Turbomachinery CFD Training Package, Intermediates, 10 Learning Products

$453.00 Student Discount

This CFD training package is prepared for INTERMEDIATE users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Turbomachinery CFD Simulation Package, ANSYS Fluent Training for INTERMEDIATE Users

This CFD training package is prepared for INTERMEDIATE users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

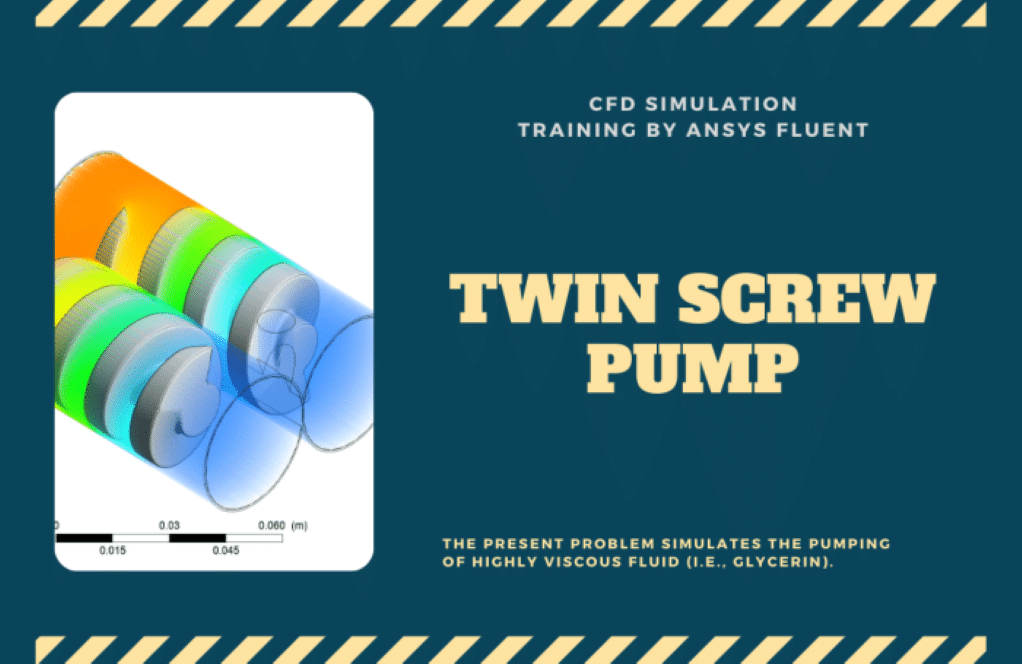

Pump

Problem number 1 simulates the pumping of highly viscous fluid (i.e., Glycerin). In this project, the glycerin fluid is sucked inside the computational domain due to the rotation of screws. The twin-screw pump increases the pressure of the Glycerin and pushes it toward the outlet.

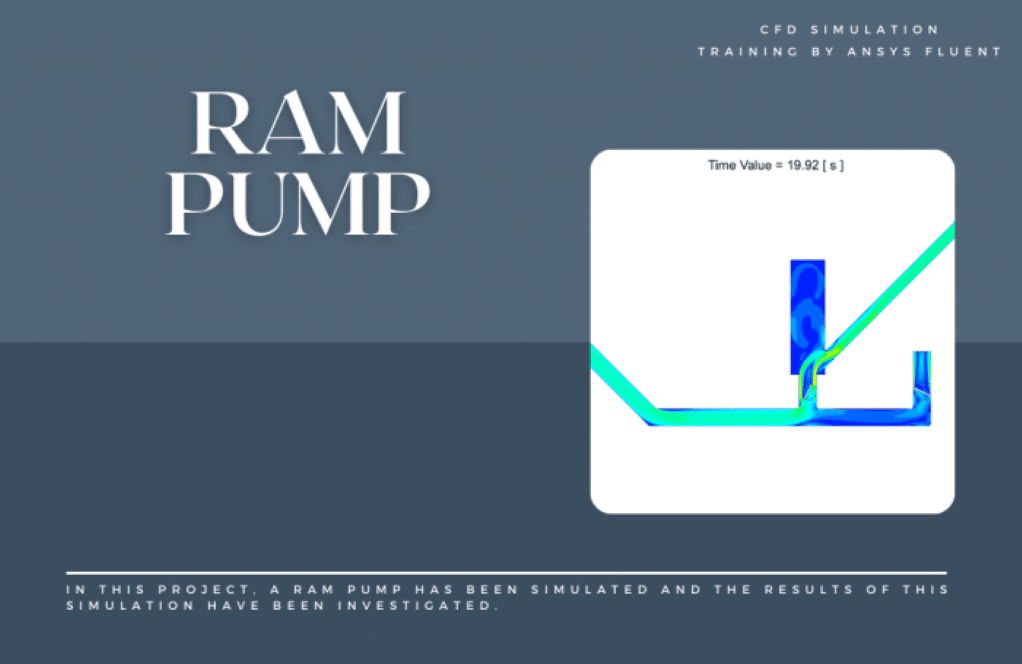

In project number 2, a ram pump has been simulated. In this simulation, a mesh motion model with an angular velocity of 1 radian per second has been used, and the input speed has Water is 1m/s, and at the outlet, water is discharged at atmospheric pressure.

Turbine

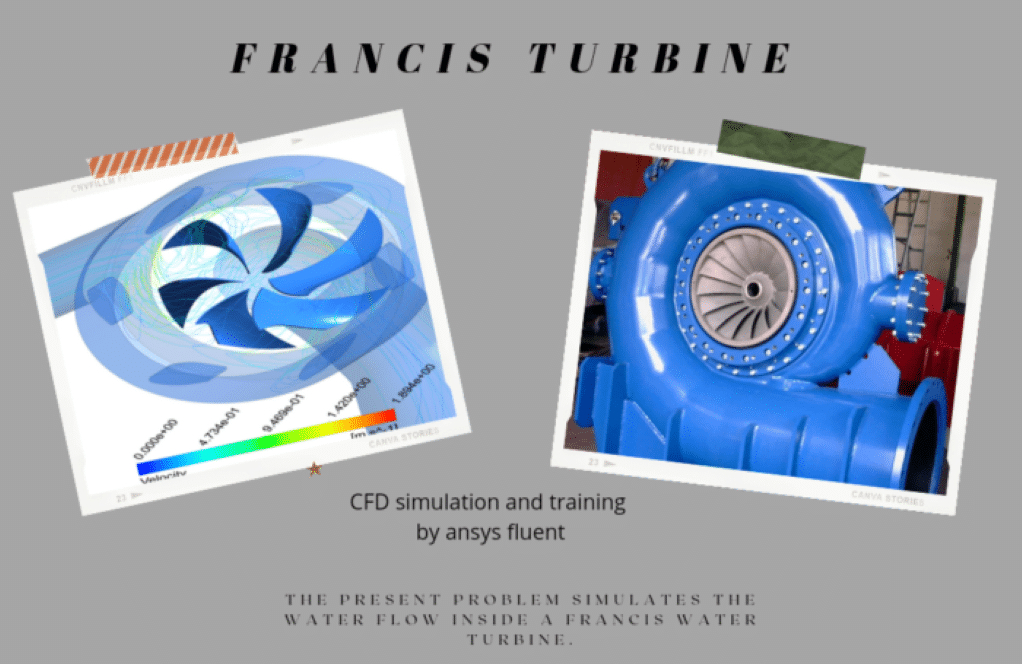

Problem number 3 simulates the water flow inside a Francis water turbine. A water turbine is a turbomachinery that converts kinetic energy from water flow or potential energy from water height differences into rotational motion. Francis turbines are one of the types of water turbines that have the ability to use both kinetic and potential energy for power generation at the same time due to the location of their blades.

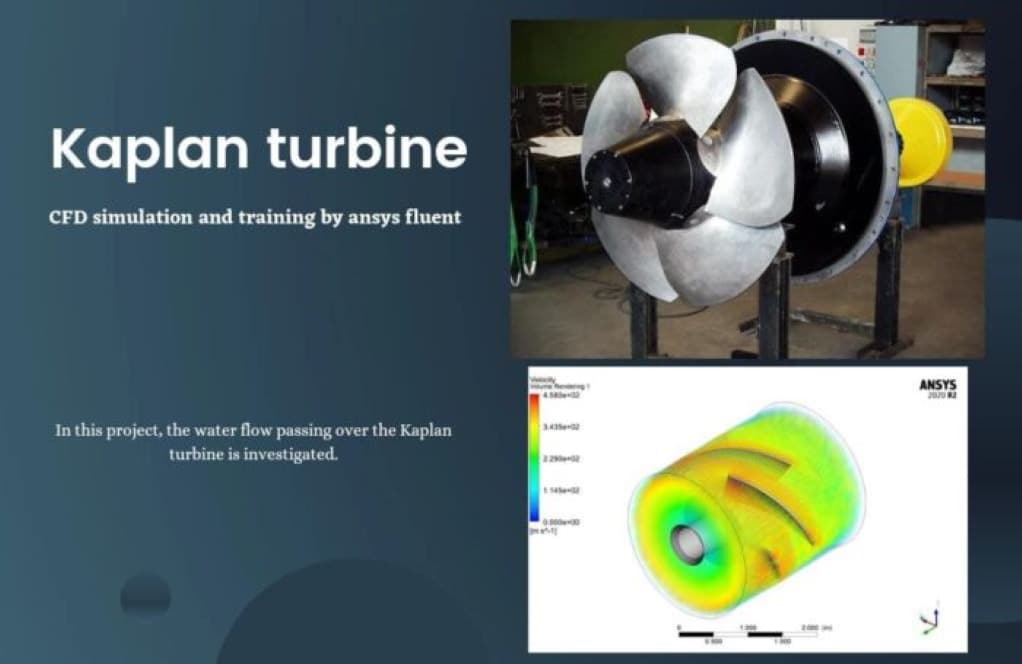

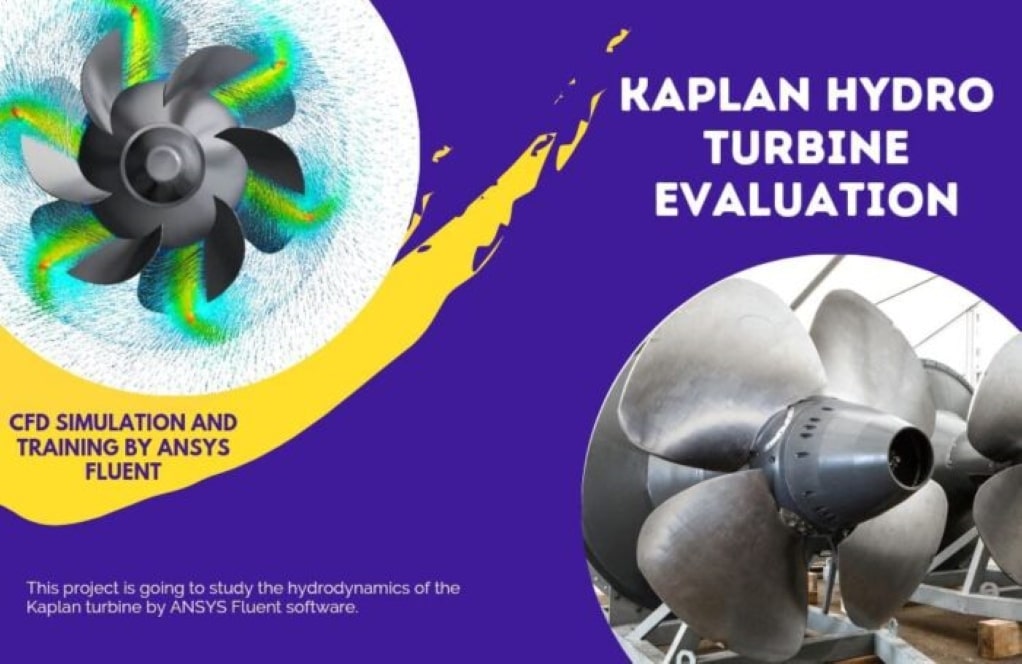

In project number 4, the water flow passing over the Kaplan turbine is investigated. The Kaplan turbine rotates at 3300 rpm and sucks the water in. RNG k-epsilon model is exploited to solve turbulent flow equations.

In project number 5, we are going to study the hydrodynamics of the Small Size Kaplan Turbine. The geometry included a small-size Kaplan turbine with 125 [mm] as a new prototype. Our static domain consists of 8 [m] long rectangles, and our rotary domain is the Kaplan geometry with 16.5 RPM as the angular velocity.

Wind Turbine

HAWT

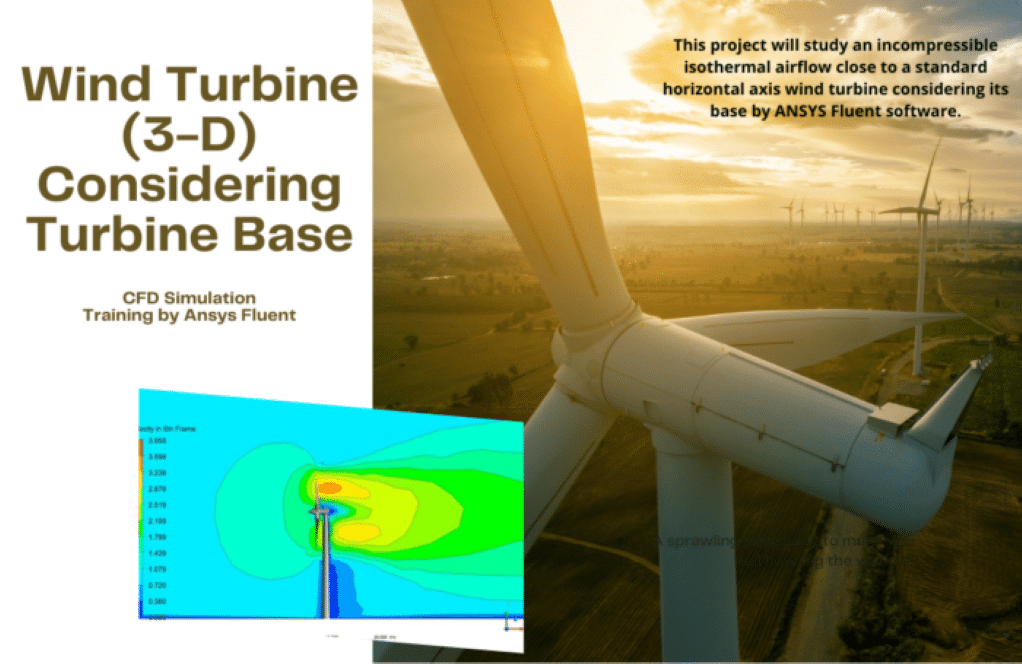

Project number 6 will study an incompressible isothermal airflow close to a standard horizontal axis wind turbine (HAWT) considering Turbine BASE. The geometry is a wind turbine with a 30-meter base inside a 300-meter wind tunnel. Also, we select the maximum speed of 1 m/s is for the wind and the turbine velocity of 30 RPM.

Problem number 7 simulates a wind farm with a series arrangement. In this project, four wind turbines are designed in a row in a specific computational domain of a large field called a wind farm (turbine farm). A wind turbine is a piece of equipment in the category of turbomachines that uses wind kinetic energy to generate electricity.

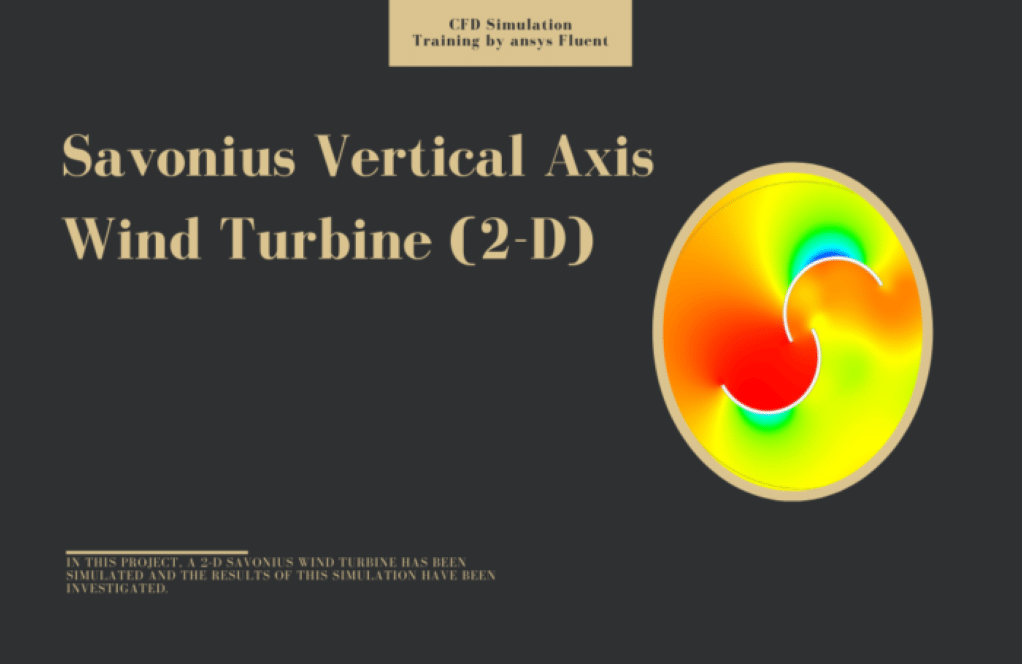

VAWT

In project number 8, a 2-D two-blade Savonius wind turbine has been simulated using moving mesh, and then the results were investigated. Air enters the fluid domain from the inlet with 10m/s velocity while the turbine rotates with a constant angular velocity of 10rpm. Our final goal is to illustrate the pressure and velocity distribution and the fluid motion animation behind the turbine.

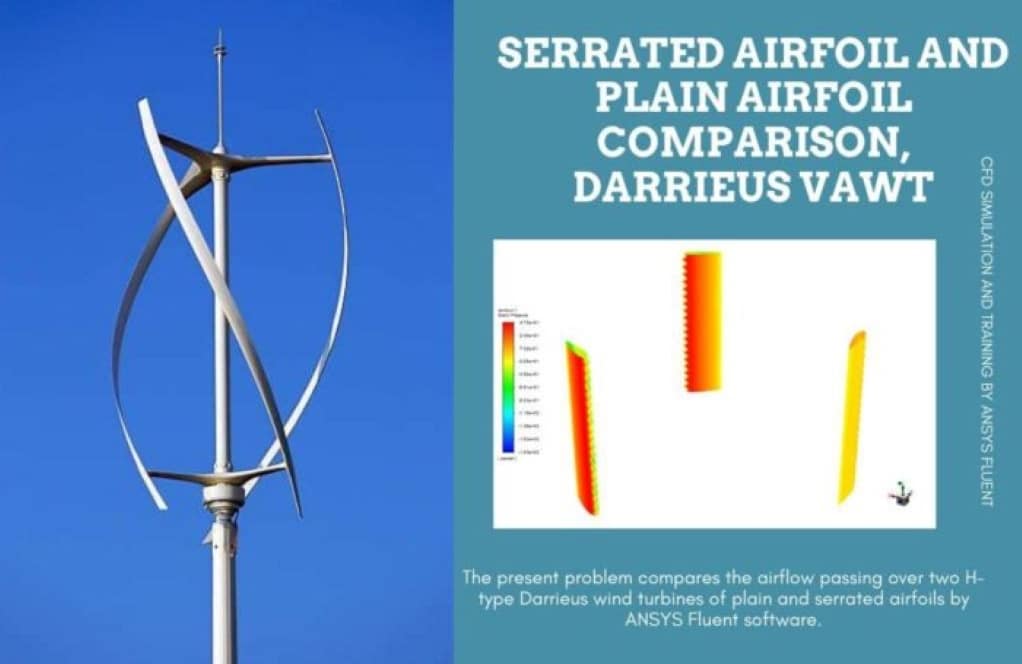

Problem number 9 compares the airflow passing over two H-type Darrieus wind turbines of plain and serrated airfoils. In this project, the airflow enters the computational domain with a velocity of 7m/s, and we apply the RNG k-epsilon model to solve the turbulent flow equations. Also, it should be noted that the Mesh Motion option was enabled to simulate the rotating motion of turbine blades, and the rotation velocity of the rotating domain was set to 2.8285 rad/s.

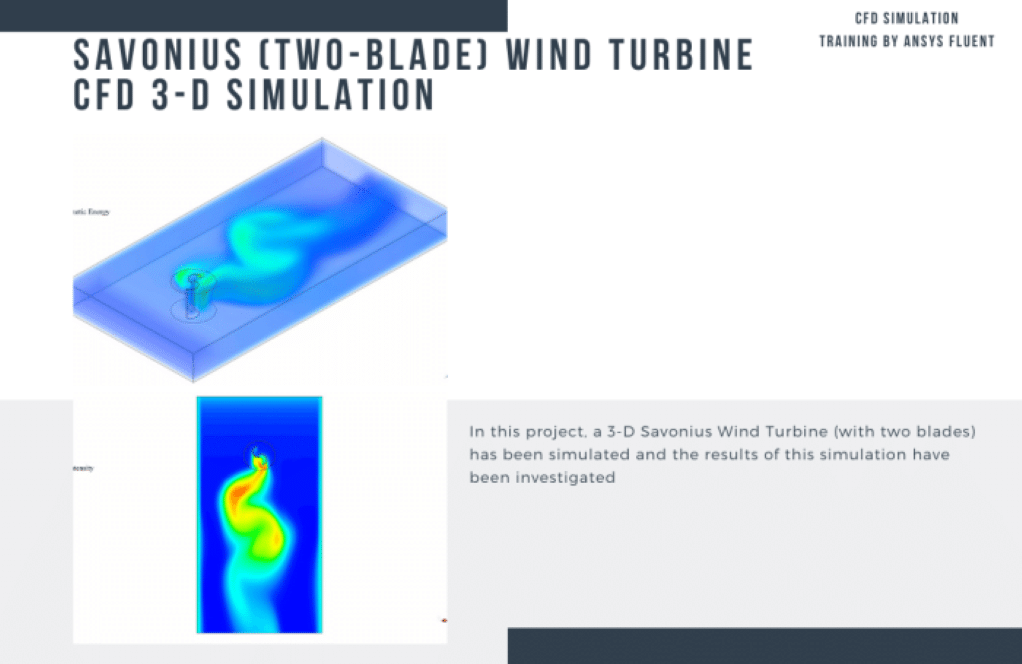

Finally, in project number 10, a 3-D two-blade Savonius wind turbine has simulated, and then the results were investigated. Air enters the fluid domain from the inlet with 10m/s velocity while the turbine rotates with a constant angular velocity of 40rpm. Our final goal is to illustrate the pressure and velocity distribution and animate the fluid motion behind the turbine.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.[/vc_column_text][/vc_column][/vc_row]

Talia Witting –

Does this package cover the simulation of chemical reactions in turbomachinery?

MR CFD Support –

Yes, it does! The training package includes exercises on chemical reaction modeling, which is important for understanding the behavior of turbomachinery in applications like combustion engines.

Chadrick Walker –

I’ve recently completed the Turbomachinery CFD Training Package and am thoroughly impressed with the depth of material provided. As an intermediate user of ANSYS Fluent, these practical exercises enhanced my understanding of various turbulent models and mesh motions. The twin-screw pump simulation was particularly enlightening – seeing how the glycerin fluid’s pressure increased really solidified my grasp on fluid dynamics within turbomachinery.

MR CFD Support –

We’re delighted to hear that the Turbomachinery CFD Training Package has been so beneficial for you! It’s fantastic that the twin-screw pump simulation provided you with valuable insights into fluid dynamics. Thank you for sharing your experience, and we are here for any further guidance you might need on your journey to mastering CFD simulations with ANSYS Fluent.

Jessika Wunsch –

I’m very pleased with the Turbomachinery CFD Training Package. The range of exercises provided a deep understanding of turbomachinery simulation principles. The step-by-step training movies were particularly helpful in explaining the complex aspects of each project. Thank you, MR CFD, for creating such a versatile learning package!

MR CFD Support –

Thank you for your positive review! We’re delighted to hear that our Turbomachinery CFD Training Package for intermediate users met your expectations and enhanced your simulation skills. We aim to deliver comprehensive learning materials that are both informative and user-friendly. We appreciate your support, and if you need further assistance or have any suggestions, please don’t hesitate to reach out to us.

Carole Hartmann –

Can you please help me understand how to optimize the design of turbomachinery components?

MR CFD Support –

Absolutely! The package includes exercises on design optimization, helping you understand how to improve the performance and efficiency of turbomachinery.

Miss Marisol Quitzon II –

I’ve completed the Turbomachinery CFD Training Package and found the variety of simulations extremely educational. The step-by-step instructions in the training movie made complex concepts much easier to understand. Highly recommend to anyone looking to deepen their understanding of CFD in turbomachinery applications!

MR CFD Support –

We’re thrilled to hear that you found the training package educational and the instructions helpful! Thank you for recommending our Turbomachinery CFD Training Package to other CFD enthusiasts. Your satisfaction is our top priority, and we look forward to providing you with more quality learning materials in the future.

Greta Boyle –

The Turbomachinery CFD Training Package has been an invaluable resource in my studies. The range of exercises from pumps to wind turbines gave me a strong handle on how to deal with varying workflows and modeling challenges across different types of machinery. Particularly, the comprehensive training on the Small Size Kaplan Turbine with its new prototype design was both challenging and rewarding. The step-by-step training videos provided excellent guidance and it felt as if I had a personal instructor by my side. Thank you!

MR CFD Support –

We’re thrilled to hear that you found the Turbomachinery CFD Training Package so beneficial and that it made a positive impact on your learning journey! It’s great to know that the range of problems provided variety and complexity that helped enhance your understanding, and that the training videos served as a good guide. Your positive feedback motivates us to continue delivering high-quality learning products. Thank you for choosing MR CFD for your learning experience!

Orville Cormier –

The training package really helped me grasp the nuances of turbomachinery CFD. The variety of projects provided a comprehensive understanding, and the step-by-step instructions in the training movie made the complex concepts much more accessible. Thanks for putting together such an educational and interesting set of simulations!

MR CFD Support –

We’re thrilled to hear you had a positive experience with our Turbomachinery CFD Training Package! It’s great to know that the projects and the training material were helpful and easy to follow. Thank you for your kind words and for choosing our product to enhance your skills in ANSYS Fluent. Keep on simulating!

Calista Boyle –

I just completed the “Turbomachinery CFD Training Package for Intermediates.” The practical exercises were spot-on, demonstrating real-world applications and challenging enough to solidify my understanding of turbomachinery simulations. The incremental complexity from pumps to advanced wind turbine models was particularly appreciated, as it built confidence at each step. The included training movies also served as an excellent visual guide. Thanks for this well-structured learning experience!

MR CFD Support –

We’re delighted to hear that our Turbomachinery CFD Training Package met your expectations and that you found the step-by-step complexity and practical exercises beneficial. Thank you for taking the time to provide such thoughtful feedback. If you ever have more questions or need further assistance in the future, please don’t hesitate to reach out!

Nasir Miller –

Wonderful training package for intermediate users in the field of turbomachinery CFD! The range of projects from pumps to wind turbines provides depth and the step-by-step training movie is incredibly helpful for understanding the simulation process.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the comprehensive training and graphical illustrations helped in deepening your understanding of turbomachinery CFD simulations. If you need any further learning resources or assistance, feel free to reach out to us.

Floy Zulauf –

The training package seems extensive and highly beneficial. I’m particularly impressed with the inclusion of hands-on projects for a diverse range of turbomachinery simulations. Kudos to the team for compiling such practical exercises that encompass both water and wind turbines as well as different types of pumps. The step-by-step guidance provided in the Training Movie is especially useful for grasping the nuances of each simulation. Well done!

MR CFD Support –

Thank you for your kind words and positive review! We’re glad you found the Turbomachinery CFD Training Package both extensive and beneficial. It’s our goal to provide practical, hands-on learning experiences with comprehensive guidance, so we’re happy to hear that the Training Movie proved useful to you. We appreciate you taking the time to share your positive feedback.

Dallas Wolf –

How comprehensive are the simulation cases included in this intermediate package for learning turbomachinery CFD in ANSYS Fluent, and are the cases based on realistic machinery?

MR CFD Support –

The simulation cases included are very thorough and offer a wide range of scenarios with various types of turbomachinery. Yes, the cases are based on realistic machinery, reflecting practical situations and ensuring that users can apply the learned skills to real-world turbomachinery simulation projects.

Prof. Edward Jacobi –

I recently finished the Intermediates Turbomachinery CFD Training Package, and I must say, the depth and clarity of the training materials were outstanding. Initially, I was unsure how to approach certain simulation scenarios, but the structured walkthroughs and explanations for each project empowered me with the insight to select the appropriate modeling techniques. Not only was I able to grasp complex concepts, but I also learned how to apply them practically. The training for the pumps, turbines, and wind turbines provided a strong foundation in these areas and were particularly helpful. The learning curve was balanced perfectly, offering substantial challenges that steadily bolstered my confidence and competence with ANSYS Fluent in the realm of turbomachinery simulations. Thank you for providing such an informative and comprehensive learning resource!

MR CFD Support –

Thank you very much for your kind words. We’re thrilled to hear that you found the Intermediate Turbomachinery CFD Training Package enlightening and beneficial. Your feedback strongly motivates us to continue creating high-quality learning resources. We hope that the knowledge you’ve gained will serve you well in your future projects and CFD challenges. If you require any further assistance or have any more CFD learning needs, do not hesitate to reach out. Best of luck in your endeavors!

Prof. Garret Ankunding I –

In what ways can this package aid in my comprehension of the impact of fluid-structure interactions on the performance of turbomachinery?

MR CFD Support –

This package contains exercises centered around fluid-structure interaction modeling. These exercises facilitate your understanding of how the interplay between the fluid and the components of the turbomachinery influences the machine’s overall performance.

Mrs. Hildegard Romaguera –

The course content seems quite comprehensive for Intermediate level users, covering different aspects of turbomachinery simulations. Is there any support available if I face difficulties while going through the training package?

MR CFD Support –

Yes, we provide customer support for all our products. If you require any assistance or have specific questions during your training, our support team and experts are available to help guide you through the process.

Floy Dickinson –

Fantastic resource for intermediate turbomachinery enthusiasts! The range of applications from water pumps to wind turbines provides a thorough understanding of various CFD scenarios. I especially appreciate the detailed explanation which covers multiple models and deals with both water and air mediums.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you’ve found the training package comprehensive and useful. Let us know if you need any further assistance as you continue exploring different CFD simulations in turbomachinery.

Rubye Rutherford –

I’ve always struggled with understanding the boundary layer effects in turbomachinery. Does the intermediate training package provide detailed insights on dealing with this, especially for the wind turbine simulations?

MR CFD Support –

Yes, the intermediate training package specifically addresses issues like boundary layer effects and offers detailed guidance on modeling and analyzing them, especially in the context of wind turbine simulations using ANSYS Fluent. The package includes practical exercises to reinforce this knowledge.

Harold Harber –

What kind of turbomachinery models are included in this package?

MR CFD Support –

The package includes a variety of turbomachinery models including turbines and compressors, providing a comprehensive understanding of turbomachinery simulations.

Prof. Tressa Witting Sr. –

Thank you for this well-rounded turbodynamic CFD training package for intermediate users. The step-by-step guidance through various types of simulations has been incredibly educational. I’ve particularly enjoyed experimenting with the intricacies of glycerin pumping in project 1 and the complexities of simulating airflow in wind turbines. Your training has been instrumental in improving my CFD skills!

MR CFD Support –

We genuinely appreciate your thoughtful review. It’s wonderful to hear that our Turbomachinery CFD Training package has been enlightening and beneficial to your learning experience. We aim to offer detailed and practical knowledge to help our users master the art of CFD simulation. Thank you for choosing our training products, and we look forward to supporting your future endeavors in the CFD field!

Dejuan Swift –

I’ve always been fascinated with Turbomachinery and the complex processes involved. Taking the CFD training package really solidified my understanding. The way the materials are organized and the clarity of the instruction allowed me to get hands-on with the software and enhance my ability to apply different modeling approaches effectively. The variety in projects, from twin-screw pumps to wind turbines, provided a holostic experience. Really well done, MR CFD Company!

MR CFD Support –

Thank you so much for your positive feedback! It’s great to hear that our Turbomachinery CFD Simulation Package has been useful for you and that you’ve enjoyed the variety in our projects. Our aim was to provide a comprehensive training that covers a wide range of turbomachinery applications and it sounds like we hit the mark. We are thrilled that we could help in furthering your understanding of Turbomachinery CFD using ANSYS Fluent. Should you have any more questions or need further assistance in the future, don’t hesitate to reach out. Best of luck in your continued exploration of CFD simulations!

Stanton Marquardt –

I’m impressed by the diversity in the exercises within the Turbomachinery package, especially the variation from subsonic to transonic flow simulations!

MR CFD Support –

We’re thrilled to hear that! Our aim is to provide a comprehensive learning experience, covering the various aspects of turbomachinery simulation. Thank you for acknowledging the diversity and depth of our training package. We appreciate your positive feedback!

Margret Kuhlman –

Thank you for an excellent learning package! The variety of turbomachinery simulations provided a robust learning experience. I particularly enjoyed the project on 3D Savonius wind turbine simulation – seeing the animation of fluid motion was enlightening. That alone helped me grasp the complex fluid-structure interactions at play.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our Turbomachinery CFD Training Package was enlightening and provided a comprehensive learning experience. It is rewarding to know that the 3D Savonius wind turbine project was particularly helpful for your understanding of fluid-structure interactions. If you have any further questions or need assistance with other projects, feel free to reach out. Happy learning!

Lucie Heaney –

I’m really impressed with the range of simulations that this training package covers! It seems like a perfect resource for honing specific CFD skills in turbomachinery. Looking forward to applying what I’ve learned in real-world situations!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you find the Turbomachinery CFD Training Package comprehensive and useful. It’s great to know that our product is helping you build practical skills for real-world applications. If you have any stories or results from applying what you’ve learned, we’d love to hear about them in the future!

Prof. Everette Durgan I –

I really enjoyed the Turbomachinery CFD Training Package. The variety of projects and exercises provided great insight into fluid dynamics and the use of ANSYS Fluent. The hands-on experience with different types of pumps and turbines reinforced my understanding of simulation processes and will definitely project my work quality.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found the Turbomachinery CFD Training Package educational and beneficial. Your understanding and application of the simulation processes reflect exactly what we aim for with our training materials. If you need further assistance or more learning materials in the future, be sure to reach out to us. Happy simulating!

Mrs. Alicia Rutherford –

I am very pleased with the Turbomachinery CFD Training Package for Intermediates. The step-by-step training movies made it so much clearer on how to set up and solve CFD problems related to turbomachinery.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our training package aided in your learning process. It’s always our goal to provide clear and practical instructional materials. Should you have any further questions or need more assistance with your simulations, don’t hesitate to reach out to us. We wish you continued success in your CFD endeavors!

Estell Kemmer DDS –

The Turbomachinery CFD Training Package is thoroughly detailed and packed with information. I appreciate how the exercises progressively build on one another which made grasping complex concepts much more manageable. The provided Geometry & Mesh files, along with the intricate Training Movie, were invaluable throughout the learning process. It simplified the problem-solving approach significantly.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Turbomachinery CFD Training Package met your educational needs effectively. It’s great to know the progressive nature of the exercises and our additional resources were helpful in your learning journey. Should you have any more questions or need further assistance as you continue to learn and use our products, feel free to reach out.

Jermain Schimmel DVM –

I used the project information on the Darrieus wind turbines with serrated airfoils to build my team’s prototype, and the results were exceptional. Not only did it increase our efficiency, but the simulations were spot on with our real-world tests. Great package for those looking into detailed CFD for Turbomachinery applications!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our Turbomachinery CFD Training Package proved useful for your project and that the simulations matched your real-world tests. If you have any more questions or need further assistance in your endeavors, don’t hesitate to reach out. Congratulations on your successful prototype!

Lauriane Cassin –

I’ve really enjoyed the Turbomachinery CFD Training Package! The mix of pump and turbine simulations has been a great way to learn about performance in different fluid dynamic scenarios. The step-by-step training videos have boosted my skills in using ANSYS Fluent. Kudos to MR CFD for such a detailed and hands-on learning approach!

MR CFD Support –

Thank you for your positive feedback on the Turbomachinery CFD Training Package. We are thrilled to hear that our training materials, including the videos and hands-on exercises, have helped enhance your skills with ANSYS Fluent. Your success is our goal, and we’re glad we could contribute. If you have any further questions or need more assistance, please feel free to reach out to us.

Cade Hoppe III –

I’m completely blown away by how comprehensive this turbomachinery package is! It gives an amazing opportunity to delve into a wide range of simulations. After stepping through the various projects, I have a much more solid understanding of turbomachinery CFD and feel equipped to tackle advanced problems thanks to the detailed guidelines and numerous examples. The diversity of simulations from pumps to turbines and the progression from water to wind applications were impressively structured. Excited to apply what I’ve learned!

MR CFD Support –

Thank you so much for your kind words and the awesome review! We’re thrilled to hear that you found the Turbomachinery CFD Training Package for INTERMEDIATE users to be comprehensive and educational. It’s music to our ears to know that it has enhanced your CFD knowledge and motivated you to tackle more complex simulations. Your enthusiasm inspires us to continue delivering high-quality educational material. Keep up the great work and don’t hesitate to reach out to us with any questions as you dive deeper into the world of CFD!