Compressible Flow CFD Training Package, Beginners, 10 Projects

Original price was: $1,080.00.$120.00Current price is: $120.00. Student Discount

Compressible Flow CFD Training Package is prepared for BEGINNER users of ANSYS Fluent software in the COMPRESSIBLE FLOW area, including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Compressible Flow CFD Simulation Package, 10 ANSYS Fluent Training for BEGINNER Users

Compressible Flow CFD Training Package is prepared for BEGINNER users of ANSYS Fluent software in the COMPRESSIBLE FLOW area, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

Compressible Flow occurs in many industrial devices and applications. Some of these cases are investigated in this training package.

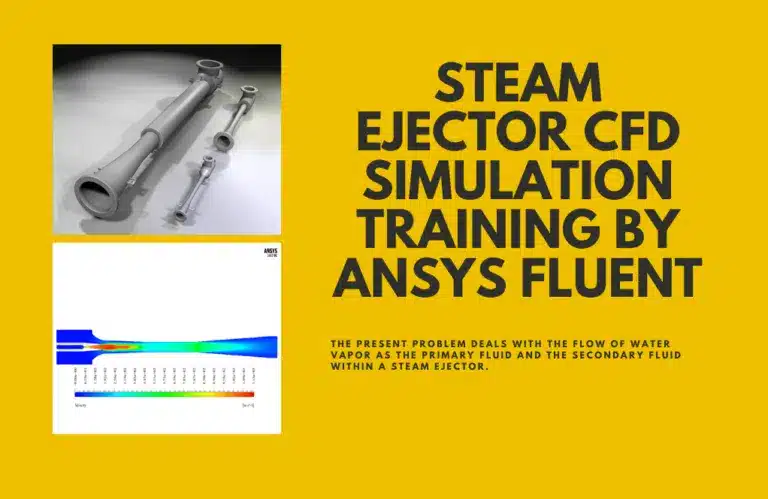

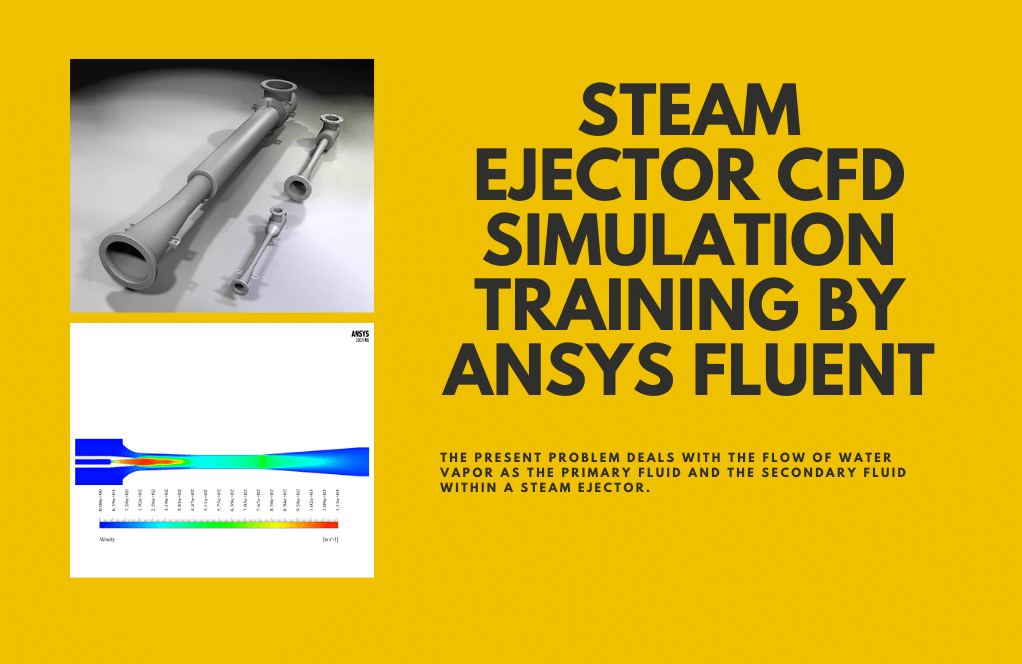

Steam Ejector

Problem 1 deals with the flow of water vapor as the main fluid (primary) and the secondary fluid (suction) within a convergent-divergent Steam Ejector. The purpose of the present simulation is to investigate the behavior of primary and secondary fluid after passing through the internal convergent-divergent nozzle and the ejector diffuser. In the present model, due to the vacuum pressure difference between the two inlet fluids, the suction phenomenon for the secondary fluid has to occur.

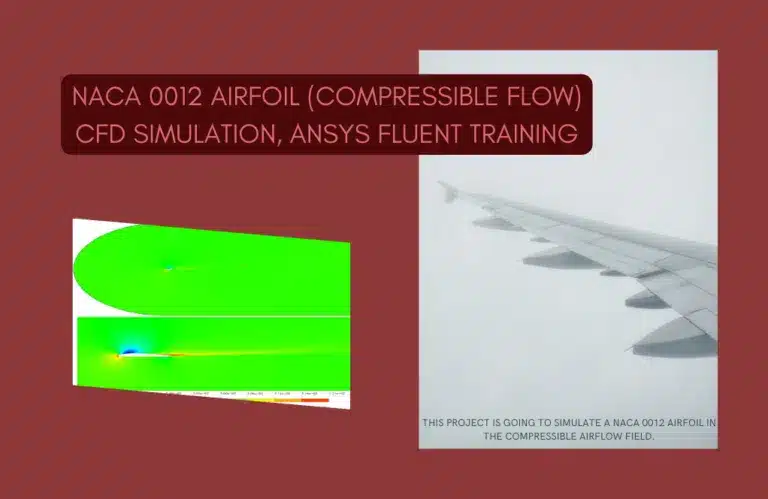

Airfoil, Wing, and Airplane

Project 2 is going to simulate a NACA 0012 airfoil in the compressible airflow field. Geometric defining parameters include chord line, angle of attack, leading edge, and trailing edge. The direction of the airflow into the airfoil body is defined by the angle of attack (the angle between the chord and the horizontal direction of the airflow velocity).

Problem 3 simulates the airflow around the aircraft wing with a flap and slat. In this project, a 3D airplane wing is designed; In such a way a Flap is on the trailing edge, and a Slat is on the wing’s leading edge.

Project 4 is going to study a Supersonic Compressible Flow adjacent to an F-35 plane. The geometry is a 20-meter F-35 plane inside a 150-meter wind tunnel. The air is considered a compressible ideal gas, and the Mach number of 2.0 was achieved at the maximum speed of 544 m/s.

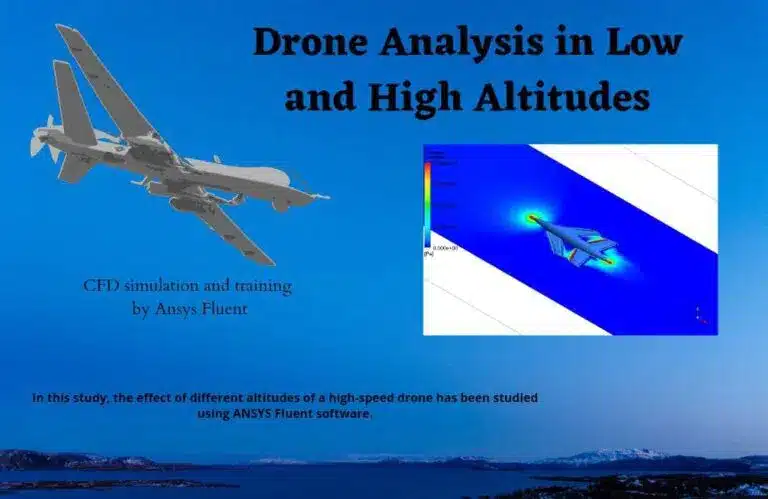

In study 5, the effect of different altitudes of a high-speed DRONE has been studied. The fluid is air, and we considered it as a compressible ideal gas. The maximum speed of the drone is 30 m/s, and the investigated altitudes are 20m and 2000m as low and high altitudes, respectively.

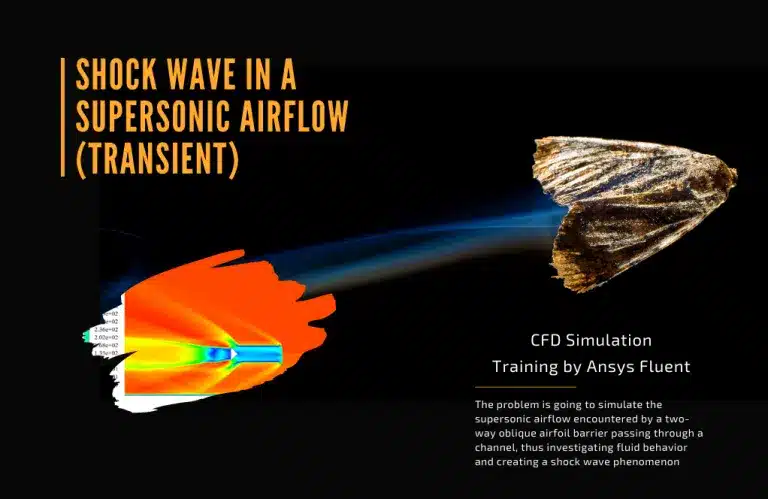

Shock Wave in Supersonic Airflow (Compressible Flow)

Problem 3 simulates the supersonic airflow encountered by a two-way oblique airfoil barrier passing through a channel, thus investigating fluid behavior and creating a shock wave phenomenon. The airflow in the simulation environment around the obstacles and canals has a temperature of 129.46 Kelvin and a Mach number of 2.49, and the direction of the airflow is generally assumed to be in the same direction. Mach number is a non-dimensional number that indicates the ratio of fluid velocity to sound velocity in the same fluid.

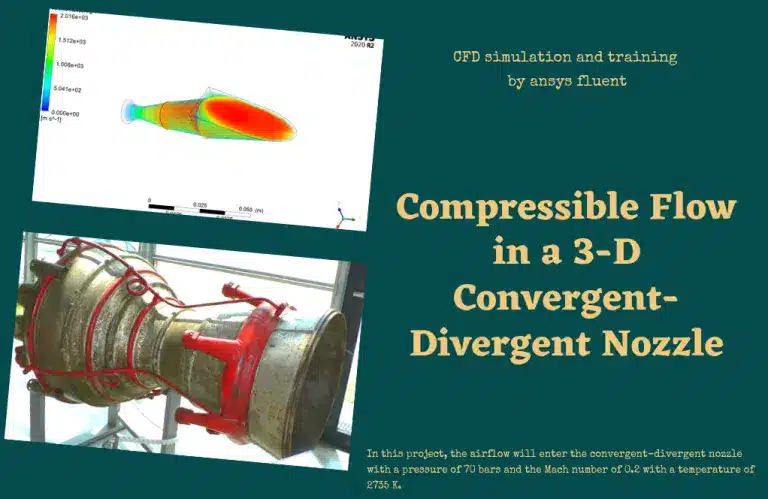

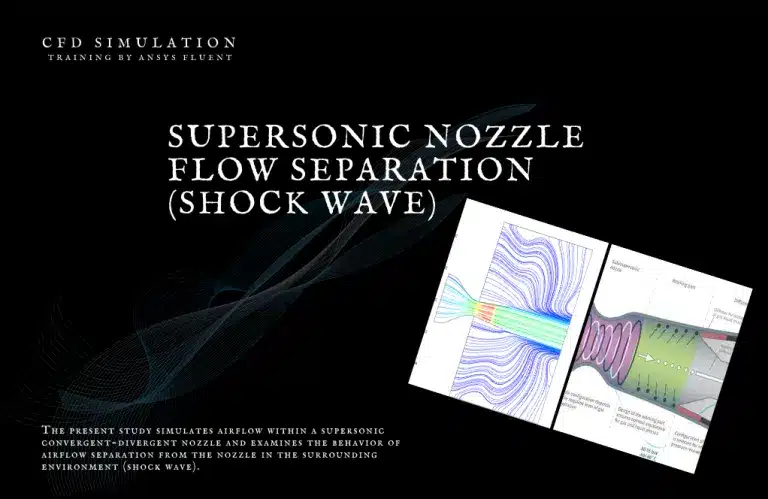

Nozzle

Study 4 simulates airflow within a supersonic convergent-divergent nozzle and examines the behavior of airflow separation from the nozzle in the surrounding environment. In order to simulate the present model, the pressure condition in the nozzle input section (pressure-inlet condition) and the ambient output sections (pressure-outlet condition) have been used. The nozzle pressure ratio (NPR) is equivalent to the ratio of the inlet air pressure of the nozzle to the ambient pressure.

In Project 5, the airflow will enter the convergent-divergent nozzle with a pressure of 70 bars and a Mach number of 0.2 with a temperature of 2735 K. After passing the throat zone. The airflow will gain speed and lose its temperature as it passes through the diffuser. The standard k-epsilon model with standard wall function is used to solve fluid flow equations. The energy model is activated, and the ideal gas equation is exploited to calculate the density changes in the computational domain.

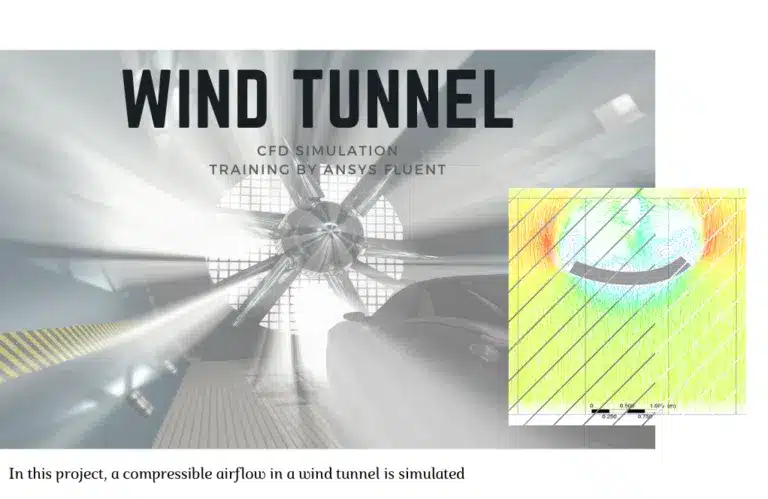

Wind Tunnel

The wind tunnel is one of the most widely used aerodynamic testing devices today.

In project number 6, a wind tunnel and a specific body that is placed inside it are modeled. The effect of drag force on this body is investigated. The energy model and standard k-epsilon model with the use of standard wall functions are activated.

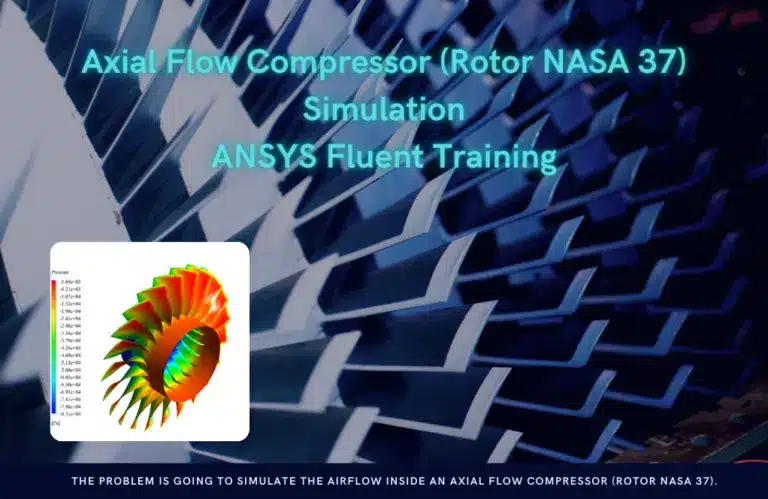

Compressor (Compressible Flow)

Finally, problem 10 is going to simulate the airflow inside an axial flow compressor (Rotor Nasa 37). The present model consists of a series of blades for an axial flow compressor connected to the central axis within a cylindrical area. To simplify the simulation model, only one row of rotating blades is drawn on the central rotor of the compressor.

[/vc_column_text][/vc_column][/vc_row]

Ms. Jazmyn Hintz Sr. –

Hey, I’ve got a specific simulation I want to do. Can you guys handle custom requests?

MR CFD Support –

Totally, we’re all for your ideas and we’re ready to tweak our simulations to fit what you need. Just spill the beans on the simulation you’re thinking about, and we’ll do our best to help you out.

Madeline Nolan –

I’m interested in aerospace applications. Does this package cover supersonic and hypersonic flows?

MR CFD Support –

Yes, this training package includes exercises that cover a wide range of flow regimes, including subsonic, transonic, supersonic, and hypersonic flows. This makes it particularly useful for aerospace applications.

Sydni Rice –

I see that this training package uses the density-based solver. Can you explain why this solver is suitable for compressible flows?

MR CFD Support –

The density-based solver is ideal for compressible flows as it directly solves the conservation equations of mass, momentum, and energy. This allows it to accurately capture shock waves and other phenomena typically associated with compressible flows.

Mr. Davin Rowe –

Can this training package help me understand the effects of Mach number on flow characteristics?

MR CFD Support –

Absolutely! The exercises included in this package are designed to provide a comprehensive understanding of compressible flows, including the effects of varying the Mach number. You will gain insights into how changes in the Mach number can affect flow characteristics such as pressure, temperature, and density.