Moving Mesh (Mesh Motion) Training Package, 10 Practical Exercises for ADVANCEDS

Original price was: $1,980.00.$660.00Current price is: $660.00. Student Discount

This product includes Geometry & Mesh file and a comprehensive Training Movie.

There are some free products to check our service quality.

To order your ANSYS Fluent project (CFD simulation and training), contact our experts via [email protected], online support, or WhatsApp.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Moving Mesh ANSYS Fluent CFD Simulation Training Package for ADVANCED Users

This training package includes 10 practical Moving Mesh exercises using ANSYS Fluent software. MR CFD suggests this package for ADVANCED users familiar with elementary Moving Mesh theories and simulation and wants to become professionals.

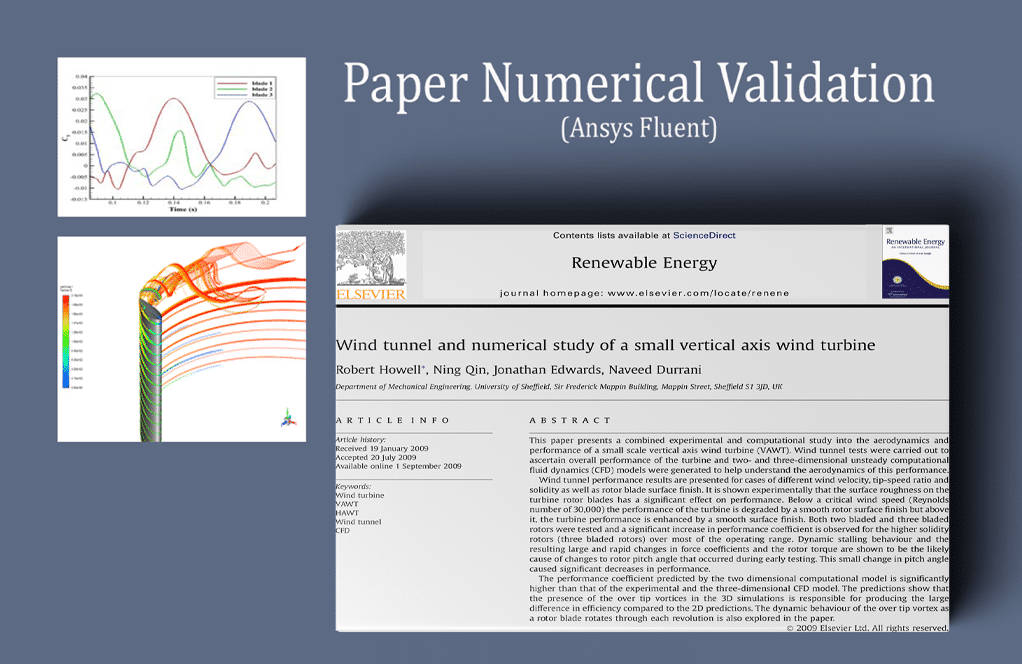

Paper Validation

Project number 1 simulates the airflow passing over an H-type Darrieus wind turbine. The simulation is based on a reference paper, “Wind tunnel and numerical study of a small vertical axis wind turbine.” Its results are compared and validated with the results in the article. In this project, the airflow enters the computational domain with a velocity of 5.07m/s, and the RNG k-epsilon model is exploited to solve the turbulent flow equations, as the paper stated.

Project number 2: Using a spherical turbine based on a lift-based in-pipe, this paper “Numerical analysis of lift-based in-pipe turbine for predicting hydropower harnessing potential in selected water distribution networks for waterlines optimization” model simulates the possibility of operating a power plant inside a pipe. Turbine hydrofoil profiles are manufactured using NACA airfoils. In this project, we intend to simulate the water turbine inside the pipe using the mesh motion method and compare the results with the results in the article. The mass flow is equal to 111 m^3/s, and the rotational speed is 153,626 rpm.

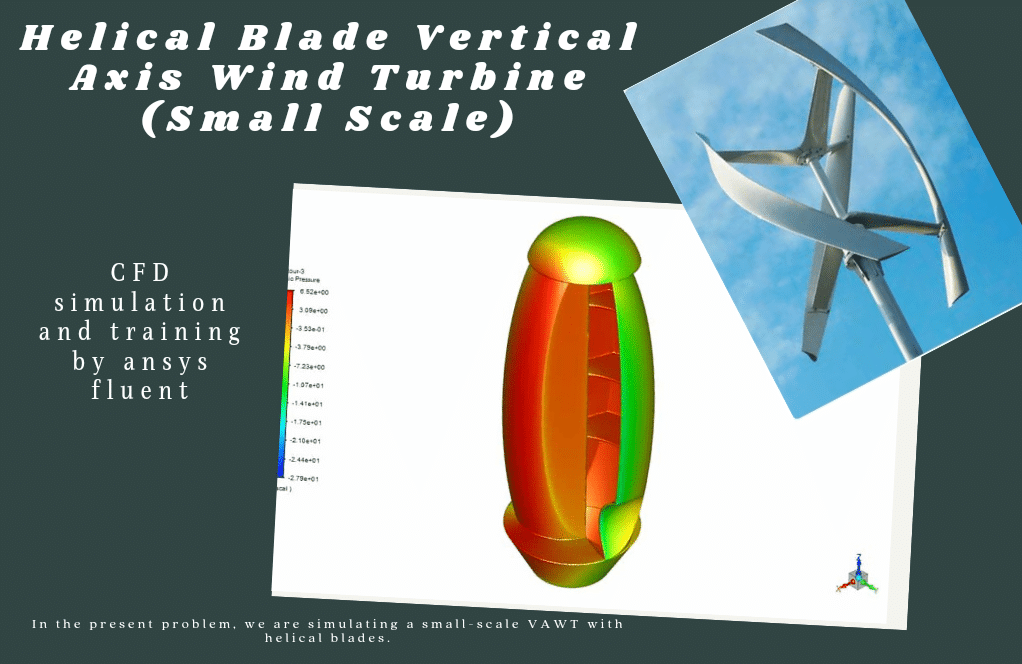

Wind Turbine

Vertical axis wind turbines were the first means of obtaining wind energy. In project number 3, We are simulating a vertical axis wind turbine (Helical Blade) with dimensions of 10 x 20 cm with an average diameter of 7 cm in the present. This simulation was performed at wind speeds of 2 m / s and speeds of 60-40-80-100-120 rpm, and torque was reported as output.

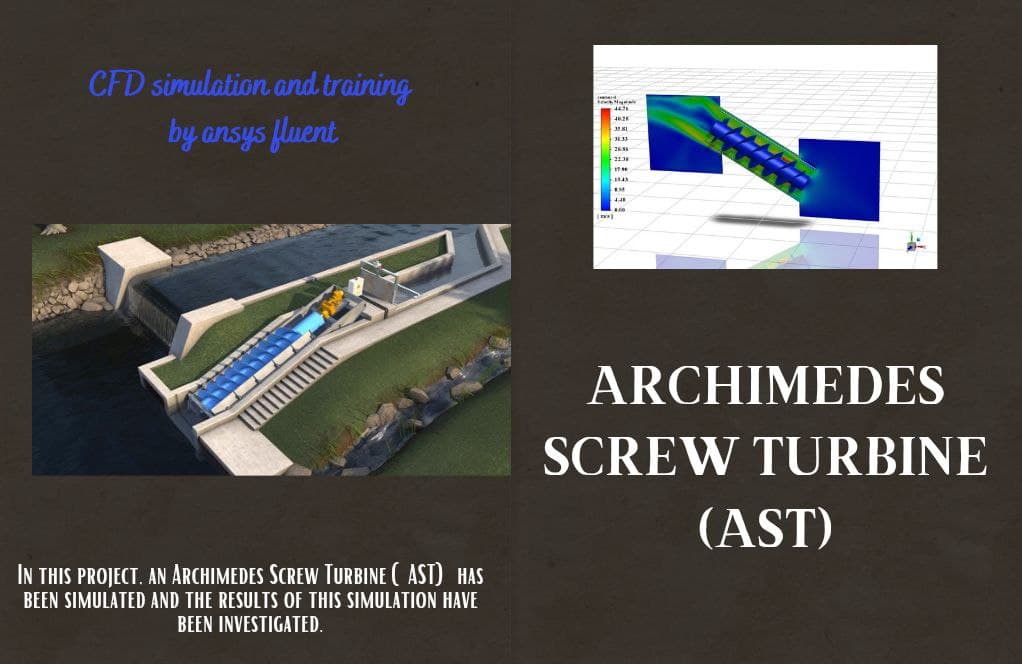

Archimedes Screw Generator

Archimedes Screw Generator, also known as Archimedes Screw Turbine (AST), or screw turbine, is a hydraulic machine that uses the principle of the Archimedean screw to convert the potential energy of flow on an upstream level into kinetic energy. In project number 4, an Archimedes Screw Turbine consisting of 3 blades is simulated in two models. The first model is an unsteady Frame Motion, and the second one is an unsteady Mesh Motion.

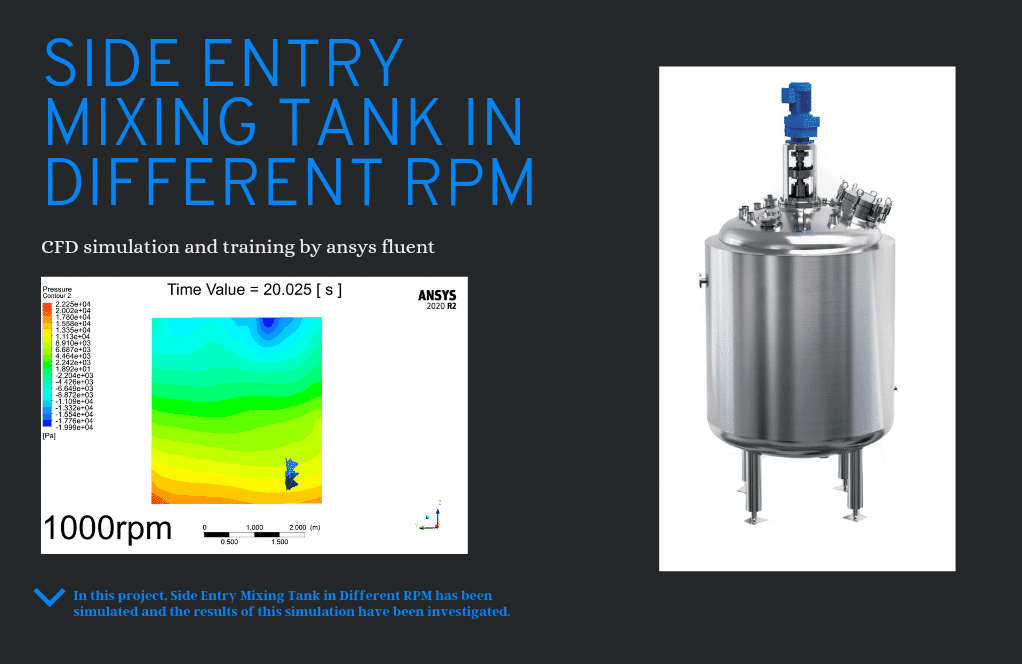

Mixing Tank

In project number 5, Side Entry Mixing Tank, which has been done by the CFD numerical simulation method, a mixing tank has been simulated. The mixing process is essential in many industries; for example, in the oil and gas industry, water deposition causes much damage to storage tanks, which causes corrosion, leakage, and perforation of the source. This simulation is performed with the Mesh Motion method at different rotational speeds of 400 and 900 and 1400 rpm.

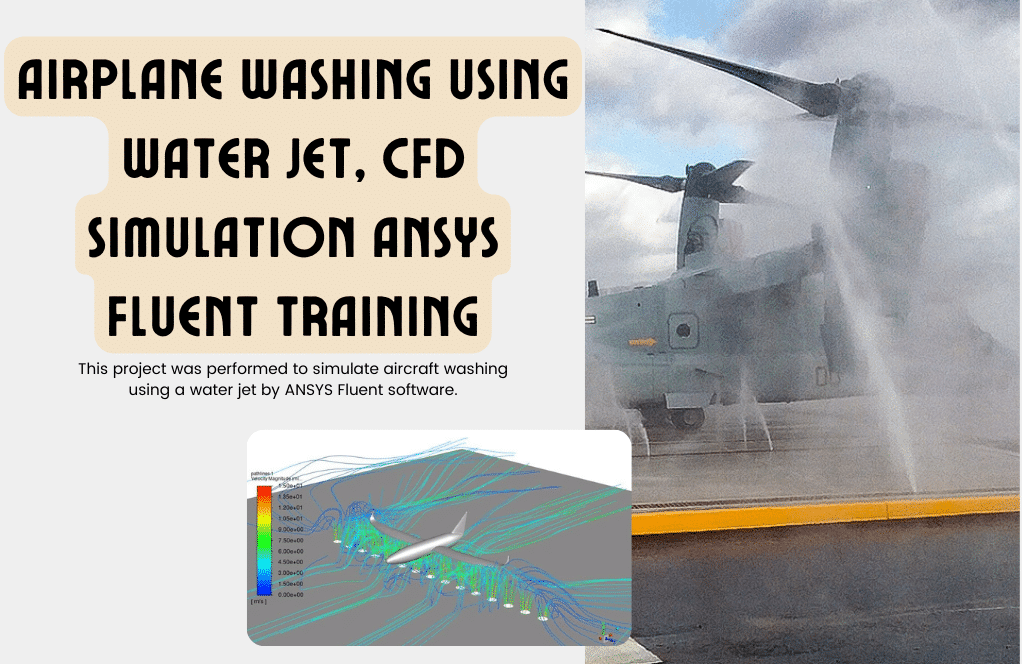

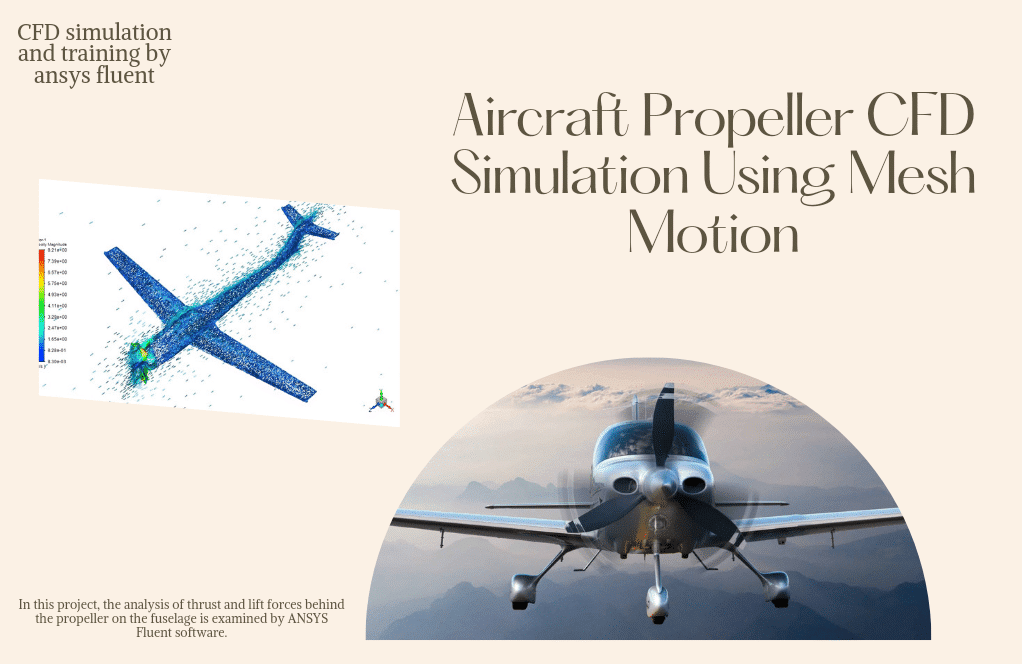

Aircraft

Propulsion is a device used to convert mechanical force into thrust in aircraft and ships. The movement of air or water provides the necessary thrust. A propeller consists of two or more twisted blades. When the propeller rotates around its axis, the lift produced by these blades moves the air horizontally. In project number 6, the thrust and lift forces analysis behind the propeller on the fuselage is examined.

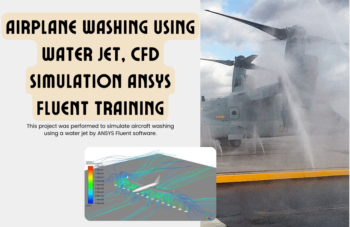

Airplane washing is done several times during the year. Airplane windows are also sensitive parts that can be easily scratched, and it is best to cover these parts before starting the washing process. Project number 7 was performed to simulate aircraft washing. The computational domain of a cube with dimensions of 46 x 8.5 x 17, in which a separate part is provided to move the sub-domain of the aircraft using the sliding mesh model. Water enters the computational domain through holes in the bottom of the slope at a speed of 15 meters per second and air in the opposite direction of the plane at a speed of 2 meters per second from the opposite side to model more realistic conditions.

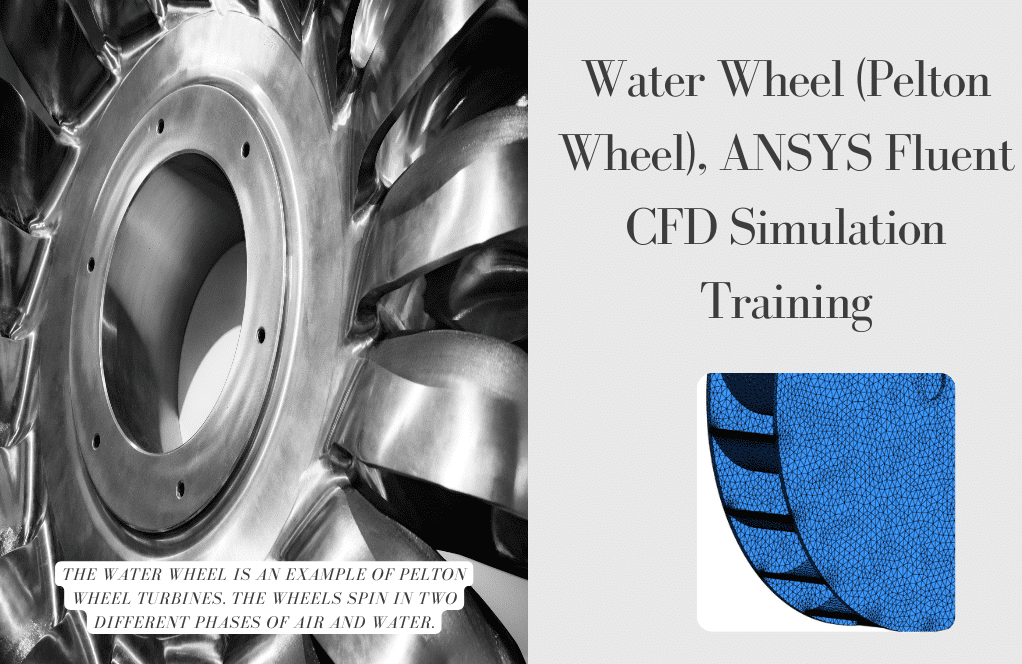

Pelton Wheel

The water wheel is an example of Pelton turbines. Most water wheels are mounted vertically on a horizontal axis and mounted horizontally on a vertical shaft. In project number 8, the rotational speed of the Pelton turbine is 60 rpm. The two-phase model also uses the VOF model. Water velocity is considered to be 3 to 5 m/s depending on the average river velocity. And accordingly, the rotational speed of the turbine should be calculated with no drag or bump in the flow.

Acoustic

Acoustics is a science that deals with the study of mechanical waves in gases, liquids, and solids, including vibration, sound, ultrasound, and infrasound. In project number 9, noise generation due to a ceiling fan in a room is investigated. The problem is simulated in two ways; at first, the Integral Method by Ffowcs Williams and Hawkings is used in which the fan is rotating by the Mesh Motion method at 240 rpm. In this case, the noise generation due to the collision between wind and the fan is examined using Method Based on the Wave Equation.

Sloshing

Project number 10 investigates the rotation of a cube containing water. The interaction of water and air inside the cube is modeled using the Volume of Fluid (VOF) multiphase approach. This project investigates the simplified sloshing effect in fluid containers where a situation similar to the one studied here can occur due to the acceleration of the carrier vehicle. A User Defined Function (UDF) defines the variable angular velocity of the cube’s rotation.

You can obtain Geometry & Mesh file and a comprehensive Training Movie that presents how to solve the problem and extract all desired results.

Forrest Schamberger –

Can this package be used to simulate the performance of hydraulic systems?

MR CFD Support –

Yes, one of the exercises included in this package focuses specifically on the simulation of hydraulic systems. The Mesh Motion methodology is ideal for such simulations as it can accurately capture the changing geometry of the system.

Tomasa Windler –

Can this package help me simulate the performance of reciprocating engines?

.

MR CFD Support –

Absolutely, the Mesh Motion methodology is well-suited for simulating the performance of reciprocating engines. One of the exercises included in this package specifically focuses on engine simulation

Maeve Hill –

I’m really pleased with the Moving Mesh (Mesh Motion) Training Package – the range of exercises provided a deep dive into various practical scenarios. It definitely enhances understanding of dynamic mesh applications in realistic CFD problems. The training materials, including the comprehensive videos, are top-notch for us advanced users.

MR CFD Support –

Thank you very much for your positive feedback! We’re thrilled to hear that our Moving Mesh CFD Simulation Training Package has been beneficial to you. At MR CFD, we take pride in providing in-depth learning resources to help advance our clients’ knowledge in the field. If you have any further queries or need assistance as you continue to work through our advanced exercises, don’t hesitate to reach out!

Lea Kuhic –

I’ve mastered some basic tutorials on moving mesh in Fluent, and your training package seems like the next logic step for me. Just curious, does it include any support material or guidance on how to handle any issues one might face while working on advanced problems?

MR CFD Support –

Absolutely! Our Moving Mesh Training Package for ADVANCED Users is designed to enhance your skills further with practical exercises. It includes detailed guidance on solving each project and a comprehensive training movie that navigates through problem-solving and result extraction. Additionally, should you encounter specific challenges while working through the examples, customer support is available to assist in clarifying issues and steering you closer to the solution.

Simone Kshlerin V –

I recently completed the

MR CFD Support –

Thank you for choosing to enhance your skills with our Moving Mesh (Mesh Motion) Training Package! It’s wonderful to hear that you’ve completed the course and found it helpful. Your feedback is highly appreciated, and we’re thrilled that our content has served its purpose in aiding your professional development. If you have specific insights or experiences from the course that you believe could benefit others, please feel free to share. We continually strive to provide valuable learning experiences for all users.

Bertha Langworth –

The practical exercises in this package look comprehensive, but I am wondering if it includes guidance on how to optimize mesh for moving mesh simulations?

MR CFD Support –

The Moving Mesh (Mesh Motion) Training Package is designed to provide you with advanced insight into setting up and solving moving mesh simulations. The package typically includes guidance on how to refine and optimize the mesh to ensure accurate and efficient results for complex motions.

Prof. Hiram Prosacco –

The Advanced Moving Mesh Training Package sounds highly technical and hands-on. Did you find the Training Movie included in the package to be sufficient in explaining how to solve the problems and extract results? Were there any particular areas you think could use additional videos or explanations?

MR CFD Support –

Thank you for your inquiry about the Moving Mesh Training Package. The Training Movie provided is designed to be comprehensive, covering each step of the problem setup and solution process. It aims to guide users through the methods of extracting all necessary results effectively. If you find any topic within the package that you feel could benefit from a more detailed explanation or additional video content, please don’t hesitate to let us know which area and we’ll consider enriching our training materials to better satisfy our advanced users’ needs.

Prof. Katherine Harvey –

The package seems really comprehensive! Just curious, how difficult was it for you to follow along and reach the advanced-level practices outlined in the training?

MR CFD Support –

I’m thrilled to hear that you’re curious about the learning process. Honestly, it was very manageable for me to get to the advanced-level exercises. The structured sequence of projects and detailed movies really helped to cement my understanding each step of the way, ensuring I became proficient in using the Moving Mesh technique within ANSYS Fluent. Very satisfying learning journey!

Devan Bayer –

I’m thrilled with the comprehensive detail and variety provided in this Moving Mesh training package! Having access to 10 diverse real-world simulations is fantastic. The projects cover a broad spectrum and seem perfectly tailored for someone like me who wants to deepen expertise in CFD applications. It’s clear that considerable effort has gone into designing these exercises to reflect challenges faced in academia and industry. A brilliant resource for any CFD enthusiast looking to step up their game!

MR CFD Support –

We’re delighted to hear that our Moving Mesh training package for advanced users meets your expectations! We strive to curate our exercises to offer challenging and realistic scenarios that simulate real-life applications. Your feedback is greatly appreciated, and we’re proud to support passionate CFD professionals like you in advancing their skills. Thank you for choosing our training package, and we wish you the best in your continued learning journey!

Noemy Wyman –

The detailed descriptions of the projects make me very excited to learn! But could you please explain the technical support system if I need help with a specific project in this package?

MR CFD Support –

MR CFD provides continuous technical support for our learning products. If you encounter any issues or need clarification on a specific project in the package, you can reach out to our support team, and they will assist you with expert advice to ensure you have a smooth learning experience.

Santina Lindgren –

What kind of solver settings are included in this package?

MR CFD Support –

The package includes a range of solver settings to control the simulations. These include settings for the time step, convergence criteria, and solver type, as well as for the turbulence, heat transfer, and multiphase flow models.

Prof. Agustin Mertz DVM –

I’ve been trying to apply moving mesh in my simulations but trouble always comes up with mesh deformation or negative volume errors. Does this advanced training package provide strategies for handling such issues?

MR CFD Support –

Absolutely, handling mesh deformation and preventing negative volume errors are critical aspects of moving mesh simulations. This advanced training package includes practical examples and techniques on how to manage mesh movement, dynamic layering, and refining your mesh motion method to avoid negative volumes or excessively skewed elements.

Katheryn Vandervort –

I’m really appreciative of the variety in the 10 practical exercises in the Moving Mesh training package. The multidisciplinary applications, from wind turbines to Pelton wheels, show a depth that offers something for ADVANCED users in various fields to benefit from. The clear mention of validation against research articles provides confidence in the methodology and the results produced.

MR CFD Support –

Thank you for your positive feedback on our Moving Mesh training package. We’re delighted to hear that you found the variety of exercises valuable and the validation process credible. Your satisfaction is our goal, and we hope the package continues to enhance your CFD skills.

Jameson Effertz –

I am thoroughly impressed with the comprehensive Moving Mesh training package. It covers various practical scenarios, touching on different industry applications. The detailed understating of dynamic simulations with moving boundaries is fantastic. Having access to geometric & mesh files along with the training video make it easy to follow along and apply different methods right away.

MR CFD Support –

Thank you for your kind review. We’re delighted to hear that the training package has met your advanced learning needs. Your appreciation for the hands-on and diverse application approach encourages us to continue providing high-quality learning products. If you ever need further assistance or have questions as you progress, don’t hesitate to reach out to us.

Felicia Davis –

I found the training package to be innovative and diverse. It helps that there’s a good mix of both common applications like wind turbines and more unique scenarios like the sloshing cube. This not only broadened my understanding of fluid dynamics in different settings but also expanded my skills in using the mesh motion techniques. Great learning tools!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our Moving Mesh Training Package for ADVANCED users was able to enhance your understanding of fluid dynamics applications and improve your ANSYS Fluent skills. Your feedback is greatly appreciated, and we aim to continue providing high-quality and diverse learning experiences. If you ever have more questions or need further assistance, don’t hesitate to reach out!

Erwin Klein DDS –

How does this package manage the simulation of thermal transfer in machinery with components in motion?

MR CFD Support –

This package incorporates the energy equation to facilitate the simulation of thermal transfer in machinery with moving components. This ensures a precise simulation of the distribution of temperature and the influence of heat transfer on the machinery’s performance.

Angeline Quigley –

The training package seems comprehensive! I’m impressed by the wide variety of applications. Just curious, is the CFD simulation for the architectural Archimedes Screw Turbine different when using unsteady Frame Motion vs. unsteady Mesh Motion? How exactly do the methodologies differ?

MR CFD Support –

In project number 4, two separate models are utilized for the Archimedes screw turbine to understand the dynamic behavior of the fluid-structure interaction. Using unsteady Frame Motion involves fixing the mesh and observing the turbine’s movement within, while the unsteady Mesh Motion simulations involve physically moving the mesh with the turbine blades. This difference allows us to compare the fluid dynamics and the turbine’s mechanical response under different simulation contexts and provides a richer learning experience regarding fluid-structure interactions.

Vicente McCullough I –

I’ve gone through several of the projects in the Moving Mesh (Mesh Motion) Training Package and I’m truly impressed with the diversity of applications covered. The subtle complexity blended with advanced features in ANSYS Fluent made me both more skilled and confident in my CFD work relating to dynamic mesh problems. Your hands-on exercises, particularly the aircraft wash simulation, provided practical insights that are hard to come by in standard textbooks or online courses. Also, the mesh quality in each project complimented the sophistication of the simulations quite well. I just wanted to drop a note here to express my gratitude!

MR CFD Support –

We’re delighted to hear that our Moving Mesh (Mesh Motion) Training Package for ADVANCED Users has significantly enhanced your skills and confidence in dynamic mesh simulations with ANSYS Fluent! Your acknowledgment, especially regarding the diversity and practicality of the applications like the aircraft wash simulation, is much appreciated. We take pride in delivering high-quality educationals assets and support to our learners. Thank you so much for your positive feedback and for choosing MR CFD for your CFD learning journey.

Lauriane Pouros –

I’m really fascinated by how diverse the training package seems! From wind turbines to acoustic analysis—it sounds thorough. I’d like to know if the package includes both the simulation setup instructions and analysis of the results?

MR CFD Support –

Thank you for the positive feedback on our product’s diversity! Yes, the training package is comprehensive and provides detailed instructions for simulation setup as well as thorough guidance on how to analyze the results for each different case in the 10 practical exercises. You will receive Geometry & Mesh files alongside a Training Movie that demonstrates how to approach the problems and extract all necessary outcomes.

Mr. Jamie Satterfield DVM –

The Moving Mesh Training Package seems incredibly comprehensive. Could you clarify if the package includes any post-processing tutorials on how to visualize and interpret the results of complex dynamic mesh simulations?

MR CFD Support –

Yes, the Moving Mesh Training Package includes comprehensive tutorials that provide guidance on post-processing as well. These tutorials demonstrate different visualization techniques and interpretation methods to analyze the results of dynamic mesh simulations effectively.

Amelie Johnson –

I am deeply impressed with the wide variety of applications covered in the Moving Mesh Training Package for advanced users. It was enlightening to see principles explained and then immediately applied into so many different practical scenarios. From Wind Turbines to Mixing Tanks and even Acoustic analysis, this package has offered a rich learning experience for those wanting comprehensive immersion in CFD techniques. The clear instructions and structured approach made the learning process both enjoyable and highly useful. Kudos to MR CFD for assembling such a valuable resource!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our Moving Mesh Training Package met your expectations and provided you with a wide spectrum of practical CFD applications. It’s great to know that the content and structure were beneficial to your learning experience. We aim to deliver high-quality resources to our users, and your review confirms that we are on the right track. If you need any further guidance or support, please feel free to reach out to us.

Dr. Zakary Schmidt –

I recently completed the Moving Mesh Training Package and found Project number 7 really fascinating. I’d love to know why in Project 7 different washing media velocities were specified?

MR CFD Support –

Thank you for the kind words! In Project 7, specifying different velocities for the washing media is crucial to mimic realistic aircraft washing conditions. The use of water at a higher velocity represents the pressure washing action, which effectively cleans the aircraft surface, while the contrasting airflow simulates the ambient wind conditions that the cleaning process might have to contend with in a real-world outdoor environment.

Mr. Shaun O’Connell V –

The comprehensive coverage of moving mesh scenarios in diverse applications is commendable. The practical exercises extend from wind turbines to water wheels, demonstrating versatility and depth. Excited to dive deeper and learn advanced mesh motion techniques!

MR CFD Support –

Thank you for your kind words! We are delighted to hear that you’re excited about the training package. At MR CFD, we do our best to cover a wide range of applications to give our users a deeper understanding of different moving mesh scenarios. We’re sure you’ll benefit greatly from these advanced exercises!

Aida DuBuque PhD –

How does this package handle the transition between the stationary and moving meshes?

MR CFD Support –

This package uses advanced mesh deformation and remeshing techniques to handle the transition between the stationary and moving meshes. This allows for an accurate simulation of the interaction between the stationary and moving components.

Prof. Otto Reinger II –

The modular nature of these practical exercises seems excellent for understanding diverse applications. I’m particularly interested in how this package can enhance visualization and analysis skills in complex simulations where moving mesh is crucial.

MR CFD Support –

Thank you for your kind words and observations! We’re glad to hear that you see the value in the practical exercises included in our Moving Mesh Training Package for advanced ANSYS Fluent users. These exercises are indeed designed to challenge and develop users’ skills in simulation, visualization, and analysis within various complex scenarios. We’re always here to support learners in taking their CFD expertise to the next level!

Susana Bradtke –

Was the Pelton wheel simulation results aligning well with theoretical expectations for simulation number 8?

MR CFD Support –

In general, the simulations performed with ANSYS Fluent and included in MR CFD’s training packages are rigorous and strive for accuracy against theoretical or experimental benchmarks. It can be expected that the Pelton wheel simulation within Project number 8 provided in the Moving Mesh (Mesh Motion) Training Package produced results that closely align with theoretical expectations, but for verification, users would typically compare them with existing literature or experimental data provided in the source material.

Bud Kovacek Sr. –

The training package sounds detailed and well thought out. The variety of applications, from wind turbines to washing aircraft and sloshing effects, offers ADVANCED users a broad spectrum of real-world CFD scenarios. It’s obvious that the included UDFs and the focus on practical exercises will be invaluable for skill enhancement. The inclusion of a paper validation project adds a layer of reliability and suggests that the training has a strong foundation in contemporary research. Excited to delve into these exercises and further refine my CFD analysis techniques!

MR CFD Support –

Thank you for your review and for recognizing the scope and depth of our Moving Mesh (Mesh Motion) Training Package specifically tailored for ADVANCED users. We’re thrilled to hear that you appreciate the incorporation of various real-world applications that offer practical, hands-on learning experiences. It’s wonderful to know you’re looking forward to applying these exercises to hone your skills. Our team is always here to support you through your learning journey, and we hope you find the training both challenging and rewarding. Should you need any assistance, please reach out to us. Happy learning!

Ronny O’Hara –

I’m thrilled with the depth covered in the Moving Mesh (Mesh Motion) Training Package. The range of projects from wind turbines to acoustic studies shows that MR CFD is dedicated to providing advanced users with multifaceted insights. Each project feels substantial, especially with the user-defined functions and system coupling. This package has undeniably sharpened my skills.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the Moving Mesh Training Package has been able to provide valuable insights and improve your computational skills. Our goal is to support advanced users like you in deepening your understanding and application of CFD in diverse scenarios. If you have any further inquiries or need additional support, please don’t hesitate to contact us.

Wayne Koss Jr. –

I’ve been going through the simulations one by one, and they’ve been incredibly insightful! I particularly enjoyed the fine details in simulation 3 involving the vertical axis wind turbine. The range of operating speeds provided a deep understanding of the performance under different conditions. This package is an amazing resource for anyone looking to dive deep into CFD for moving meshes!

MR CFD Support –

Thank you so much for your kind words! It’s great to hear that the training package is serving its purpose and that you found the simulations, especially on the vertical axis wind turbine, insightful and educational. We’re glad you appreciate the level of detail in our exercises. Should you require any further information or wish to continue enhancing your skills, please don’t hesitate to explore our other training packages.

Elmer Pollich –

This package of advanced Moving Mesh exercises sounds very comprehensive. Could you clarify whether the necessary UDFs (User Defined Functions) for complex mesh motion are included for each exercise or if we need to program them ourselves?

MR CFD Support –

In this advanced package, the necessary UDFs for the mesh motion simulations have already been provided and configured to match the requirements of each specific exercise. You won’t need to program any custom UDFs yourself; they’re all part of the comprehensive resources included to ensure a smooth learning experience.

Dr. Barney Johnston II –

I love the variability of the projects in this training package! The practical exercises seem tailored for enhancing advanced skill sets in CFD.

MR CFD Support –

We’re delighted that you find our Moving Mesh Training Package for ADVANCED users comprehensive and beneficial! Thank you for the positive feedback.

Mr. Vinnie Adams PhD –

I recently completed the ‘Moving Mesh (Mesh Motion) Training Package’ and I have to say, it exceeded my expectations! As an advanced user, I was looking for materials that could help me deepen my understanding and hone my skills further, and this package delivered just that. The variety of projects ranging from aerodynamics to hydrodynamics simulations provided a robust learning experience. Moreover, the project based on the actual paper validation was particularly engaging, giving me a sense of confidence in applying these methods to real-world scenarios. Fantastic work by the MR CFD team!

MR CFD Support –

We greatly appreciate your detailed review and are thrilled to hear that the ‘Moving Mesh (Mesh Motion) Training Package’ not only met but exceeded your expectations. Our aim is to provide a comprehensive learning experience that can take advanced users to professional levels, and your feedback confirms that our efforts are hitting the mark. Thank you for recognizing the variety and real-world applicability of the projects included. Your success is our success, and we look forward to continuing to support your CFD learning journey! If you have any more feedback or require further assistance, please do not hesitate to reach out.

Dr. Samara Kautzer III –

This comprehensive training package seems ideal for advancing my Moving Mesh CFD skills. Just a question though, are the exercise files compatible with the latest version of ANSYS Fluent?

MR CFD Support –

Yes, all of the files included in the Moving Mesh ANSYS Fluent CFD Simulation Training Package are updated and fully compatible with the latest version of ANSYS Fluent, ensuring a smooth and seamless learning experience for you.

Prof. Dave Kiehn –

The acoustic simulation for the ceiling fan mentions two methods, Integral Method by Ffowcs Williams and Hawkings and Method Based on the Wave Equation. Could you explain a bit more about how each method contributes to analyzing the noise generation in this context?

MR CFD Support –

The Integral Method by Ffowcs Williams and Hawkings is a widely-used approach for calculating noise generated by rotating machines like fans. Its strength lies in accounting for the noise induced by the interaction between the moving blades and the airflow. On the other hand, the Method Based on the Wave Equation deals with noise propagation through the air following the sound source’s disturbance. Together, these methods provide comprehensive insights into both the source of the sound – the fan’s interaction with air – and how this sound spreads and is experienced in the surrounding space.

Mr. Lucas Streich –

This training seems comprehensive! The practice with different applications like wind turbines, mixers, and aircraft is perfect sensor the range of impacts

MR CFD Support –

Thank you for your kind feedback! We’re delighted to hear you find the training comprehensive and cover a wide range of applications. If you ever have any specific questions or need further assistance while working through the exercises, don’t hesitate to contact us.