Turbomachinery CFD Training Package, Expert Users, 10 Learning Products

Original price was: $2,300.00.$767.00Current price is: $767.00. Student Discount

This CFD training package is prepared for EXPERT users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Turbomachinery CFD Simulation Package, 10 ANSYS Fluent Training for EXPERT Users

This CFD training package is prepared for EXPERT users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

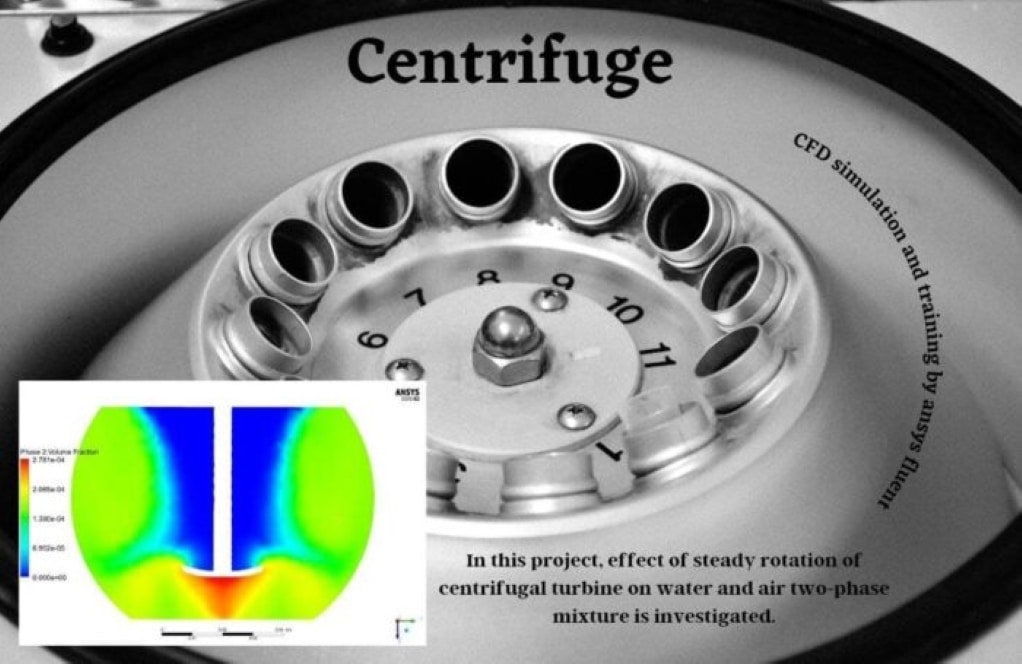

Centrifuge

In Project 1, the effect of steady rotation of a centrifugal turbine on a water and air two-phase mixture is investigated. The MIXTURE multiphase model is used to solve water and air phases interactions. The secondary phase (air) volume fraction has very low values in the 0.0001 order which proves the validity of the mixture multiphase model in this project since for applying the Mixture Multi-Phase model the secondary phase volume fraction should be less than 15%.

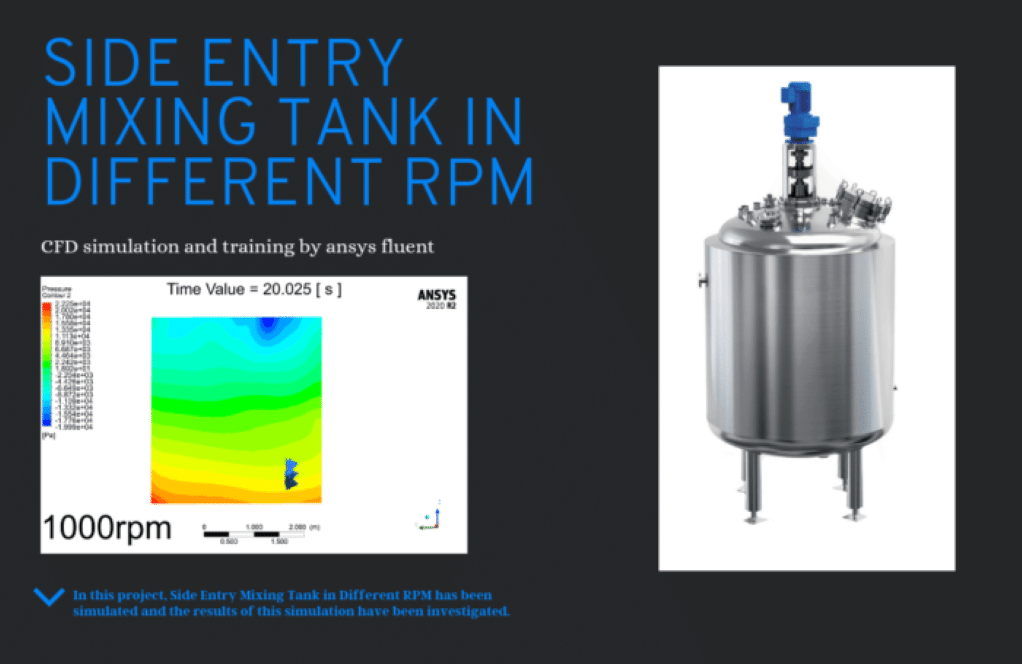

Mixer

In Project 2, Side Entry Mixing Tank in Different RPMs has been simulated. The mixing process is essential in many industries; for example, in the oil and gas industry, water deposition causes much damage to storage tanks, which causes corrosion, leakage, and perforation of the source.

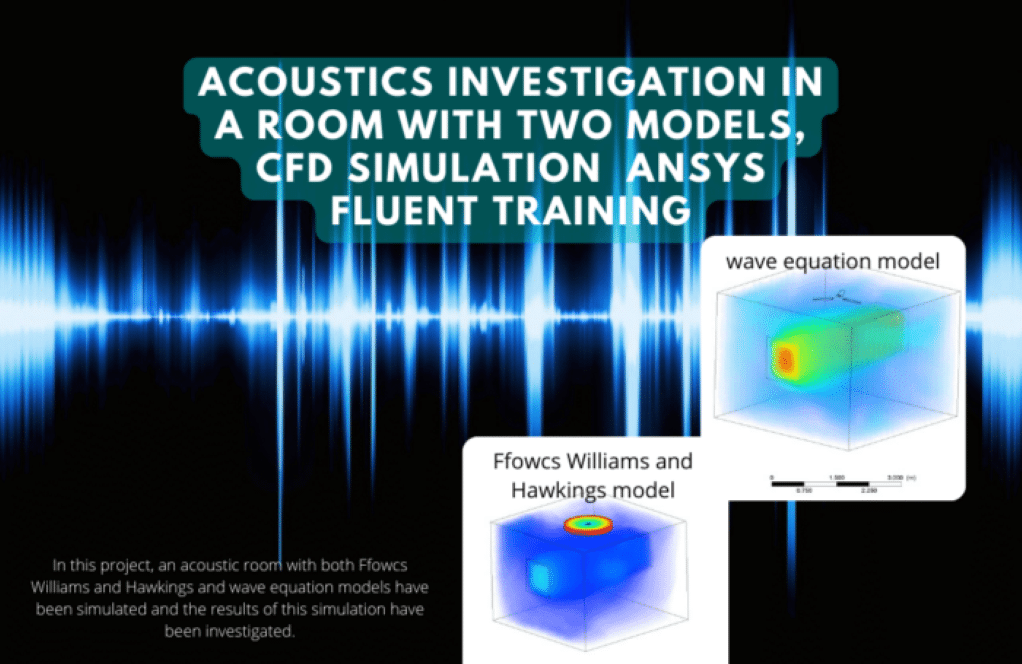

Acoustic (Turbomachinery)

In Project 3, noise generation due to a CEILING FAN in a room is investigated. There is a 3d square shape room in which exists a fan in it. Also, there are two square windows considered as inlets and outlets in which wind is blowing inside by the incoming velocity of 3 m/s.

Problem 4 simulates the airflow inside a turbojet and examines the acoustic wave and the sound produced inside this TURBOJET. The model includes a turbojet that has a fan in its inlet. This fan is rotating at 2000 rpm and around the X-axis in the current model.

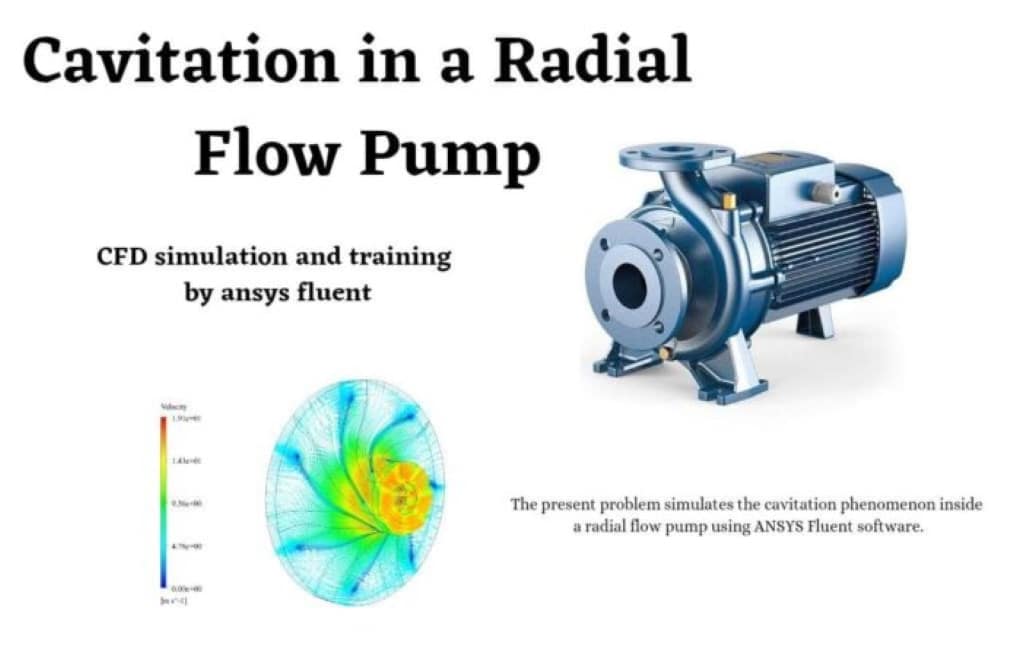

Cavitation (Turbomachinery)

Problem 5 simulates the Cavitation phenomenon inside a Radial Flow Pump. This pump is of the centrifugal pump (radial flow) type; In this way, the desired fluid enters it parallel to the central axis and exits it radially or perpendicular to the inlet path.

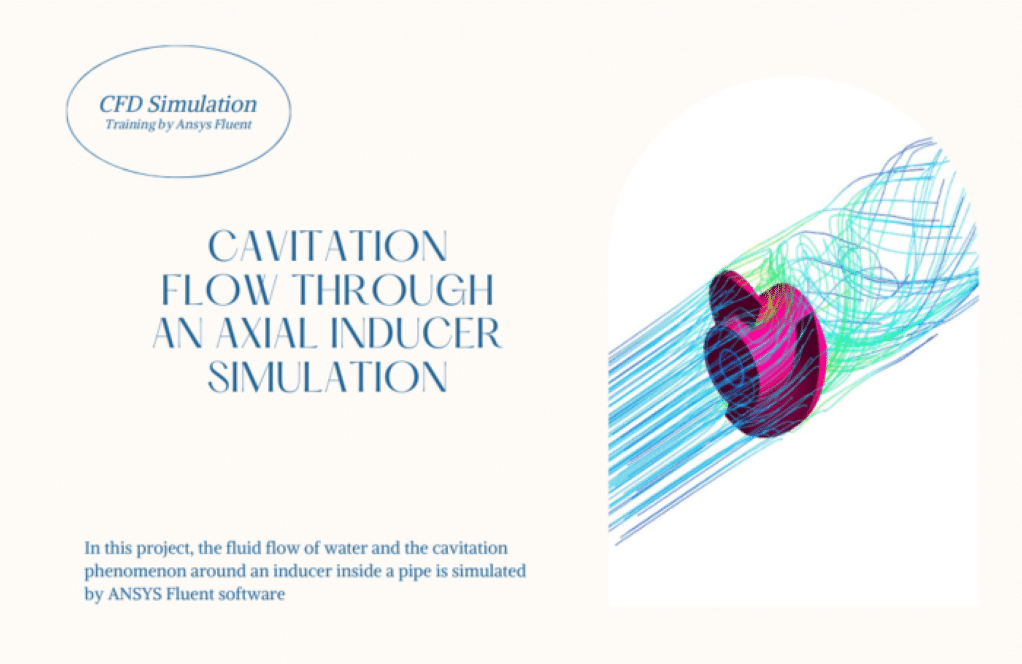

In Project 6, the fluid flow of water and the Cavitation phenomenon around an INDUCER inside a pipe is simulated. The cavitation phenomenon is one of the phenomena that vapor bubbles are formed in the part of the fluid whose pressure is low. The phenomenon of cavitation can cause many problems, including corrosion.

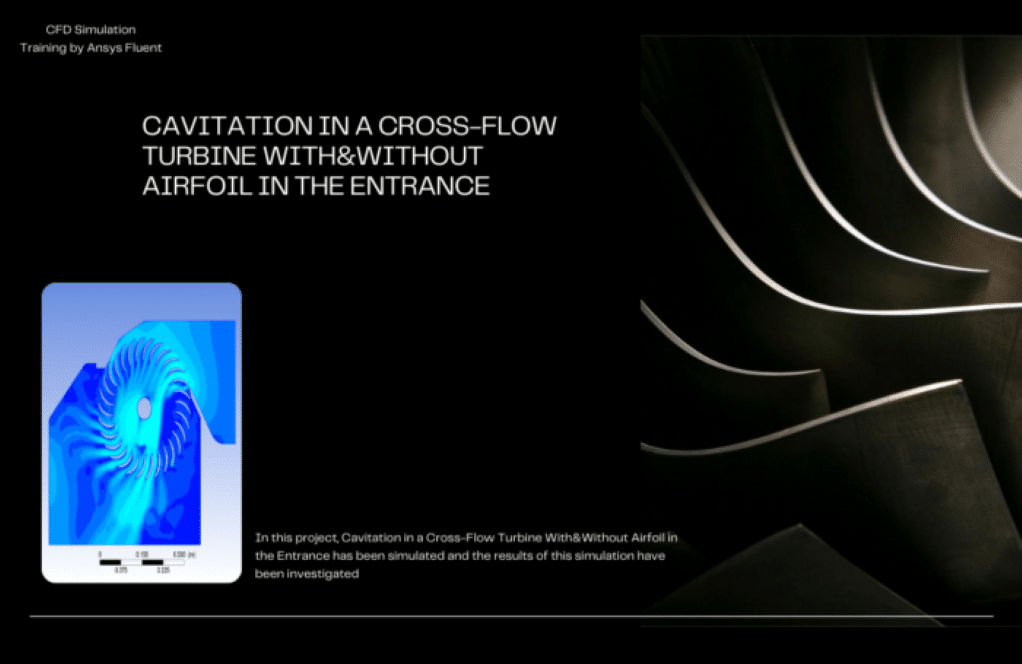

In project 7, which has been done by the CFD numerical simulation method, cavitation has been simulated in a cross-flow turbine. Unlike most turbines where the flow is axial or radial, the fluid flows crosswise. This type of turbine has a low speed and is used for places where low head and high flow are required.

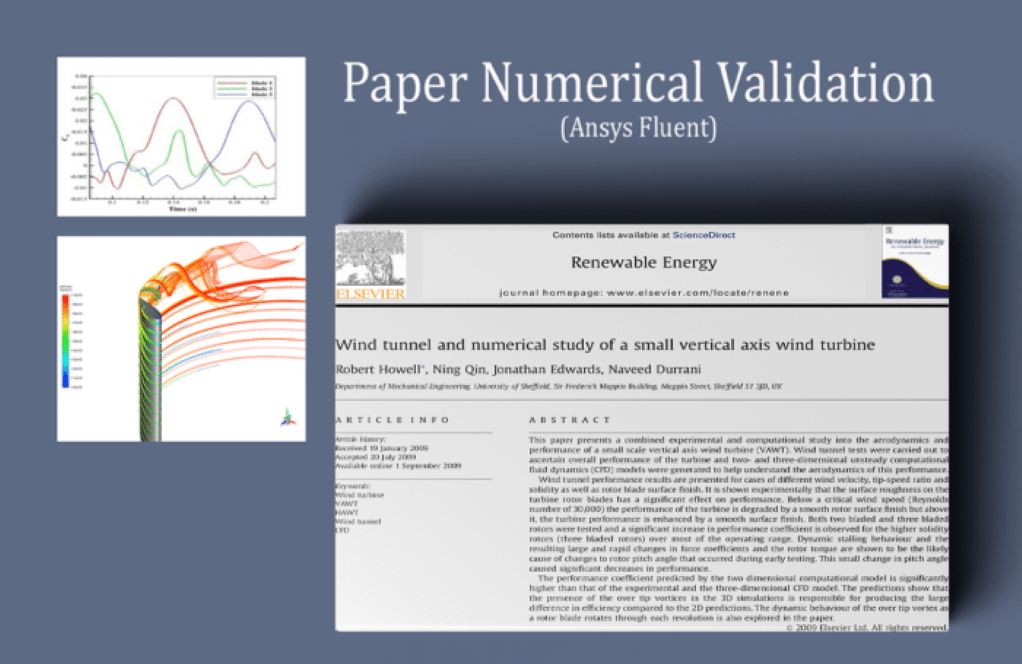

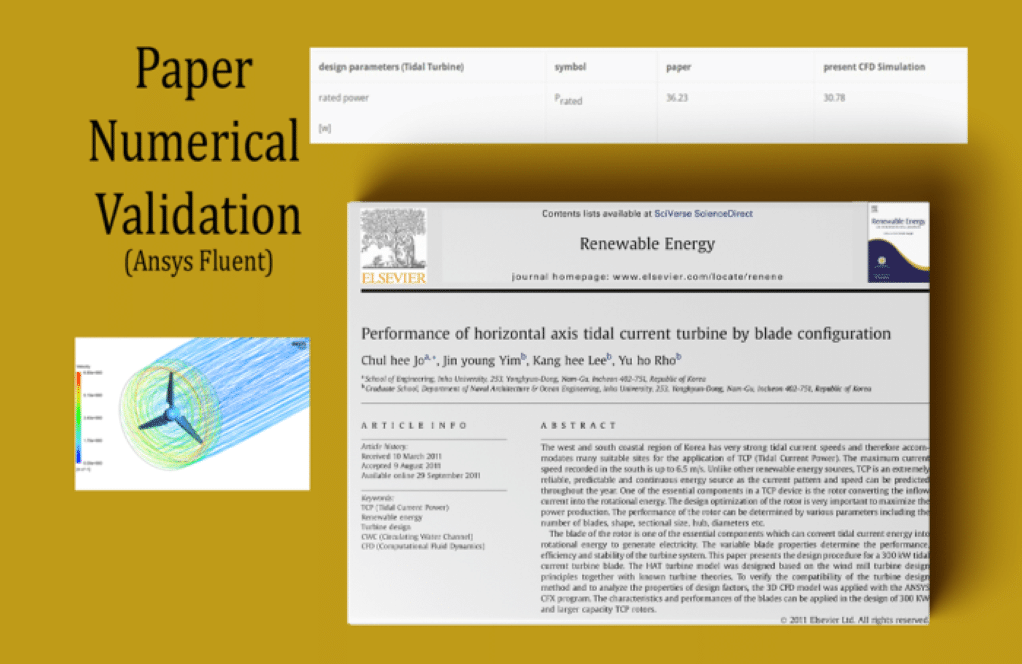

Paper Numerical Validation

Problem 8 simulates the airflow passing over an H-type Darrieus wind turbine. The simulation is based on a reference paper, “Wind tunnel and numerical study of a small vertical axis wind turbine.” Its results are compared and validated with the results in the article. In this project, the airflow enters the computational domain with a velocity of 5.07m/s, and the RNG k-epsilon model is exploited to solve the turbulent flow equations, as the paper stated.

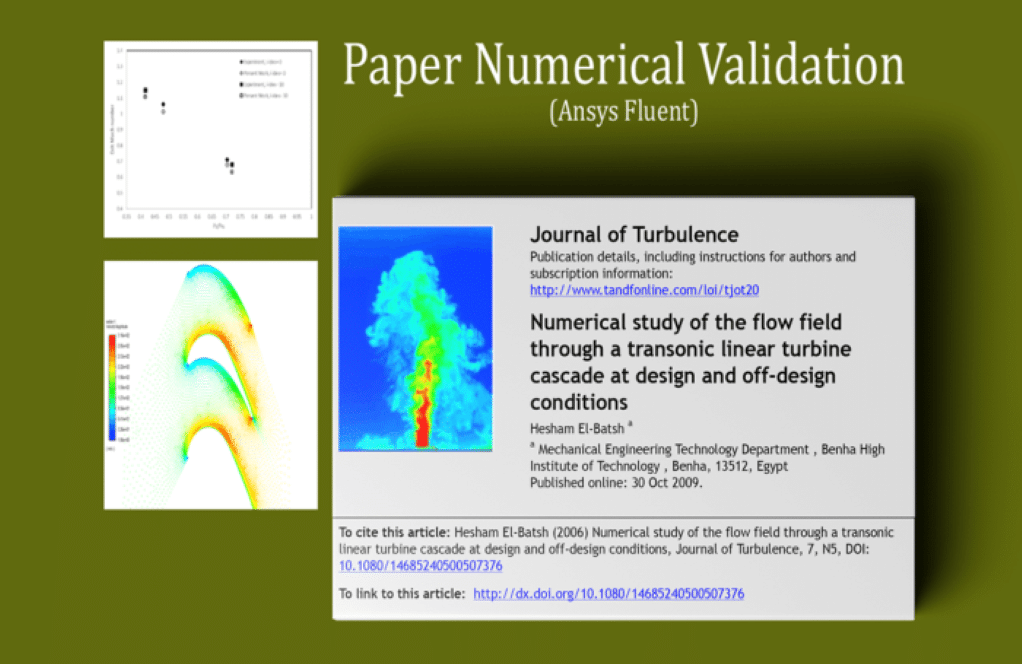

Problem 9 simulates the two-dimensional compressible flow field through a transonic linear turbine cascade. The present project’s results are compared with the experimental results of the paper “Midspan Flow-Field Measurements for Two Transonic Linear Turbine Cascades at Off-Design Conditions”. Turbulence modeling and Computational procedures (boundary conditions, etc.) are simulated based on the article “Numerical study of the flow field through a transonic linear turbine cascade at design and off-design conditions”.

Finally, project 10 simulates the rotational water flow around the blades of the horizontal axis water turbine and the result is compared and validated with the results of the article “Performance of horizontal axis tidal current turbine by blade configuration“. There are two areas around the blades for water flow; Thus, an area is considered as a cylindrical shape just around the blades and a rectangular cube area with a larger scale around this cylinder.

[/vc_column_text][/vc_column][/vc_row]

Angelica Langosh –

Can this package help me understand the effects of different blade designs on the performance of turbomachinery?

MR CFD Support –

Definitely! Our package can simulate the effects of different blade designs on the performance of turbomachinery.

Joey Borer –

I’ve learned so much from the Turbomachinery CFD Training Package! The variety of projects from mixers to cavitation and acoustic simulations has been incredible. It’s like each project challenged me with a new aspect of fluid dynamics. I’m particularly impressed with how the cavitation phenomena are handled and presented in Project 5 and Project 6. Thank you for such a well-rounded and comprehensive training experience.

MR CFD Support –

We’re thrilled to hear that you have had a great learning experience with our Turbomachinery CFD Training Package! It’s wonderful to know that the diverse range of projects enriched your understanding of complex fluid dynamics and that you appreciated the treatment of specific phenomena like cavitation. Your feedback is greatly valued, and we thank you for taking the time to share your positive review. If you ever need further support or wish to delve deeper into any aspect of turbomachinery CFD, don’t hesitate to reach out to us. Thank you once again!

Tad Wilderman –

The mixture model used for simulating the two-phase mixture in a turbomachinery environment is impressive. I’m curious, how are the finer details of turbulence and phase interactions captured using this model, and what post-processing capabilities does this package offer to visualize the intricate flow patterns?

MR CFD Support –

In the Turbomachinery CFD Training Package, the MIXTURE model assists in resolving the flow of multiphase scenarios where there’s a dominant continuous phase and one or more dispersed minor phases. Turbulence is resolved using appropriate turbulence models tailored to capture the unique characteristics of such complex flows. As for post-processing capabilities, ANSYS Fluent provides extensive tools for visualizing flow patterns, including contour plots, vector fields, particle tracking for phase distribution, as well as animations for dynamic results. Expert users can extract detailed insights from simulations to study phenomena such as phase segregation, mixing effectiveness, and affected turbulence structures.

Bria Reynolds –

In project 6, how is the cavitation modeled around the inducer in the pipe, given the complexities of cavitation phenomena?

MR CFD Support –

In project 6, the cavitation around the inducer in the pipe is modeled using a dedicated cavitation model available in ANSYS Fluent, which can capture the phase change from liquid to vapor and back due to pressure changes in the fluid flow. The model accounts for vapor bubble formation and collapse, typically by considering the pressure drop below the vapor pressure of the fluid, and by applying transport equations that describe the vapor volume fraction within the flow.

Brionna Hilpert –

Can this package help me simulate the effects of different types of seals on turbomachinery leakage and performance?

MR CFD Support –

Yes, it can! The package includes exercises that focus on the simulation of different types of seals, a critical aspect in controlling leakage and optimizing turbomachinery performance.

Miss Baby Becker –

I find the in-depth approach taken in these simulations to be impressive, particularly in examining real-world turbulence and cavitation behaviors in turbomachinery. The validation against academic papers provides great confidence in the accuracy of these training modules.

MR CFD Support –

Thank you so much for your kind words! We are thrilled to hear that our attention to detail and rigorous validation process have contributed positively to your learning experience. We strive to provide accurate and comprehensive training for expert users like yourself and are glad it is reflected in our turbomachinery package. If you have any further feedback or questions, we would love to hear from you.

Prof. Jett Jerde –

The Expert package sounds comprehensive! Can I only purchase individual components if I’m interested in specific projects like acoustic or cavitation modeling, or is the package sold as a whole?

MR CFD Support –

Currently, our training package is offered as a whole to provide a complete learning experience covering various aspects of turbomachinery CFD simulations. This integrated approach allows learners to understand the interactions between different physics and modeling techniques in turbomachinery. Nonetheless, for tailored learning paths or specific project interests, feel free to reach out for potential options. We strive to accommodate our users’ educational needs where possible.

Elias Crooks –

The Turbomachinery CFD package seems comprehensive. It appears to offer real practical experience from centrifuge to cavitation experiments. I look forward to applying this advanced training in my future projects!

MR CFD Support –

Thank you for your positive review. We’re delighted to hear that you find our Turbomachinery CFD Training Package for Expert Users comprehensive and valuable for practical experience. It’s great to know you’re excited about applying this knowledge to your future projects. If you have any questions while working through the projects, please don’t hesitate to reach out to our support team.

Mrs. Linnea Brakus –

Extremely pleased with the training package. Each project provided distinct scenarios, equipping me with the skills to handle complex simulations in turbomachinery. The practical exercises solidified my understanding of multiphase flows and acoustic analysis, meanwhile simulation verification against well-documented papers boosted my confidence in the accuracy of my work.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that the training package was beneficial to you and provided comprehensive learning experiences across various aspects of turbomachinery CFD simulations. Your confidence in the material is our highest compliment. If you need further assistance in the future, our team is always here to support you!

Hazel Reichert –

Can this package simulate the effects of different outlet conditions on the performance of turbomachinery?

MR CFD Support –

Absolutely, our Turbomachinery Ansys Fluent Training Package is designed to handle a variety of outlet conditions and their impact on the performance of turbomachinery.

The outlet conditions in a turbomachinery system play a crucial role in determining its overall performance. These conditions include factors like pressure, temperature, and flow velocity at the outlet. Each of these factors can significantly affect the system’s efficiency, power output, and operational stability.

Our package enables you to simulate and analyze these effects comprehensively and in detail. For instance, you can investigate how changes in outlet pressure can cause the flow to become choked or how variations in temperature can influence the density and speed of sound in the exhaust gases, thereby affecting the Mach number and the flow regime.

Gus Doyle –

I just completed the Turbomachinery CFD Training Package for Expert Users, and I’m truly impressed by the range of projects covered—from centrifuges to cavitational studies, and even cross-flow turbines! Each module guided me with practical insights into complex flow phenomena and helped me master turbulence modeling. These exercises are wonderfully productive for anyone looking to deepen their expertise in turbomachinery CFD simulations with ANSYS Fluent.

MR CFD Support –

We are thrilled to hear that you have completed our Turbomachinery CFD Training Package and found the range of projects and exercises beneficial for mastering advanced aspects of CFD simulations in turbomachinery. Your enthusiasm and satisfaction with our program mean a lot to us. Thank you for choosing our training package, and we wish you all the best in your future simulations!

Marilyne Bergnaum –

I am absolutely thrilled with the Turbomachinery CFD Training Package for Expert Users. The diversity of projects ranging from centrifuges and mixers to cavitation in pumps and acoustic issues in turbomachinery provided a robust training experience. The step-by-step guide through the simulation of complex phenomena and the cross-reference with academic articles significantly enhanced my understanding and confidence in applying CFD in my turbomachinery projects. MR CFD Company has exceeded my expectations and provided an invaluable resource that has improved my computational analysis skills.

MR CFD Support –

Dear user, we are delighted to hear that our Turbomachinery CFD Training Package has provided an insightful and comprehensive learning experience for you! It’s great to know that the real-world project simulations and validation with academic articles added significant value to your understanding of CFD applications in turbomachinery. Thank you for sharing your positive feedback, and we are here for any further queries or support you might need in the future.

Marietta Cormier MD –

I found the contents of the training package to be very detailed and comprehensive for expert users. The mix of theory with practical exercise reflects a deep understanding of turbomachinery and CFD simulation principles. How recent are the CFD models in the package, and how often is the content updated to include the latest advancements in the field?

MR CFD Support –

Thank you for your positive feedback on our Turbomachinery CFD Training Package. Our team consistently works to keep the CFD models and methodologies up-to-date. We include the latest advancements and ensure the content is revised annually to reflect the most current industry trends, software updates, and best practices in the field.

Rosalia D’Amore V –

Can this package simulate the flow in various types of turbomachinery?

MR CFD Support –

Absolutely, Shima! Our package is designed to simulate flow in a wide range of turbomachinery, including turbines, compressors, and pumps.

Dewayne Greenfelder –

My CFD skills have improved significantly thanks to the detailed activities and real-world applications within the Turbomachinery CFD Training Package. The projects span various turbomachinery applications, challenging me to apply and expand upon my knowledge in different scenarios. Particularly insightful was the practical approach to learning about cavitation, and acoustic modeling alongside multiphase flow simulations. The comparison with experimental data helped me understand the accuracy and predictive capabilities of computational simulations, ensuring that I can confidently validate my work. Thank you for putting together such a comprehensive learning experience!

MR CFD Support –

We are thrilled to hear that your CFD expertise has grown through our Turbomachinery CFD Training Package for expert users! At MR CFD Company, we strive to provide rigorous and practical learning experiences to empower our customers. It is gratifying for us to learn of your significant developments in various areas of turbomachinery simulation, and we consider your successes as our own achievement. Thank you for taking the time to leave such a positive review. We look forward to continuing to support your journey in mastering CFD simulations in ANSYS Fluent.

Ignacio Quitzon II –

I was deeply impressed by the breadth of analysis covered in this Turbomachinery CFD Training Package for expert users. The clear structure and navigated complexities in each project significantly enhanced my confidence in designing and analyzing advanced turbomachinery systems. Your careful consideration of acoustic effects and cavitation across different applications truly sets this series apart. It challenged me to incorporate vital aspects that are often overlooked in routine simulations. Well done MR CFD for assembling such an enlightening curriculum!

MR CFD Support –

We are thrilled to read about your positive and rewarding experience with our Turbomachinery CFD Training Package! MR CFD takes pride in crafting comprehensive learning tools for expert-level users, ensuring efficient understanding and execution of specialized analyses. Your success in mastering the facets of heavy-duty machinery simulations, including acoustic and cavitation effects, is precisely what we aim to help our customers achieve. Thank you for your kind words, and we wish you the best in all your engineering endeavors!