Pressure Cooker CFD Simulation by ANSYS Fluent

$140.00 $56.00 HPC

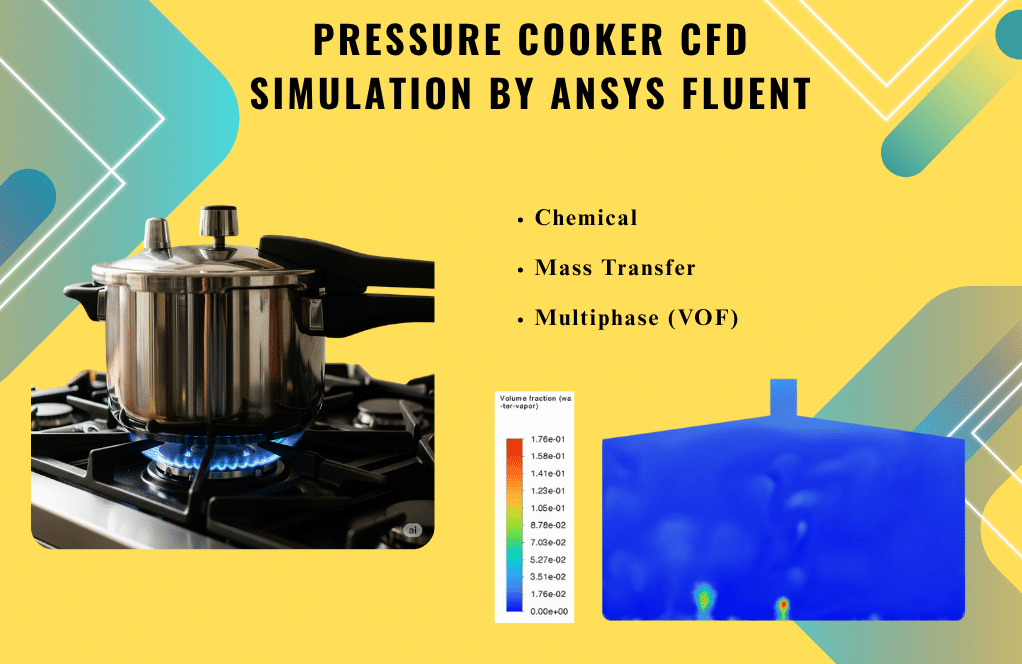

- This report presents a simulation which investigates the multiphase flow and mass transfer phenomena within a pressure cooker, focusing on the interactions between liquid water, water vapor, and air.

- The evaporation rate, pressure build-up, and temperature distribution within the pressure cooker were analyzed over a 30-second period.

- A high-quality tetrahedron elements mesh was generated using ANSYS Meshing software.

- Appropriate multiphase settings and boundary conditions were applied to correctly simulate the boiling process and vapor generation.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Pressure Cooker CFD Simulation: Mass Transfer (Evaporation) Analysis

The pressure cooker is a common appliance used for rapid and efficient cooking by utilizing pressurized steam. Understanding the dynamics of boiling, vapor formation, and pressure buildup within a sealed system is crucial for optimizing its safety and performance. This study aims to numerically simulate the mass transfer between liquid water, water vapor, and trapped air inside a conventional pressure cooker using ANSYS Fluent software. The key objective is to analyze the vapor generation and the evaporation process under constant heat input at the base of the cooker in an enclosed domain.

A conventional pressure cooker geometry was modeled in ANSYS SpaceClaim software. An unstructured tetrahedral mesh (2,953,408 elements) was generated in ANSYS Meshing software, ensuring high-quality resolution of fluid interfaces and near-wall regions. The numerical investigation focuses on capturing the complex three-phase interactions and transient boiling behavior through high-fidelity CFD modeling. A realistic representation of the thermodynamic relationship between saturation pressure and temperature is provided via a tabulated data obtained from the saturation temperature versus saturation pressure diagram for water.

Methodology

A pressure-based, unsteady solver was employed to capture the temporal evolution of the boiling process and vapor generation within the pressure cooker. The Volume of Fluid (VOF) multiphase model was implemented to track the interface between liquid water and the gas phase (air and water vapor), accounting for surface tension effects and interfacial mass transfer. The k-omega turbulence model was selected for this simulation due to its superior performance in predicting near-wall flows and free-surface turbulence, which are critical aspects in boiling phenomena.

The phase change process was modeled using a saturation temperature-pressure relationship provided through a tabulated input, allowing for accurate prediction of evaporation rates as pressure builds within the cooker. A constant heat flux boundary condition was applied to the bottom surface of the pressure cooker to simulate the heating element, initiating and sustaining the boiling process. The simulation was conducted for a total physical time of 30 seconds to capture the initial transient behavior of the system.

Results and Conclusion

From the simulation, the following results are obtained:

- The vapor mass fraction contours demonstrate progressive generation of steam from the heated bottom surface, with accumulation in the upper region of the pressure cooker.

- The temperature distribution shows highest values at the bottom heating surface with gradual stratification throughout the fluid domain, driving the evaporation process.

- Pressure build-up within the cooker is observed as vapor generation progresses, elevating the saturation temperature of water in accordance with the provided saturation data.

- The mass transfer rate between liquid water and vapor phase increases over time as the system approaches thermal equilibrium, with significant influence from the air presence in the headspace.

You must be logged in to post a review.

Reviews

There are no reviews yet.