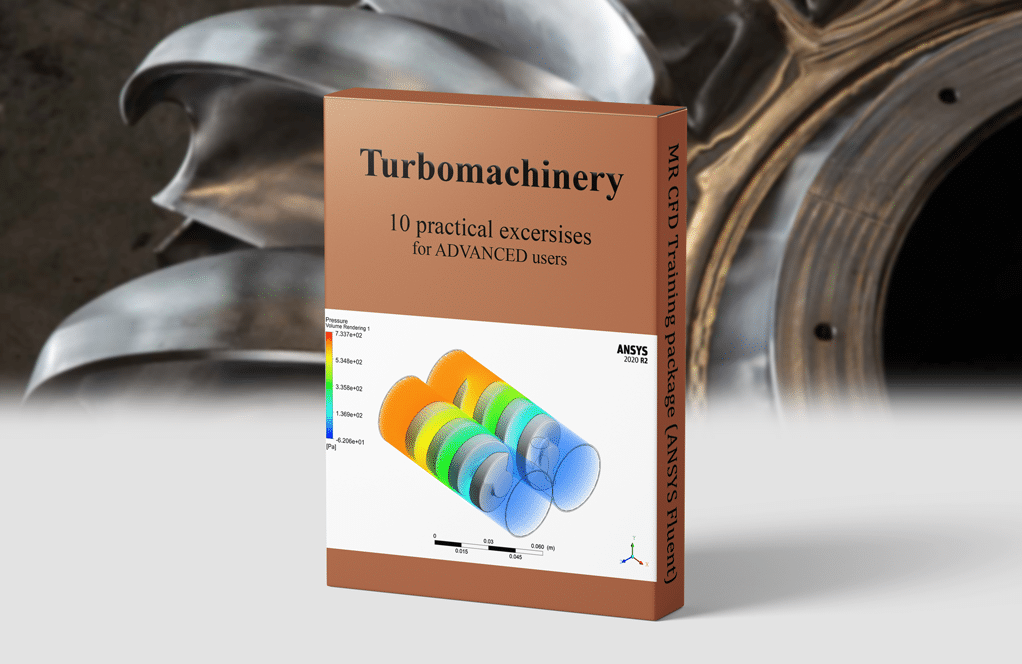

Turbomachinery CFD Training Package, Advanced Users, 10 Learning Products

$480.00 Student Discount

This CFD training package is prepared for ADVANCED users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Turbomachinery CFD Simulation Package, 10 ANSYS Fluent Training for ADVANCED Users

Turbomachinery CFD Simulation Training Package is prepared for ADVANCED users of ANSYS Fluent software in the Turbomachinery area including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

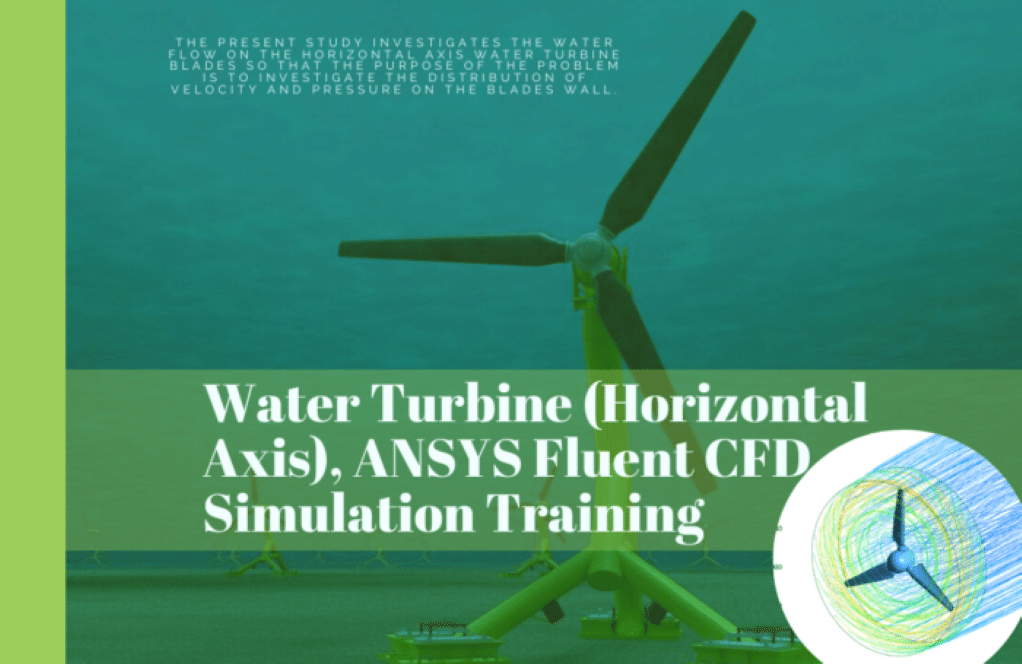

Water Turbine

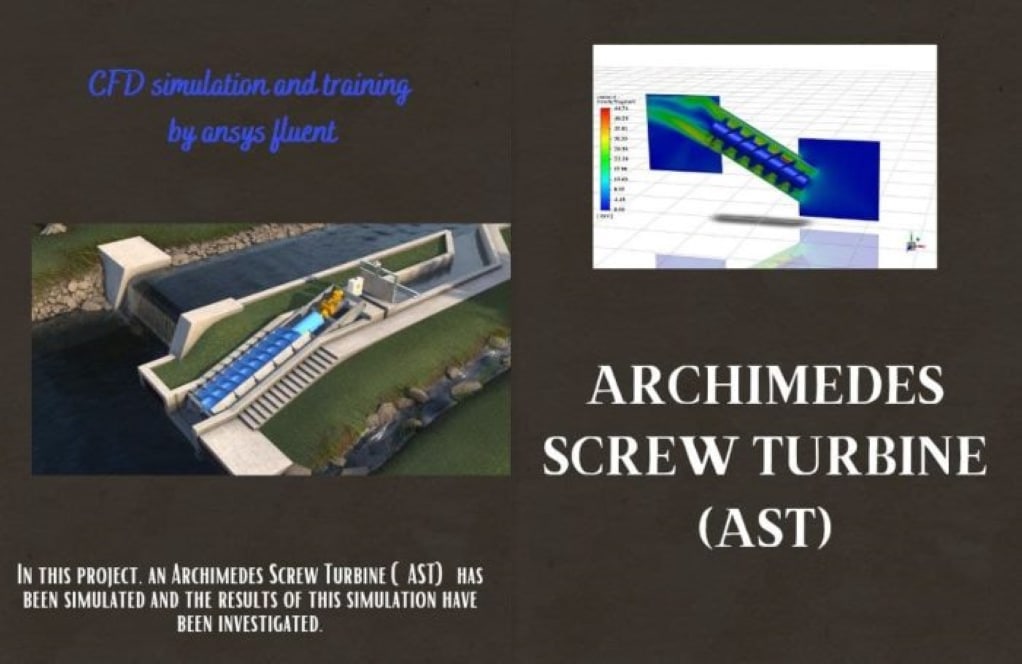

In project number 1, an Archimedes Screw Turbine (AST) consisting of 3 blades is simulated in two models. The first model is an unsteady Frame Motion (MRF), and the second one is an unsteady Mesh Motion. Considering the conception of both methods, the turbine in the frame-motion method is in a stationary state, and the fluid around it is rotating, while in the Mesh Motion method, the rotating zone that contains the Screw Turbine rotates independently.

Study number 2 investigates the water flow on the horizontal axis water turbine (HAWT) blades so that the purpose of the problem is to investigate the distribution of velocity and pressure on the wall of the blade. There are two areas around the blades, including a cylindrical area just around the blades and a large area around the cylinder. The flow of water in the large outer space behaves like a normal flow, while in the cylindrical region around the blades, the rotational flow is caused by the rotational motion of the blades.

In project number 3, a water wheel as an example of Pelton turbines is simulated. Most water wheels are mounted vertically on a horizontal axis, and can also be mounted horizontally on a vertical shaft. The wheels are perpendicular to certain parts of the turbine due to reduced friction force and increased nozzle thrust.

Study number 4 investigates the water flow around a vertical water turbine considering unsteady CFD simulation. In the present case, it is assumed that the turbine blades are affected by the flow of the passing fluid; that is, the fluid flowing through the turbine blades impedes forces on the turbine body and these forces cause deformation or resizing of the body of these blades. Therefore, the present problem consists of two fluid and solid solutions at the same time and hence, the FSI method and the coupling between the fluid flow and the Transient Structural are used.

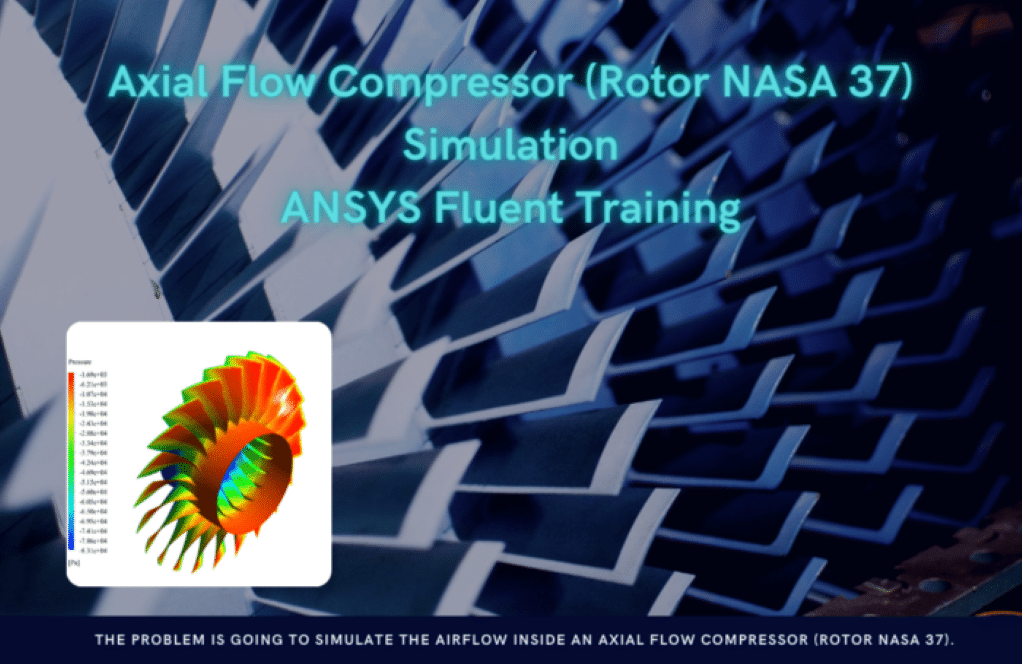

Compressor CFD Simulation

Problem number 5 is going to simulate the airflow inside an axial flow compressor (Rotor Nasa 37). The present model consists of a series of blades for an axial flow compressor connected to the central axis within a cylindrical area. To simplify the simulation model, only one row of rotating blades is drawn on the central rotor of the compressor.

Problem number 6 simulates the air compression inside a Rampressor. The Rampressor is a unique type of ultrasonic compressor rotor that operates at a high-pressure ratio, and engine technology and gas compression are the ramjet ultrasonic shock wave. The operating mechanism of these compressors is such that the gas flow passes through a fixed outer cover and a sloping surface or inner ramp.

Mixer CFD Simulation

In project number 7, a mixer tank is modeled and the effect of its rotating impeller on the mixing procedure is investigated. The simulation is done using the VOF model for the three phases of air, water, and salt. The k-epsilon model is applied for solving the turbulent flow inside the tank.

Impeller

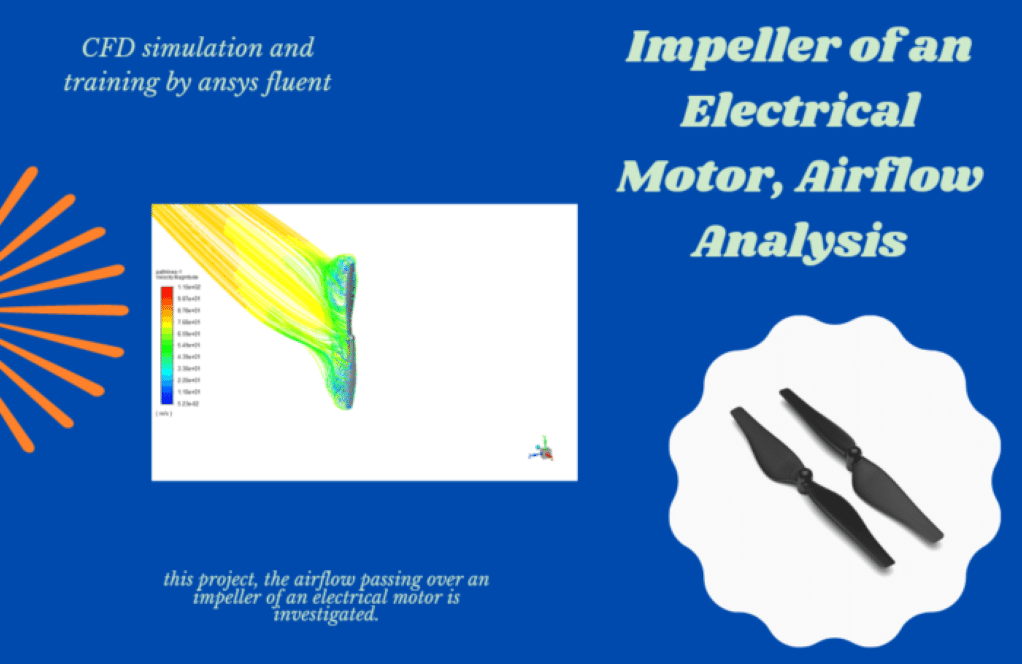

In project number 8, the airflow passing over an impeller of an electrical motor is investigated. The airflow enters the computational domain at 80m/s, and the impeller rotates at 1000rpm. A Realizable k-epsilon model is exploited to solve turbulent flow equations.

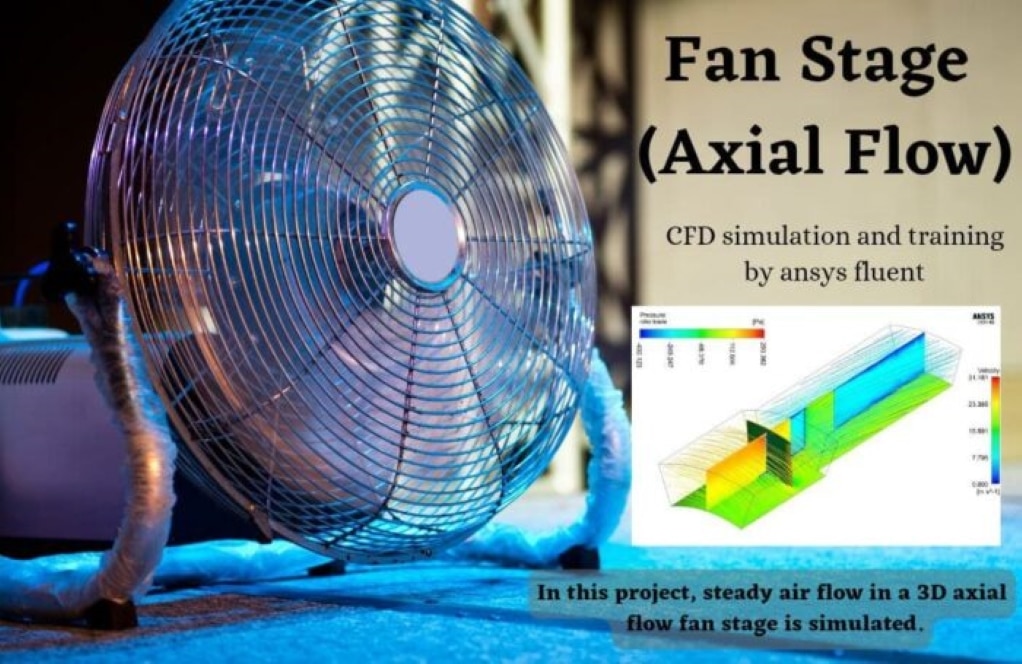

Fan CFD Simulation

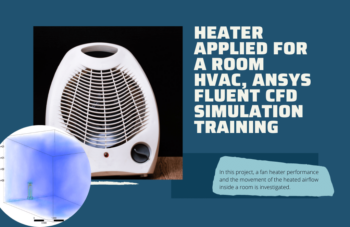

In project number 9, steady airflow in a 3D geometry of the fan stage is simulated. The fan stage is a common apparatus used for creating steady airflow in industrial applications used in the cooling process of newly painted body parts. The periodic boundary condition is used for the simulation of the real fan stage at the lowest computational cost.

Wind Turbine (turbomachinery)

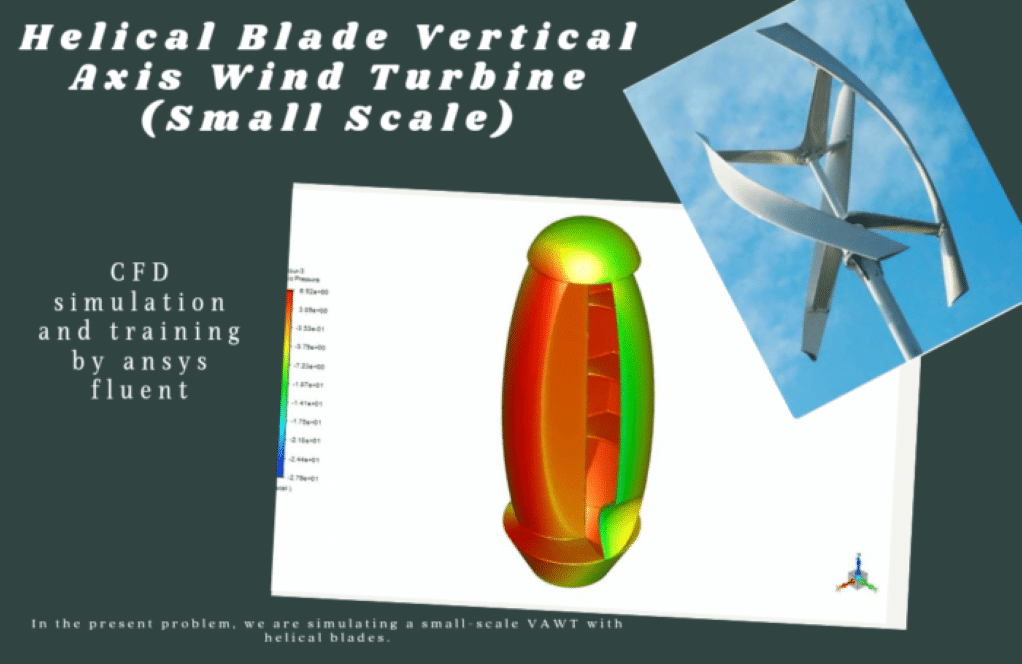

Finally, in problem number 10, we are simulating a small-scale VAWT with helical blades. We are simulating a wind turbine with dimensions of 10 x 20 cm with an average diameter of 7 cm in the present problem. This simulation was performed at wind speeds of 2 m / s and speeds of 60-40-80-100-120 rpm, and torque was reported as output.

[/vc_column_text][/vc_column][/vc_row]

Viola Lemke –

Does this package cover the simulation of cavitation phenomena in turbomachinery?

MR CFD Support –

Yes, it does! The training package includes exercises on cavitation modeling, which is a key aspect of turbomachinery simulations.

Mrs. Elody Weimann –

I’ve started working through the Turbomachinery CFD Training Package for Advanced Users, and it’s been incredibly detailed and informative. The wide range of projects offers a deep dive into different simulation scenarios, and the tutorials seem to cover all the necessary steps comprehensively. I’m particularly impressed by the complexity of the setups and the detailed tutorials provided to handle them.

MR CFD Support –

Thank you for sharing your positive experience with our Advanced Turbomachinery CFD Training Package. We are delighted to hear that our range of detailed projects and comprehensive tutorials are meeting your expectations and providing you with the knowledge you need. Your feedback is greatly appreciated, and we are here to support your learning journey with any further assistance you might need!

Jacklyn Welch –

What classes of turbomachinery models are incorporated in this package?

MR CFD Support –

This package incorporates a wide range of turbomachinery models, including different types of turbines and compressors, to provide a comprehensive understanding of turbomachinery simulations.

Russell Beatty –

I recently completed the Advanced Turbomachinery CFD Training Package and was thoroughly impressed by the depth of material covered across the 10 learning projects. The hands-on approach allowed me to apply theoretical concepts directly to practical simulations. The diverse range of applications, from water turbines to compressors and fans, made the learning process engaging and very informative. It’s remarkable how each project shed light on different aspects of turbomachinery modeling and provided me insight into the intricacies of flow dynamics and meshing strategies in complex geometries. Great job on curating a comprehensive and challenging training suite!

MR CFD Support –

Thank you so much for your wonderful feedback! We’re thrilled to hear that you found the Turbomachinery CFD Training Package for advanced users rewarding and insightful. Your satisfaction with the variety of projects and the depth of knowledge covered is exactly what we aim for. We’re delighted that our materials could enhance your understanding and skills in such a complex field as turbomachinery CFD. Your engagement and success inspire us to keep improving our training products. If you have further inquiries or require assistance as you continue to explore CFD simulations, please don’t hesitate to reach out.

Prof. Ferne Konopelski MD –

Can this package assist me in comprehending the impact of turbulence on turbomachinery performance?

MR CFD Support –

Certainly! The package includes exercises that concentrate on modeling turbulence and its impact on turbomachinery performance.

Dr. Chad O’Reilly –

This package really boosted my confidence in simulating complex turbomachinery projects! I appreciate the variety of examples, all of which come with their unique challenges and learning opportunities.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that our Turbomachinery CFD Training Package for advanced ANSYS Fluent users met your needs and helped you gain confidence in your simulation skills. It’s our goal to provide comprehensive learning resources that cover a wide range of scenarios, equipping users like you with the necessary expertise to face various engineering challenges. If you have any further questions or need more assistance in the future, please don’t hesitate to reach out.

Ms. Liliane Harvey DVM –

I’m thrilled with the level of detail and variety offered in the Turbomachinery CFD Training Package! The hands-on exercises were particularly helpful in understanding the practical aspects of turbomachinery CFD simulation.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training package met your expectations and that you found the exercises valuable for gaining practical experience in turbomachinery CFD. If you have any further questions or need assistance as you continue to work through the projects, feel free to reach out!

Mariam Hegmann –

Does this package address both steady-state and transient simulations?

.

MR CFD Support –

Indeed, it does! The training package incorporates exercises for both steady-state and transient simulations, enabling you to comprehend the behavior of turbomachinery under diverse conditions

Roel Monahan –

The Turbomachinery CFD Training Package has wonderfully deepened my understanding of various simulations in turbomachinery. Each project was well-designed, providing incremental learning that seems to perfectly build upon the previous exercises. The in-depth coverage of different types and methods of turbomachinery simulations equipped me with the necessary skills to tackle complex real-world problems in CFD. The transition from water turbines to compressors, and from mixers to fans and wind turbines was seamless, and it speaks volumes about the thoughtfulness put into this curriculum. Truly exemplary work by the MR CFD team!

MR CFD Support –

We are thrilled to hear that our Turbomachinery CFD Training Package has significantly contributed to your understanding and skill development in the field of CFD simulations of turbomachinery. Your exceptional feedback is greatly appreciated, and it motivates us to continue delivering high-quality educational material. Thank you for recognizing the careful planning and execution of our curriculum. We are looking forward to supporting you in your ongoing and future projects. If you ever have further inquiries or need assistance, remember that our team of experts is just a message away. Thank you once again for your complimentary review!

Kiel Jerde IV –

Cheers to MR CFD for this in-depth Turbomachinery CFD Training package for advanced users! The range of projects, from water turbines to compressors and wind turbines, is impressive. It’s incredibly helpful to have diverse scenarios to fully understand a variety of simulations and the ANSYS Fluent software capabilities.

MR CFD Support –

We greatly appreciate your feedback! It’s wonderful to hear that our comprehensive training package caters well to advanced users and supports a solid understanding of various turbomachinery simulations. Thank you for choosing our products for enhancing your CFD skills.