MIXTURE Multiphase Model, CFD Training Package, 10 Practical Exercises

$523.00 Student Discount

This CFD training package is prepared for BEGINNER, INTERMEDIATE, and ADVANCED users of ANSYS Fluent software who are interested in the Mixture Multiphase Model modules, including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

MIXTURE Multiphase Model ANSYS Fluent CFD Simulation Training Package, 10 Practical Exercises

This CFD training package is prepared for BEGINNER, INTERMEDIATE, and ADVANCED users of ANSYS Fluent software who are interested in the Mixture Multiphase Model modules, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

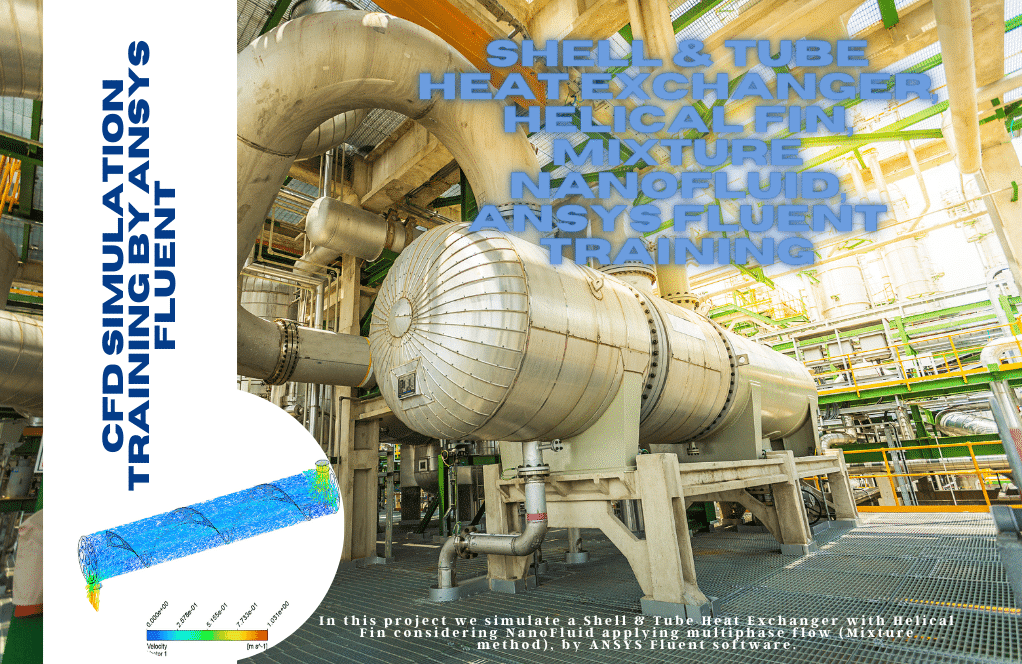

Heat Exchanger

Heat exchangers must satisfy the characteristics of the overall process of the system. Also, sites should use a durable heat exchanger depending on the environmental conditions. They must be repairable according to working conditions. In project number 1, we simulate a Shell & Tube Heat Exchanger with Helical Fin considering NanoFluid applying multi-phase flow (Mixture method).

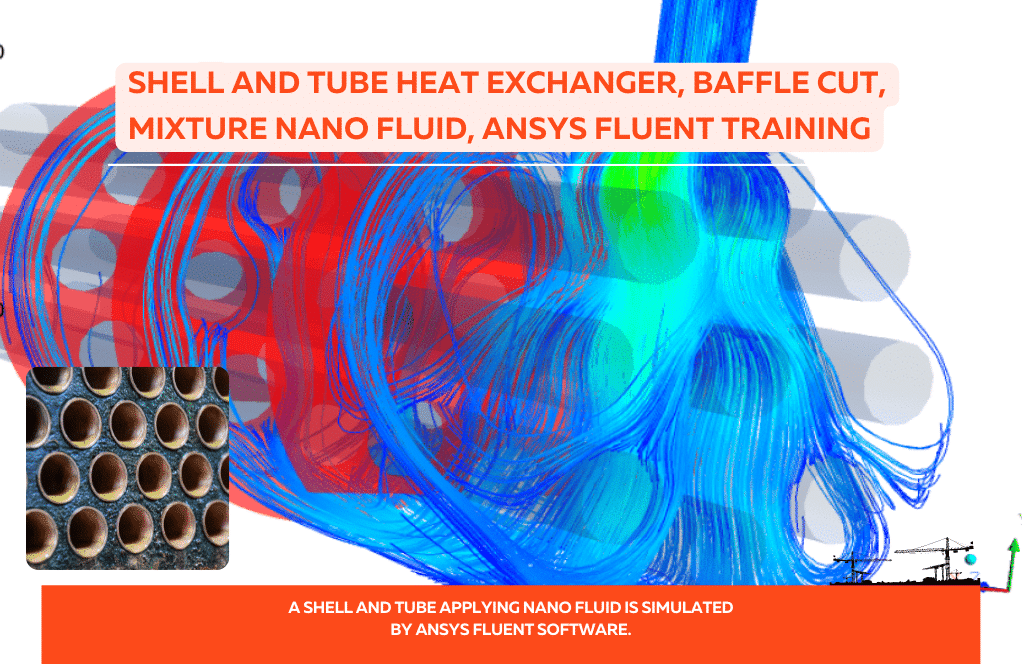

In project number 2, we simulate a shell and tube heat exchanger considering a baffle cut. Many materials can be used as nanoparticles. Since the thermal conductivity of materials, whether in the form of metal or non-metallic state Al2O3, CuO, TiO2, SiC, TiC, Ag, Au, Cu, and Fe are generally several times higher, even at a low concentration, which results in an effective heat transfer coefficient.

Evaporation & Condensation

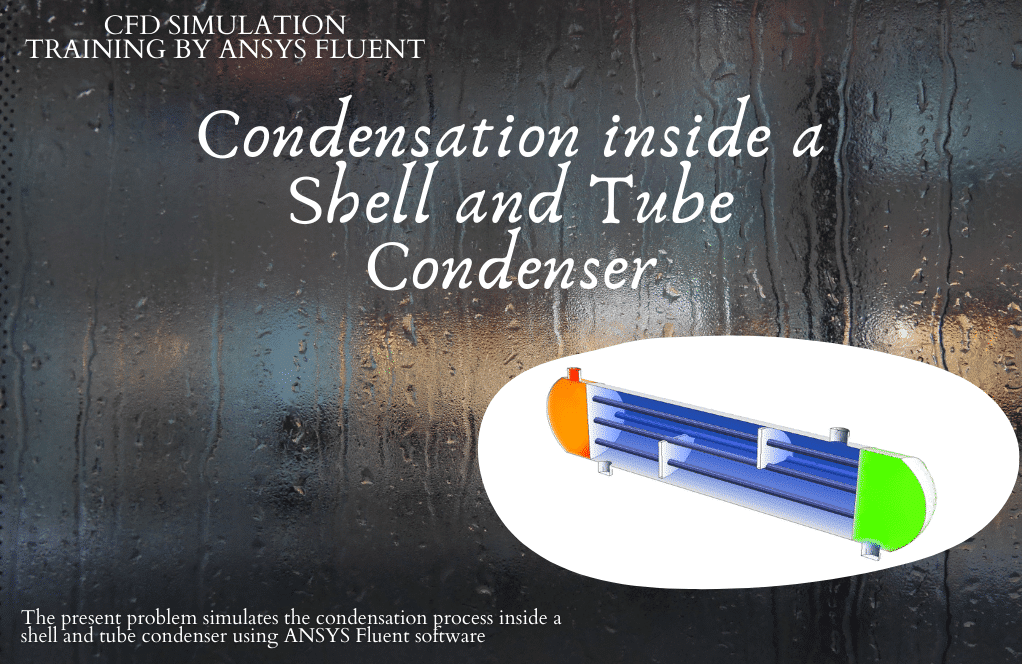

Project number 3 simulates the condensation process inside a shell and tube condenser. A multi-phase Mixture model is used; Because the two phases of liquid water and water vapor are thoroughly mixed together. Also, a Mass Transfer in the form of evaporation-condensation must be defined to define the condensation.

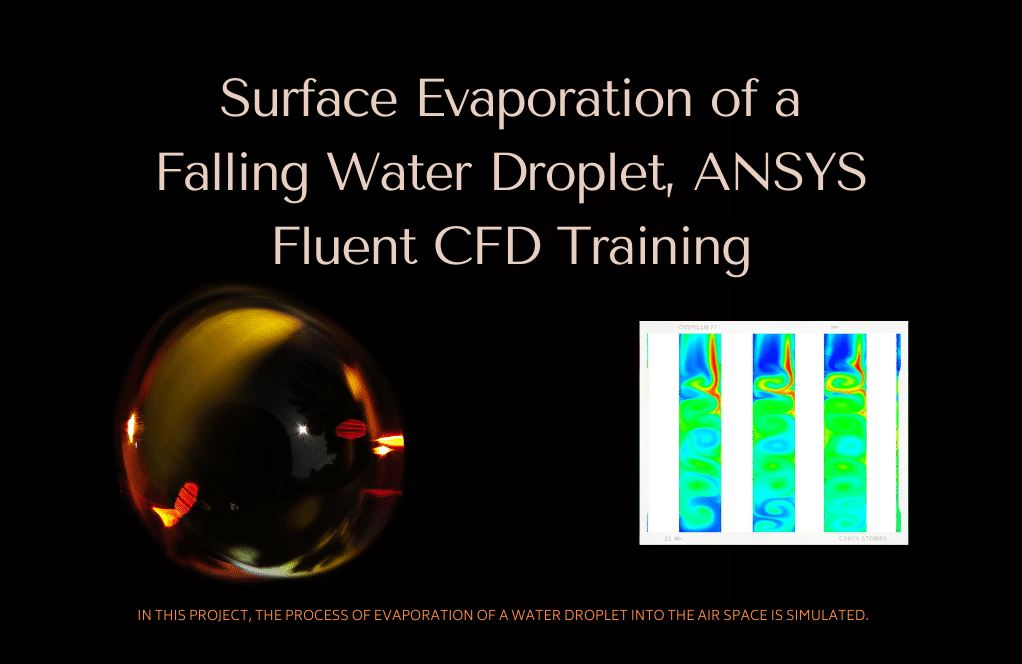

In project number 4, the evaporation process of a water droplet into the air space is simulated. Therefore, the Multi-phase model simulates the initial phase of air and the secondary phases of water and water vapor. A droplet surface evaporation in the air should be simulated. The simulation aims to investigate the droplet behavior during the falling and the amount of vapor produced in the air due to the water surface evaporation.

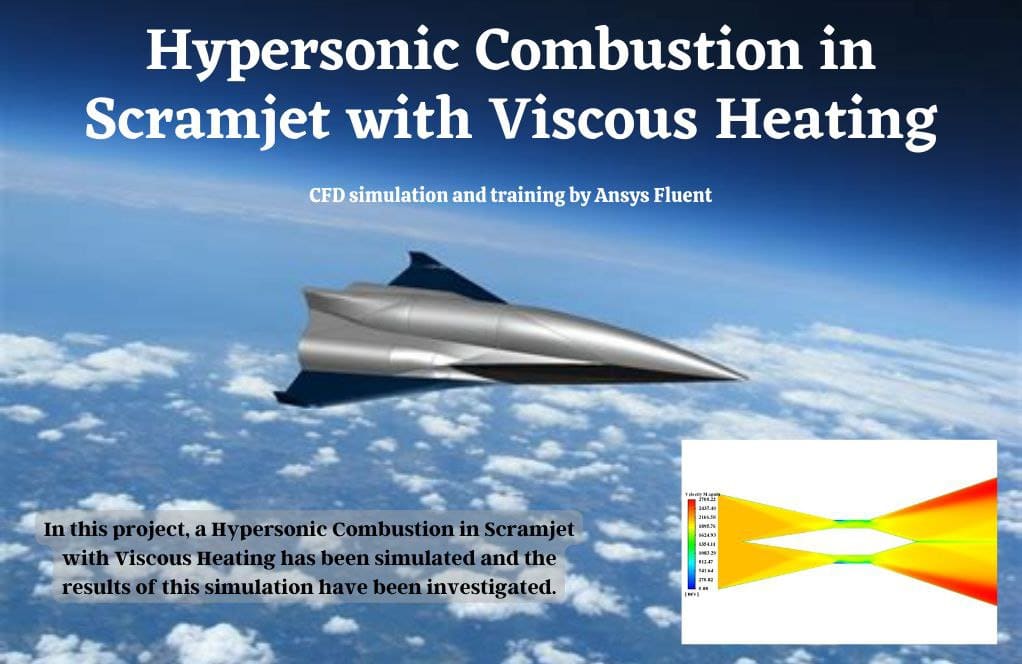

Combustion (MIXTURE Multiphase Model)

Scramjets are a type of ramjets that can travel at hypersonic speed while there is no motion device in its engine. Scramjet technology started with the development of the ramjet. The ramjets might not achieve supersonic speed, while scramjets necessarily fly at hypersonic speed. In project number 5, Hypersonic Combustion in a Scramjet engine with Viscous is simulated. The Mach number of inlet air is set to 6, and the temperature of the whole domain equals 300k.

In general, a fuel injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid so that a lower-pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. In project number 6, a three-phase flow fuel injector has been simulated. The Mixture multi-phase model for three phases of air, liquid, and vapor has been used to investigate the phase interactions.

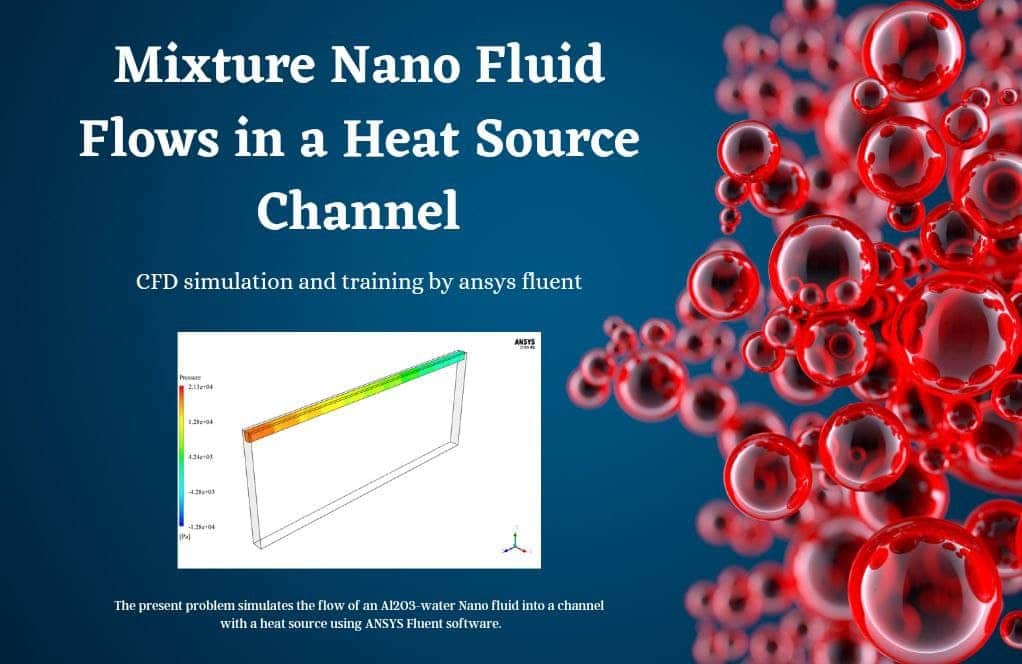

Nanofluid

Project number 7 simulates the flow of an Al2O3-water nanofluid into a channel with a heat source. This channel has a square cross-section and has ten categories of obstacles inside. Each of these obstacles has two diagonal plane barriers facing each other and a cylindrical barrier between them. So that the presence of these barriers determines the path of nanofluid flow through the channel. To define the nanofluid, a multi-phase mixture type model is used.

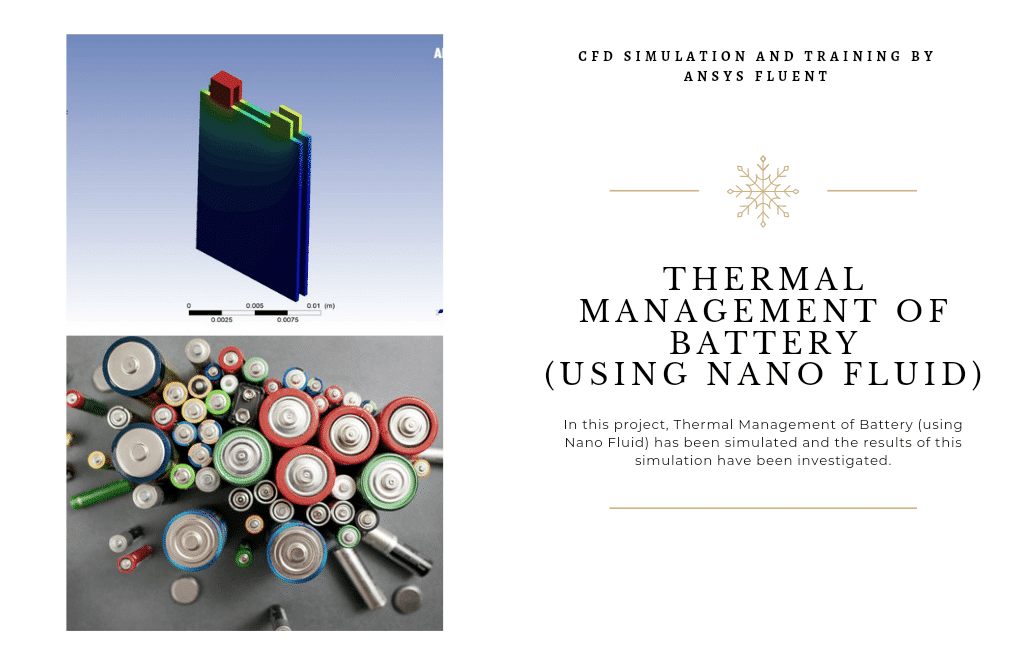

Project number 8 simulates the thermal features of the Battery using a Two-Phase Nanofluid. This simulation is related to a Dual-Potential MSMD (multiscale multidomain) battery model. The present simulation is performed with a Mixture multi-phase model, and the effect of nanofluid flow in heat transfer enhancement of battery is investigated. This work aims to investigate the effectiveness of phase change materials in the cooling process of the battery.

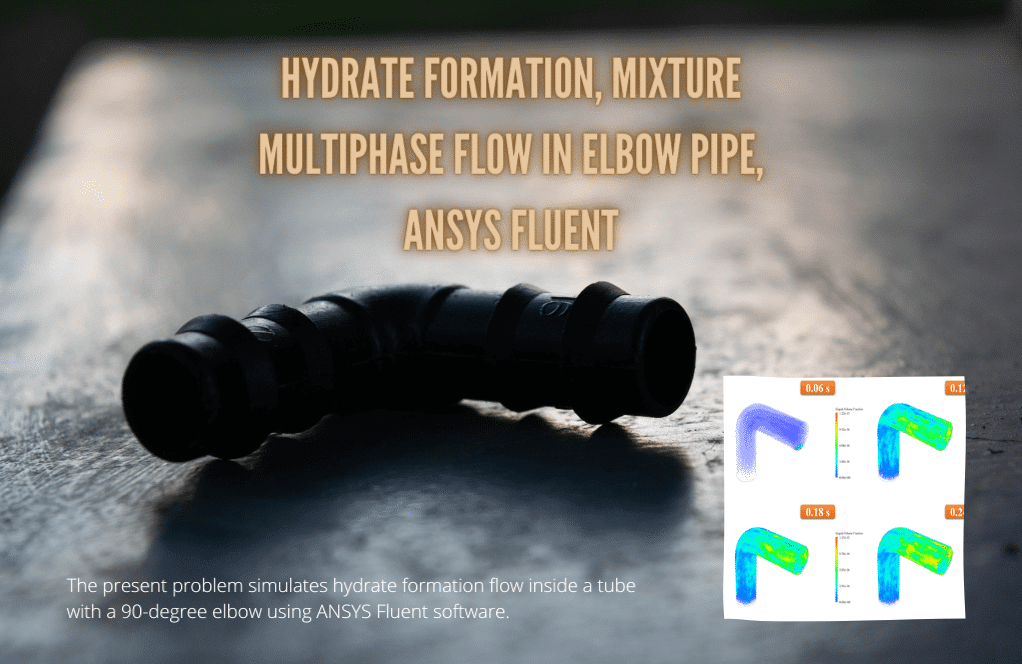

Hydrate Formation

Project number 9 simulates hydrate formation flow inside a tube with a 90-degree elbow. Hydrates are organic substances that contain water. The hydrate in this project combines three different materials of water, water vapor, and methane. Also, between the liquid water phase and water vapor, mass transfer is defined as the evaporation-condensation process.

Turbine (MIXTURE Multiphase Model)

In Project number 10, the effect of the steady rotation of a centrifugal turbine on a water and two-phase air mixture is investigated. The multiphase mixture model is used to solve water and air phase interactions. The secondary phase (air) volume fraction has very low values in the 0.0001 order, which proves the validity of the mixture multiphase model in this project. The secondary phase volume fraction should be less than 15% for applying the Mixture Multi-Phase model. Slip velocity has been considered at the water and air contact interface. The Frame Motion (MRF) model has been applied for the rotation simulation.

Meaghan Kuhic –

I recently completed the MIXTURE Multiphase Model CFD Simulation Training Package, and it was incredibly informative. Going through the 10 practical exercises thoroughly boosted my understanding of multiphase models in ANSYS Fluent. I highly appreciate how the package caters to multiple skill levels. The step-by-step approach taken in project 7, simulating the Al2O3-water nanofluid flow, was so insightful for visualizing the complexities of multiphase flow and heat transfer.

MR CFD Support –

Thank you for your kind words and for taking the time to write such a positive review. We’re delighted to hear that you found the training package educational and that it enhanced your understanding of multiphase models in ANSYS Fluent. It’s great to know that our materials were able to support different skill levels and that you especially enjoyed the nanofluid simulation exercises. Your feedback is much appreciated and motivates us to keep delivering high-quality CFD learning resources. If you have any further questions or need additional guidance in your learning journey, please don’t hesitate to reach out.

Kara Purdy –

This CFD training package has tremendously enhanced my grasp of the MIXTURE multiphase model in ANSYS Fluent. The progression of exercises from beginner to advanced levels allowed me to incrementally build my skills. Moreover, the focus on various real-life applications like heat exchangers, combustion, and nanofluid simulations provided a broad base of knowledge. The simulations’ outputs were accurate and very comprehensible, aiding in my understanding of complex flow behaviors in different systems. Happy customer here!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our training package has been so beneficial to your learning experience with the MIXTURE multiphase model in ANSYS Fluent. If you continue to have inquiries or need further support as you delve deeper into your simulations, don’t hesitate to reach out. Your success is our motivation—happy simulating!

Prince Trantow –

The training package has significantly improved my understanding of the MIXTURE multiphase model in ANSYS Fluent. The hands-on approach with 10 diversified exercises catered to different levels heightened my simulation skills. The transitions from beginner-level simulations to more complex setups helped me grasp the fundamentals and intricacies of multiphase flows. The description of each problem was clear, making it easier to understand the purpose and objectives of the simulations.

MR CFD Support –

We’re delighted to hear the MIXTURE Multiphase Model CFD training package met your needs so effectively! It’s fantastic that you found the range of exercises beneficial for enhancing your simulation expertise. Thank you for sharing your positive experience, and we hope you will find our other training materials just as useful.

Marcel Durgan –

Are all ten projects in this MIXTURE multiphase model training package suitable for a beginner in ANSYS Fluent, or are some of them designed for more advanced users?

MR CFD Support –

While the training package is designed to cater to a range of users from beginners to advanced, each project may have varying levels of complexity. Beginners can certainly get started with some of the initial exercises to build foundational skills but might find more advanced projects challenging. It is recommended for beginners to work through the exercises sequentially as skills progress.

Norval Vandervort –

I recently finished the ‘MIXTURE Multiphase Model, CFD Training Package’ with the 10 practical exercises, and I’m thoroughly impressed! Each simulation offered a unique challenge that helped solidify my understanding of ANSYS Fluent’s multiphase capabilities. From heat exchanger analyses using nanofluids to combustion dynamics in scramjets, I truly appreciated the breadth of applications covered. It was especially intriguing to see how the modeling approaches differed between a water droplet’s evaporation and hydrate formation in pipelines. The step-by-step procedures were well laid out and made complicated concepts accessible, even for beginners like myself. By the time I reached the turbine simulation with its rotating flow fields, I felt confident in my ability to navigate the software and interpret the results. Hats off to MR CFD for putting together such an informative and practical learning experience!

MR CFD Support –

Thank you for your detailed and positive feedback on our ‘MIXTURE Multiphase Model, CFD Training Package’. We’re thrilled to hear that the package served its purpose by enhancing your CFD skills across a wide range of applications and improving your confidence with ANSYS Fluent. Your enjoyment and success with the exercises motivate us to continue delivering high-quality educational materials. If there’s anything more we can assist you with on your learning journey, please let us know!

Izaiah Oberbrunner –

The MIXTURE Multiphase Model package covers a wide range of applications, making it an excellent resource for in-depth learning. It’s remarkable how the training seamlessly caters to beginners as well as advanced users. I especially appreciate the clear step-by-step guidance provided in each of the practical exercises. Keep up the great work!

MR CFD Support –

Thank you for your positive review! We are pleased to hear that you find the breadth of applications and the detailed instructions in our MIXTURE Multiphase Model training package valuable. If you have any further questions or need assistance with your CFD simulations, feel free to reach out. We’re here to help! Your satisfaction is our motivation!

Meagan Klein –

I’ve just finished practicing with the MIXTURE Multiphase Model training package and the detailed theoretical explanations and practical exercises were a tremendous help as I navigated through the complexities of CFD simulations. Each practical exercise was laid out clearly and helped build my confidence. The progression from simple to complex scenarios truly honed my skills.

MR CFD Support –

Thank you for the positive feedback! We’re thrilled that the training package served as a helpful guide and effectively aided in enhancing your simulation skills. We strive to provide resources that assist our users in mastering CFD analysis, and it’s rewarding to hear about your progress and confidence as a result. We appreciate you taking the time to share your experience!

Vincent Hickle II –

I’ve just finished going through the MIXTURE Multiphase Model training package, and the blend of theory with the ten hands-on exercises was incredibly beneficial. From evaporating and condensing simulations to tackling combustion in scramjets and investigating nanofluids, each project honed additional skills. It was also excellent seeing real applications like heat exchangers and turbomachinery. Detailed explanations in each exercise, alongside ANSYS visuals, clarified how to operate within different regimes and leverage the Mixture model effectively. An impressive and rewarding learning endeavor!

MR CFD Support –

Thank you for your positive feedback on the MIXTURE Multiphase Model training package! We’re delighted to hear that you found the balance between theory and practical exercises useful for building a deep understanding of the Mixture model in ANSYS Fluent. It’s particularly gratifying to know that our detailed explanations and application-based examples provided you with both clarity and skills applicable to real-world engineering problems. We appreciate you taking the time to send such thorough compliments. Your success is what we value most at MR CFD Company, and we hope to continue supporting your learning journey.

Dawson Fay –

I’ve never worked with the MIXTURE multiphase model before. Do you think this training package would be a good starting point for someone like me who’s new to this concept?

MR CFD Support –

Absolutely, this CFD training package is designed to cater to users from beginner to advanced levels. Those new to ANSYS Fluent and the MIXTURE multiphase model will find the practical exercises especially helpful in building a foundational understanding. The step-by-step instructions and variety of included simulations are perfect for newcomers to get to grips with the software and the specific multiphase modeling techniques.

Jeramy Roberts –

I’ve just completed the ‘MIXTURE Multiphase Model’ training package with the practical exercises and I must say it was an incredibly enriching experience! The variety of simulations, from heat exchangers to scramjets, has significantly boosted my understanding of multiphase flow. The step-by-step guidance through each project has bridged the gap between theoretical knowledge and practical application for me. Well-structured and thorough—highly recommended for anyone looking to master CFD in ANSYS Fluent!

MR CFD Support –

Thank you so much for your heartfelt review! We’re delighted to hear that our training featuring the ‘MIXTURE Multiphase Model’ met your learning needs and helped enhance your understanding of multiphase flows in various applications. It’s great to know that the step-by-step instructions were helpful in your learning process. Your success is what drives us to provide the best learning resources possible. Please continue to enjoy our products and reach out if you have any further feedback or if we can assist you in any other way!

Mrs. Kelly Flatley I –

I recently completed the ‘MIXTURE Multiphase Model, CFD Training Package’ and was really impressed with the range of exercises and the depth of knowledge conveyed. The progression from beginner to advanced levels allowed me to build my understanding effectively. Plus, the practical application of concepts such as heat transfer in heat exchangers and flow behaviours in turbines gave me insights that I can implement right away in my work. Thank you for such a well-structured learning experience!

MR CFD Support –

Thank you very much for your kind words and for sharing your positive experience with the ‘MIXTURE Multiphase Model, CFD Training Package’. We’re thrilled to hear that you found the practical exercises and the progression through various difficulty levels beneficial to your understanding and professional applications. We appreciate your review and look forward to assisting you with any further learning needs in computational fluid dynamics.

Monica Bartell –

I’ve just finished all the exercises in the MIXTURE Multiphase Model training package and learned a lot. Thank you for the diversity and complexity in the exercises which covered different aspects of multiphase simulation.

MR CFD Support –

We’re thrilled to hear that you found the MIXTURE Multiphase Model training package beneficial and full of variety. We are happy that it enhanced your CFD simulation skills. Thank you for choosing our product and for sharing your positive experience!