Volume of Fluid (VOF), Package for Beginners, Part 1, 10 Learning Products

$762.00 Original price was: $762.00.$254.00Current price is: $254.00. Student Discount

This training package includes 10 practical Multi-phase Volume Of Fluid (VOF) exercises using ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Volume Of Fluid (VOF) Multi-phase ANSYS Fluent CFD Simulation Training Package for BEGINNER Users (Part-I)

This training package includes 10 practical Multi-phase Volume Of Fluid (VOF) exercises using ANSYS Fluent software. MR CFD suggests this package for BEGINNER users who tends to learn the simulation process of multi-phase problems without any strong background.

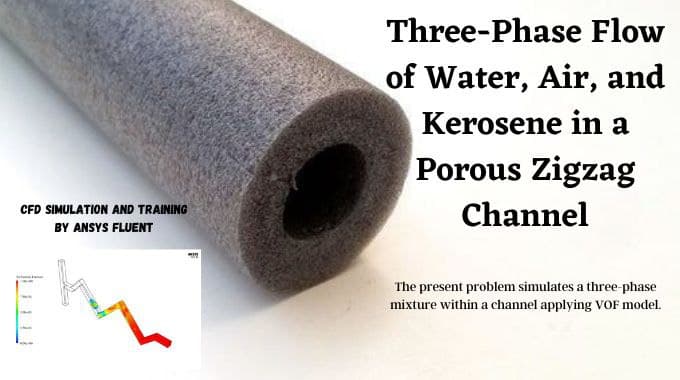

Porous

Project number 1 simulates a three-phase flow mixture within a channel with a square cross-section. These three phases include air, water, and kerosene. The channel consists of a vertical section consisting of two inlet sections at its top and bottom and a zigzag section in the horizontal direction with an outlet section at its end. To simulate multi-phase flow in the present model, the VOF multiphase model has been used. Also, inside the canal, a porous environment with a porosity coefficient of 0.1 is located. The trigger for air and oil flowing into the duct is the pressure difference

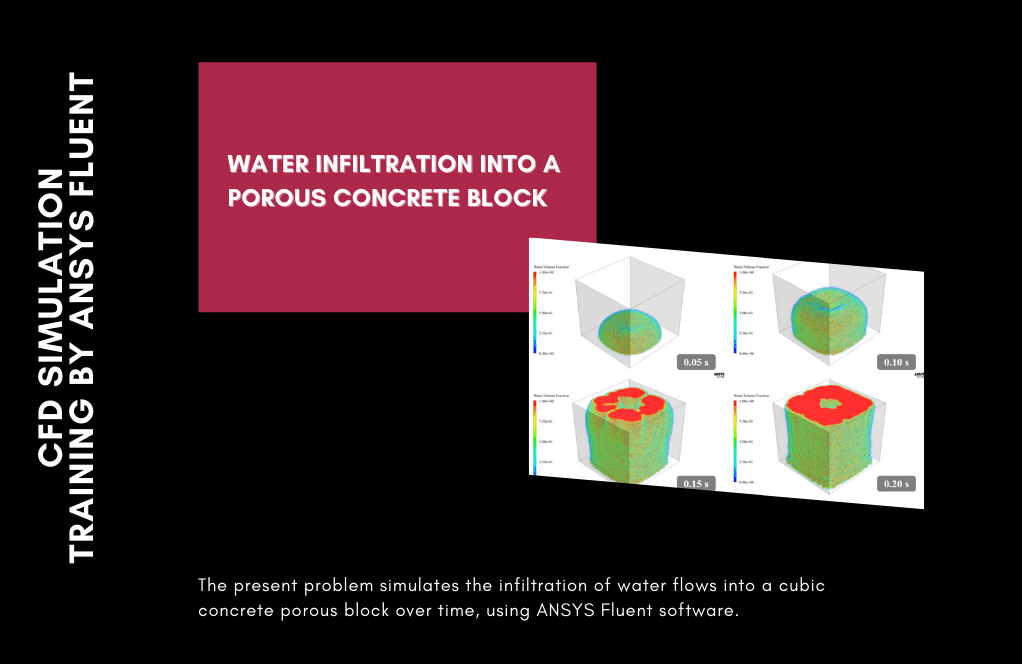

Project number 2 simulates the infiltration of water flows into a cubic porous medium. In this modeling, a cube block is designed as a porous medium. The water flow enters it from a circular section at the bottom of the blocks is also assumed that there is only the air inside the block in the initial state, and then water flow penetrates it. Therefore, to define a two-phase flow consisting of water and air, the VOF or volume of fluid model is used.

Cohesion & Adhesion

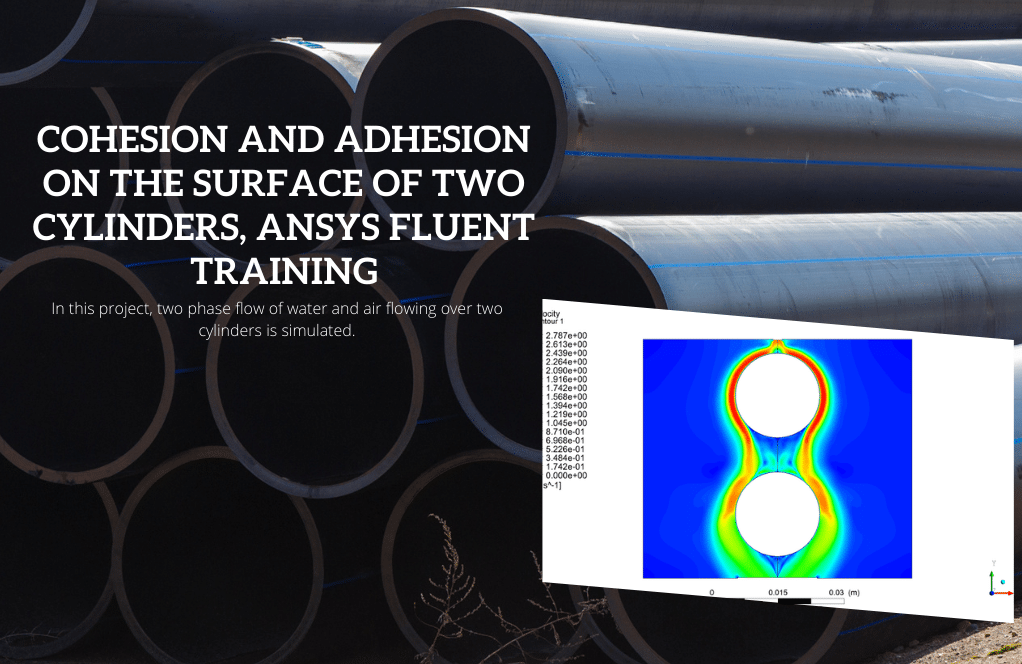

In project number 3, the two-phase flow of water and air flowing over two cylinders considering cohesion and adhesion is simulated. The water will enter the computational domain with a velocity of 2.6m/s, and it flows over the cylinders’ surfaces. The realizable k-epsilon model is exploited to solve fluid flow equations, and VOF multiphase model is used to investigate the phase interactions.

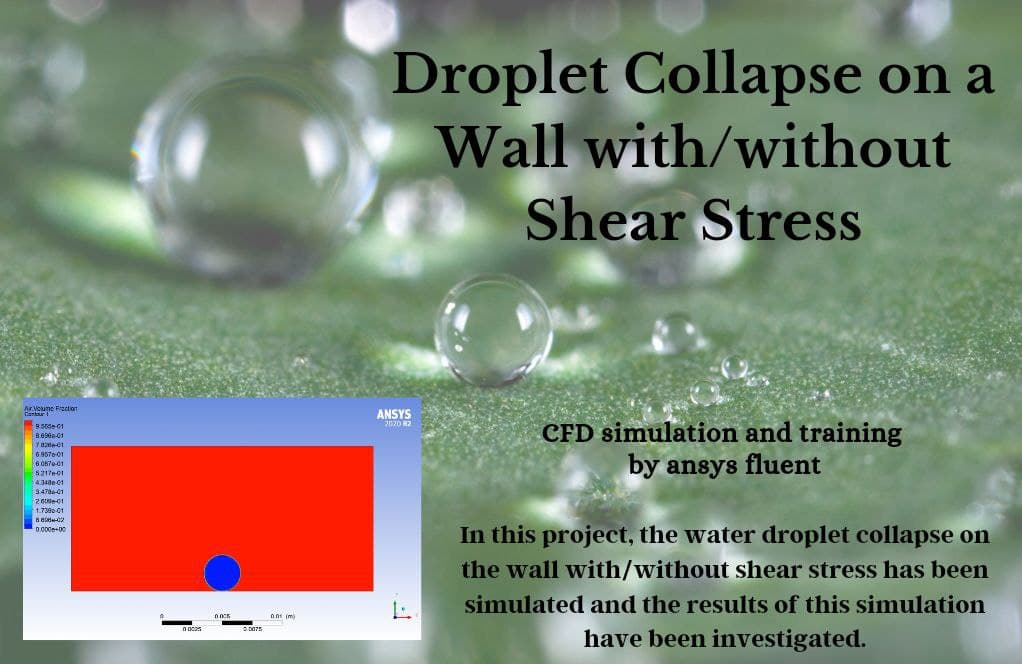

In project number 4, ANSYS Fluent software has been used for numerical simulation of water droplet collapse on the wall in two modes of non-slip condition and shear stress condition. The VOF model has been used to simulate and solve the two-phase flow field equations.

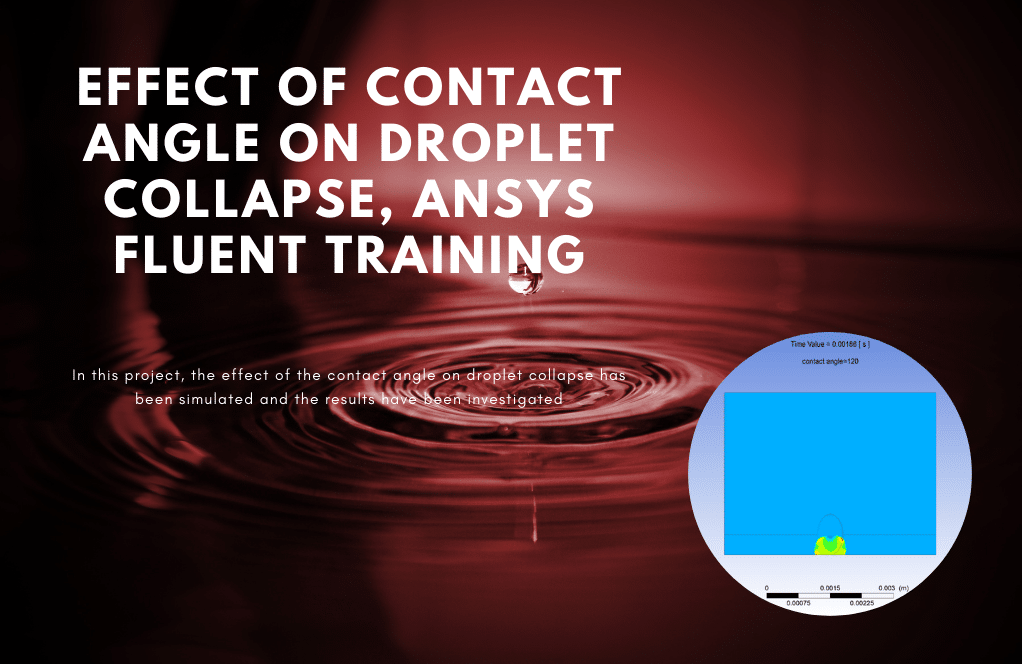

In project number 5, a numerical simulation of droplet collapse with two different contact angles has been done. The VOF model has been used to simulate and solve the two-phase flow field equations. The purpose of this project is to investigate the collapse of water droplets on the wall at the contact angle of 90 degrees and 120 degrees.

In project number 6, a water droplet falling in the air is simulated. Therefore, the two-phase flow model is used to simulate the initial air phase and the secondary water phase. This simulation only includes fluid analysis and does not discuss thermal analysis. The purpose of the simulation is to investigate the drop behavior during a downward slope and the extent of its volume changes.

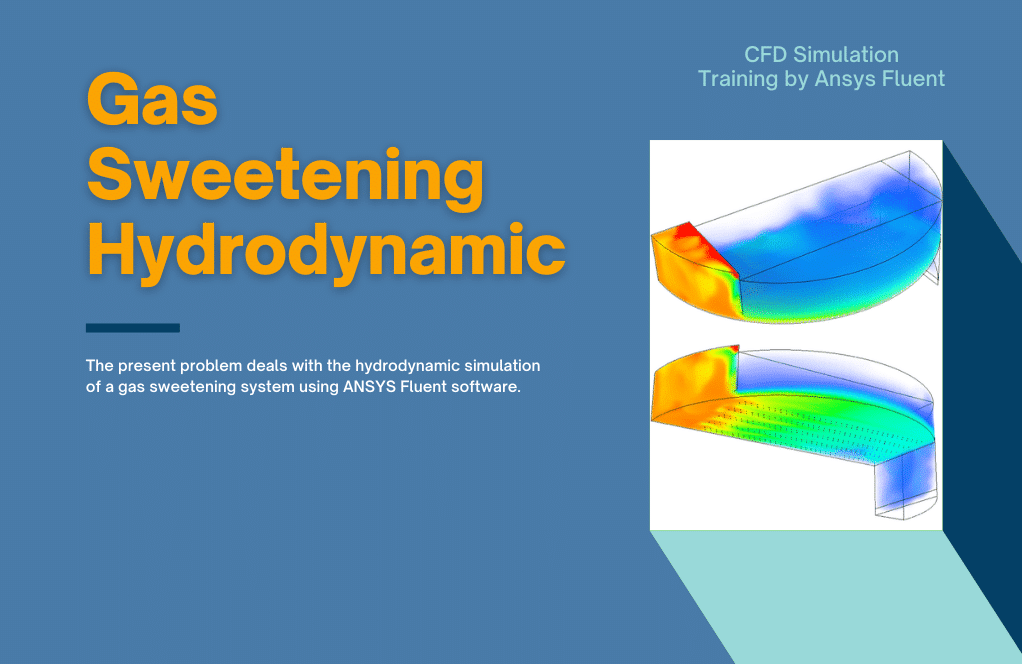

Gas Sweetening (Volume of Fluid)

Project number 7 deals with the hydrodynamic simulation of a gas sweetening system. Gas sweetening is generally the process of removing hydrogen sulfide, carbon dioxide, mercaptans, and other impurities from natural gas streams and synthetic gas to make the gas suitable for transportation and use. In this project, two materials are defined within the computational domain, which includes a particular sour gas and an amine stream; However, because this project only deals with the hydrodynamic modeling of this process, the gas removal process does not occur due to the occurrence of a physical or chemical phenomenon

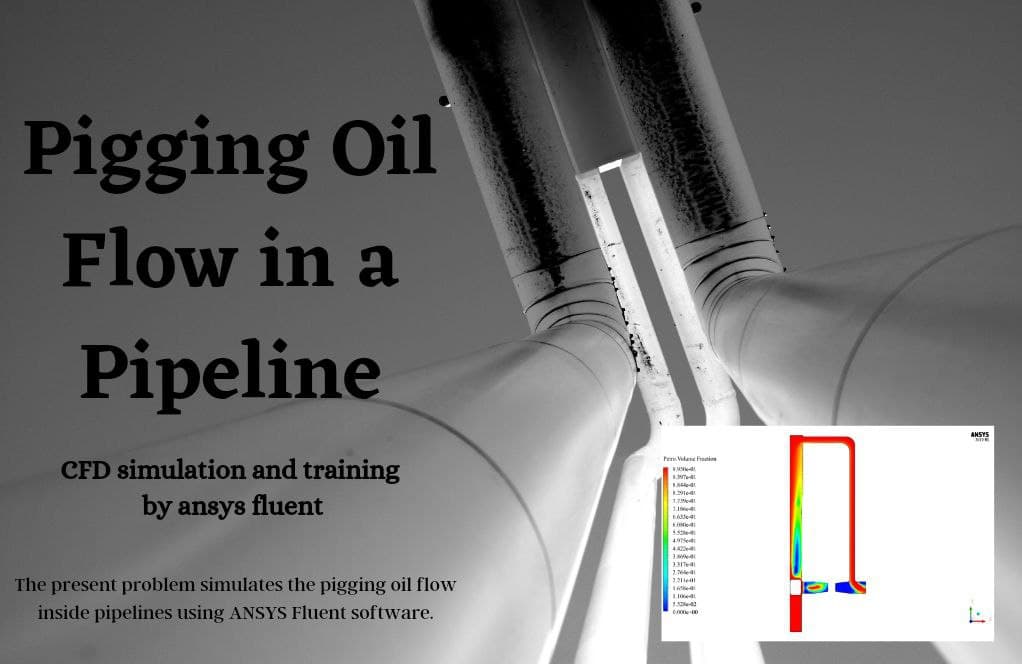

Pigging oil flow

Project number 8 simulates the pigging oil flow inside pipelines. Inside the pipelines in this model, there is a piece called a pig. the simulation process is performed in two different modes; Thus, oil flow with different inlet speeds including 0.9 m/s and 1.9 m/s enters the interior of the pipeline. Also, the VOF multiphase model has been used to define the oil and gas materials in the pipelines, and two materials have been defined as gas-oil and petro in the present model.

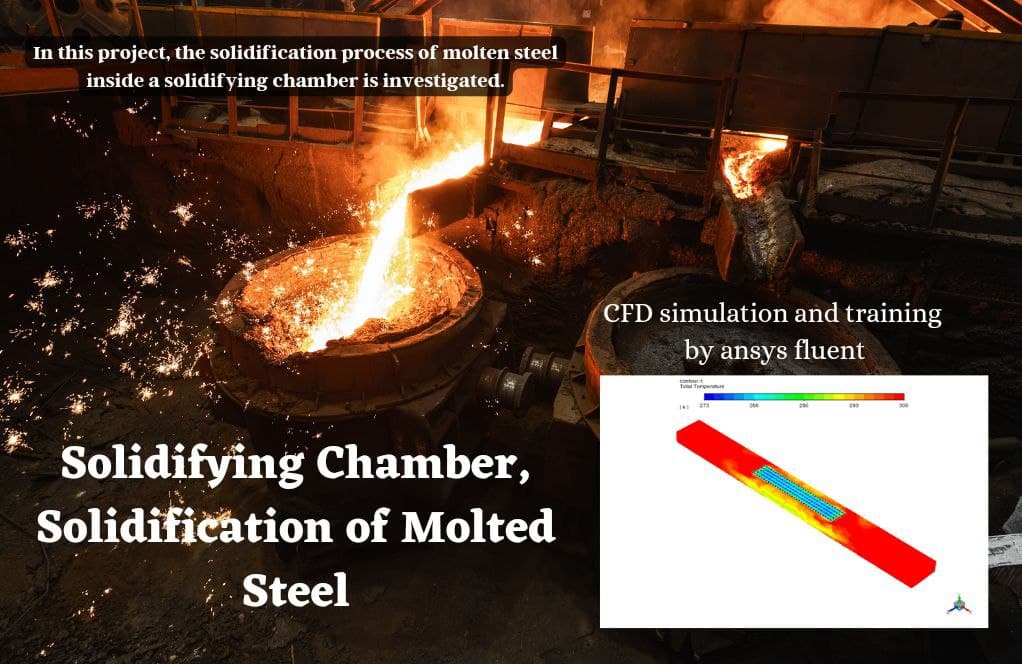

Solidifying Chamber

Solidification, also known as freezing, is a phase change of matter that results in the production of a solid. Generally, this occurs when the temperature of a liquid is lowered below its freezing point. In project number 9, the solidification process of molten steel inside a solidifying chamber is investigated. Water is used to lower the molten steel’s temperature and accelerate the solidification process. The simulation is done using the VOF model for the three phases of air, water, and steel.

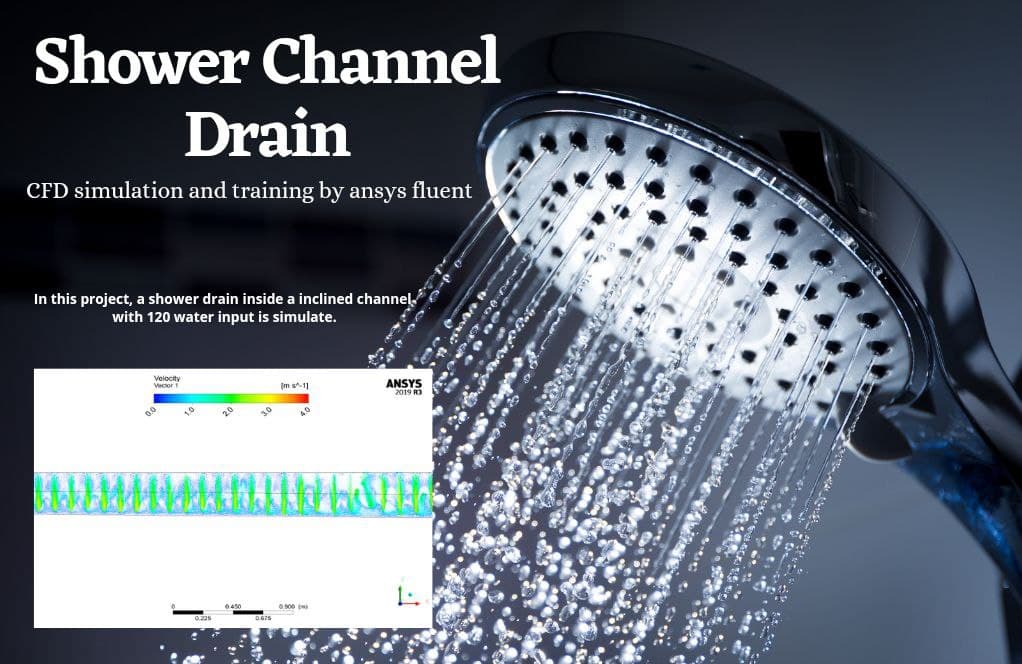

Shower Channel Drain (Volume of Fluid)

In project number 10, a shower drain inside an inclined channel with 120 water inputs is simulated and analyzed. In order to analyze the air and water flow inside the channel, the standard k-epsilon model with the use of standard wall functions is exploited. The multi-phase VOF model has been used to investigate the two-phase flow of air and water within this channel.

Dr. Santino Nikolaus MD –

I have just started with the VOF training package, and it’s been great! What I’d like to know is whether project number 3 covers the necessary steps to properly adjust cohesion and adhesion properties for my simulation?

MR CFD Support –

We’re glad you’re enjoying the training package! In project number 3, you will learn how to adjust the interaction parameters between different phases, including cohesion and adhesion properties, to reflect the behavior of water and air moving over solid obstacles. The project will guide you through setting up and interpreting the results of such multiphase simulations using ANSYS Fluent.

Prof. Curtis Grady –

I’m impressed with the range of scenarios covered in this VOF package for beginners. From multi-phase flow in porous media to gas sweetening processes, each seems well-designed to enhance understanding in different phenomena. It would be great to see more of such packages covering advanced levels too!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you’ve found the variety of scenarios in our VOF package educational and beneficial. Your feedback is appreciated, and we’ll certainly consider creating more packages catering to advanced users in the future. Keep an eye on our offerings, and happy learning!

Wilber Boyle –

I’m intrigued by the range of applications in this training package. Could you tell me more about how the VOF model handles the interaction between different phases in these simulations?

MR CFD Support –

The Volume of Fluid (VOF) model in these simulations captures the interface between different fluid phases by solving a single set of momentum equations and tracking the volume fraction of each fluid throughout the domain. The VOF model handles the interaction by assigning a certain value of volume fraction for each cell, which represents the percentage of the cell’s volume occupied by a particular phase. This ensures accurate depiction of the interface for multiphase flows like those in the training exercises. The package offers practical examples with step-by-step guidance, allowing even beginners to understand and apply the VOF method effectively in ANSYS Fluent.

Efrain Wilderman IV –

I’ve just started with CFD simulations and am interested in the Package for Beginners Part 1. I’m curious, does the package include step-by-step tutorials on how to set up the simulations using the VOF method in ANSYS Fluent?

MR CFD Support –

Yes, the Package for Beginners Part 1 includes step-by-step tutorials specifically designed for users new to CFD. It guides you through the entire process of setting up simulations using the VOF method in ANSYS Fluent, ensuring you can follow along without the need for advanced background knowledge.

Anabel Koss III –

I purchased the VOF package for beginners, and it has been an insightful experience. The variety of projects gave a real depth of understanding on multiphase flows.

MR CFD Support –

We’re thrilled to hear that our Volume Of Fluid (VOF) training package for beginners met your expectations! Thank you for sharing your positive experience. It’s great to know that the diversity of projects aided in enhancing your understanding of multiphase flows. We appreciate your feedback!

Shanel Walter MD –

The training package seems quite comprehensive, but I have a question. Are all the principles of the VOF method covered in this package, including dealing with splashing and free-surface phenomena?

MR CFD Support –

Yes, this training package covers a broad range of applications of the VOF method. It includes exercises that address different multi-phase flow situations, including free-surface phenomena, so you will get a comprehensive understanding of handling splashing and similar challenges using VOF in ANSYS Fluent.