Mechanical Engineering Training Package, Intermediates, Part 3, 10 Exercises

$1,280.00 Original price was: $1,280.00.$209.00Current price is: $209.00. Student Discount

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all INTERMEDIATE users.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Mechanical Engineering – ANSYS Fluent Training Package, 10 Practical Exercises for INTERMEDIATE Users (Part 3)

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all INTERMEDIATE users.

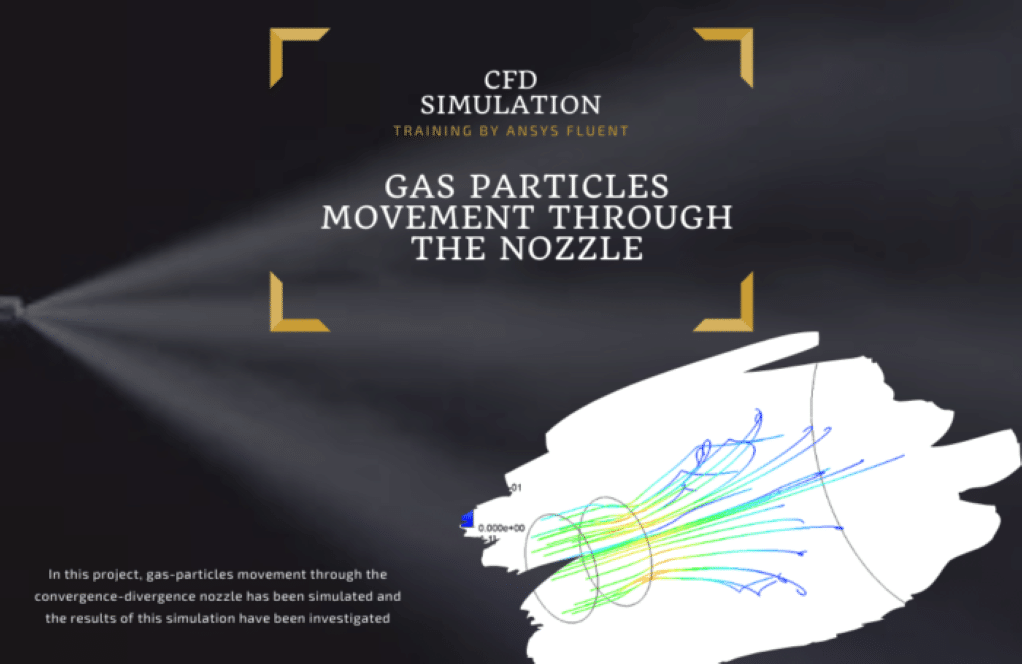

Simulation number 1 is modeling gas-particles movement through the convergence-divergence nozzle by a two-way DPM model. The nozzle is in grossly overexpanded condition. These kinds of nozzles are used in the gas and petrochemical and also MECHANICAL industry.

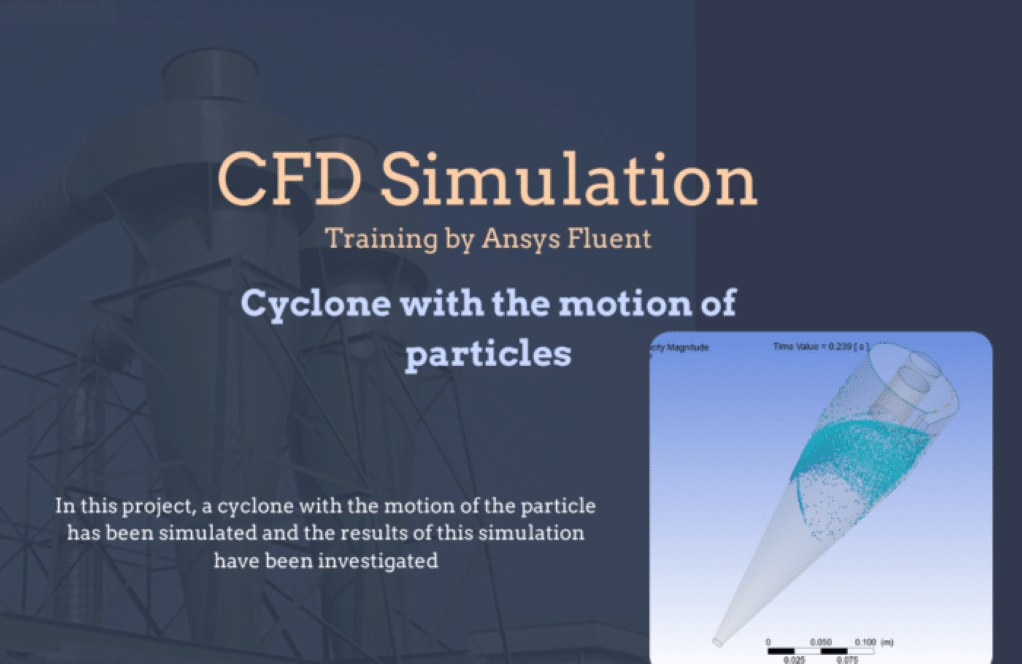

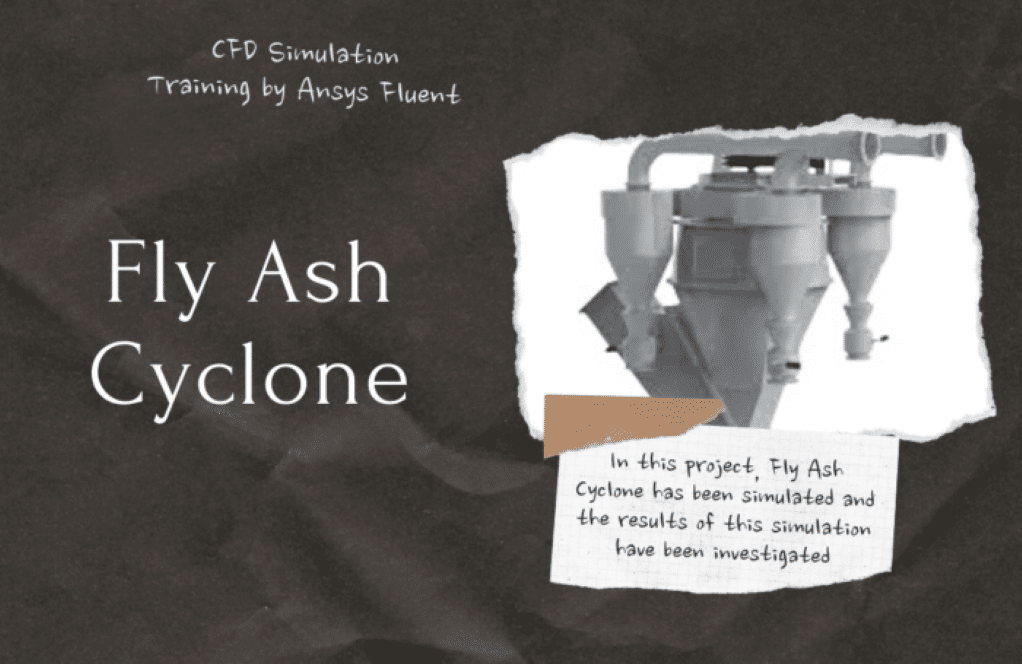

In project number 2, the motion of particles in a cyclone has been simulated. We used the one-way DPM to simulate the discrete phase. A cyclone is a device used to separate particles from gas and has many applications in the mechanical industry. In practical exercise number 3, the motion of particles in a Fly Ash Cyclone has been simulated. The Eulerian-Lagrangian technique is applied in the cyclone separator simulation. In this approach, the gas is treated as a continuum, and individual solid particles are tracked through the flow field by Lagrangian tracking to determine their position.

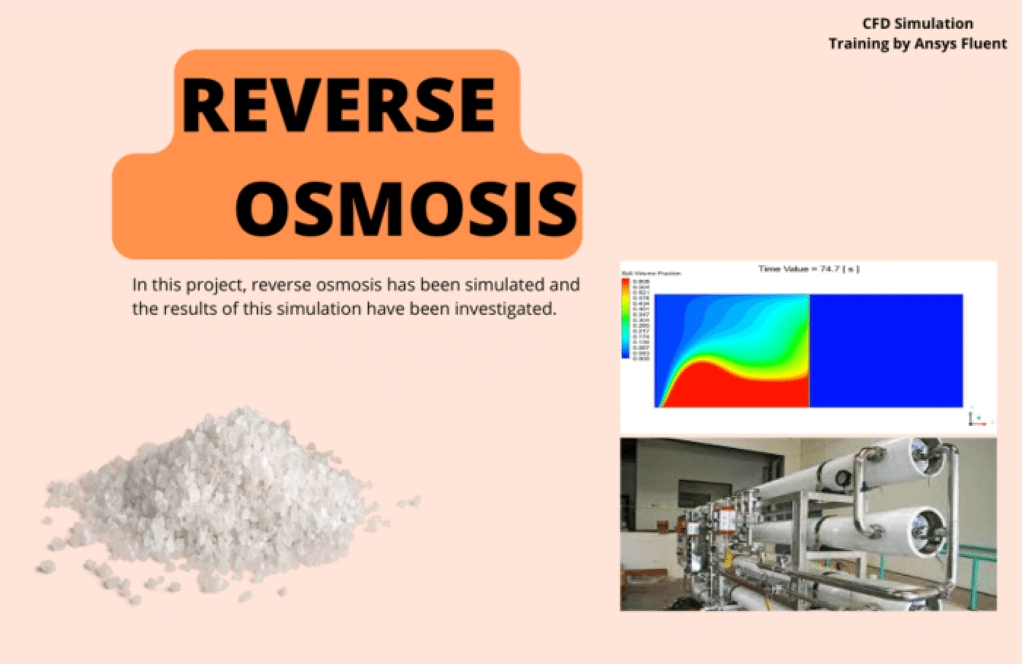

In project number 4, the reverse osmosis mechanism is simulated. This mechanism is used to purify water so that a membrane is placed in front of the water movement and does not allow the salts in the water to leave and pure water leaves. Eulerian Multiphase model has been used in this project.

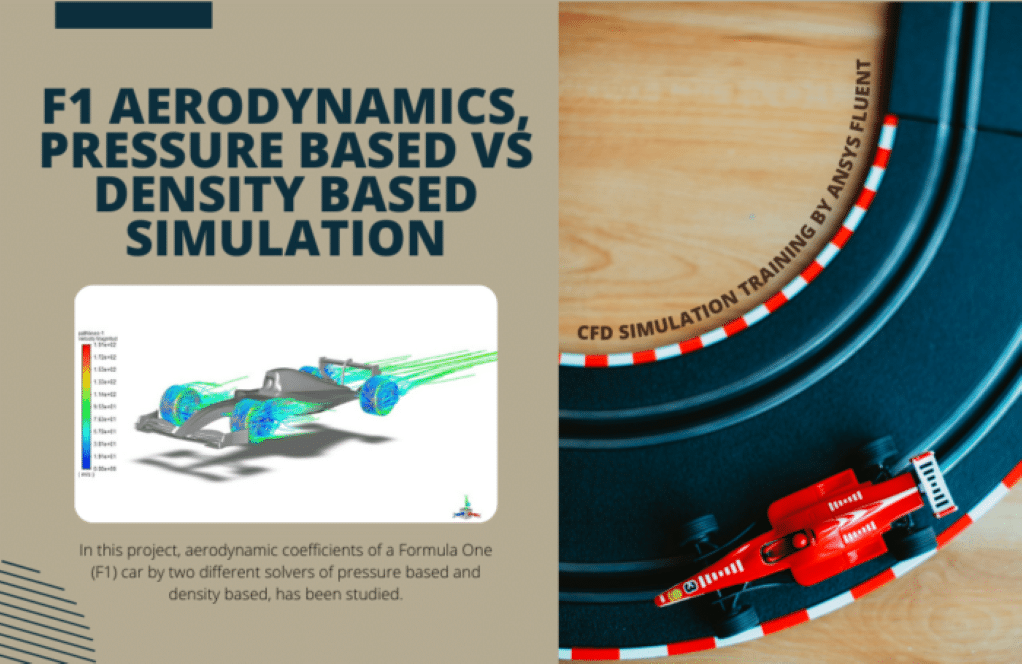

In practical exercise number 5, the aerodynamic coefficients of a Formula One (F1) car by two different solvers of pressure-based and density-based, has been studied, at a speed of 108 meters per second at a lateral angle of zero degrees (actually a straight path). This velocity at the ground level is equivalent to Mach number approximately 0.32. We know this area from Mach number is the transition zone from incompressible to compressible flow, so on this geometry, the drag coefficient is investigated using two pressure-based and density-based solvers is discussed.

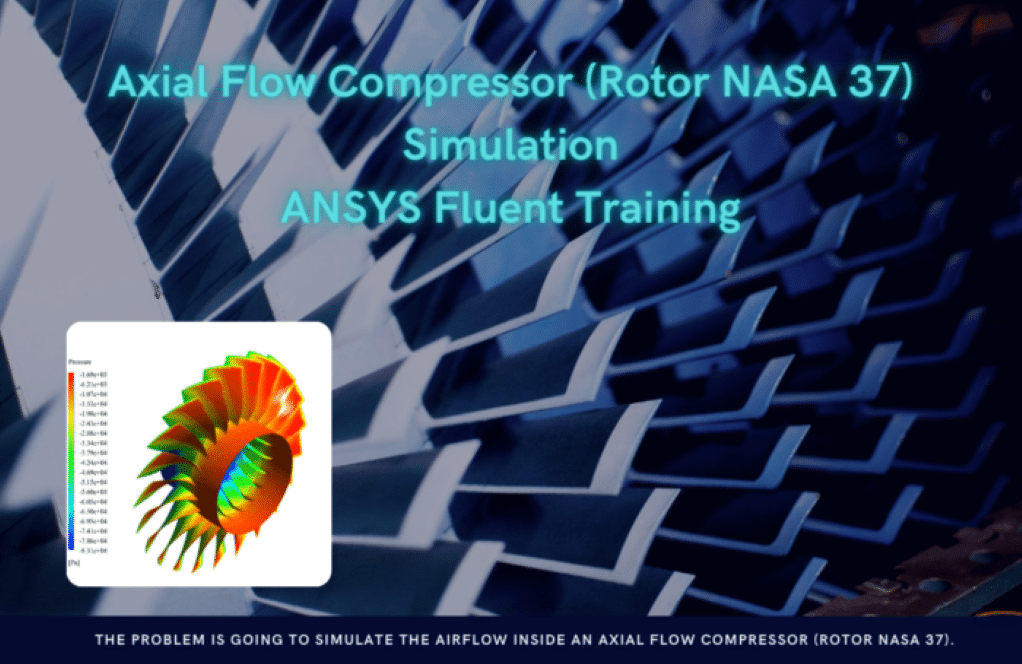

Problem number 6 is going to simulate the airflow inside an axial flow compressor (Rotor Nasa 37). The present model consists of a series of blades for an axial flow compressor connected to the central axis within a cylindrical area. To simplify the simulation model, only one row of rotating blades is drawn on the central rotor of the compressor.

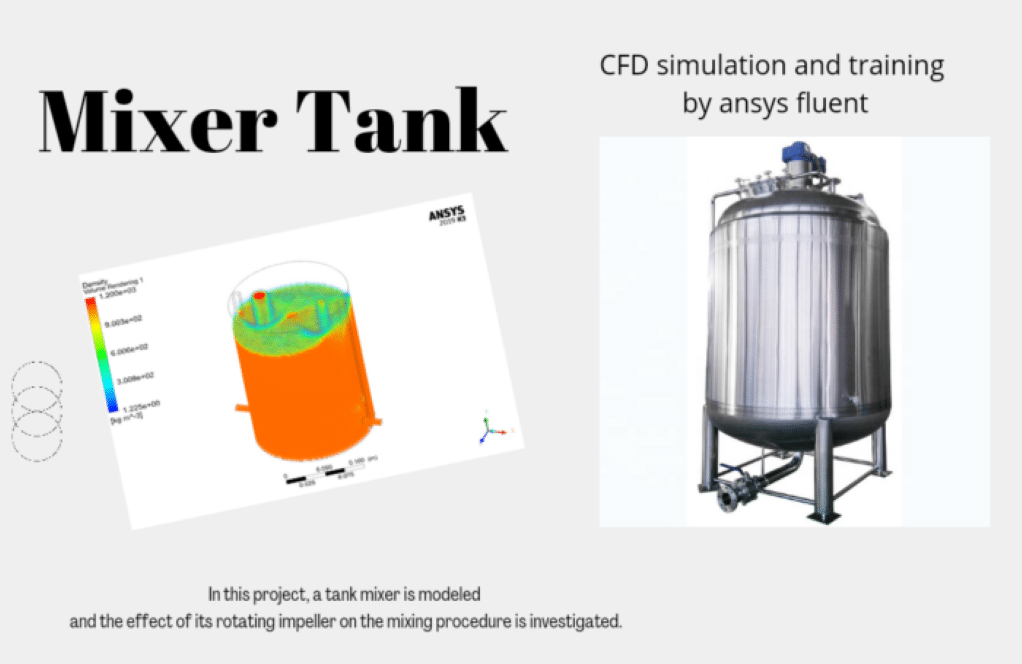

In project number 7, a mixer tank is modeled and the effect of its rotating impeller on the mixing procedure is investigated. The simulation is done using the VOF model for the three phases of air, water, and salt. The k-epsilon model is applied for solving the turbulent flow inside the tank. MRF (Moving Reference Frame) model is also used to model the rotation of the impeller.

In practical exercise number 8, the heat conduction of a brake disk system is modeled and simulated. The disk revolves at the speed of 20rad/s and a braking pad is set to make contact with the disk. This frictional contact will result in heat generation inside the disk and the pad.

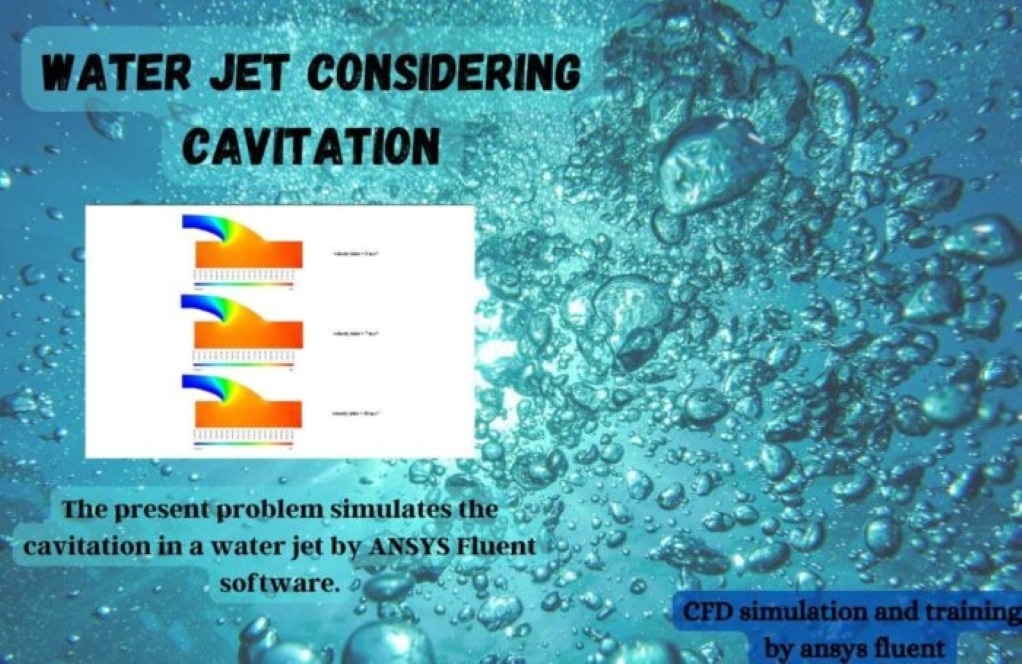

Problem number 9 simulates the water flow in a water jet. A water jet is a mechanical tool for creating a high-pressure water flow for use in operations such as cutting or cleaning surfaces of objects. The working mechanism of this tool is that it consists of a thin layer of water at a very high speed to which an abrasive substance is injected to cut hard materials, and as a result, the mixture of water and abrasives can make a narrow cut on the piece.

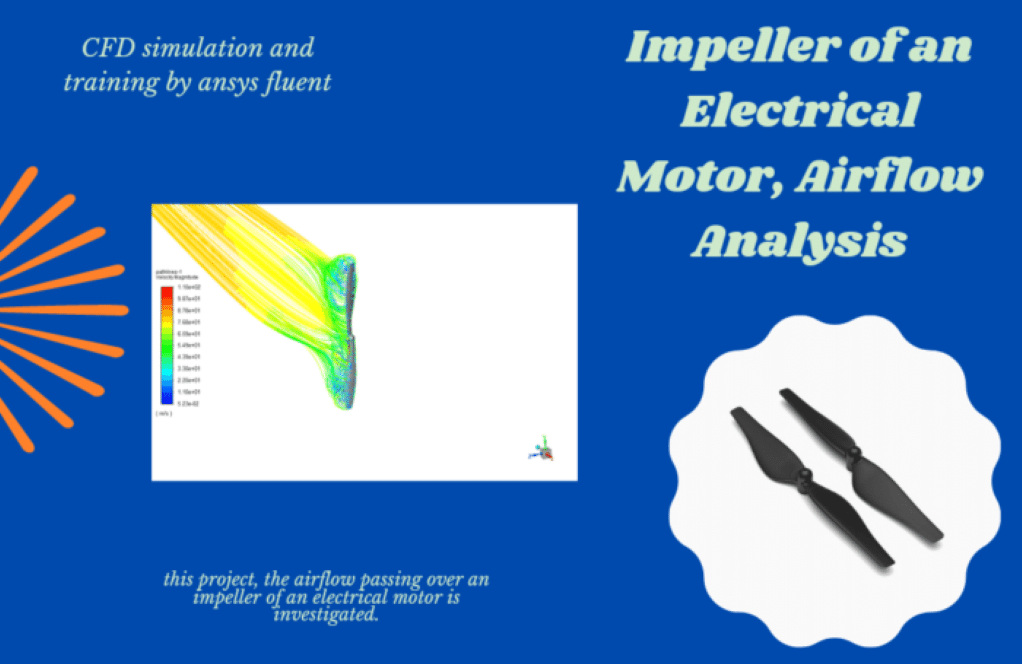

Finally, in project number 10, the airflow passing over a mechanical impeller of an electrical motor is investigated. The airflow enters the computational domain with 80m/s, and the impeller rotates with 1000rpm. A Realizable k-epsilon model is exploited to solve turbulent flow equations. It should be noted that the MRF (frame motion) option has been activated to model the rotation of the impeller.

Prof. Godfrey Moen –

Can this package help me understand how to simulate reactive flows?

MR CFD Support –

Indeed, this package includes exercises that cover the simulation of reactive flows, helping you understand the complex interactions in these types of flows. We can also adapt these simulations to your specific needs.

Sheridan Cruickshank –

Can I simulate natural convection using this training package?

MR CFD Support –

Yes, this package includes exercises that cover the simulation of natural convection. We can also tailor these simulations to your specific needs.

Prof. Candice Ernser MD –

Just finished Practical Exercise 4 about reverse osmosis simulation from the Mechanical Engineering Training Package, and I am truly impressed by the detail and quality of the tutorial. The Eulerian Multiphase model implementation was clearly explained and witnessing the simulation successfully separate the salt from water was particularly satisfying. Great material for intermediate learners who wish to enhance their understanding of complex simulations in ANSYS Fluent.

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that Practical Exercise 4 met your expectations and provided you with a deep understanding of the reverse osmosis simulation process using ANSYS Fluent. If you ever have any questions or need further assistance as you continue to work through the other exercises, don’t hesitate to reach out. Happy learning!

Dr. Ressie Strosin PhD –

The Mechanical Engineering Training Package Part 3 seems to cover a comprehensive range of exercises. Are these practical exercises suitable for someone with previous basic knowledge but looking to improve to an intermediate level? Also, is the detailed tutorial for each exercise, including step-by-step instructions?

MR CFD Support –

Yes, these exercises are designed specifically to help individuals with basic knowledge to progress to an intermediate level. Each practical exercise includes a detailed step-by-step tutorial that guides the user through the process of setting up the simulation, solving the problem, and extracting the desired results.

Ms. Vicky Donnelly –

The training seems very thorough. I particularly appreciate the variety of exercises included. How often do updates to the training materials get released to keep up with the latest ANSYS Fluent updates?

MR CFD Support –

Updates to the training materials are released periodically to ensure that the content remains relevant to the latest versions of ANSYS Fluent software. The interval for such updates depends on the advancements in the software and feedback from users, but we aim to provide the most current information to enhance the users’ learning experience.

Dr. Lisette Hermann PhD –

I loved going through the Mechanical Engineering Training Package – Part 3. Each exercise challenged my understanding, and the variety of mechanical simulations kept me engaged. Having hands-on examples from different areas like aerodynamics, thermal systems and multiphase flow simulations really enhanced my knowledge. Moreover, the training movie is an excellent resource that complements the geometry & mesh files. Thank you for this well-curated intermediate-level learning experience!

MR CFD Support –

We’re thrilled to hear that you found the Part 3 Mechanical Engineering Training Package engaging and beneficial! It’s rewarding to know that the variety and depth of the simulations, as well as the included resources like the training movie and mesh files, have enhanced your learning experience. Thank you for choosing our learning product, and we look forward to providing you with even more comprehensive and challenging material in the future.

Ms. Zetta Schmidt IV –

I’m excited to practice the simulations in the Mechanical Engineering Training Package. Are there any prerequisites or specific knowledge I need before starting with these intermediate exercises?

MR CFD Support –

Before starting the intermediate exercises in the Mechanical Engineering Training Package, it is recommended that you have a basic understanding of fluid dynamics and mechanical systems, as well as familiarity with ANSYS Fluent software. Knowing how to operate the Design Modeler and Meshing tools in ANSYS will also be beneficial as the exercises range from simulating gas-particle movements to analyzing the airflow over mechanical impellers. Having completed some beginner level exercises would be a valuable foundation.

Freda Stokes –

This Mechanical Engineering ANSYS Fluent Training Package seems quite comprehensive and diverse. The variety of simulations seems very beneficial for those looking to expand their knowledge in different mechanical applications. Well done!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that you find our Mechanical Engineering ANSYS Fluent Training Package comprehensive and valuable for learning various simulations. We aim to provide a wide spectrum of practical exercises and are glad you appreciate the diversity. If you have any further questions or need assistance, feel free to reach out.

Kayla Ortiz –

The Mechanical Engineering Training Package sounds comprehensive. Was curious, does the training include how to interpret and apply the simulation results effectively in real engineering scenarios?

MR CFD Support –

Indeed, the training package is designed to guide users through both the simulations and the post-processing of results. It encompasses interpretation of the data to apply the results effectively in practical mechanical engineering scenarios, including decision-making processes for design and optimization.

Gwen McLaughlin –

This training package sounds very comprehensive. Are the training materials suitable for self-paced learning or is additional instructor support recommended?

MR CFD Support –

The training package is designed with detailed simulations to cater especially to intermediate learners. High-quality training materials like Geometry & Mesh files and comprehensive Training Movies should enable self-paced learning effectively. Additional instructor support would depend on the individual’s learning style but is not a requirement to get started with this package.

Dr. Minerva Schowalter –

Could you tell me if support is provided for this package if beginners encounter difficulties with these intermediate-level exercises?

MR CFD Support –

We offer support for all of our products. The Mechanical Engineering Training Package for Intermediates comes with a comprehensive training movie that guides you through the problem-solving process. If further assistance is needed, our experts are ready to help. Beginners who are advancing to intermediate level often find the videos sufficient, but in case of additional questions, feel free to reach out!

Mr. Deshawn Kreiger –

Terrific resource! It’s refreshing to work through these unique challenges and gain invaluable skills in mechanical CFD simulations. Kudos to the entire team at MR CFD for compiling this impressive set of exercises for intermediate users.

MR CFD Support –

Thank you so much for the kind words! We’re thrilled to hear that the training package has served as such a valuable resource to you and that you appreciate the efforts of our team to provide a diverse and educational experience. If you ever have any questions or need further assistance, don’t hesitate to reach out!

Elliot Bins –

I have recently finished the Mechanical Engineering Training Package for Intermediates and found the mix of practical exercises incredibly enriching. The step-by-step guides in the training videos were particularly helpful in understanding the complex simulations, especially for the gas-particles modeling in the convergence-divergence nozzle. Keep up the good work!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the training package and our tutorials enriching and helpful. Our goal is to provide high-quality learning materials that empower our users with a deeper understanding of complex simulations. If you have any more feedback or require further assistance, please don’t hesitate to reach out!

Mr. Jorge Volkman –

What a great bundle! The exercises are challenging yet rewarding and provide insight into a variety of mechanical applications.

MR CFD Support –

Thank you for the positive feedback! We’re delighted to hear that the Mechanical Engineering ANSYS Fluent Training Package has been beneficial and provided valuable hands-on experience across different applications. If you ever have any questions or need further assistance, please don’t hesitate to reach out to us.

Coby Carter –

Does this package cover the fundamentals of the finite volume method?

MR CFD Support –

Yes, this package provides a practical understanding of the finite volume method, which is the basis of ANSYS Fluent. We can also customize the exercises based on your specific requirements.

Franz McClure –

I’m thrilled with the variety of exercises in this intermediate training package. Each tutorial seems distinct and covers a broad range of mechanical engineering concepts. It’s impressive that both pressure-based and density-based solvers were used in studying the aerodynamics of an F1 car – a critical analysis for performance in racing.

MR CFD Support –

Thank you so much for your positive review! We’re delighted to learn that you’re impressed by the breadth and depth of our Mechanical Engineering training package. Our goal is to provide a comprehensive learning experience that equips our intermediate users with the necessary skills and knowledge to tackle a wide range of engineering problems. If you have any further questions or need more information, please do not hesitate to contact us. Your feedback is greatly appreciated, and we wish you the best of success in your ongoing and future projects!

Maudie Collins Jr. –

The capstone of all these exercises complements the coursework perfectly. I’ve gained a richer understanding and proficiency in mechanical engineering simulations that I can directly apply in practice. The step-by-step guidance makes complex simulations clear and approachable, and the broad range of applications from nozzles to impellers are outstanding.

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that you found the Mechanical Engineering Training Package both informative and practical. It’s great to know that our step-by-step approach makes complex simulations accessible – that’s exactly what we strive for. We appreciate your kind words and look forward to supporting your future learning endeavors!

Cordie Beahan –

What are the key elements covered in the Mechanical Engineering Training Package for INTERMEDIATE users?

MR CFD Support –

The Mechanical Engineering Training Package designed for INTERMEDIATE users covers various elements, including two-way and one-way Discrete Phase Models (DPM), the Eulerian-Lagrangian technique for particle movement in cyclones, reverse osmosis simulation, aerodynamic analysis of an F1 car, airflow simulation in an axial flow compressor, multi-phase simulation in a mixer tank with moving reference frame, heat conduction in brake disks, water jet flow simulation, and airflow over mechanical impellers with rotating capabilities.

Delbert Shanahan II –

I’ve worked through the exercises in the Mechanical Engineering Training Package for Intermediates and have been deeply impressed by the examples covered. Exercise number 4 on reverse osmosis particularly stood out due to its real-world application for water purification. The step-by-step guidance helped me understand the Eulerian Multiphase model in greater detail, and I feel much more confident in my ability to simulate similar mechanisms moving forward.

MR CFD Support –

We’re truly grateful for your positive feedback! It’s always rewarding to hear about our customers’ successful experiences with the training materials. Exercise 4 is indeed a pivotal part of the training, and it’s fantastic to know it has enhanced your simulation skills and understanding. Should you ever have more questions or need further assistance as you delve into other applications, don’t hesitate to reach out. Thank you for choosing our training package for your learning journey!

Arthur Ryan –

The selection of exercises in Intermediates Part 3 looks comprehensive. Can you notify how the learning progresses—is it just through the training movies, or is there any additional support material included?

MR CFD Support –

In addition to the training movies, the package includes Geometry & Mesh files for each exercise. These are particularly useful for learners to directly engage with the simulation setup. However, to ensure a complete educational experience, MR CFD provides comprehensive support for its buyers, which includes technical support through answer to questions and further clarifications if needed.

Joana Oberbrunner –

Does this training package provide both the Geometry & Mesh files as well as tutorial videos for each exercise?

MR CFD Support –

Yes, the package includes Geometry & Mesh files for each exercise and also a comprehensive Training Movie for each problem to guide you through solving the problem and extracting all the necessary results.

Mrs. Tyra Trantow –

I just completed the exercise on simulating the reverse osmosis mechanism. The step-by-step procedures were clear and the outcomes matched the expected results closely. The insight on how the Eulerian Multiphase model works was quite enlightening, and I could easily see the difference in water purity before and after the process!

MR CFD Support –

Thank you for your review! We’re glad to hear the training on the reverse osmosis mechanism was helpful and that the results met your expectations. Your feedback on the clarity of our step-by-step procedures and the effectiveness of the Eulerian Multiphase model is much appreciated. Should you have any further inquiries or require advanced learning resources, feel free to connect with us!

Lynn Stroman –

I recently purchased the ‘Mechanical Engineering Training Package: Intermediates: Part 3’ and have gone through all the exercises. By performing the simulations, I gained insightful knowledge about a variety of mechanical systems and enhanced my skills with ANSYS Fluent. The tutorials were clear, and the transition from problems like gas-particles movement simulation in nozzles to analyzing aerodynamics of an F1 car, further to modeling a mixer tank’s impeller effect, and ending with heat conduction in brake systems were seamless, demonstrating a well thought out educational trajectory. Definitely a 5-star review for how each practical exercise was tied to real-world applications, making the learning experience not just academically beneficial but highly practical as well.

MR CFD Support –

Thank you so much for your kind words and taking the time to leave us a 5-star review! We’re thrilled to hear that you found the intermediate exercises beneficial and that they helped enhance your skills in ANSYS Fluent. It is our goal to provide practical, real-world applicable CFD training and we’re delighted to know we’ve achieved that with you. We look forward to continuing to support your learning journey. Keep excelling!

Scot Abshire –

Amazing collection of practical exercises! The diversity of applications and methods covered here, from DPM modeling to VOF and various turbulence algorithms, seems to provide a rich and nuanced learning experience. Looking forward to diving into project number four about reverse osmosis – the relevance to water purification is particularly interesting. Movement through computational problem-solving is a great way to understand fluid dynamics better!

MR CFD Support –

Thank you for your wonderful review of our Mechanical Engineering Training Package, Intermediates, Part 3! We’re delighted to hear that you appreciate the diversity and practical applications of the exercises included. It’s our aim to equip learners with the skills necessary to handle complex simulations in mechanical engineering. We hope you find the reverse osmosis project enlightening and that it enhances your understanding of fluid and membrane interactions. Your enthusiasm for learning makes our effort in putting together such resources worthwhile!

Rudolph Wilkinson Jr. –

Can I use this package to simulate flows in porous media?

MR CFD Support –

Absolutely, this package includes exercises that cover the simulation of flows in porous media. We can also adapt these simulations to your particular needs.

Prof. Adrian Collier –

Absolutely amazed by the comprehensive content in the Intermediates Part 3 Mechanical Engineering training package. Each exercise is thoroughly designed to enhance practical CFD skills, from multiphase flows to high-speed aerodynamics. Kudos to the MR CFD team for such detailed and user-oriented simulations!

MR CFD Support –

Thank you for your kind words and positive feedback! We’re delighted to know that our Mechanical Engineering training package for intermediate users has been so helpful to you. It’s always our goal to provide detailed and practical simulations that enhance CFD knowledge and skills. If there’s anything more we can assist you with, don’t hesitate to ask.

Dr. Zella Sipes –

The mechanical engineering package seems comprehensive. What specific skills will I be able to develop with these exercises? Can I expect to gain proficiency in turbulence and multiphase flow simulations?

MR CFD Support –

Absolutely, this Mechanical Engineering package covers various simulations that should help you build proficiency in both turbulence modeling and multiphase flows. By practicing these exercises, you will get hands-on experience with different turbulence models like k-epsilon and learn how to handle different phases in flow simulation using techniques like the VOF model and DPM. These skills are crucial for mechanical engineers working in computational fluid dynamics (CFD).

Prof. Joannie Hane IV –

Can you explain the advantages of using the Realizable k-epsilon model in project number 10 for solving turbulent flow equations?

MR CFD Support –

The Realizable k-epsilon model includes refinements that improve the accuracy for flows involving rotation, boundary layers under strong adverse pressure gradients, separation, and recirculation. This makes it more suitable for predicting the airflow over the mechanical impeller in project number 10, especially considering the impeller’s rotational forces and potential for complex flow patterns.

Miss Bridgette Halvorson –

The training package seems comprehensive for INTERMEDIATE users. Can you tell me if the simulations cover any heat transfer analyses that are not mentioned in the description?

MR CFD Support –

In the Mechanical Engineering Training Package you’ve mentioned, specifically in practical exercise number 8, the heat conduction of a brake disk system is analyzed and simulated addressing heat generation due to friction, which is a form of heat transfer. The simulations primarily focus on a set of mechanical phenomena, but the mentioned exercise includes the thermal aspect of the mechanical system, thus encompassing heat transfer analysis.

Kyla Kunde –

I’ve completed the training package exercises, and the real-world applicability has truly boosted my confidence. I especially appreciated the in-depth tutorials that allowed me to understand each step of CFD simulation.

MR CFD Support –

Thank you so much for your positive feedback! We are delighted to hear that our Intermediate Mechanical Engineering Training Package, with its detailed tutorials and practical exercises, has enhanced your CFD simulation skills and confidence in applying them to real-world scenarios. Your success is our top priority! If you have further inquiries or require assistance, feel free to reach out.

Lew Graham –

I am quite impressed with the diversity of the exercises in the Mechanical Engineering Training Package for intermediates. It’s certainly been a holistic learning experience. Can you tell me what main skills I would have developed upon completion of all 10 exercises?

MR CFD Support –

Congratulations on completing the 10 practical exercises in the Mechanical Engineering Training Package! Upon completion, you will have developed a broad range of skills including understanding and setting up multiphase flows, discrete phase simulation, turbulence modeling with different numerical solvers, handling geometric complexities such as moving boundaries with the help of MRF, simulating thermal analysis with heat transfer, and mastering the modeling of fluid-solid interaction scenarios. These skills are crucial for effectively approaching real-world mechanical engineering CFD problems using ANSYS Fluent.

Prof. Nathanael Hickle MD –

Absolutely thrilled with the Mechanical Engineering Training Package for intermediates! The diversity of exercises encompassing fluid dynamics, particle motion, and heat transfer through simulations like nozzle flows, cyclone separators, and reverse osmosis really gives a great deal of practical insight. Progressing through each exercise, I found my skills sharpening and confidence growing. The addition of rotational models like the mixer tank and compressor brought in a nice complexity. Instructions are clear, and the training movies are invaluable for visual learners like me.

MR CFD Support –

Thank you for your kind words and positive feedback on our Intermediate Mechanical Engineering Training Package! We’re pleased to hear that our exercises and additional materials such as the Geometry & Mesh file and Training Movies helped you enhance your knowledge and skills. At MR CFD, we always strive to provide clear instructions and practical insight into CFD analysis. If you need further assistance or educational products in the future, please do not hesitate to reach out. Happy learning!

Marta Grant –

I’ve worked through a few of the exercises in this intermediate Mechanical Engineering package and they’re quite detailed! Particularly impressive was the simulation of the gas-particles flow in the overexpanded nozzle. It has truly taken my understanding to a new level. Looking forward to delving into the others!

MR CFD Support –

Thank you for your positive feedback! It’s fantastic to hear that our Mechanical Engineering ANSYS Fluent package is helping to elevate your understanding. Keep enjoying the rest of the exercises, and should you have any questions or need further insight as you progress, don’t hesitate to reach out!