Chemical Reactions CFD Simulation Training Package, 10 Learning Products

Original price was: $1,660.00.$185.00Current price is: $185.00. Student Discount

Chemical Reactions CFD Simulation by ANSYS Fluent Training Package, 10 Practical Exercises

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Chemical Reactions CFD Simulation by ANSYS Fluent Training Package, 10 Practical Exercises

This CFD training package is prepared for all users of ANSYS Fluent software at BEGINNER, INTERMEDIATE, and ADVANCED levels, in the Chemical Reactions field, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

BEGINNER

We start this training package with a sample practical exercise for BEGINNER users, who want to learn the related CFD simulations in the field of CHEMICAL REACTIONS.

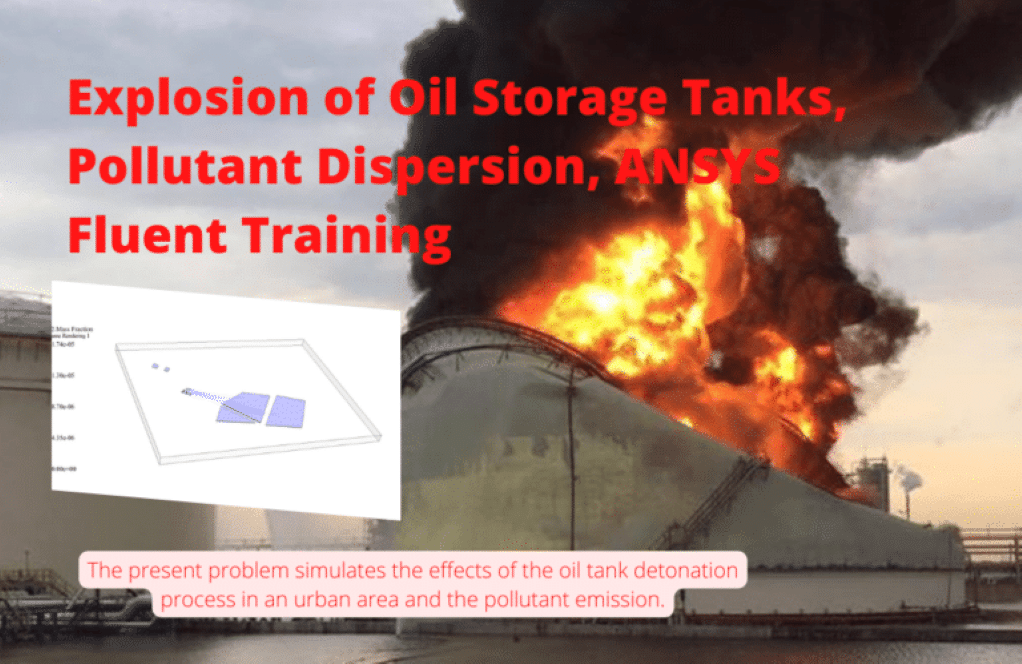

Explosion

The explosion and detonation of the oil tank is a major phenomenon that occurs because of specific chemical reactions.

In the present modeling, a sample urban zone is defined as a computational domain in which there are several oil reservoirs and around these reservoirs, there are several residential areas and industrial units. Whereas large chemical reactions occur at the time of an explosion, in which different gaseous species are involved; The model of species transport has been used. Problem 1 simulates the effects of the oil tank detonation process in an urban area and the pollutant emission. In fact, in areas where there are oil reservoirs, one of the potential dangers is an explosion. The explosion of these oil tanks can lead to the release of many pollutants such as carbon dioxide into the environment.

Combustion

One the other practical example of chemical reactions is combustion.

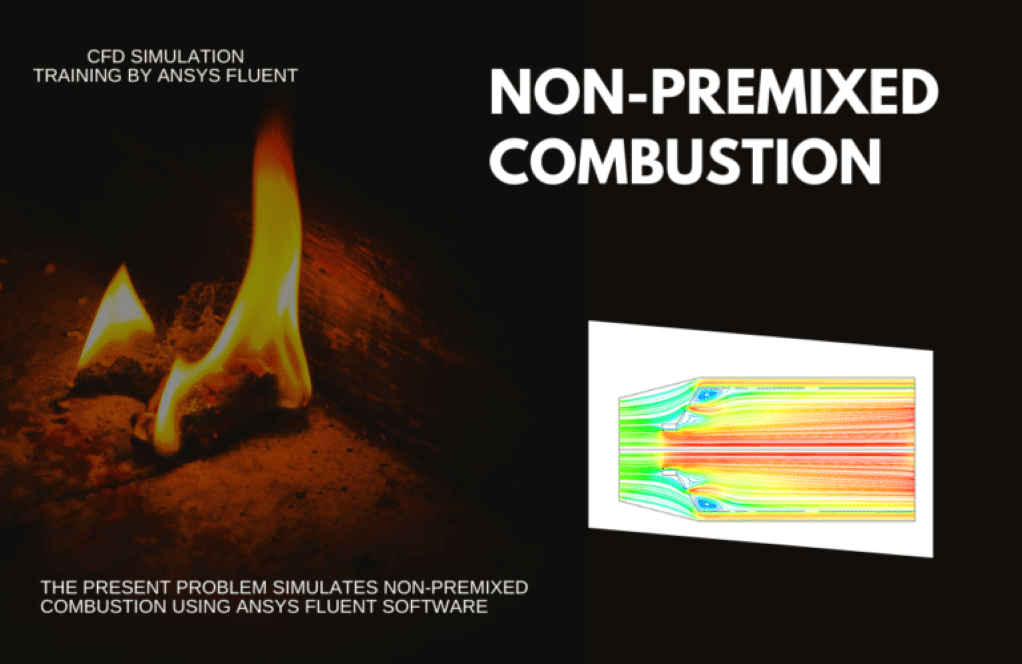

Problem 2 simulates non-premixed combustion. In fact, a two-dimensional combustion chamber is designed in which airflow and fuel flow enter simultaneously from two different inlets with different flow rates. The combustion process occurs when some air is combined with some hydrocarbon fuel to convert fuel energy into heat energy.

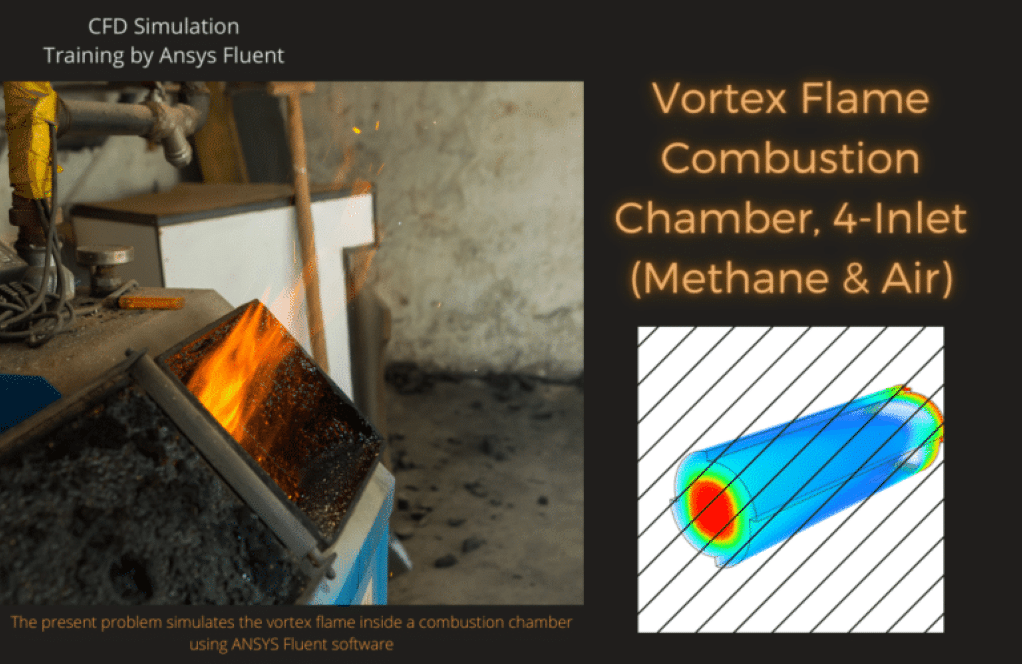

Problem 3 simulates the vortex flame inside a combustion chamber. The combustion chamber has a cylindrical structure. The reactants, including fuel flow and airflow, enter the combustion chamber separately from four different inlet sections from the upper part.

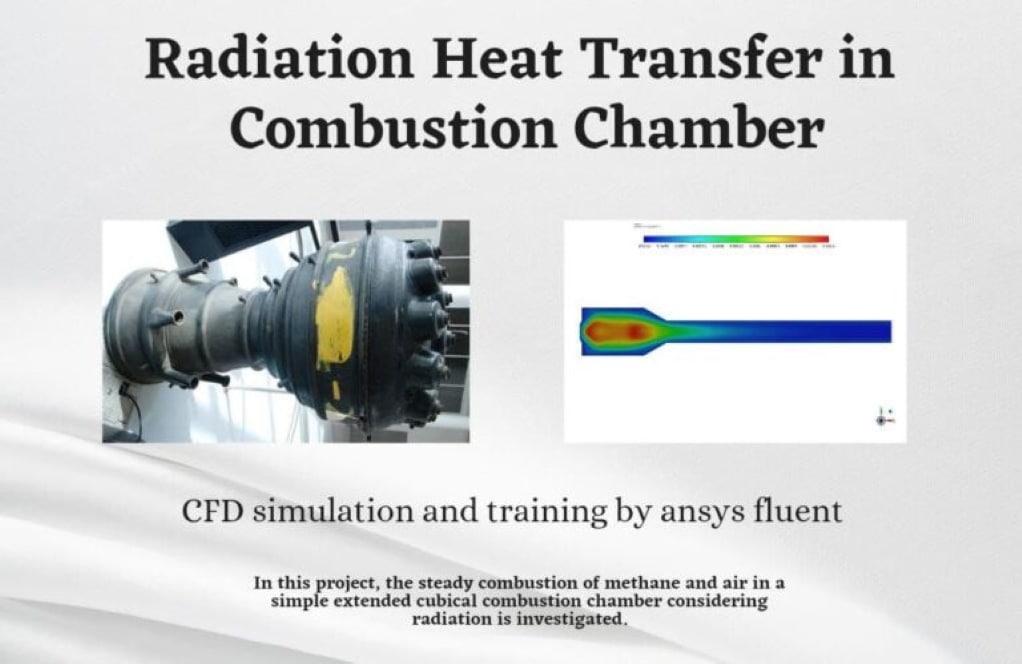

In project 4, the steady combustion of methane and air in a combustion chamber considering RADIATION heat transfer is investigated. Radiation heat transfer must be taken into account since combustion chambers undergo extremely high temperatures. In this project, the mixture’s static temperature has a maximum value of 3500 k within the chamber.

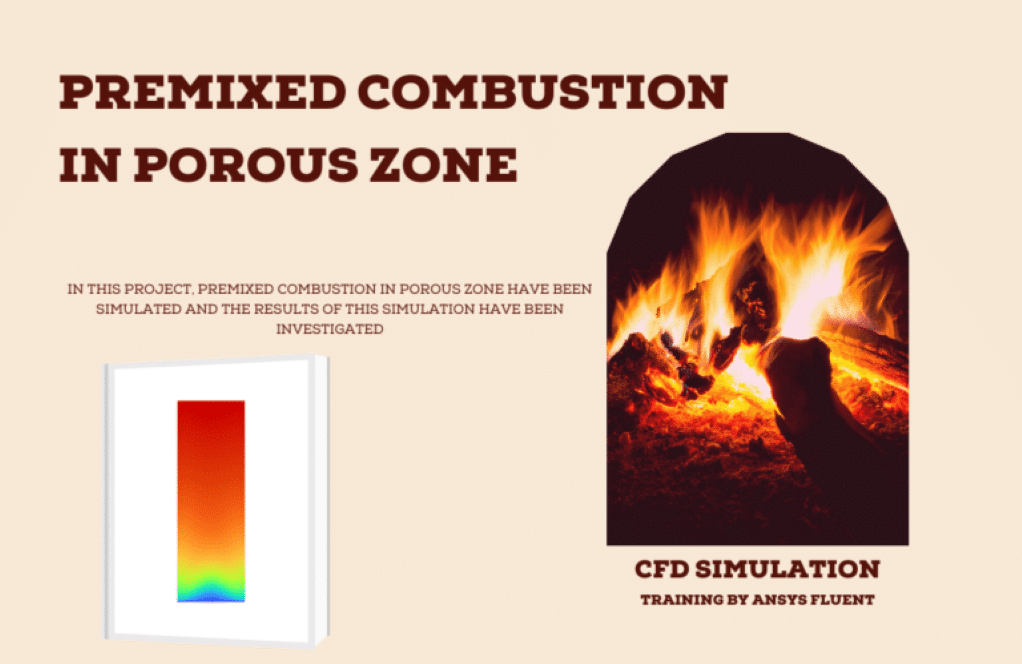

Simulation 5 aims to model Simple Premixed Combustion in a POROUS zone and see how the porous zone affects combustion temperature and stabilizes it. This simulation is a matrix-stabilized burner, and the results are compared to the same premixed combustion without porosity. the Species transport model has been used.

INTERMEDIATE

We continue this training package with 2 practical exercises for INTERMEDIATE users related to FLARE, who want to learn the related CFD simulations in the field of CHEMICAL REACTIONS.

Flare

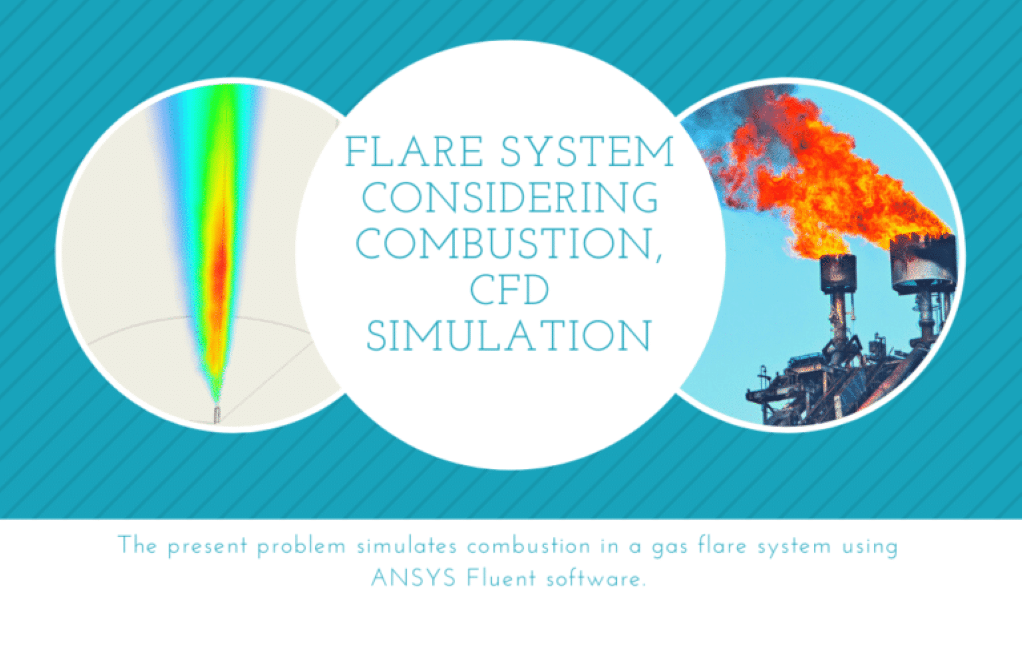

The flare system, also known as a gas flare, is a combustion device used in industrial units such as oil and gas refineries and the production of oil and gas wells, especially in offshore platforms, applying chemical reactions.

Problem 6 simulates combustion in a gas flare system. Gas flares are responsible for burning the natural gases released during oil extraction in a completely controlled manner. During the oil extraction process, some natural gas accumulates on top of the oil in the reservoirs. In general, it is better to try to collect and store natural gas, but if this is not possible, we should burn it.

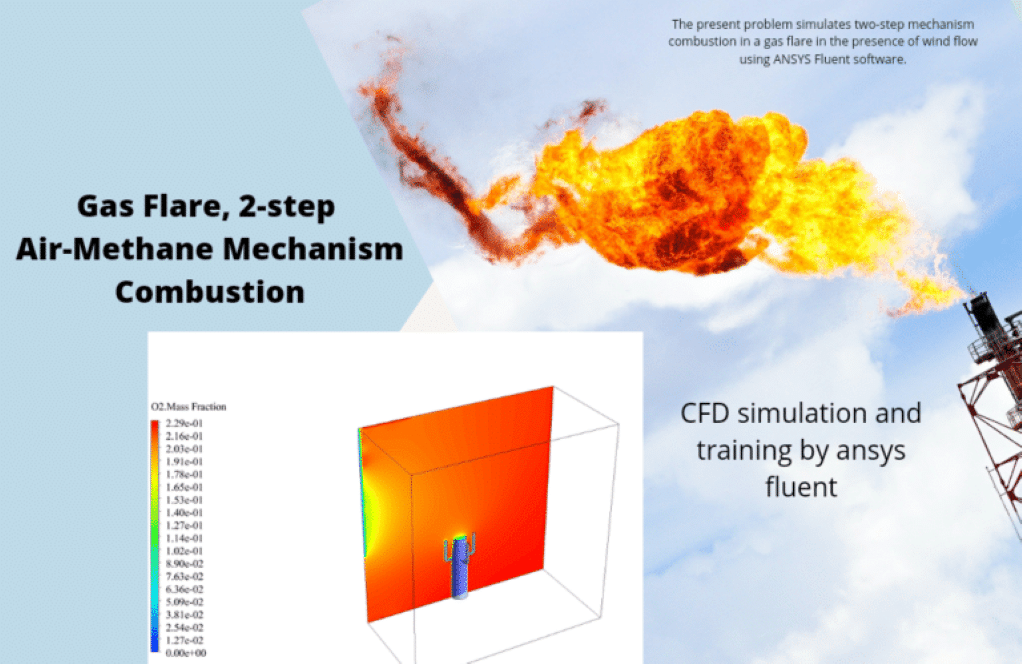

Problem 7 simulates a two-step mechanism of combustion in a gas flare in the presence of wind flow. The combustion of the mentioned gases using the flare system causes, firstly, prevents the combustion and burning of these gases dangerously and uncontrollably. Secondly, burning and converting methane to carbon dioxide and releasing them in the open space, has less damage than methane release.

ADVANCED

We finish this training package with 3 practical exercises for ADVANCED users, who want to learn the related CFD simulations in the field of CHEMICAL REACTIONS.

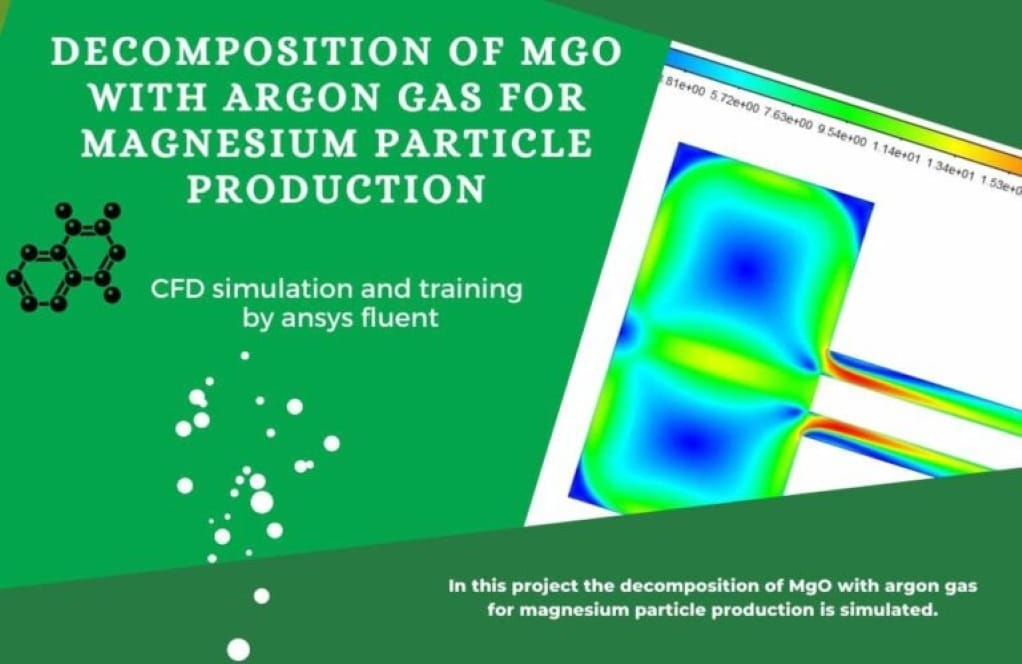

Decomposition

Thermal decomposition, or thermolysis, is a chemical decomposition caused by heat.

In study 8, the combination of DPM (discrete particle method) and species transport methods was used to investigate the DECOMPOSITION effect of magnesium oxide particles. The thermodynamic properties of the particles, along with the necessary boundary conditions, were applied in the settings. This reaction is exothermic in the reactor chamber and increases its temperature.

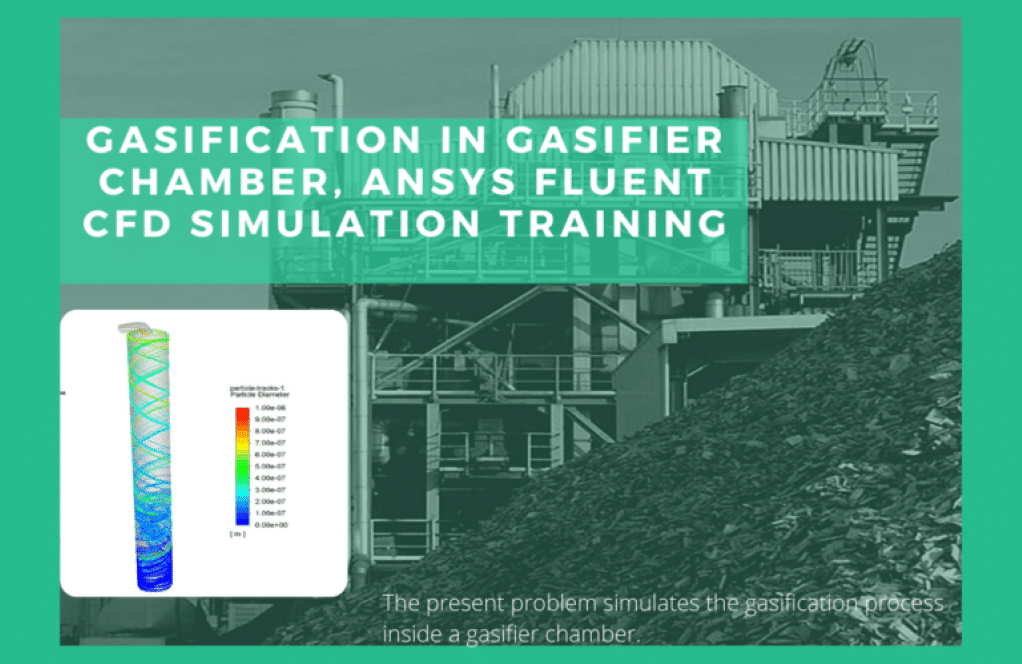

Gasification

The gasification process is a set of chemical reactions in which a carbon-based substance is converted to carbon monoxide, hydrogen, and carbon dioxide.

Problem 9 simulates the Gasification process inside a gasifier chamber. The product of this process is considered a renewable energy source that has many applications in the industry. In this case, a material is defined as fuel, with a density of 1550 kg.m-3 and a specific heat capacity of 1680 j.kg-1.K-1, which is sprayed into the chamber and reacts with water vapor at high temperature.

Lime Kiln

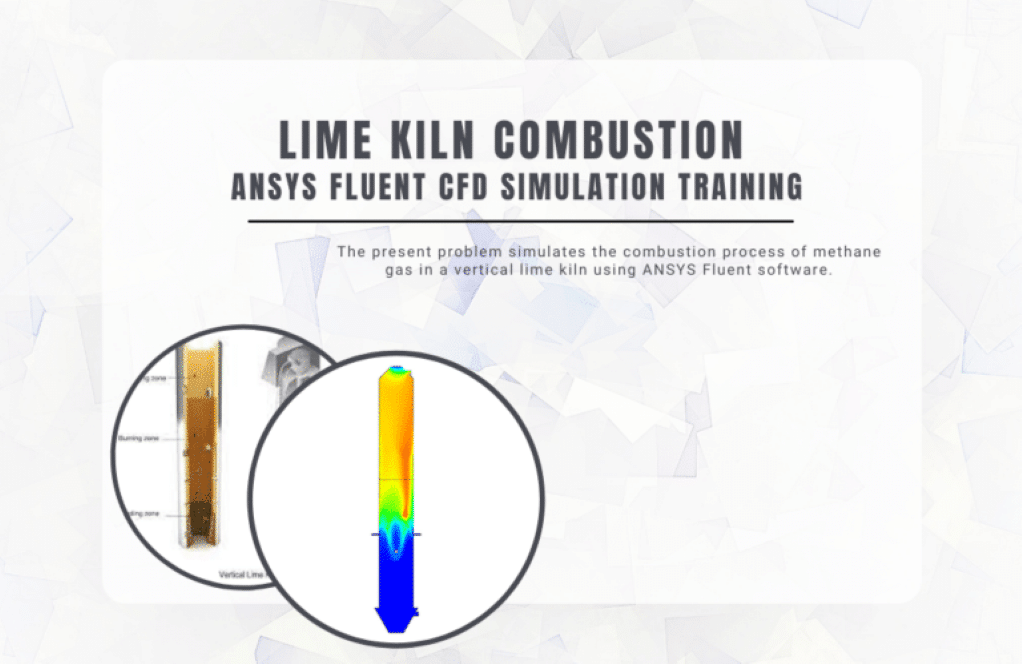

Lime Kiln CFD simulation is one of the ADVANCED practical exercises in the CHEMICAL REACTIONS field.

Finally, problem 10 simulates the combustion process of methane gas in a vertical lime kiln. The construction of a vertical lime kiln consists of two main parts, including the combustion zone and the preheating zone. The fuel and air enter the building from the middle of the lime kiln and form a combustion reaction.

Dr. Jermaine Spencer DVM –

I’m particularly interested in the capabilities of this package in relation to plug flow reactors. Can it facilitate simulations for chemical reactions occurring within this specific type of reactor?

MR CFD Support –

Absolutely, Shima! Our comprehensive package is indeed capable of facilitating simulations for reactions that take place in a plug flow reactor. Plug flow reactors, as you may know, are commonly used in chemical processes and it’s crucial to understand the reactions occurring within them. Our package has been designed with this in mind, and it allows for simulations that can accurately represent the conditions and reactions within a plug flow reactor. This feature of our package enables users to gain valuable insights into the behavior of reactions in such a reactor, which can be extremely beneficial for both academic and industrial applications.

Samantha Bins –

Does this package include simulations for reactions in a slurry reactor?

MR CFD Support –

Yes, our package can simulate reactions in a slurry reactor.

Winfield Klein –

Can I use this package to simulate reactions involving ionic liquids?

MR CFD Support –

Absolutely, our package can simulate reactions involving ionic liquids.

Ressie O’Reilly –

How can I access the source code of the simulations?

MR CFD Support –

The source code of the simulations can be accessed by contacting us directly.

Citlalli O’Kon –

I just finished the advanced Lime Kiln CFD simulation exercise and it was incredibly insightful! The detailed explanation and simulation exercised really clarified how methane gas combustion works in a vertical lime kiln setting!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Lime Kiln CFD simulation exercise insightful and that it enhanced your understanding of the combustion process. If you ever need more clarification or further assistance with our learning products, please don’t hesitate to reach out.

Miguel Mayer –

The depth and range of the Chemical Reactions CFD Simulation Training Package is impressive. Each progressive level builds upon the last, offering both breadth and specialty in learning the unique applications of chemical reactions in ANSYS Fluent. The practical exercises deliver a hands-on approach to understanding complex reactions such as explosions, combustion dynamics, and gasification. Truly invaluable for anyone pursuing mastery in the CFD field.

MR CFD Support –

Thank you for your detailed review! We’re thrilled to hear that the Chemical Reactions CFD Simulation Training Package met your expectations and provided a comprehensive learning experience. It’s great to know that the practical exercises helped enhance your understanding of the complex simulations you can perform with ANSYS Fluent. Your feedback is deeply appreciated!

Destin Jaskolski –

I recently completed the ‘Chemical Reactions CFD Simulation Training Package’ and was very impressed with the breadth and detail of content covered. As a beginner, I found the explanations clear and the progression to more advanced concepts was well-structured. The practical exercises were engaging and reinforced the theory effectively. Excellent material for anyone looking to master chemical reactions simulations in ANSYS Fluent!

MR CFD Support –

Thank you so much for your positive feedback! We’re thrilled to hear that our Chemical Reactions CFD Simulation Training Package met your needs as a beginner and helped you advance your skills. It’s great to know that the practical exercises were useful in reinforcing the learning material. We appreciate you choosing MR CFD for your learning journey and we look forward to supporting you in your future projects.

Aubrey Hickle –

I’ve recently worked through the beginner level exercises from this Chemical Reactions CFD Simulation Training Package. I found the structured approach to introducing fundamental concepts in CFD particularly helpful. The real-life applications, like the explosion and combustion simulations, brought the theory to life. It really clarified complex chemical behaviors through an iterative learning process.

MR CFD Support –

We’re thrilled to hear that you found our beginner level exercises both informative and practical. Thank you for acknowledging our efforts in creating an engaging learning experience. Your feedback is a testament to our commitment to providing high-quality CFD education that bridges theory and real-world applications. If you’re ever interested in delving deeper into the world of CFD, don’t hesitate to check out our intermediate and advanced exercises!

Marcia Turner MD –

This training package was fantastic! The progression from beginner to advanced helped deepen my understanding immensely. The series of practical exercises and applications gave me a strong grasp of the fundamental aspects. Particularly, the hands-on approach with problem sets such as combustion reactions and gas flare systems not only reinforced learning but also piqued my curiosity in the field. Well-structured and comprehensive!

MR CFD Support –

Thank you for taking the time to leave such a positive review! We are thrilled to hear that you found the Chemical Reactions CFD Simulation training package beneficial and that it helped you advance from a beginner to an advanced level with ease. We take great pride in curating our training materials to cater to learners at different levels. Your appreciation motivates us to continue delivering high-quality learning experiences. Keep exploring and happy simulating!

Emanuel Leannon –

I cannot speak highly enough about the Chemical Reactions CFD Simulation Training Package. The gradient from beginner to advanced problems exposes you to an impressive array of chemical reaction simulations. The realism in the scenarios, from urban explosions to combustion and gasification processes, deeply enhances the learning experience!

MR CFD Support –

Thank you very much for your positive feedback! We’re thrilled to hear that you appreciate the depth and range of our simulations. It’s great to know that the step-by-step progression is helpful to users looking to get a comprehensive understanding of chemical reaction simulations in CFD. We continually strive to provide quality training materials, and your satisfaction as a learner is a priority to us. If you need further assistance or information about other packages and applications, don’t hesitate to reach out.

Roberto Shanahan –

I just completed the Chemical Reactions CFD Simulation Training Package with the 10 practical exercises and I have to say, I am thoroughly impressed. As a beginner, I found the gradual complexity curve extremely helpful. Starting with basic explosion simulations and building up to more complex combustion processes allowed me to really grasp the core principles. By the time I reached the intermediate flare simulations, I was confidently applying what I learned to simulate and analyze the chemical reactions involved. The advanced decomposition and gasification processes were challenging, but the training had equipped me well to tackle them. I especially appreciated the lime kiln simulation as it brought together everything I learned in a real-world application. Kudos to MR CFD Company for such a well-structured and comprehensive learning journey!

MR CFD Support –

We are delighted to hear that you’ve had a positive experience with our Chemical Reactions CFD Simulation Training Package and that the progression from beginner to advanced level exercises met your educational needs. Our goal is to provide a thorough understanding of simulations across various levels of complexity. Thank you for your thoughtful review and for acknowledging the structure of our training program. We wish you all the best in applying these skills in your future projects!

Prof. Boris Rippin –

Can I use this package for my research on heterogeneous catalysis?

MR CFD Support –

Absolutely, our package is perfect for research on heterogeneous catalysis.

Unique Kertzmann DVM –

The depth and variety in this training package are awesome! Working through the beginner to advanced simulations has deepened my understanding of chemical reactions phenomenally. Particularly, simulating the vortex flame in a combustion chamber was both challenging and incredibly educational. The intuitive progression from problem to problem really helps cement key concepts in computational fluid dynamics applications for chemical reactions. Keep up the great work!

MR CFD Support –

Thank you so much for the positive feedback! We’re delighted to hear that you found our Chemical Reactions CFD Simulation Training Package extensive and educational. It’s fantastic to know that the problems were both challenging and helpful for your learning progression. We continually strive to deliver learning materials that enhance understanding and skills in CFD. We appreciate your support and hope our products will continue to aid in your growth. If you have any further comments or need assistance on your CFD journey, feel free to reach out!

Mr. Lourdes Kihn –

This training package would be my recommendation for anyone looking to dive deeply into CFD analysis specifically within the realm of chemical reactions. The progression from beginner to advanced levels ensures a thorough understanding and hands-on experience, which is invaluable.

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the training package on chemical reactions comprehensive and helpful. It’s great that the structured progression from beginner to advanced levels met your expectations. Your recommendation means a lot to us!

Earline Veum –

The package is incredibly comprehensive! It seems to cover everything from basic combustion to advanced gasification and lime kiln operations. I especially value the progression from beginner to advanced levels which really helps solidify understanding of chemical reaction simulations.

MR CFD Support –

We greatly appreciate your feedback! We’re delighted to hear that our training package has effectively provided you with a progressive learning experience. Thank you for recognizing the comprehensive nature of our Chemical Reactions CFD Simulation training and its alignment with your learning journey. If you have deeper interests or require further assistance in the field of simulations, please feel free to explore more with us.

Don Monahan –

This was such a brilliant learning experience! I had no idea how thoroughly I could grasp the process of chemical reactions across different levels from beginner to advanced applications. The practical exercises, especially the combustion and the flare system simulations, stood out to me—they were challenging yet immensely instructive! Major kudos to the team who put together this training package.

MR CFD Support –

Thank you for your kind words! We’re elated to hear that our training package contributed significantly to your understanding of chemical reactions and simulations. Your acknowledgment of the combustion and flare system practical exercises is highly appreciated. If you encounter any queries in your ongoing learning journey or wish to delve even deeper into the topic, please don’t hesitate to contact us. Happy simulating!

Jonas Hand –

Fantastic resource! I had the opportunity to work through the entire ‘Chemical Reactions CFD Simulation Training Package’, and every single exercise was meticulously designed and extremely informative. Whether you’re at a beginner, intermediate, or advanced level, this package has something for you. The range of applications, from oil tank explosions to gas flare systems, and the transition from premixed combustion to complex gasification processes, illustrates real-world scenarios and sharpens understanding of the underlying principles in chemical reaction engineering. A must-have for anyone serious about CFD in chemical processes!

MR CFD Support –

Thank you for your amazing review! We are thrilled to hear that you found the ‘Chemical Reactions CFD Simulation Training Package’ comprehensive and applicable to a wide range of skill levels and scenarios. Your appreciation for the range of exercises and their relevance to real-world applications means a lot to us. We’re glad the package is assisting you in progressing through the complexities of CFD in chemical engineering. Remember, if you have any questions or need further assistance, our team of experts is always here to help you deepen your learning experience.

Imelda Waters –

The training package seems extensive, covering various levels of expertise. But how can I ensure that the instructions and simulations are updated with the latest best practices and methods for each level?

MR CFD Support –

The training package is designed to be comprehensive and covers different levels of users. The exercises and methods are based on the latest practices at the time of the creation of the training materials. The team at MR CFD Company keeps up-to-date with developments in the field to ensure that information provided is relevant and current for users. Additionally, updates to the training materials are made periodically to reflect any changes or advancements in the field of CFD simulations and ANSYS Fluent software.

Deion Murphy –

Wow! The Chemical Reactions CFD Simulation Training Package from MR CFD has been truly insightful. As a newbie, I found the structured levels from beginner to advanced incredibly helpful. The variety of scenarios covered from explosions to combustion and even gasification has deepened my understanding of applying CFD to real industry problems. Each exercise seemed to be constructed with such detail, making the learning process both informative and engaging.

MR CFD Support –

Thank you so much for your positive review! We’re really glad to hear that the training package met your expectations and that it has been an excellent learning resource for you. Our aim is to provide comprehensive and detailed examples to help users at all levels gain proficiency in the application of CFD to simulate various chemical reactions. If you ever have more feedback or need further assistance as you continue your learning journey, don’t hesitate to reach out. We wish you success in all your future simulations!

Palma Ebert –

The training package has such a comprehensive spectrum of real-world applications. After completion, what are the next steps for further advancing one’s proficiency in simulating chemical reactions using ANSYS Fluent?

MR CFD Support –

Thank you for your positive feedback! Once you’ve completed this Chemical Reactions CFD Simulation Training Package, you can further enhance your expertise by working on more complex CFD projects, possibly focusing on multiphysics simulations where chemical reactions interact with other physical phenomena. Additionally, attending advanced workshops or pursuing certification in CFD can also be beneficial. Regular practice and staying updated with the latest software features and simulation strategies will help you continuously improve your skills.

Abigale Ruecker –

I’m delighted with the Chemical Reactions CFD Simulation Training Package. The variety from simple to advanced problems really helped build my understanding step by step. A reminder of key academic concepts coupled with the hands-on application truly solidified my comprehension of combustion processes, flare systems, and gasification. The pore-scale combustion exercises also opened my eyes to complex reactions in different materials. Accessible to both beginners and those more experienced, I feel much more confident tackling chemical reaction simulations!

MR CFD Support –

It’s wonderful to hear our Chemical Reactions CFD Simulation Training Package has significantly enriched your learning experience. We are thrilled that the progression from beginner to advanced exercises has bolstered your confidence in simulation work, and our intention to cater to various skill levels seems to have met your expectations. Your insight on pore-scale combustion is immensely appreciated, and we look forward to providing you with valuable educational resources in the future. Thank you for taking the time to share your positive feedback!

Giles Effertz –

The training for non-premixed combustion seems very interesting. However, I’m curious, how does this model account for different emissions that might result from the combustion process?

MR CFD Support –

Thank you for showing your interest! In the non-premixed combustion model, emissions are accounted for by using the species transport model. This involves solving conservation equations for the species involved to simulate their evolution and interaction during the combustion process. The software is capable of tracking the concentrations of different combustion products which allows you to assess the formation of various emissions, such as NOx, carbon dioxide, and other pollutants.

Prof. Vita Tromp I –

After going through these comprehensive exercises, I’m incredibly impressed with the scope and depth of the package. The progression from beginner to advanced level was well-structured, allowing for a solid understanding of chemical reaction simulations. It’s refreshing to find a resource that aligns so precisely with the learning curves!

MR CFD Support –

We’re thrilled to hear that you’ve had a positive learning experience with our Chemical Reactions CFD Simulation Training Package. Thank you for recognizing the structure and depth we have aimed for. We always strive to provide resources that meet the educational needs of all levels, and your feedback is very much appreciated!

Margaret Macejkovic –

Wow, the list of problems contained within the package seems extremely thorough and covers a broad spectrum. It’s really great that the package is categorized by skill level, as it ensures a smooth learning curve. Did the package also include any comparative analysis or real-world case studies as part of the learning experience?

MR CFD Support –

Thank you for your positive review! We are delighted to hear that you appreciate the organization of the training package by skill level. We aim to provide a graduated learning experience that grows with you. The training package indeed covers practical exercises that reflect real-world scenarios. Moreover, some of these exercises are based on comparative analysis using different computational approaches to showcase the effectiveness of diverse methods under various circumstances. This hands-on approach is designed to give you a deeper understanding of the complexities involved in CFD simulations.

Martine Paucek –

I really enjoyed the Chemical Reactions CFD Simulation Training Package. The projects ranged from beginner to advanced, which helped me build my skills progressively. The practical examples were spot on and the combustion simulations gave me a thorough understanding of both the theory and application in CFD.

MR CFD Support –

We’re delighted to hear that you found our Chemical Reactions CFD Simulation Training Package very educational and helpful for your skill growth. It’s always encouraging to know that our practical examples and structured progression from beginner to advanced projects meet the needs of users like you. Thank you for your feedback, and we wish you great success in all your future simulations!

Prof. Isom Armstrong PhD –

This training package has been a fantastic resource for understanding the complex dynamics of chemical reactions in CFD simulations. The progression from beginner to advanced levels – with clear, challenging examples – allowed me to grasp both the basic and nuanced aspects of simulation. I was particularly impressed with the inclusion of practical real-world applications like the oil tank explosion and lime kiln combustion.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our Chemical Reactions CFD Simulation Training Package met your learning needs and helped you better understand the practical applications of CFD in chemical reaction simulations. If there’s anything more we can assist you with on your simulation journey, please let us know.

Lilla Wiza –

I’m thrilled with the comprehensive scope of the Chemical Reactions CFD Simulation Training Package! It offers a deep dive into the field with much-needed theoretical and practical insights, from basic to advanced challenges. The careful step-by-step approach in teaching combustion, flare processes, and gasification is excellent for improving skills progressively.

MR CFD Support –

Thank you for your kind feedback! We’re delighted to hear that you find the training package encompassing and educational, providing a good progression through various levels of difficulty. Your satisfaction with the depth and breadth of content is truly appreciated. If you need any further assistance, feel free to reach out.

Jeffery Gleichner IV –

I recently completed the Chemical Reactions CFD Simulation Training Package and I found the array of examples extremely beneficial. The examples progressed from simple to complex which was perfect for growing my confidence and skills in modeling chemical reactions in ANSYS Fluent. Explosions, combustion, flare systems, thermal decomposition, gasification, and even lime kiln simulations provided a comprehensive overview. Your training has been instrumental in my projects!

MR CFD Support –

Thank you for your wonderful review! We are thrilled to hear that you found our Chemical Reactions CFD Simulation Training Package diverse and educational. It’s great to know that our step-by-step progression through different levels of complexities has helped you in your learning journey and enhanced your modeling skills using ANSYS Fluent. Should you have any further needs or questions in the future, please do not hesitate to reach out. Keep up the good work on your CFD projects!

Dr. Emery Bartell II –

I enjoyed the broad coverage of topics in the Chemical Reactions CFD Simulation Training Package. How I can apply different chemical reaction models easily after this course is encouraging. My favorite was the challenge of simulating the lime kiln combustion process, it was rewarding to see the results.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Chemical Reactions CFD Simulation Training Package informative and practical. It’s great to know you could navigate through different models, and we congratulate you on overcoming the challenge of simulating the lime kiln combustion process. Should you have any questions or wish to further expand your skills, please don’t hesitate to reach out.

Virginie King –

This training package on Chemical Reactions CFD Simulation seems extensive and covers various expertises! Do the included practical examples provide step-by-step guides for setting up the simulations?

MR CFD Support –

Every example in the Chemical Reactions CFD Simulation Training Package includes a detailed step-by-step guide, facilitating the setup process for each type of simulation covered. Beginners receive walkthroughs for simpler scenarios, while intermediate and advanced users are guided through more complex models and corresponding boundary conditions, physics setups, and post-processing steps.

Rashad Purdy –

I’ve always struggled with understanding the choices behind various modeling techniques for different applications. The diversity of practical exercises in this training package seems perfect to overcome that hurdle. Is there supplementary material to further explain when to choose a particular type of model, like non-premixed versus premixed combustion, or is everything covered within the exercises?

MR CFD Support –

We’re glad the training package piques your interest! While the practical exercises themselves are comprehensive and designed to teach you the differences between various modeling techniques, we do provide supplementary material that dives deeper into the theory behind choosing a specific model for a given scenario. Understanding the fundamentals and nuances of non-premixed versus premixed combustion, among other concepts, is crucial and well-documented in our training material.

Gabriel Krajcik –

The practical exercises across different difficulty levels appear to cover a range of scenarios and applications. As a novice in CFD simulations, I’m intrigued by the promise of step-by-step progression from beginner to advanced exercises. It sounds perfectly aligned for a learner like me.

MR CFD Support –

Thank you for the positive feedback! We are glad to hear that our Chemical Reactions CFD Simulation Training Package caters to your learning needs. It’s great knowing that the progression from beginner to advanced exercises aligns with your learning journey. Should you require any further assistance or clarification as you work through the exercises, please don’t hesitate to reach out.

Laurine Bashirian –

I just completed the Chemical Reactions CFD Simulation Training Package and found the variety of projects highly valuable. Each exercise was diverse, well-structured, and enriched my skills immensely through each difficulty level. With simulations ranging from explosions to combustion and gas flares, I could really appreciate the complex nature of chemical processes and the simulation possibilities using ANSYS Fluent. A big thanks to the MR CFD team for creating such a comprehensive learning tool.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that you found our Chemical Reactions CFD Simulation Training Package to be diverse and thorough, appreciating the range of practical exercises provided. Your success and enhanced skills are what motivate us to continue creating high-quality learning resources. If you need further assistance or have questions in the future, don’t hesitate to reach out. Keep enjoying the world of CFD simulation, and happy simulating!

Mr. Melvina Johnson DVM –

After finishing the CFD training, what’s the most suitable way to practice my acquired knowledge minimally in order to not forget the simulations methods?

MR CFD Support –

A great way to keep your simulation skills sharp is to apply them to small-scale personal or academic projects. You can also challenge yourself by recreating scenarios from the training with variations, or by participating in online forums and contributing to discussions related to CFD simulations.

Colin Dibbert DVM –

I am thoroughly impressed with the CFD training package focusing on chemical reactions simulations using ANSYS Fluent. From beginners to advanced users, the practical exercises encompass a diverse range of real-world phenomena like explosions, combustion, and gasification. Each problem provides unique scenarios that help in understanding chemical reactions and their effects in various environmental contexts. The inclusion of radiation in combustion chambers and the use of the species transport model have undoubtedly broadened my understanding of CFD. It’s commendable how the exercises scale up in complexity, providing a comprehensive learning curve. Kudos to MR CFD for creating an invaluable learning resource.

MR CFD Support –

Thank you for your kind review! We’re delighted to hear that our Chemical Reactions CFD Simulation Training Package has provided you with a comprehensive and satisfactory learning experience. It’s wonderful to know that the problems from beginner to advanced levels have enriched your understanding of chemical reactions through hands-on simulation. We are committed to offering educational materials that cater to students and professionals across various fields. We appreciate your positive feedback and look forward to continuing to support your learning journey.