Mechanical Engineering Training Package, Advanced Users, Part 2, 10 Exercises

$349.00 $174.50 Student Discount

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all ADVANCED users.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Mechanical Engineering – ANSYS Fluent CFD Simulation Training Package, Practical Exercises for ADVANCED Users (Part 2)

There are 10 practical exercises in this training package by ANSYS Fluent software for Mechanical Engineers. This package presents how to simulate different mechanical devices for all ADVANCED users.

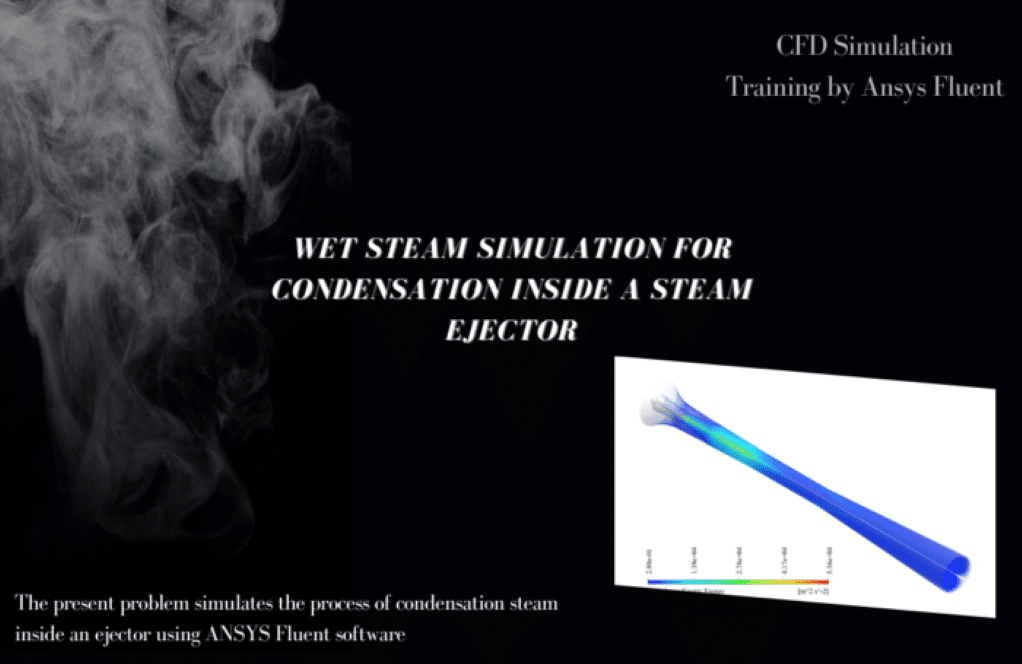

Wet Steam

Problem number 1 simulates the process of condensation inside a steam ejector using WET STEAM. When the Wet Steam multiphase model is used, two sets of transport equations are solved: the mass fraction of the condensed liquid phase and the number or concentration of droplets per unit volume.

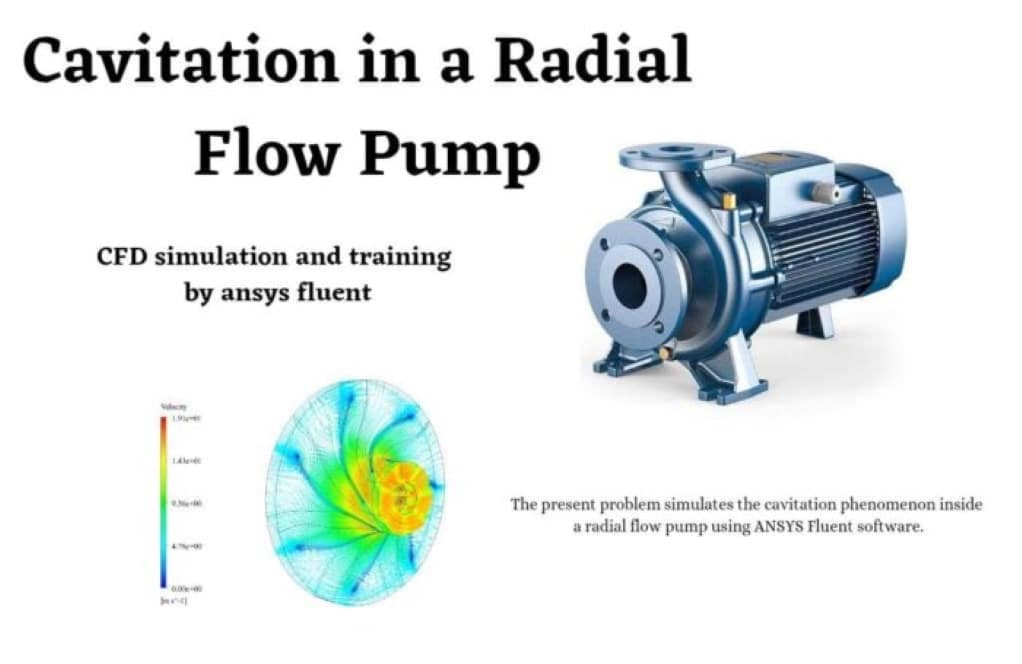

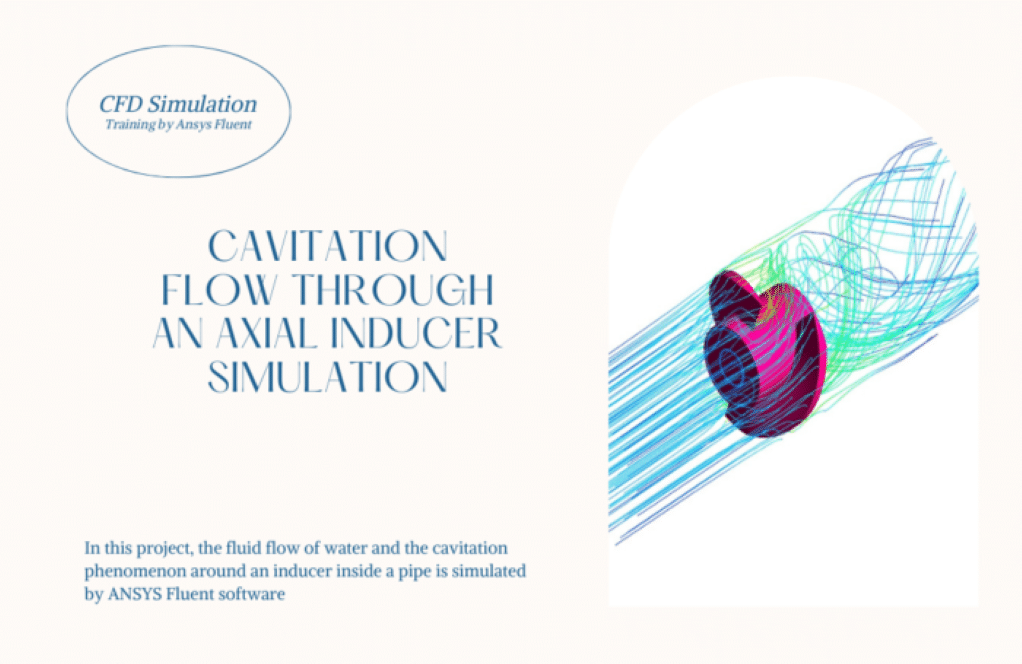

Cavitation

Problem number 2 simulates the cavitation inside a radial flow pump. This pump is of the centrifugal pump (radial flow) type; In this way, the desired fluid enters it parallel to the central axis and exits it radially or perpendicular to the inlet path. In project number 3, the fluid flow of water and the cavitation around an inducer inside a pipe is simulated. The cavitation phenomenon is one of the phenomena that vapor bubbles are formed in the part of the fluid whose pressure is low. The phenomenon of cavitation can cause many problems, including corrosion.

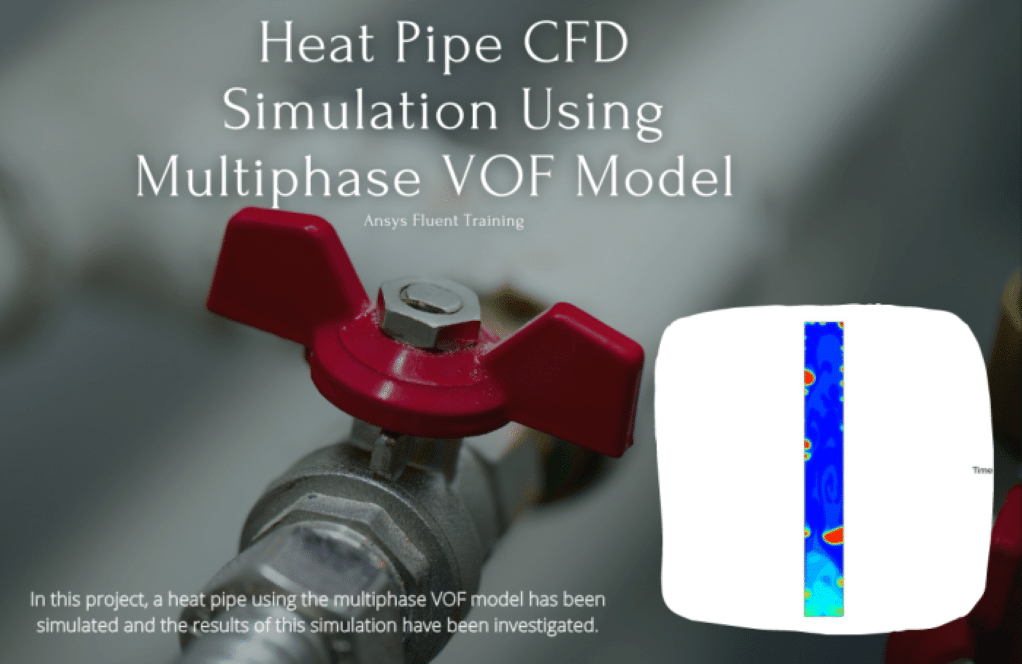

Heat Pipe

In study number 4, the heat pipe problem was simulated. The project was analyzed using the multiphase VOF model and activating the mass transfer of evaporation and condensation. A hot wall with a temperature of 400 K and a cold surface with a temperature of 300 K was assumed.

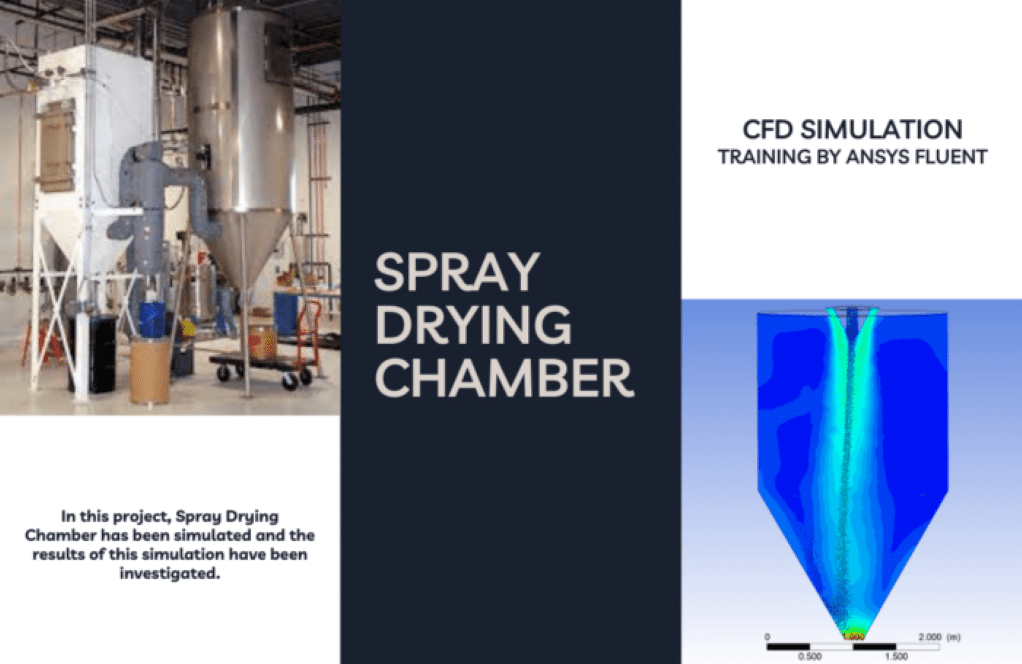

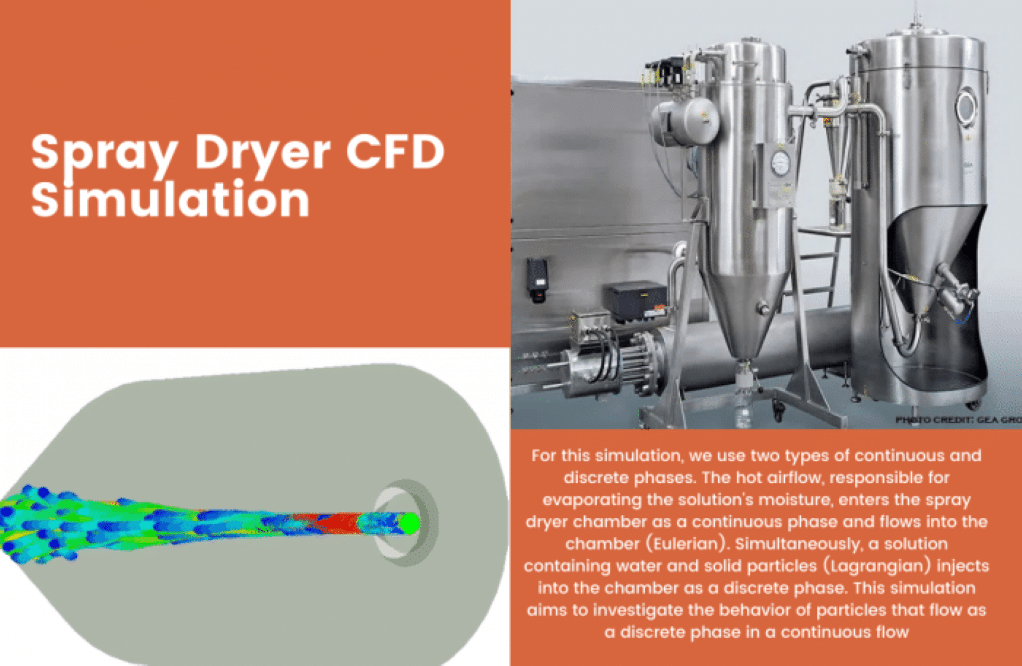

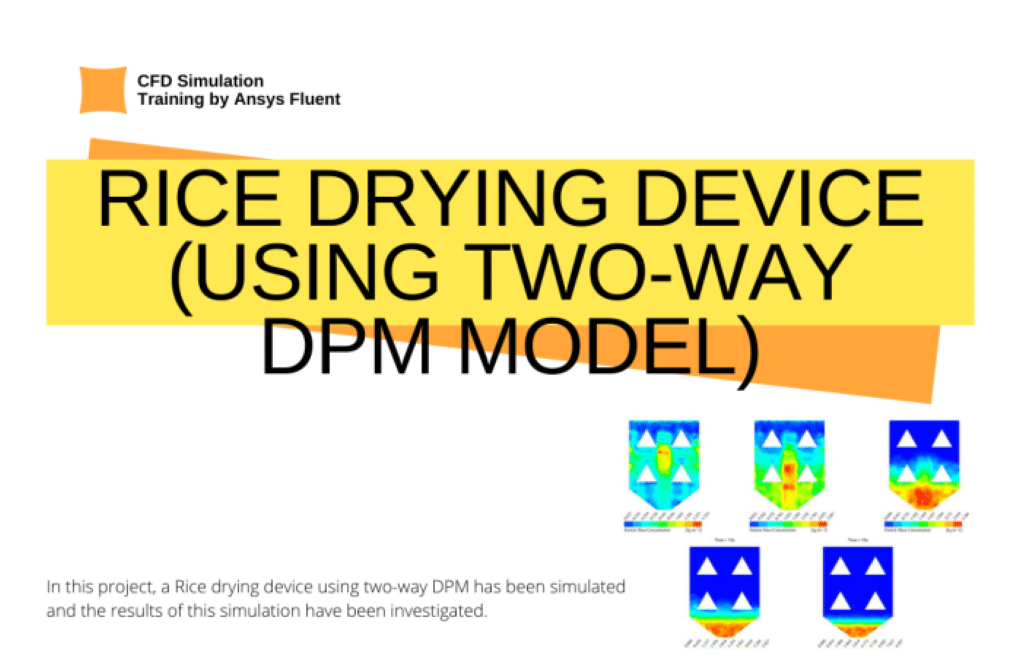

Dryer

For simulation number 5, we use two types of continuous and discrete phases. In fact, the hot airflow, which is responsible for evaporating the moisture contained in the solution, enters the spray dryer chamber as a continuous phase and flows into the chamber (Eulerian). While a solution containing water and solid particles (Lagrangian) injects into the chamber as a discrete phase. In fact, the main purpose of this simulation is to investigate the behavior of particles that flow as a discrete phase in a continuous flow. In project number 6, which has been done by CFD numerical simulation method, a spray drying chamber is simulated by the two-way DPM and Species Transport model. The particle diameter is 1 mm, and the flow moves at a speed of 1 m/s. Also, the gravity effect is equivalent to -9.81 m.s-1. In project number 7, a rice drying device has simulated using the Two-way Discrete Phase Model (DPM) & Species Transport Model, and then the results were investigated. Hot air enters the drying device, and then 120000 rice grains with 10% moisture are injected randomly for 6 seconds. The evaporation process continues for 9 seconds after complete injection.

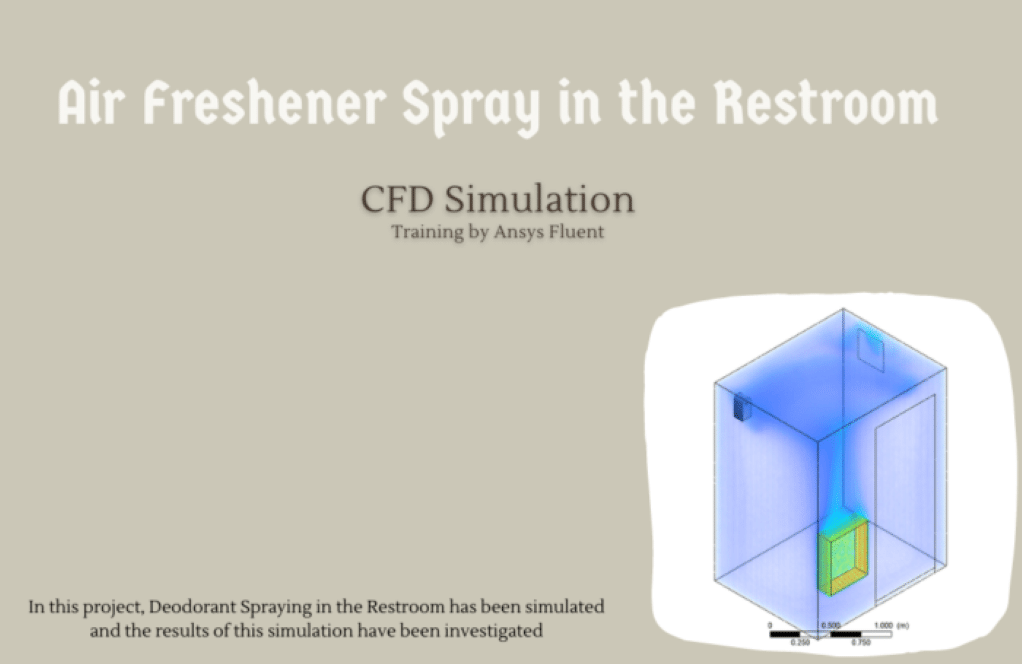

Air Freshener Spray

Practical exercise number 8 investigates the spraying of Air Fresheners in the restroom by the 2-way DPM method. According to this definition of injection, fragrance particles are physically expelled from the device by water droplets that evaporate in space. These droplets have a temperature of 310 K, a velocity of 50m.s, and a mass flow of 0.018 kg.s-1, which are emitted at intervals of 0s to 0.1s.

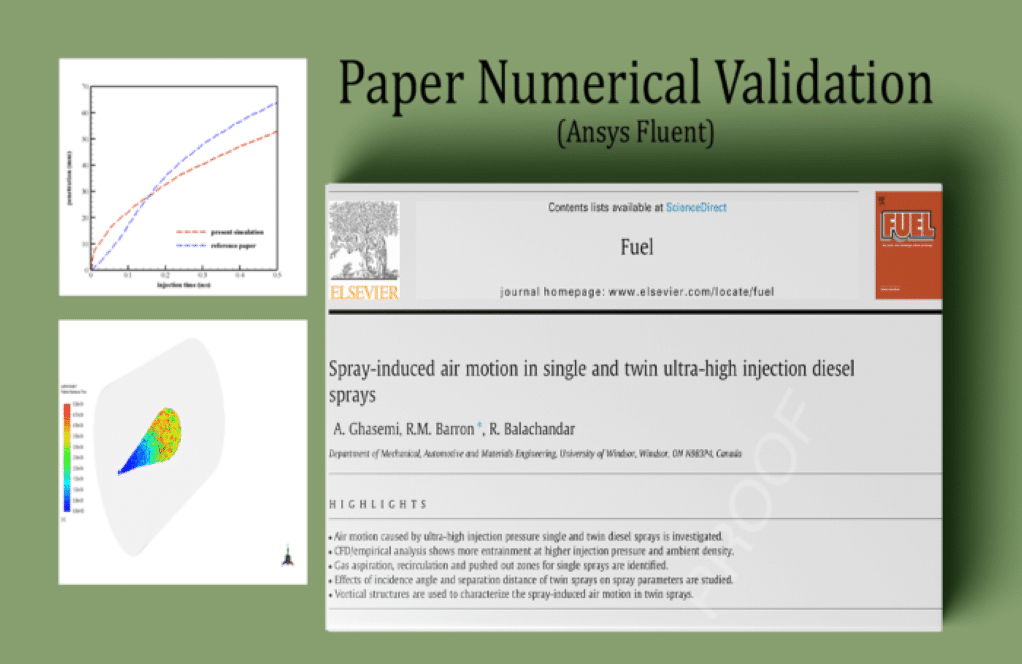

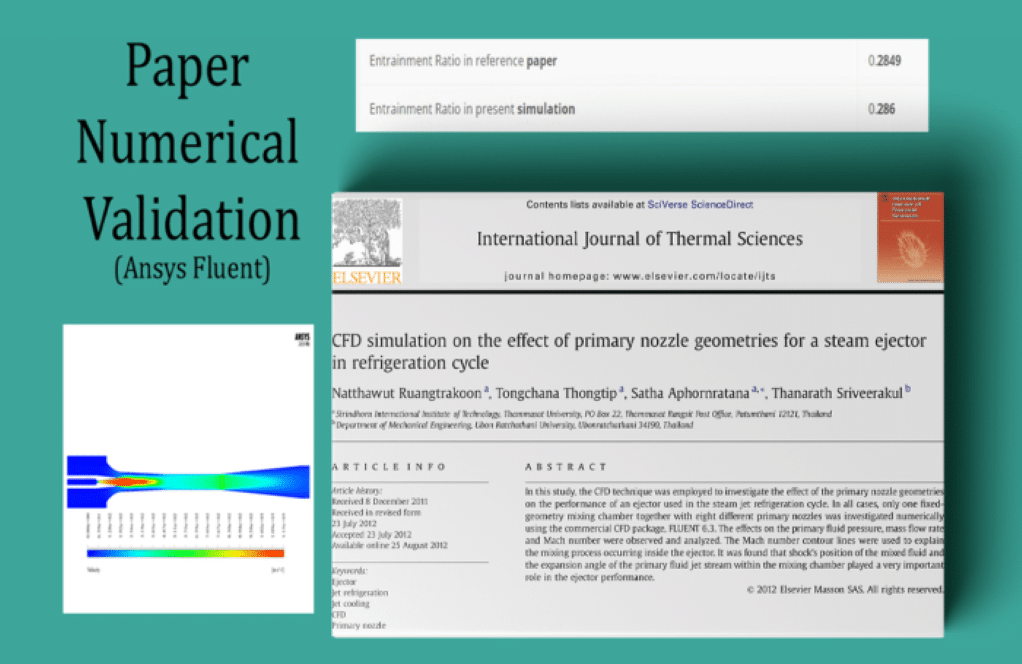

Paper Numerical Validation (Mechanical Engineering)

Problem number 9 simulates fuel injection through an injector into a chamber. This simulation is based on the information in the article “Spray-induced air motion in single and twin ultra-high injection diesel sprays” and its results are compared and validated with the results in the article. The fuel used in this model is diesel and its properties include density equal to 830 kg.m-3, specific heat capacity equal to 1680 j.kg-1.K-1, droplet surface strain equal to 0.0255 nm -1 and the viscosity is equal to 0.0027888 kg.m-1.s-1. Finally, practical exercise number 10 simulates the water vapor flow inside a steam ejector. This numerical simulation is based on the reference paper “CFD simulation on the effect of primary nozzle geometries for a steam ejector in refrigeration cycle” and the results of the present numerical work are compared and validated with the results in the reference article. An ejector is a mechanical device that uses an actuator fluid to suck a secondary material (gas, liquid, or solid particles), and finally, the actuator fluid and the suction substance are mixed together and exit from the system.

Jerrod Lockman –

How can these exercises help me understand heat transfer mechanisms?

.

MR CFD Support –

These exercises offer a comprehensive understanding of different heat transfer mechanisms, such as conduction, convection, and radiation. They can be tailored to reflect your specific scenarios or requirements

Doyle Barton Sr. –

What types of boundary conditions are used in these exercises?

MR CFD Support –

Great question! These exercises use a variety of boundary conditions, including pressure, velocity, and temperature, to simulate real-world scenarios. We can adjust these conditions based on your unique requirements.

Prof. Jaeden Kris –

As an advanced user, I found the Mechanical Engineering Training Package very effective. It covers a wide range of simulations specific to mechanical engineering. The step-by-step guides helped me with the intricacies of ANSYS Fluent and provided insights into multiphase flow models, including handling cavitation and wet steam challenges. The real-world problems and their CFD solutions broadened my understanding of each process. Great work on curating such a pragmatic learning experience for professionals like us!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Mechanical Engineering Training Package for Advanced Users met your expectations and was instrumental in enhancing your CFD simulation skills using ANSYS Fluent. Our goal is to provide comprehensive and hands-on learning experiences, and we’re glad the varied exercises broadened your knowledge. We appreciate you taking the time to share your positive experience, and we look forward to continuing to support your professional development!

Timothy Bartoletti –

How does this package handle the simulation of fluid-structure interactions?

MR CFD Support –

This package includes exercises that cover fluid-structure interaction simulations. It helps you understand how the interaction between fluids and structures can affect the system’s performance. We can also adapt these simulations to your specific requirements.

Reilly Torp DVM –

I just finished all the exercises in the Advanced Users Part 2 Mechanical Engineering Training Package – incredible depth and complexity! Can you tell me if there are any new modules or advanced topics planned for future updates of the training package?

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear about your successful experience with the Mechanical Engineering Training Package, Advanced Users, Part 2. As for your question, we continuously work on updating our training materials with new and advanced topics to ensure our customers are at the forefront of CFD simulation knowledge. Keep an eye on our website or subscribe to our newsletter for announcements regarding future updates and additional modules in the training series.

Dr. Joshua Ebert –

I’ve learned so much from the Mechanical Engineering Training Package, Advanced Users, Part 2. The diversity and complexity of the exercises provided an excellent challenge, greatly improving my simulation skills. I particularly enjoyed the different phase interaction scenarios such as the Wet Steam and Cavitation problems. Kudos to MR CFD for an incredibly well-structured learning journey!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the Mechanical Engineering Training Package so educational and beneficial to your skills. It’s great to know that the exercises challenged you and provided a detailed insight into phase interaction scenarios. Your feedback is greatly appreciated, and we are delighted to have been part of your learning experience.

Tyrell Abernathy II –

I am thrilled with the variety of exercises in the Advanced Users Mechanical Engineering Training Package. Each simulation provided me with an in-depth understanding of complex phenomena. The inclusion of validation exercises with academic research was particularly helpful for honing my practical simulation skills.

MR CFD Support –

We’re delighted to hear that the exercises in our Advanced Users Training Package met your expectations and provided you valuable, in-depth understanding. We believe hands-on practice paired with academic validation is essential for mastering CFD simulations. Thank you for taking the time to share your positive experience!

Prof. Zoila McClure III –

What a fantastic resource for diving deeper into mechanical simulations with ANSYS Fluent! The variety of exercises offers a solid platform to tackle advanced CFD challenges. Each project brings a unique aspect of mechanical analysis to the fore, perfect for honing skills and expanding knowledge in simulation techniques.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you found the Advanced Users training package to be a valuable tool for enhancing your simulation skills. It’s always our aim to provide comprehensive learning materials to tackle real-world CFD challenges. If you have any further feedback or need assistance as you proceed through the exercises, don’t hesitate to reach out to us!

Nash Labadie –

I thoroughly enjoyed the Advance Users Part 2 package from MR CFD Company! The range of simulations covered—from the intricacies of wet steam through cavitation scenarios and spray dynamics—provided a diverse and rich learning experience. The step-by-step approach with clear objectives for each lesson reinforced my understanding. Plus, the connection with real-world mechanical engineering applications added immense value, making the theoretical knowledge gained from each exercise directly applicable to my field of work.

MR CFD Support –

Thank you for taking the time to share your valuable feedback with us! We are delighted to hear that our Advanced Users Part 2 training package met your expectations and provided you with a comprehensive and applicable learning experience. It’s our pleasure to contribute to the deepening of your mechanical engineering skills, and we look forward to continuing to support your professional growth.

Fermin Rice –

I just completed the wet steam simulation in the training package and it was very instructive on solving condensation processes. Handling the transport equations for the condensed phase was challenging at first, but the tutorials were clear and helpful. The practical application of simulating an ejector was particularly rewarding. It’s seminars like these that refine our skills as mechanical engineers!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our training package helped you gain a better understanding of condensation processes and the intricacies of wet steam simulation. Our aim is to provide comprehensive and clear instructions to tackle complex problems and it’s great to know we’re achieving that. Your success in applying these skills reflects the quality of our seminars, and we couldn’t be happier to contribute to your growth as a mechanical engineer. If you have any more insights or need further assistance in future simulations, don’t hesitate to reach out. Cheers to your continued learning and accomplishments!

Corene Abbott –

What I absolutely loved about the Mechanical Engineering Training Package for advanced ANSYS Fluent users is the variety of practical exercises that are meant for someone like me – someone who’s looking to challenge their skills and understanding of different simulation scenarios. The breadth of problems, from cavitation to dryer simulations, provided me with a well-rounded experience and tested my knowledge extensively. Each project was unique, pushing me to adapt and learn, which is invaluable for maintaining a competitive edge in the field of mechanical engineering. A big thumbs up for MR CFD for compiling this educational journey!

MR CFD Support –

Thank you so much for your kind words about our Mechanical Engineering Training Package for advanced ANSYS Fluent users. We are absolutely thrilled to hear that you found the practical exercises challenging and beneficial for your skill development. Our aim is always to provide rich learning experiences that contribute to the growth of professionals in the field, and we’re glad we could do that for you. Your feedback is greatly appreciated, and it encourages us to keep delivering quality educational content. Thanks again!

Liana Sanford –

The ‘Mechanical Engineering Training Package, Advanced Users, Part 2, 10 Exercises’ provided an excellent practice and skill improvement opportunity for me. I am particularly impressed with the variety of scenarios and challenges each exercise offers, which definitely honed my skills in computational fluid dynamics using ANSYS Fluent. The projects on cavitation gave me better intuition about the phenomenon and how to interpret its maintenance implications in practical machinery. Moreover, the exercises on multiphase flows, especially the heat pipe simulation, expanded my understanding significantly. Great work providing such a comprehensive learning tool!

MR CFD Support –

Thank you for taking the time to share your experience with our Mechanical Engineering Training Package for Advanced Users. We are thrilled to hear that our exercises in this package have successfully aided your understanding and skills in complex computational fluid dynamics concepts and simulations with ANSYS Fluent. Your feedback is invaluable as we continually strive to deliver educational products that meet the practical needs of users like you. We look forward to providing you with even more opportunities to advance your expertise in the future.

Dr. Silas Schoen –

Thanks to the Mechanical Engineering Training Package, Advanced Users, Part 2, I was able to enhance my understanding of the complex simulations in ANSYS Fluent. My knowledge on multiphase flows, heat transfer, and particle transport has significantly increased. The hands-on exercises were perfectly aligned with what an advanced user needs to tackle real-world CFD challenges.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our Advanced Users Part 2 training package met your expectations and provided substantial benefit for your studies of CFD simulations in ANSYS Fluent. We pride ourselves on contributing to the knowledge and skills of our users. If you need further assistance or have questions about other products, feel free to reach out to us.

Kristoffer Swaniawski –

I recently completed the Mechanical Engineering Training Package for Advanced Users Part 2, and I must say, the depth and variety of exercises provided a challenging yet highly enriching experience. The projects helped in expanding my understanding of various mechanical simulations, especially the cavitation and wet steam problems that not only present the problems but also demonstrate the practical implementation of ANSYS Fluent. Worthy of note is the heat pipe simulation, which exemplified a realistic thermal transfer scenario using the VOF model – it provided a clear visualization of evaporation and condensation processes within the system. Exercise number 5 on spray drying chambers excellently portrayed the discrepancies between continuous and discrete phases, which was a crucial learning point for me. Also, the inclusion of the species transport model in several projects magnificently associated theoretical knowledge with real-world applications.

MR CFD Support –

Thank you so much for your comprehensive and thoughtful review of our Mechanical Engineering Training Package for Advanced Users Part 2. We are thrilled to hear that the exercises expanded your understanding of complex simulations and that you found the incorporation of real-world phenomena such as cavitation, wet steam problems, and species transport models to be practically beneficial and visually compelling. Your feedback is highly appreciated, and we are glad that our training package has contributed positively to your learning journey. It’s always fulfilling to know that our users gain significant insights and practical knowledge from our learning resources. Keep up the great work!

Evelyn Graham –

I’m impressed by the comprehensive coverage provided in the advanced mechanical engineering training package. I can see that it encompasses a wide range of practical simulations explaining critical aspects like wet steam condensation, cavitation in pumps and inducers, heat transfer in heat pipes, multiphase flow in spray dryers, and air freshener spray dynamics. Moreover, the paper numerical validation exercises add a layer of academic rigor by comparing and validating results with existing literature. The step-by-step illustration of each example is elucidating and I look forward to seeing more such training packages. Thank you for crafting such a detailed learning tool for advanced users.

MR CFD Support –

Thank you for your kind words and detailed review! We’re thrilled to hear how much you’re enjoying the training package. We’re proud to provide a resource that not only improves practical skills but also strengthens understanding through validation with research literature. If a new package is released that matches your interest, we will be sure to share it. Happy learning!

Miss Jana Cruickshank Sr. –

This training package for advanced users really helped me understand the complexities of mechanical CFD simulations! I particularly enjoyed the challenge of the Cavitation exercises and seeing how the condensation was simulated in the wet steam problem. Great set of exercises for professionals who want to delve deeper into CFD analysis!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our Advanced Users training package met your expectations and provided you with a deeper understanding of mechanical CFD simulations. It’s wonderful to know that the cavitation exercises were engaging and beneficial for you. We appreciate your recognition and are here to support you in your ongoing learning journey!

Miss Jolie Keebler V –

I’m excited to dive into the Mechanical Engineering Training Package. Is it suitable for users looking to develop expertise in niche areas like autoclaves and heat exchangers or is it focused on general knowledge?

MR CFD Support –

This package is primarily designed for advanced users who wish to focus on simulating mechanical devices, including topics such as cavitation, wet steam, and drying machines. However, while it might touch a broad range of mechanical engineering simulations, for specific expertise in niche areas like autoclaves and heat exchangers, you might need additional targeted learning materials or simulations that focus on those areas.

Hosea King –

This Advanced Mechanical Engineering package seems amazing for practicing complex simulations! The diversity of exercises appears to tackle a wide array of phenomena. Can you please tell me if the package includes any support or tutorials for understanding the set-up and analysis of the results?

MR CFD Support –

Thank you for your kind words! Yes, the Mechanical Engineering Training Package includes detailed instructions for setting up each simulation as well as an explanation of analyzing the results. The step-by-step guidelines, along with necessary theoretical background, make it easier for advanced users to understand the complexities involved in each project.

Mr. Narciso Wisoky Jr. –

Just wanted to say thank you for creating the Mechanical Engineering Training Package, especially for advanced users. As an engineer constantly seeking to enhance my skills, these practical exercises have been incredibly helpful in understanding complex phenomena like cavitation and wet steam physics! They’ve really supplemented my existing knowledge and pushed my abilities. Keep up the great work!

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that our Advanced Mechanical Engineering Training Package has been beneficial to your continuous learning and skill development. We work hard to create comprehensive and practical material, so it’s rewarding to know that it’s making a positive impact. We appreciate your feedback, and if ever in need of further guidance or have any suggestions, don’t hesitate to contact us. Wishing you continued success in all your engineering pursuits!

Trycia Vandervort –

I’ve been working through the advanced mechanical engineering package and everything was great so far, but I’m a bit confused with the simulation on paper numerical validation, specifically Problem number 9. Could you provide clarification on how the boundary conditions affect the fuel injection process in this simulation?

MR CFD Support –

In Problem number 9, the fuel injection simulation’s boundary conditions are crucial to accurately mimic the conditions presented in the referenced article. The fuel injector is set as a mass flow inlet with specified properties of diesel fuel, including mass flow rate and temperature, which directly affects the spray formation and air motion inside the chamber. Different boundary conditions like pressure outlet are applied on other surfaces to allow for proper ejection of gases. Subsequently, these correctly set boundary conditions make sure the behavior of the fuel conforms to real-world expectations and helps in matching up with the data from the validation reference.

Amya Feest –

I am thoroughly impressed by the practical relevance of the simulations in the Advanced Users training package, especially the Heat Pipe and Dryer simulations. These exercises provided me with a profound understanding of multiphase models and mass transfer which are critical in the design of efficient thermal and drying systems in industry. Keep up with the outstanding work!

MR CFD Support –

Thank you so much for your kind words! It’s fantastic to hear that the Advanced Users training package has significantly contributed to your understanding of thermal and drying system design. We strive to provide valuable and practical learning experiences to our users. If you have any further feedback or need assistance with other simulations, please feel free to reach out. We appreciate your enthusiasm and look forward to providing more enriching content!