phase Change Material (PCM) CFD Training Package was of great help to you. It’s rewarding for us to know that the projects included offered you a comprehensive and progressing challenge, and that your understanding of PCMs and their application in CFD simulations has been enhanced. If you have any further questions or wish to explore more projects, feel free to reach out to us. Keep up the great work in your learning journey!

Skylar Hintz II –

I couldn’t be happier with the Phase Change Material (PCM) CFD Training Package! The diversity of projects provided a really broad view of different scenarios and applications. Learning how PCMs are used in a room’s air conditioning as well as in industrial applications like heat exchangers was incredibly informative. The gradual increase in complexity from beginner to advanced levels is well thought out, allowing learners to progressively build their skills. Such a practical and hands-on approach to learning CFD analysis is exactly what I was looking for!

MR CFD Support –

Thank you very much for your positive feedback! We’re delighted to hear that the PCM CFD Training Package met your expectations and provided a comprehensive learning experience. Our goal is to offer a practical approach to understanding the application of CFD across various industries and scenarios. Your success is a testament to our commitment to quality education. If you need any further assistance or have additional inquiries in the future, feel free to reach out to us.

Mr. Anastacio Kshlerin –

Is this training package suitable for someone with no prior experience with ANSYS Fluent or should I have some foundational understanding before starting?

MR CFD Support –

This training package is designed to cater to different levels of experience including BEGINNER, INTERMEDIATE, and ADVANCED users. It gradually builds knowledge from basic to more complex simulations, making it suitable for someone with no prior ANSYS Fluent experience. You will learn how to effectively use the Solidification & Melting modules in ANSYS Fluent through practical exercises.

Mr. Sigrid Kozey DVM –

The variety and complexity of the projects included are really impressive, and they seem great for practical learning at all levels!

MR CFD Support –

Thank you for sharing your positive experience! We’re glad to hear that the complexity and variety of the PCM CFD Training Package met your expectations and provide valuable learning resources for all skill levels.

Prof. Diamond Reichert –

The comprehensive coverage and practical focus of the PCM CFD Training Package have thoroughly equipped me for various applications. Have you considered adding a project that explores PCM integration in wearable technology, like heated clothing?

MR CFD Support –

Thank you for your positive feedback and an interesting suggestion! Currently, our training package focuses on more conventional uses of PCM in systems like air conditioning and heat exchangers. Wearable tech is indeed an innovative application for PCM, and we will consider this for our future updates. Stay tuned!

Candido Bauch –

Absolutely outstanding learning experience! The 10-project PCM CFD Training Package provided an in-depth and hands-on approach to understanding solidification and melting in ANSYS Fluent. From passive air conditioning applications to complex solar heater designs, each exercise contributed greatly to my grasp of thermal storage systems using PCM. The gradation from beginner to advanced level kept things challenging yet achievable. I especially applaud the finned tube PCM project – seeing the simulations come to life with such precision is educational, and in a practical sense, hugely satisfying!

MR CFD Support –

Thank you so much for your kind words and positive feedback on our PCM CFD Training Package. We greatly appreciate the time you took to write this delightful review. It’s excellent to hear that the range of projects and the progression from basic to advanced levels have significantly enhanced your simulation skills and understanding of PCM applications in thermal energy systems. It’s always rewarding to see our users not only complete our training packages but also genuinely benefit from the depth and practicality of the materials. We look forward to supporting you on your continued journey in CFD! If you ever have additional feedback or require further assistance, please don’t hesitate to reach out.